A method for preparing tin gradient coating on the surface of titanium alloy with low laser power

A technology of laser power and gradient coating, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as complex process, and achieve the effect of simple process, easy automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

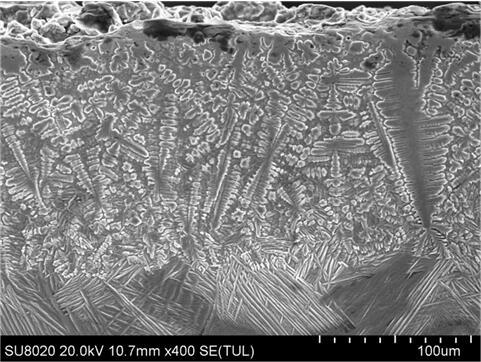

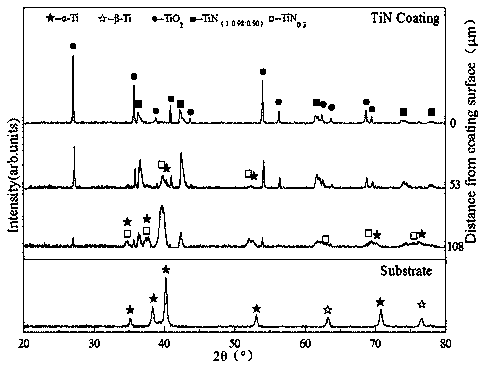

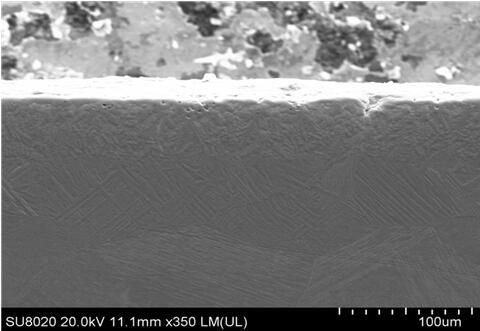

Image

Examples

Embodiment 1

[0034] A method for preparing a TiN gradient coating with low laser power on the surface of a titanium alloy, comprising the following steps:

[0035] 1. Titanium alloy substrate pretreatment; select the sample as TC4 titanium alloy, wire-cut the TC4 titanium alloy substrate into a size of 30mm*22mm*6mm, and use 80#, 120#, 240#, 320#, 400#, 600 # of water abrasive paper for surface treatment, then dry with absolute ethanol ultrasonic cleaning for 15min;

[0036] 2. Air supply treatment: put the pretreated TC4 titanium alloy substrate into the air supply controller, and send high-purity nitrogen laterally through the air supply nozzle, the purity of which is greater than 99.999%; the air supply parameters are set: the distance between the nozzle opening and the light spot is 5~ 15mm, the nitrogen flow rate meter controls the nitrogen flow rate to 20L / min;

[0037] 3. Laser nitriding treatment: After the TC4 titanium alloy substrate is air-supplied for 5 to 10 seconds, turn on ...

Embodiment 2

[0039] A method for preparing a TiN gradient coating with low laser power on the surface of a titanium alloy, comprising the following steps:

[0040] 1. Titanium alloy substrate pretreatment; select the sample as TC4 titanium alloy, wire-cut the TC4 titanium alloy substrate into a size of 30mm*22mm*6mm, and use 80#, 120#, 240#, 320#, 400#, 600 # of water abrasive paper for surface treatment, then dry with absolute ethanol ultrasonic cleaning for 15min;

[0041] 2. Air supply treatment: put the pretreated TC4 titanium alloy substrate into the air supply controller, and send high-purity nitrogen laterally through the air supply nozzle, the purity of which is greater than 99.999%; the air supply parameters are set: the distance between the nozzle opening and the light spot is 5~ 15mm, the nitrogen flow rate meter controls the nitrogen flow rate to 20L / min;

[0042] 3. Laser nitriding treatment: After the TC4 titanium alloy substrate is air-supplied for 5 to 10 seconds, turn on ...

Embodiment 3

[0044] A method for preparing a TiN gradient coating with low laser power on the surface of a titanium alloy, comprising the following steps:

[0045] 1. Titanium alloy substrate pretreatment; select the sample as TC4 titanium alloy, wire-cut the TC4 titanium alloy substrate into a size of 30mm*22mm*6mm, and use 80#, 120#, 240#, 320#, 400#, 600 # of water abrasive paper for surface treatment, then dry with absolute ethanol ultrasonic cleaning for 15min;

[0046] 2. Air supply treatment: put the pretreated TC4 titanium alloy substrate into the air supply controller, and send high-purity nitrogen laterally through the air supply nozzle, the purity of which is greater than 99.999%; the air supply parameters are set: the distance between the nozzle opening and the light spot is 5~ 15mm, the nitrogen flow rate meter controls the nitrogen flow rate to 20L / min;

[0047]3. Laser nitriding treatment: After the TC4 titanium alloy substrate is air-supplied for 5 to 10 seconds, turn on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com