Downward-sliding conveying device for cylinder batteries

A technology of cylindrical batteries and conveying devices, which is applied in the direction of transportation, packaging, and slideways, etc. It can solve problems affecting the stability and efficiency of equipment, blockage of conveying channels, and equipment shutdown, so as to improve equipment stability and work efficiency and prevent stacking , to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

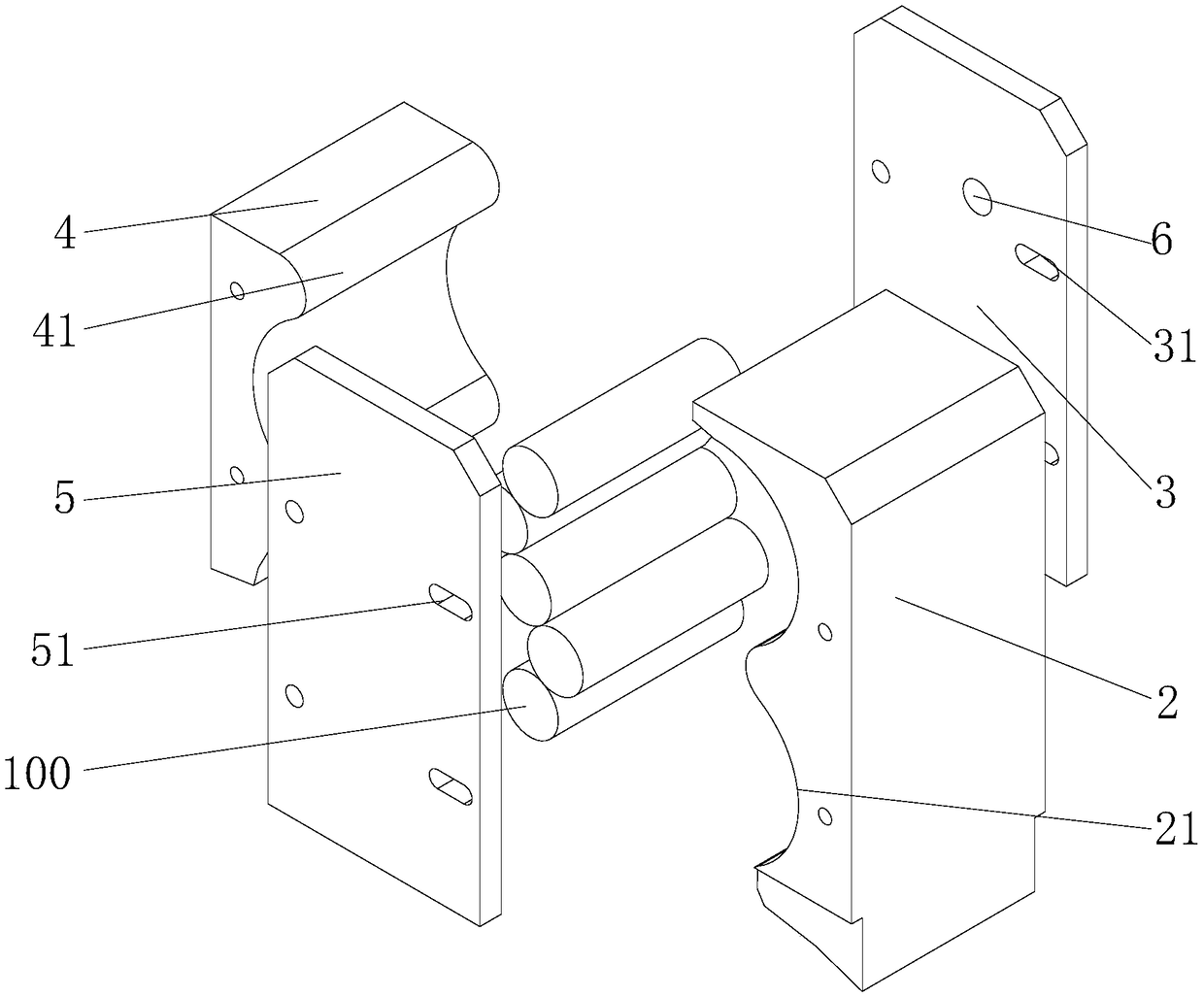

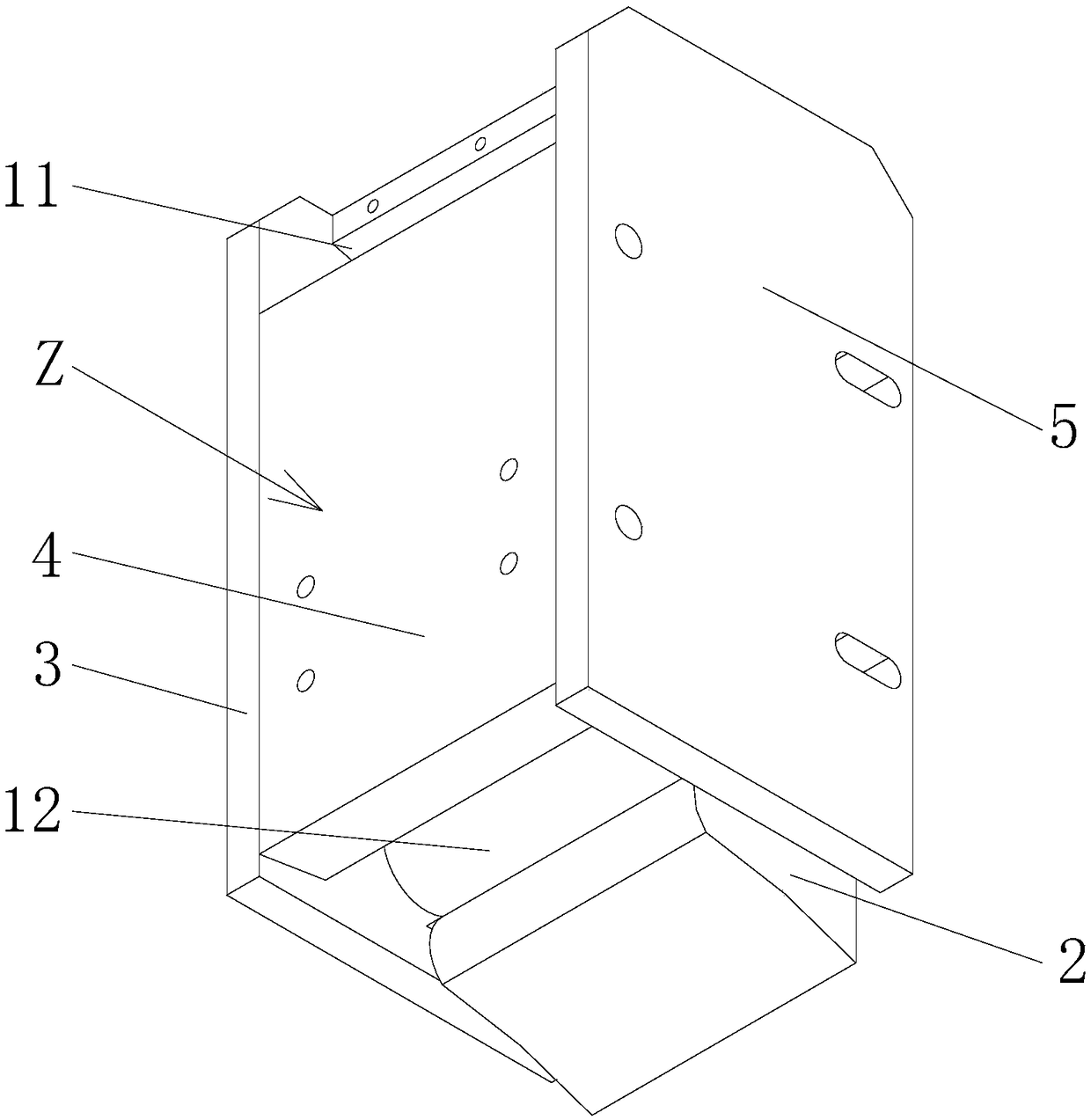

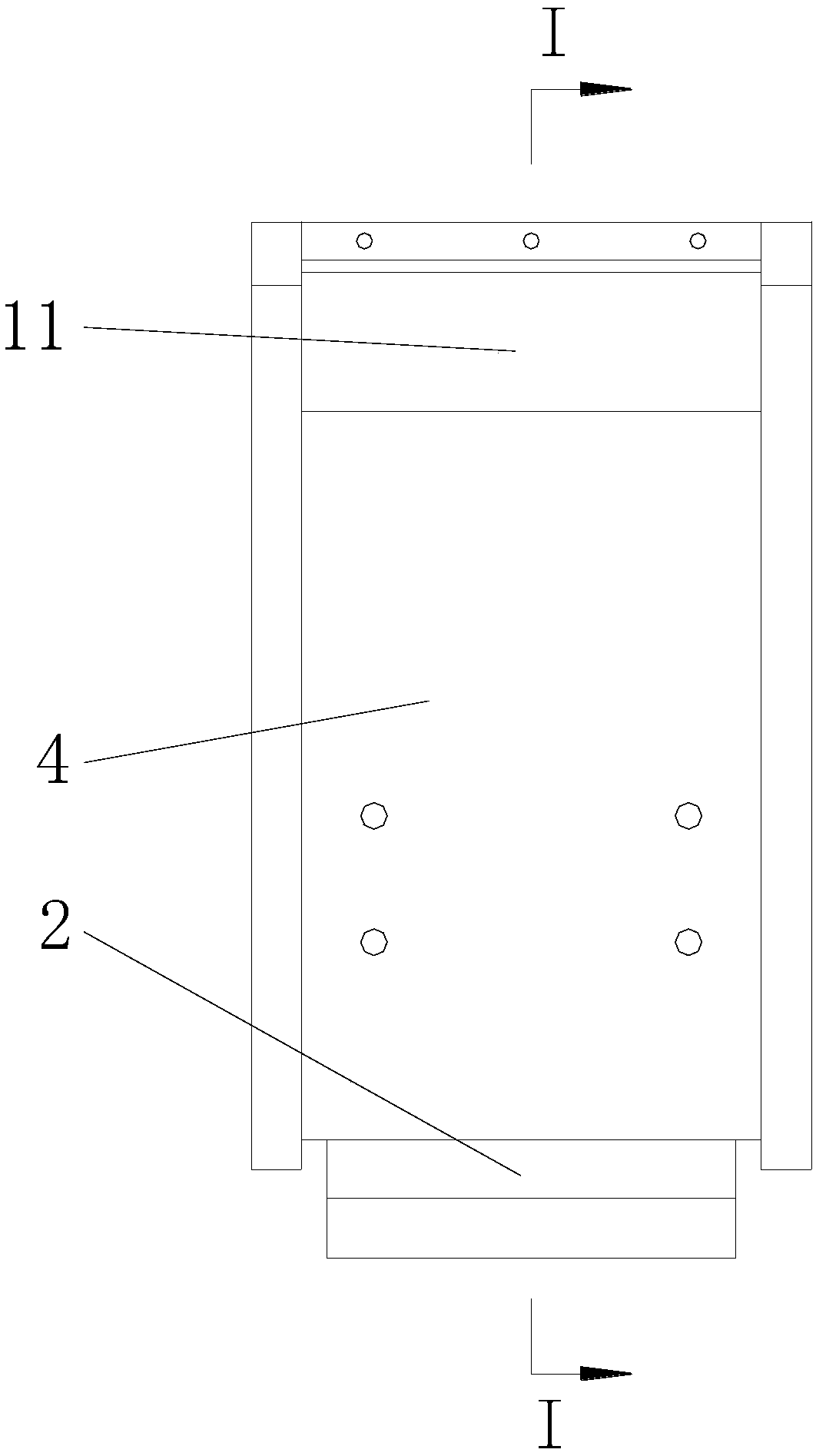

[0023] A cylindrical battery sliding conveying device, such as Figure 1~4 As shown, it includes an inductor and a box with a channel 1 inside. The box is a cuboid, including the first slider 2, the first sealing plate 3, the second Slider 4, second sealing plate 5.

[0024] A through hole 31 is opened at the joint with the first slider 2 on the first cover plate 3, and at least two through holes 31 are arranged vertically, and the first cover plate 3 passes through each through hole 31. A fastener is connected to the first slider 2; the second sealing plate 5 is provided with a second through hole 51 at the connection with the first slider 2, and the second through hole 51 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com