Method for preparing peroxide phosphoric acid

A technology of peroxyphosphoric acid and peroxypyrophosphoric acid, which is applied in the field of phosphorus chemical industry, can solve the problems of low hydrogen peroxide active oxygen yield and high heat transfer cost, achieve high economy and practicability, less active oxygen loss, and simple control conditions easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

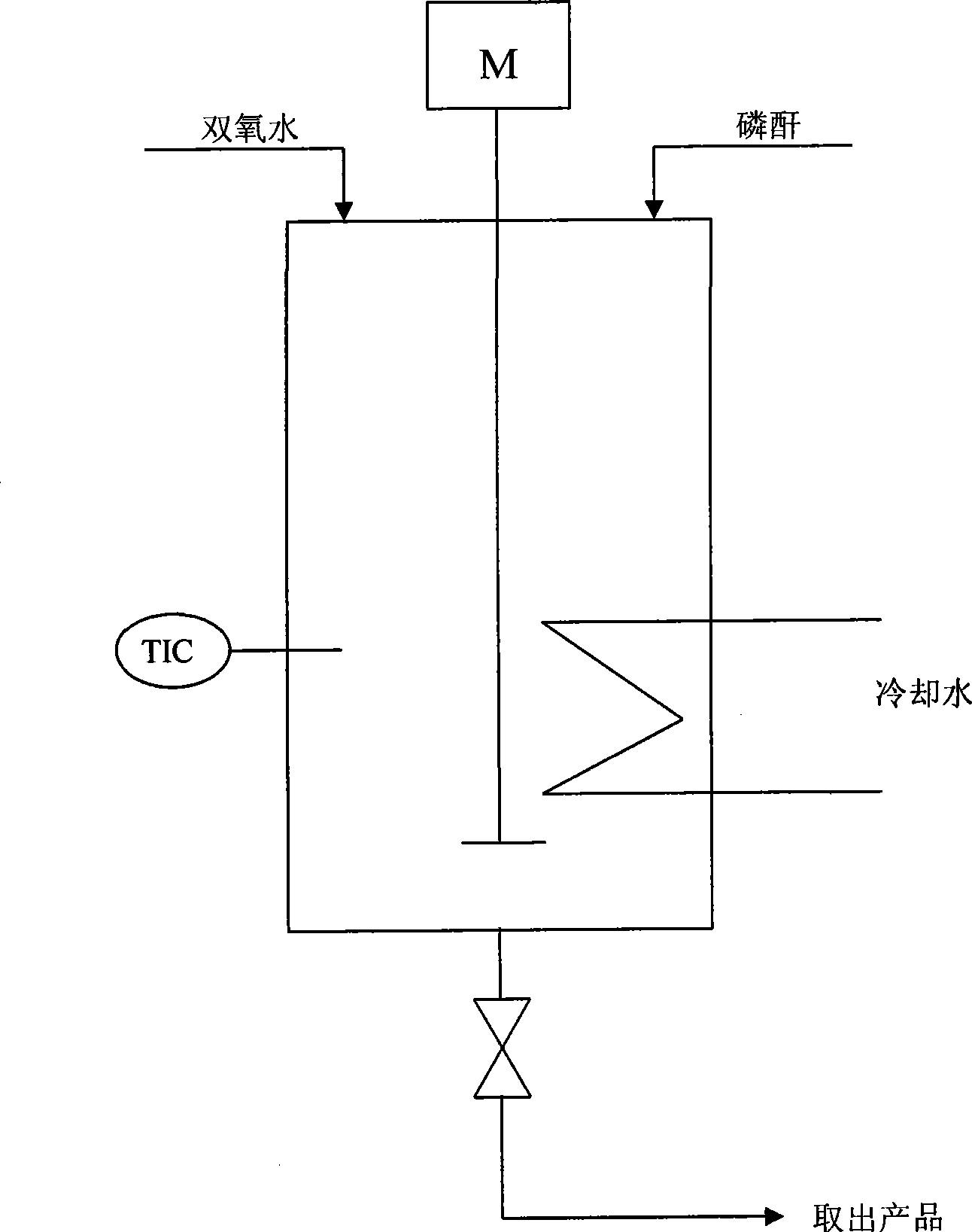

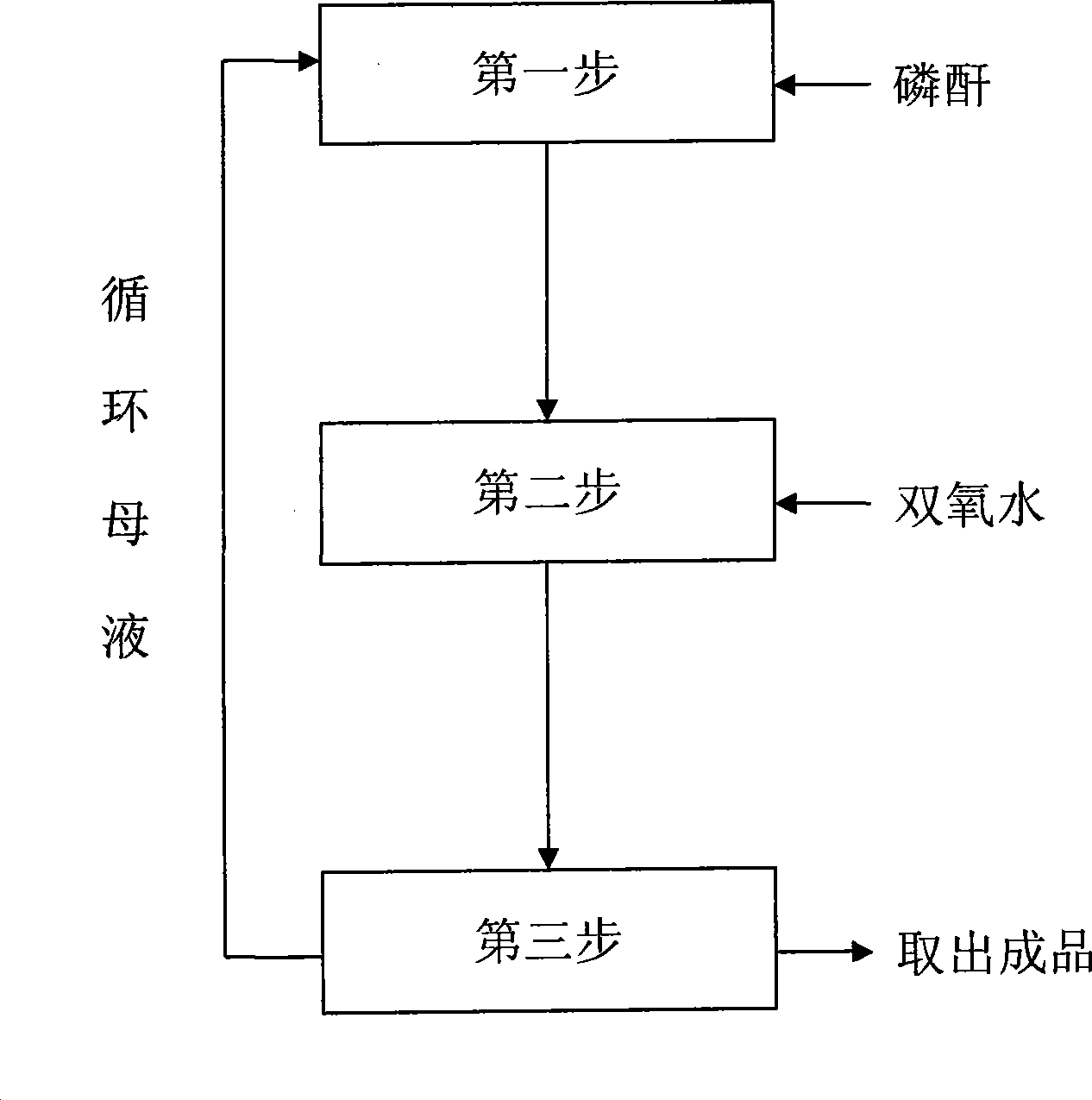

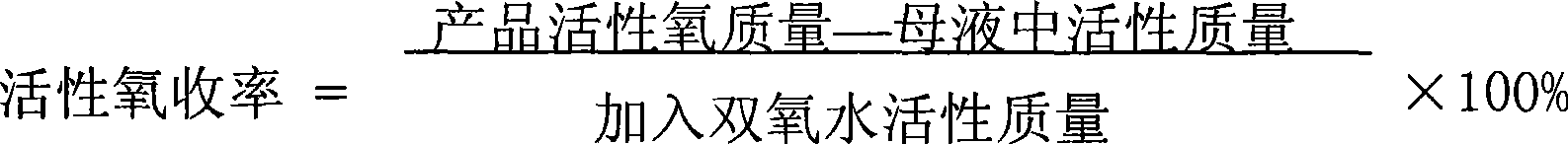

[0044] Embodiment 1, add 5 kilograms of 90% peroxyphosphoric acid mother liquor in 10 liters of jacketed reactors, add phosphoric anhydride under the condition of feeding cooling water while stirring, add phosphoric anhydride speed to show that the temperature is not high At 35°C, add a total of 2.8 kg of phosphoric anhydride and continue to mix and dissolve for 10 minutes. After all the solids are dissolved, slowly add 61.3% hydrogen peroxide under the above-mentioned control conditions, keep the temperature of the feed liquid below 35°C, and add hydrogen peroxide together. 2.208 kg were then stirred and matured for two hours to obtain about 10 kg of product, and 5 kg of finished product peroxyphosphoric acid was taken out, and the remaining 5 kg continued to circulate as mother liquor.

Embodiment 2

[0045] Embodiment 2, add 5 kilograms of 80% peroxyphosphoric acid mother liquor in the reaction kettle of example 1, add phosphoric anhydride under the condition of cooling water cooling while stirring, add phosphoric anhydride speed to show that the temperature is not higher than 38 DEG C , add 2.52 kg of phosphoric anhydride in total, continue to mix and dissolve for 8 minutes, and after all of them are dissolved, slowly add 48.2% hydrogen peroxide under the above-mentioned control conditions, still keep the temperature of the feed liquid below 38°C, add 2.49 kg of hydrogen peroxide, and then stir and mature Two hours, about 10 kilograms of products were obtained, 5 kilograms of finished product peroxyphosphoric acid were taken out, and 5 kilograms of remaining mother liquor continued to circulate.

Embodiment 3

[0046] Embodiment 3, add 1.25 kilograms of 80% peroxyphosphoric acid mother liquors in the reactor of example 1, add phosphoric anhydride under the condition of passing cooling water while stirring, add phosphoric anhydride speed to show that the temperature is not higher than 38 ℃, the first After adding 0.63 kg of phosphoric anhydride at one time, continue to mix and dissolve for 8 minutes, then add 48.2% hydrogen peroxide under the above conditions, and keep the temperature of the feed liquid not higher than 38°C, add 0.623 kg of hydrogen peroxide, and then mix and mature for 20 minutes; then add Phosphoric anhydride, the control conditions are the same as the first time. After adding 1.25 kg of phosphoric anhydride for the second time, continue to mix and dissolve for 8 minutes, then add 48.2% hydrogen peroxide, and control the temperature below 38 ° C while still mixing. Add 1.24 kg of hydrogen peroxide for the second time , the feed liquid continued to ripen for 20 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com