Continuous-work stone cutter rail

A cutting machine and track technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of unsatisfactory mechanical properties, poor stability of the whole machine, and low use efficiency, so as to improve stability and prolong service life , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

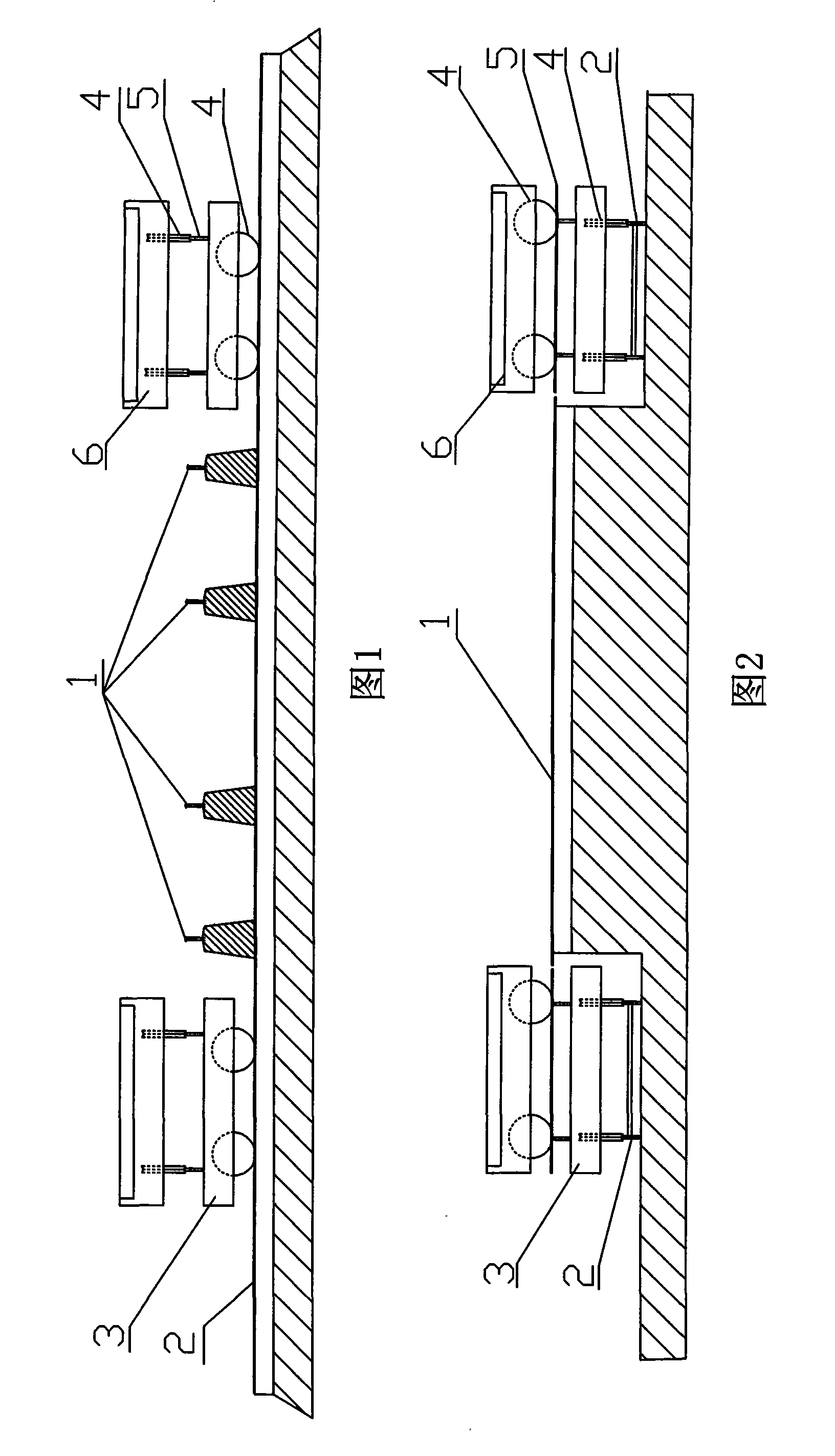

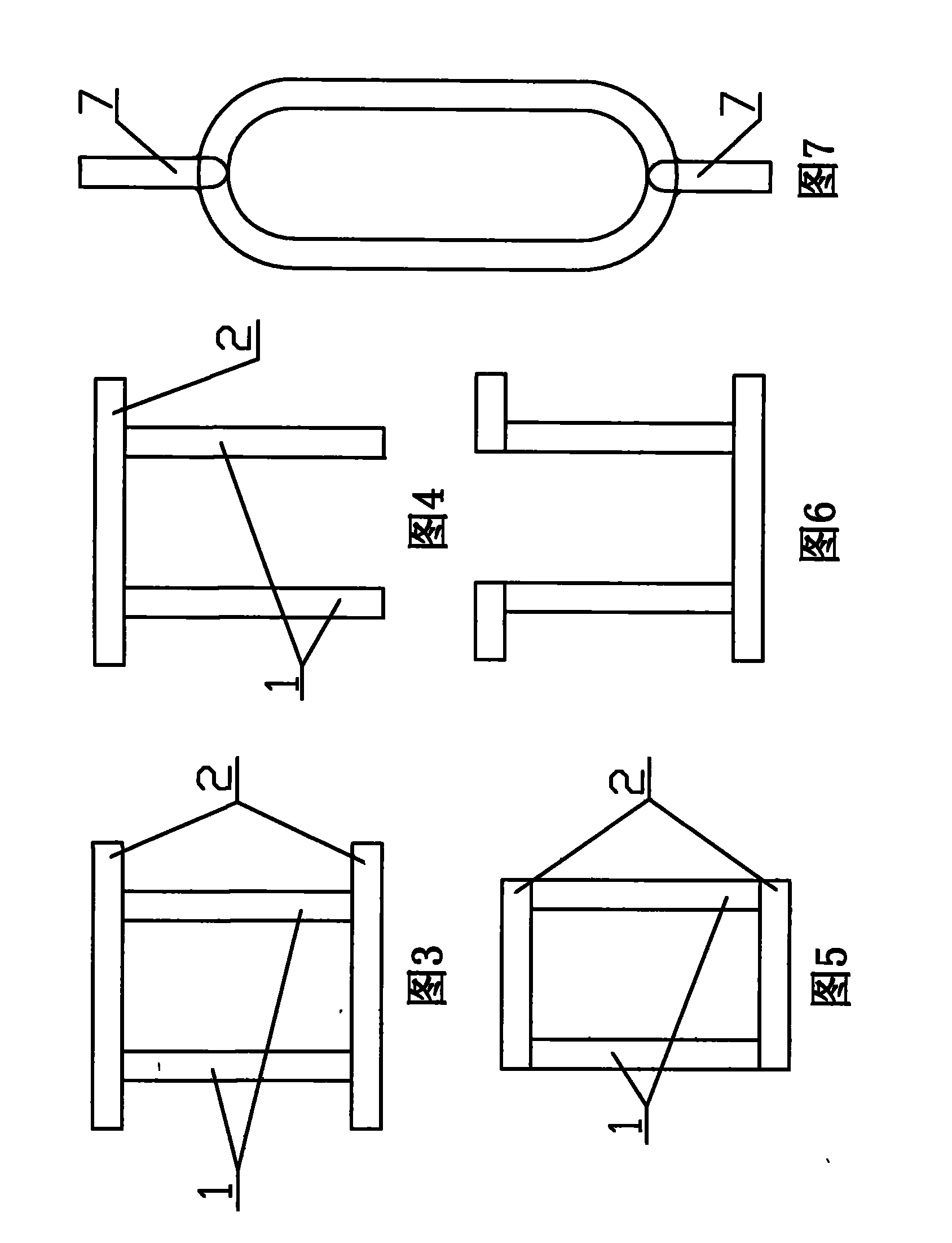

[0015] As shown in Figure 1-7: the present invention is made up of two groups of vertically distributed linear longitudinal rails 2, on which a traveling frame 3 or vehicle frame 6 that can walk on the rails is arranged, and it is also composed of horizontally distributed Horizontal track 1 is formed, is provided with driving frame 3 and or vehicle frame on vertical or horizontal track, is provided with roller 4 below driving frame, is provided with driving frame track 5 above driving frame, and vehicle frame is arranged on row Roll on frame tracks or on longitudinal or transverse tracks.

[0016] One end or two ends of two sets of longitudinally distributed linear longitudinal tracks 2 are provided with a transverse track 1 between the two sets of longitudinal tracks, and the longitudinal tracks are provided with a vehicle frame that can run on the longitudinal tracks through rollers. The upper surface of the vehicle frame is provided with a vehicle frame track, and the setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com