Assembling and spraying production line device

An assembly line and spray booth technology, which is applied in spraying devices, spray booths, etc., can solve problems such as high labor intensity, low yield, and single-handling, and achieve the effects of ensuring spraying performance, reducing defective products, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

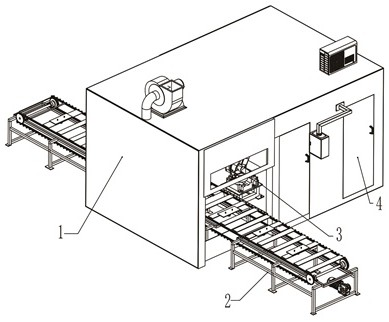

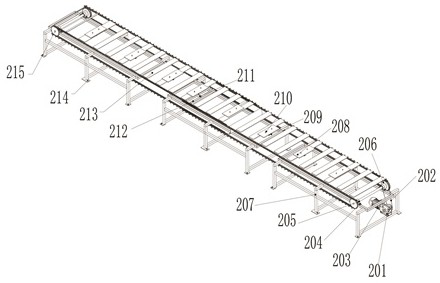

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown is an assembly spraying line device. The spraying booth assembly 1 is a spraying booth, the chain conveying line 2 is fixed inside the spraying booth assembly 1, and is used for conveying functional parts, and the spraying robot 3 is fixed inside the spraying booth assembly 1, and is a spraying execution part, a thermostatic chamber The assembly 4 is located on the other side of the spray booth assembly 1, and provides the spraying robot 3 with stable spray paint.

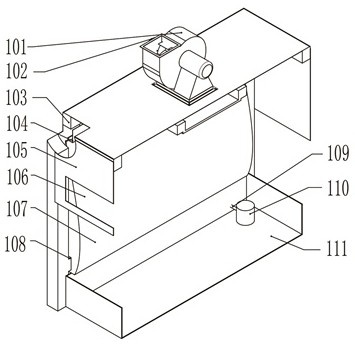

[0027] The specific structure of the spray booth assembly 1 is as follows: figure 2 As shown, the negative pressure fan 101 is fixed on the spray booth frame 103, the negative pressure pipeline 102 connects the negative pressure fan 101 and the negative pressure equalizing pipe 108 to generate downward air negative pressure for the spray booth assembly 1, and the circulating water supply pipe 109 Connect the circulating wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com