Thermal spraying device for engine piston ring production

A technology for producing heat and spraying devices, which is applied in coating, fusion spraying, metal material coating processes, etc., can solve the problems of not using ceramics, reducing the friction and wear performance of the piston ring, reducing the scratch resistance of the coating, and achieving The effect of improving friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

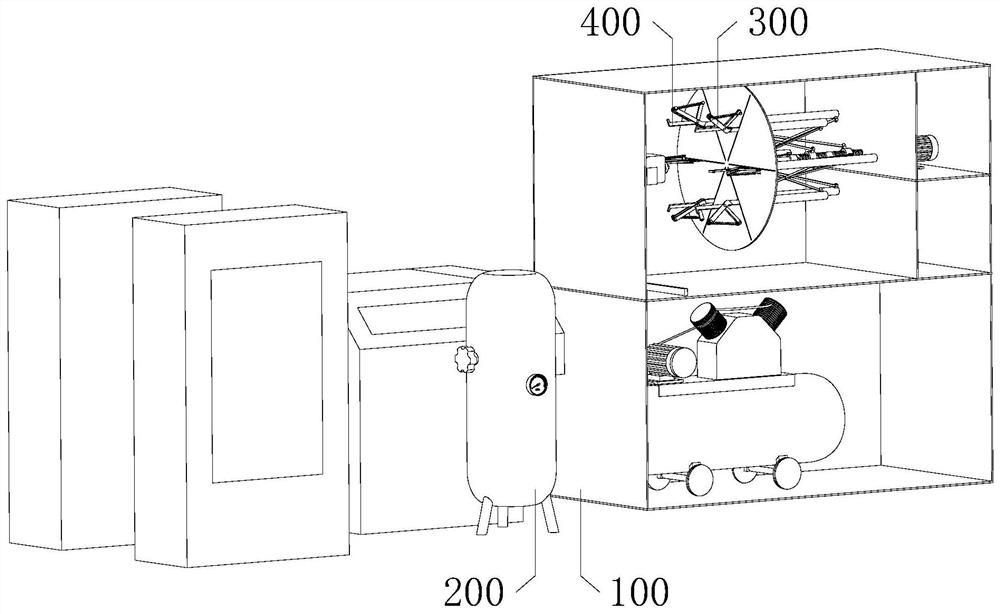

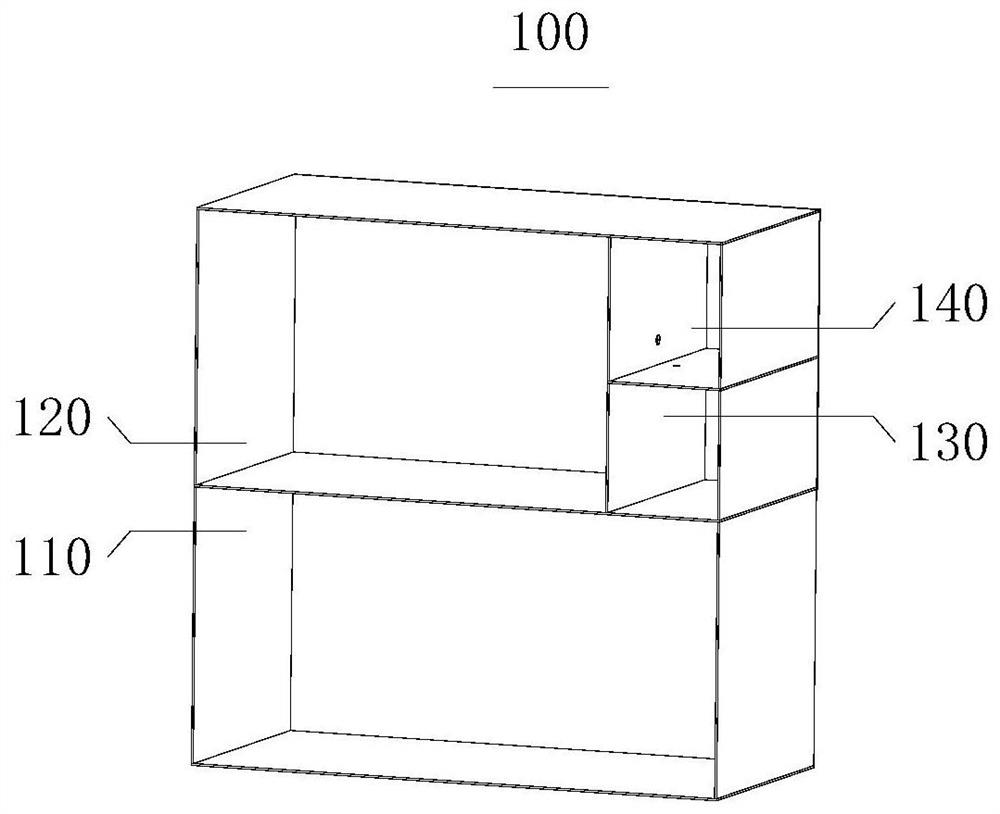

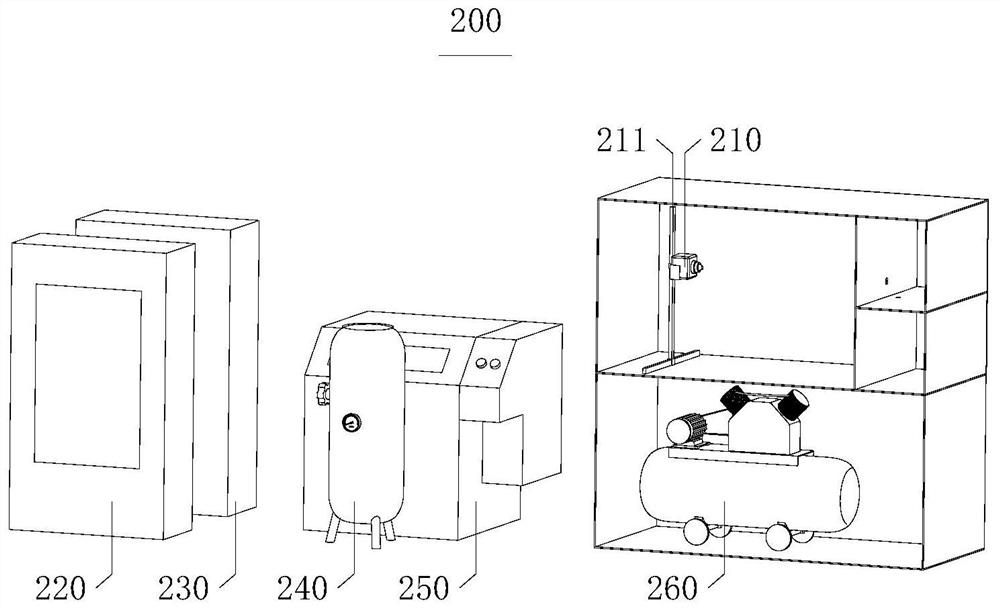

[0044] like Figure 1-Figure 9 As shown, a thermal spraying device for producing engine piston rings according to an embodiment of the present application includes: a casing 100 , a thermal spray assembly 200 , a main support mechanism 300 and an auxiliary support mechanism 400 .

[0045] The thermal spray assembly 200 is arranged on the inside and outside of the casing 100, the main supporting mechanism 300 is arranged on the top side of the casing 100, the auxiliary supporting mechanism 400 is installed on the top side of the casing 100, the auxiliary supporting mechanism 400 and the main supporting mechanism 300 With the cooperation, the thermal spray assembly 200 makes the whole device not be affected by material restrictions, which improves the wear resistance and scratch resistance of the coating. The main support mechanism 300 makes the piston ring more stable during the thermal spraying process, which can make the coating The layer has no macroscopic defects such as pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com