Bending combined two-dimension time-varying load loading unit

A technology of bending and torsion combination and loading device, which is applied in measuring device, position/direction control, non-electric variable control and other directions, can solve the problem that torque loading cannot fully reflect the real load condition of the loaded object, and can reach the bending moment loading point. Real-time variable, reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below.

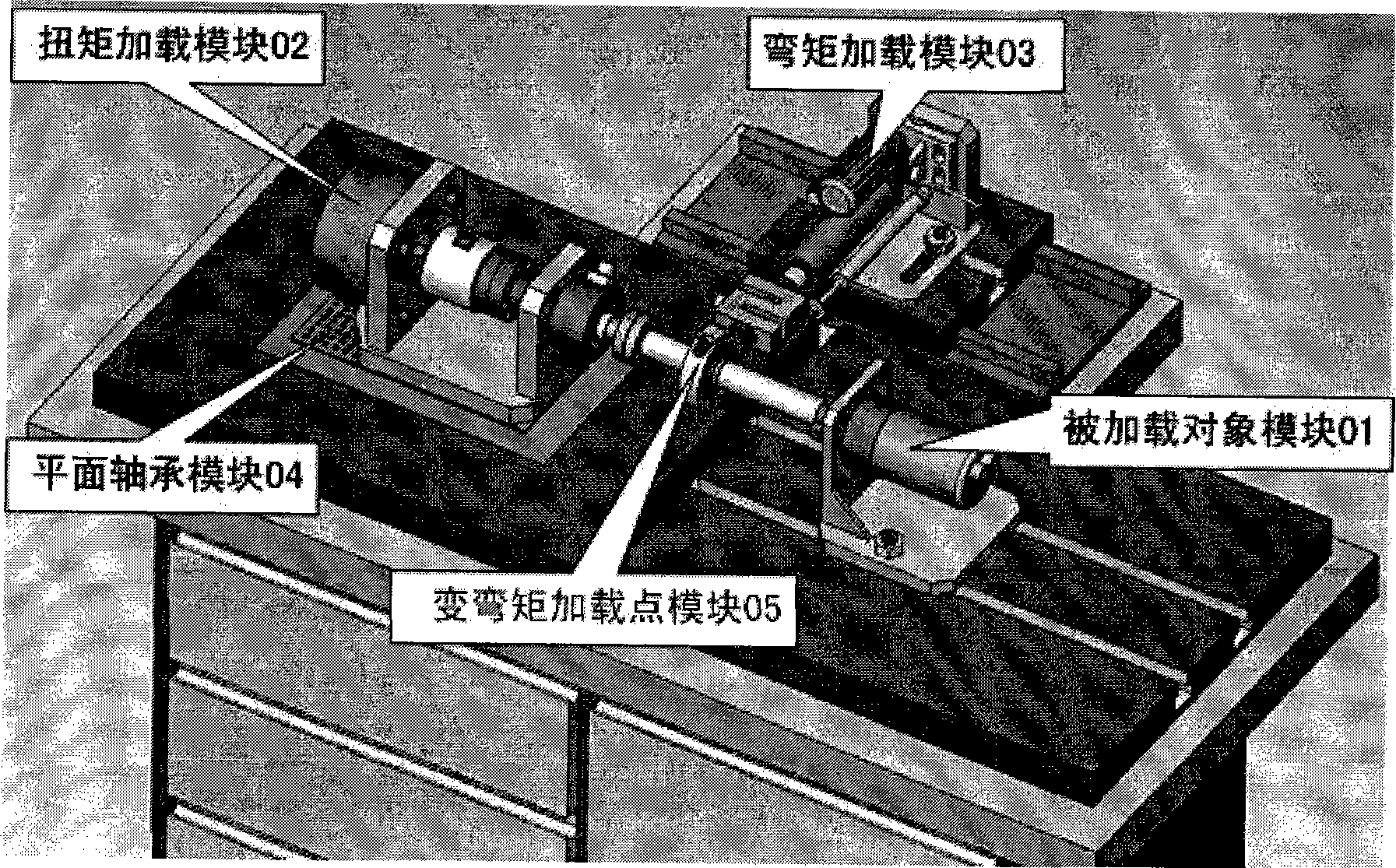

[0033] 1. Bending torsion combined two-dimensional time-varying load loading device of the present invention, its executive mechanism is formed (referring to figure 1 ).

[0034] (1) The loaded object module 01 is the action object of the system;

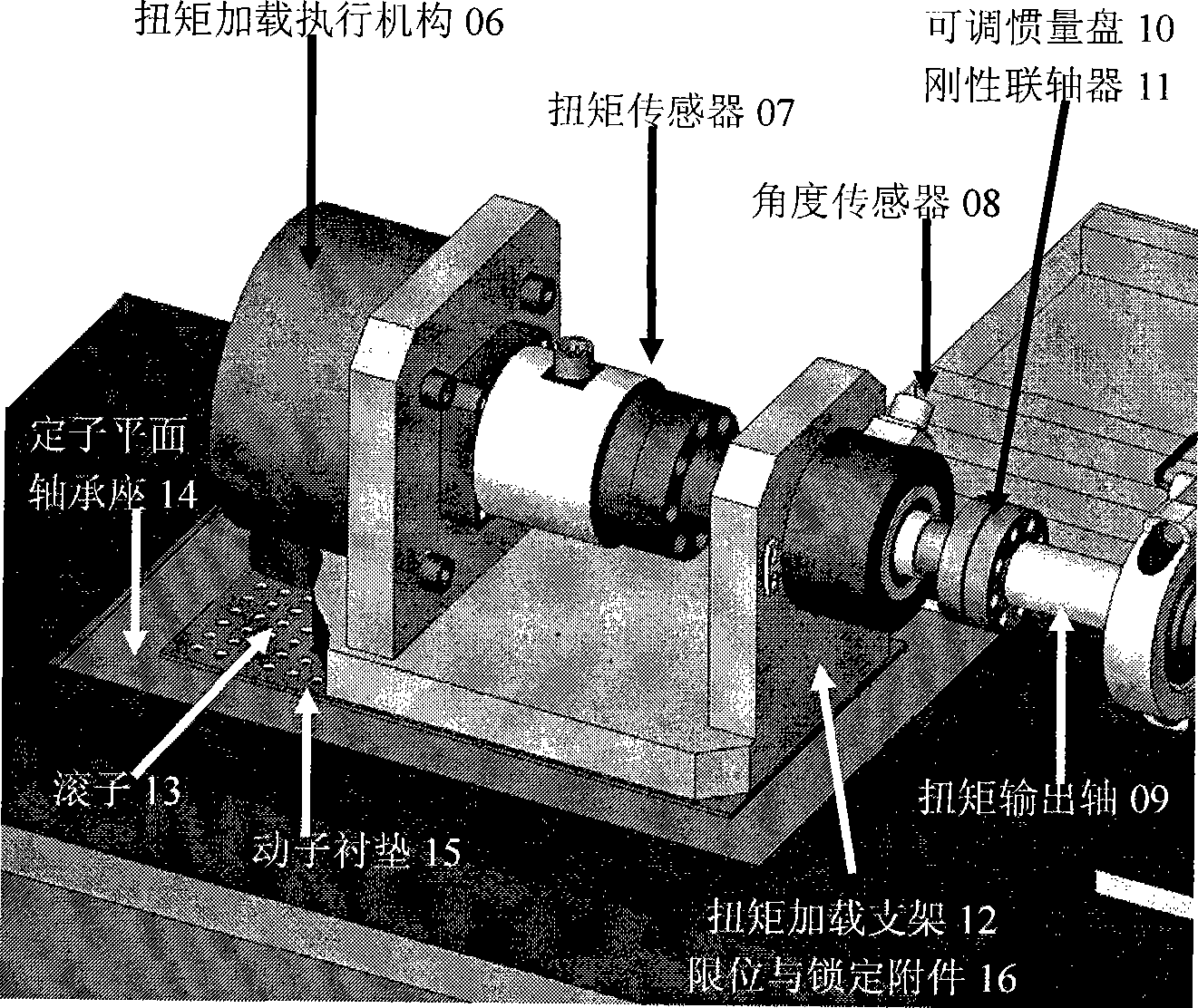

[0035] (2) The torque loading module 02 adopts a rigidly connected electric, hydraulic or pneumatic closed-loop servo system;

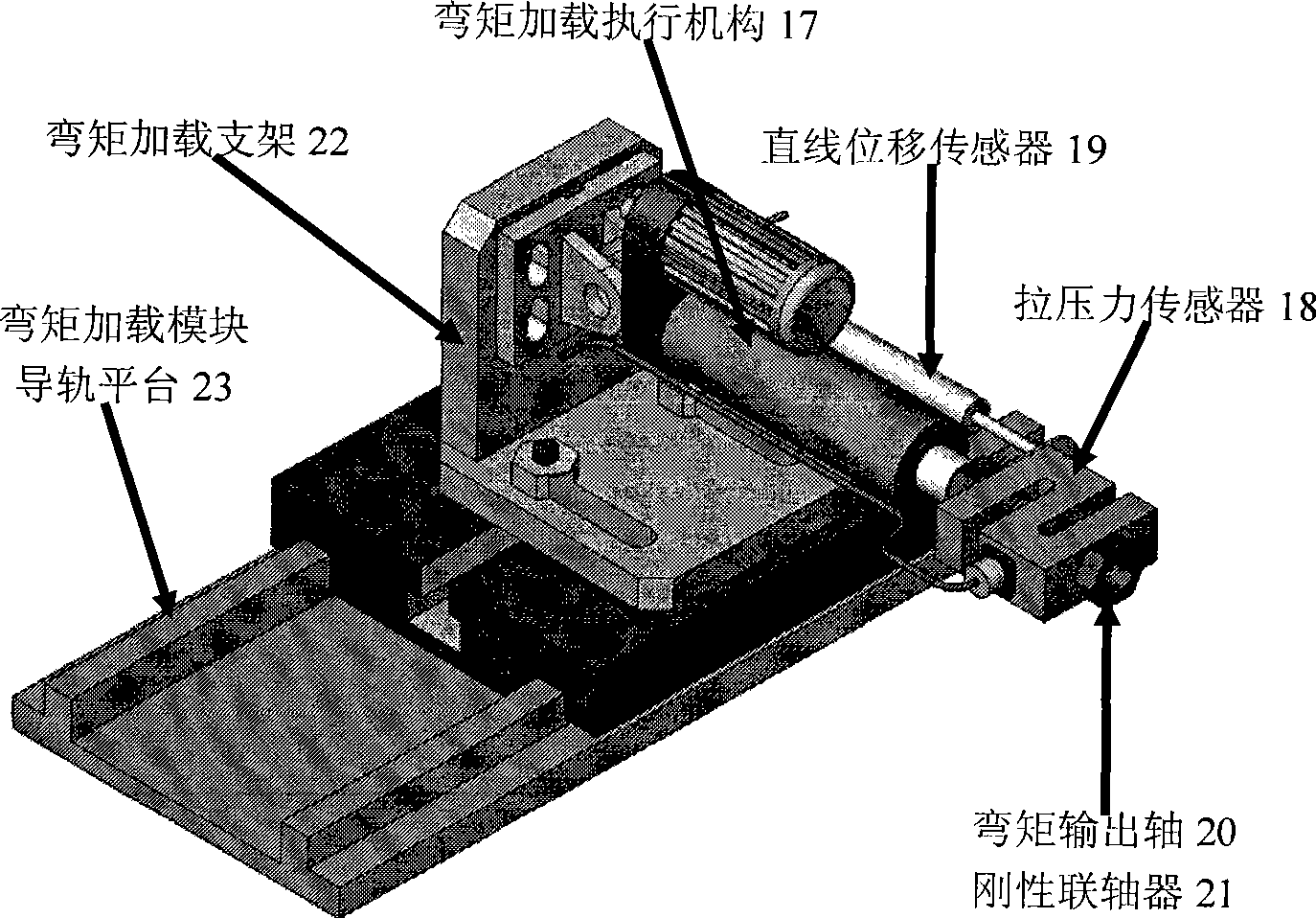

[0036] (3) The bending moment loading module 03 adopts a rigidly connected electric, hydraulic or pneumatic closed-loop servo system;

[0037] (4) plane bearing module 04, used to support the above-mentioned torque loading module 02, and make it have degrees of freedom in the plane;

[0038] (5) The variable bending moment loading point module 05 is combined to connect the torque loading module 02 and the bending moment loading module 03 , and rigidly connect the whole with the loaded object module 01 .

[0039] 2. The composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com