Light combined beam moving trolley

A combined and lightweight technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as difficult approval of blockade plans, increased manpower and material resources, and increased safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

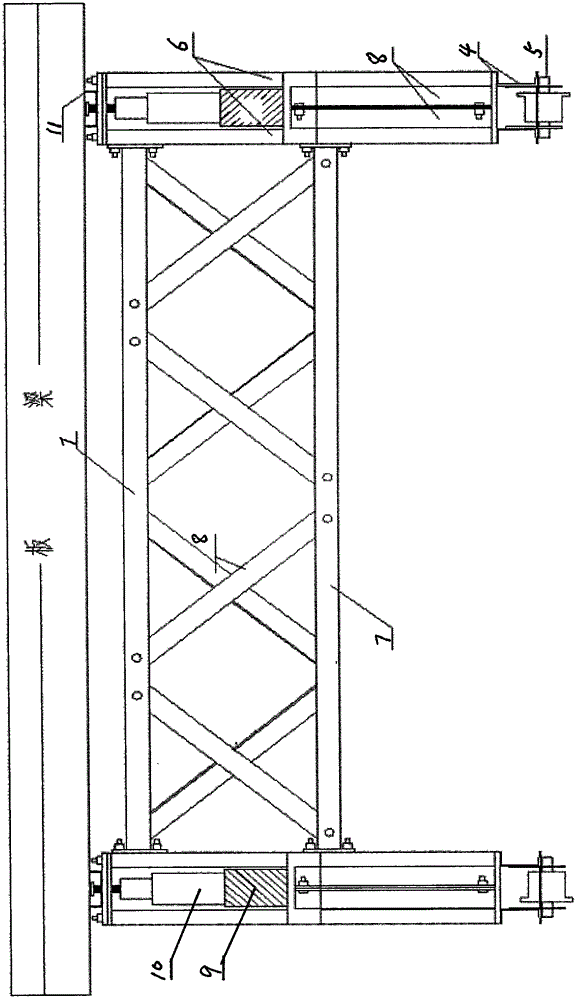

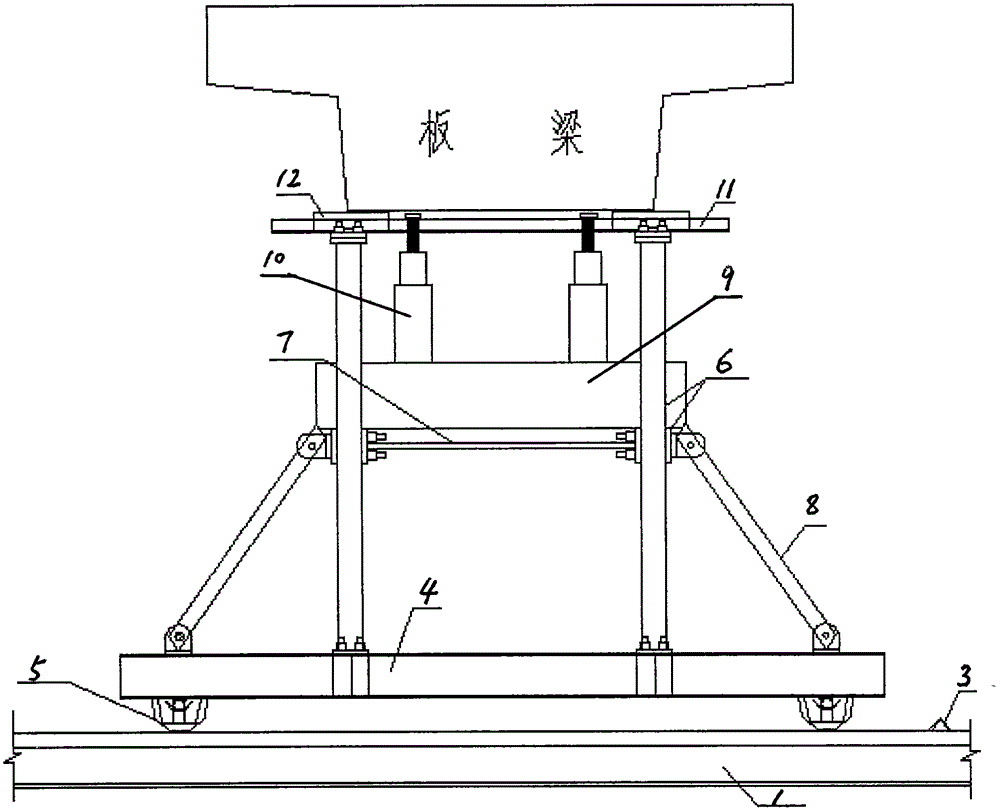

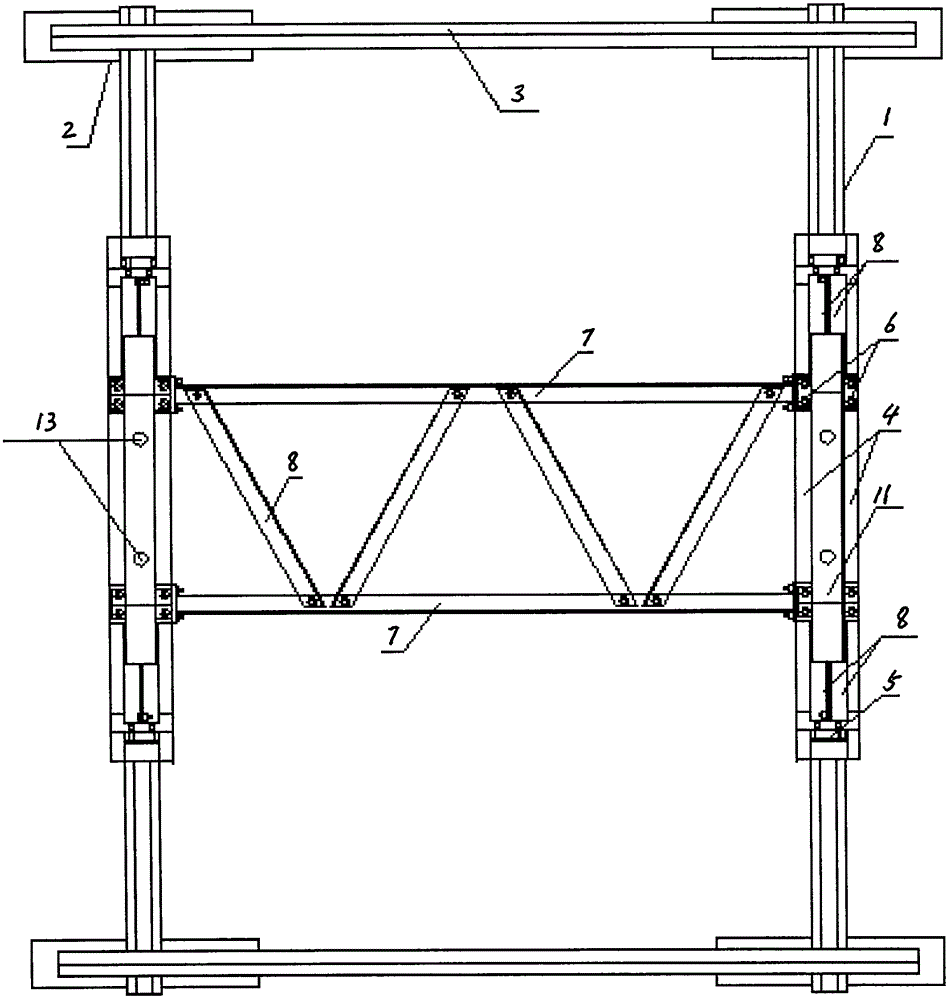

[0012] Such as Figure 1-Figure 3 As shown, at the beam position that needs to be slid out, two tracks 1 are laid along the sliding direction, and short wooden sleepers 2 (spacing 0.5m) are set up under the track 1, and car stops 3 are set at both ends of the track 1 to prevent the car from slipping. Bottom steel frame 4 adorns two pairs of wheels 5 to cooperate with track 1. The supporting steel frame is divided into a vertical supporting steel frame 6, a horizontal supporting steel frame 7 and an oblique supporting steel frame 8. The four symmetrical vertical supporting steel frames 6 are connected with the bottom steel frame 4 through bolts, and the vertical supporting steel frame 6 and the horizontal support steel frame 7 are added with an oblique support steel frame 8 and fixed with bolts, and the upper and lower horizontal support steel frames 7 and the vertical support steel frames 6 are spliced into a load-bearing frame. An oblique support steel frame 8 is added bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com