Shaped photovoltaic cell structure and preparation method thereof

A photovoltaic cell and special-shaped technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as large dead zone, low battery conversion efficiency, and limited output current, and achieve high effective utilization, beautiful structure, and high conversion efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

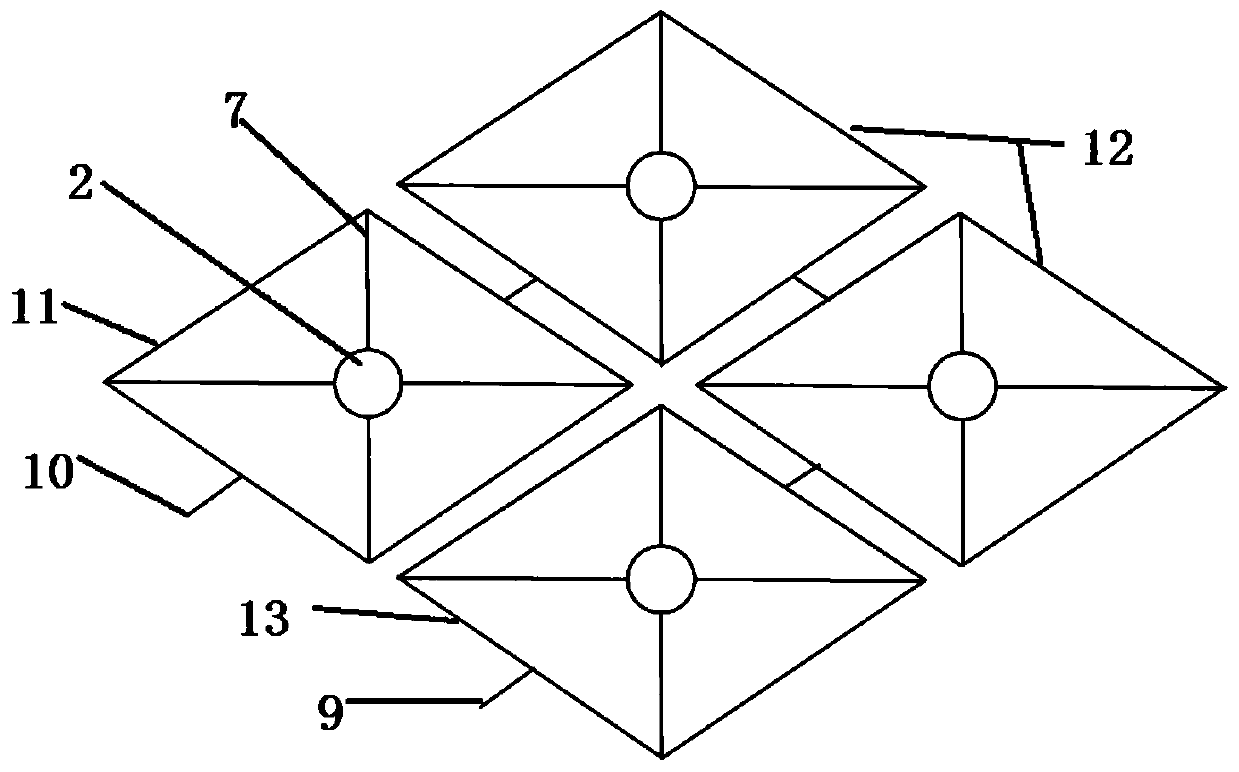

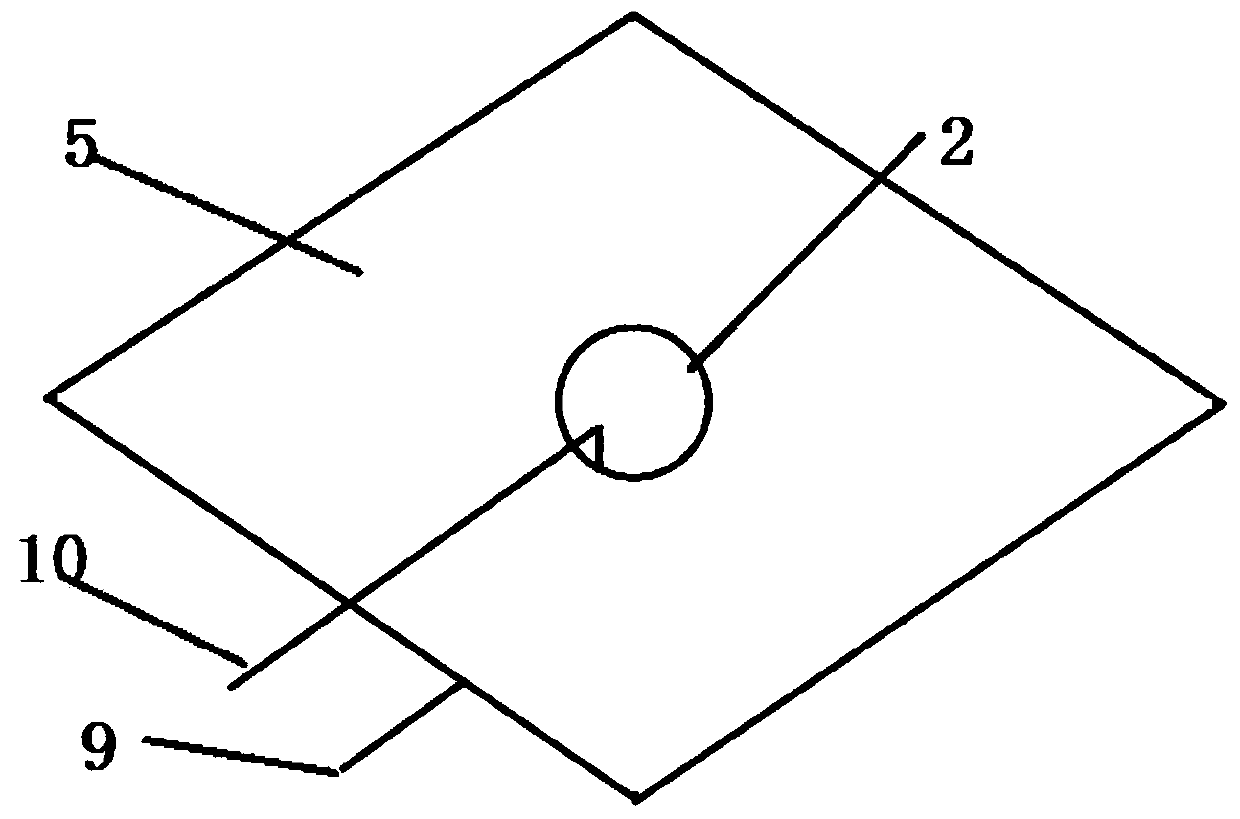

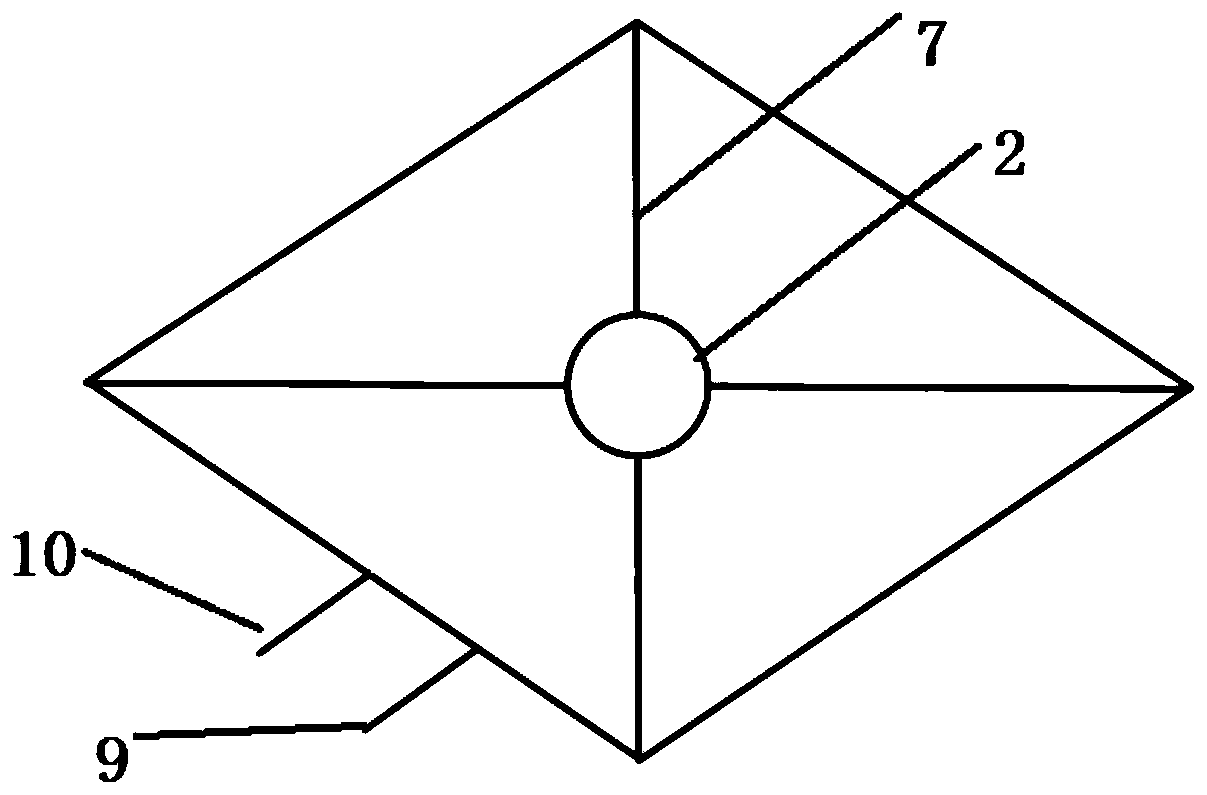

[0031] Example 1 as figure 2 , image 3 , Figure 4 As shown, a special-shaped photovoltaic cell structure includes a special-shaped photovoltaic cell structure body and positive and negative output. The special-shaped photovoltaic cell structure body includes a special-shaped structure sub-battery 1. through holes 2; special-shaped sub-batteries 1 are made of conventional battery chips or battery chips that do not meet the standard size, including crystalline silicon cells, thin-film cells, or flexible thin-film cells, etc., and then undergo mechanical stamping and mechanical cutting. Or cut and design the battery chip into the required special-shaped structure, such as triangle, prism, trapezoid, etc., by means of laser. The cutting process is a fine processing process to ensure that the positive and negative electrodes are disconnected, there is no short circuit and the battery is not broken under abnormal conditions. Such as figure 2 As shown, a hole is drilled in th...

Embodiment 2

[0033] Example 2 as figure 1 , figure 2 , image 3 , Figure 4 The heterogeneous photovoltaic cell structure shown includes a plurality of heterogeneous structure subcells 1, the heterogeneous structure subcell 1 arranged at the first position is called the first heterogeneous structure subcell 11, and the heterogeneous structure subcell 1 arranged in the middle position is collectively referred to as It is the middle special-shaped structure sub-cell 12 , and multiple middle special-shaped structure sub-cells 12 can be selected and provided according to needs, and the terminal special-shaped structure sub-cell 13 is called the terminal special-shaped structure sub-cell 13 . On the heterogeneous structure sub-battery 1, there is provided a threading hole 2 that allows the current collection wire to pass through; Or flexible thin-film battery sheets, etc., and then cut and design the battery chips into required special-shaped structures, such as triangles, prisms, trapezoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com