High-pressure self-adaptive clearance sealing double-plunger synchronous hydraulic cylinder

A synchronous hydraulic cylinder, self-adaptive technology, applied in the direction of fluid pressure actuating device, servo meter circuit, mechanical equipment, etc. load and improve dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

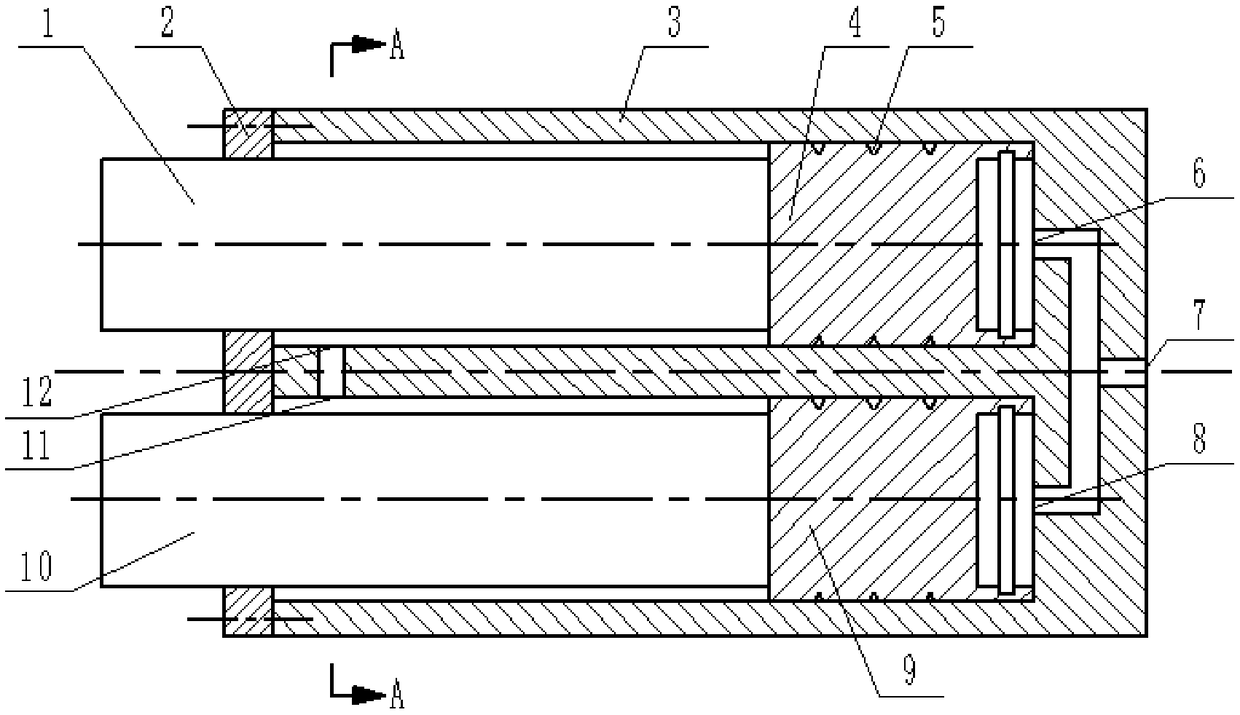

[0026] A high-pressure self-adaptive gap seal double-plunger synchronous hydraulic cylinder. Such as figure 1 with figure 2 As shown, the double-plunger synchronous hydraulic cylinder includes a cylinder barrel 3 , a cylinder head 2 , a first plunger rod 1 , a second plunger rod 10 , a first plunger 4 and a second plunger 9 .

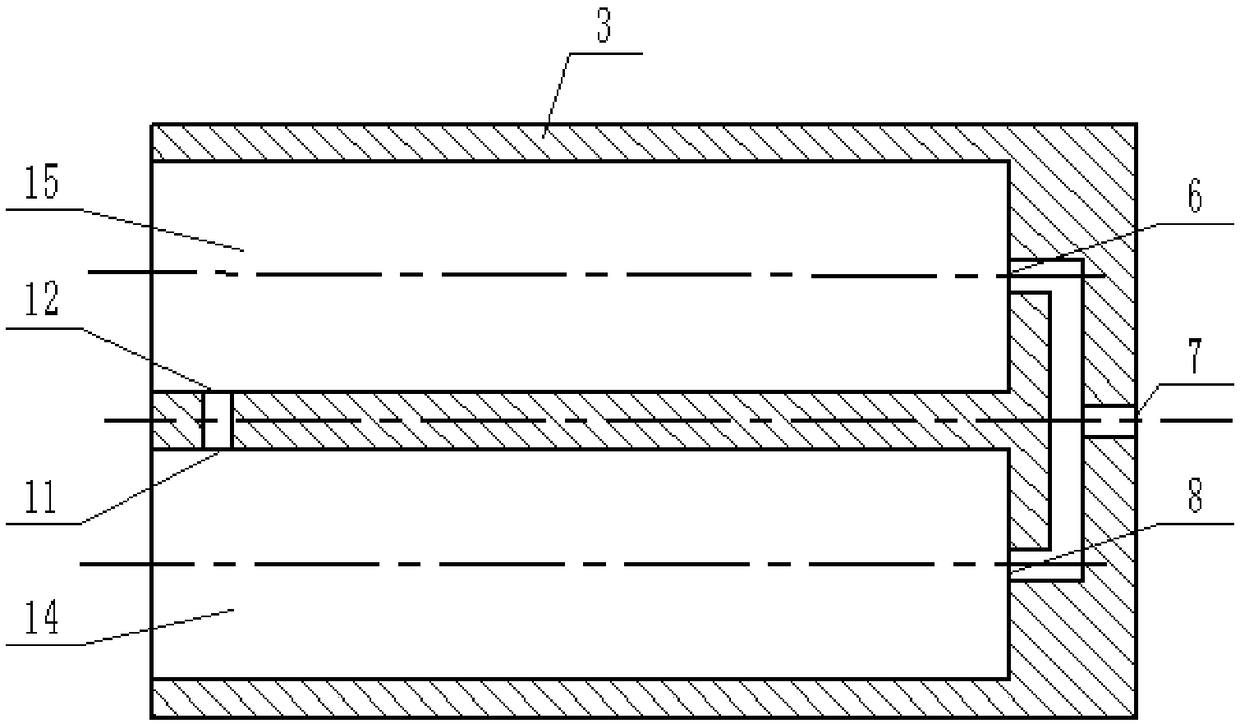

[0027] Such as figure 1 As shown, the first plunger 4 and the second plunger 9 are correspondingly installed in the first plunger chamber 15 and the second plunger chamber 14 of the cylinder 3, the first plunger rod 1 and the second plunger rod 10 It is fixedly connected with the connecting ends of the corresponding first plunger 4 and the second plunger 9, the cylinder head 2 is fixed on the open end of the cylinder barrel 3, and the protruding ends of the first plunger rod 1 and the second plunger rod 10 are respectively Thread out the cylinder head 2.

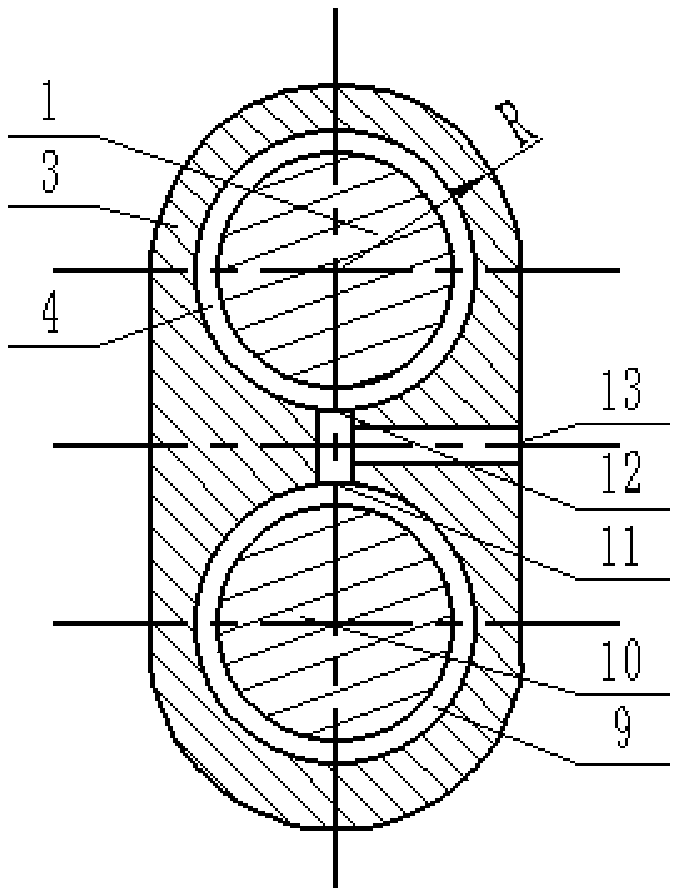

[0028] Such as figure 2 As shown, the cylinder barrel 3 is a cylindrical body of equal sect...

Embodiment 2

[0034] A high-pressure self-adaptive gap seal double-plunger synchronous hydraulic cylinder. Except following technical parameter, all the other are with embodiment 1:

[0035] The distance between the centers of the two semicircles is (2.7~3.0)R;

[0036] lip thickness b =2~3mm, the length of lip a=15~30mm;

[0037] The width a1=1.0~1.2mm of the annular groove, the depth of the annular groove is b1=0.5~0.6mm;

[0038] The cylindrical surface of the cylinder is evenly provided with 4 to 7 pressure equalizing grooves 5;

[0039] The width C of the pressure equalizing groove 5 is 1.0-1.2 mm, and the depth h of the pressure equalizing groove 5 is 0.5-0.6 mm.

[0040] Compared with the prior art, this specific embodiment has the following advantages:

[0041](1) The ends of the first plunger 4 and the second plunger 9 in this specific embodiment are provided with lip edges. When the high-pressure oil entering from the first main oil port 7 enters the first plunger 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com