Method for preparing peroxide phosphoric acid

A technology of monophosphoric acid and superdiphosphoric acid, which is applied in the field of phosphorus chemical industry, can solve the problems of high heat transfer cost and low yield of active oxygen in hydrogen peroxide, achieve less loss of active oxygen, high economy and practicability, and simple process control convenient effect

Active Publication Date: 2010-11-10

YUNNAN JIANGLIN GROUP

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

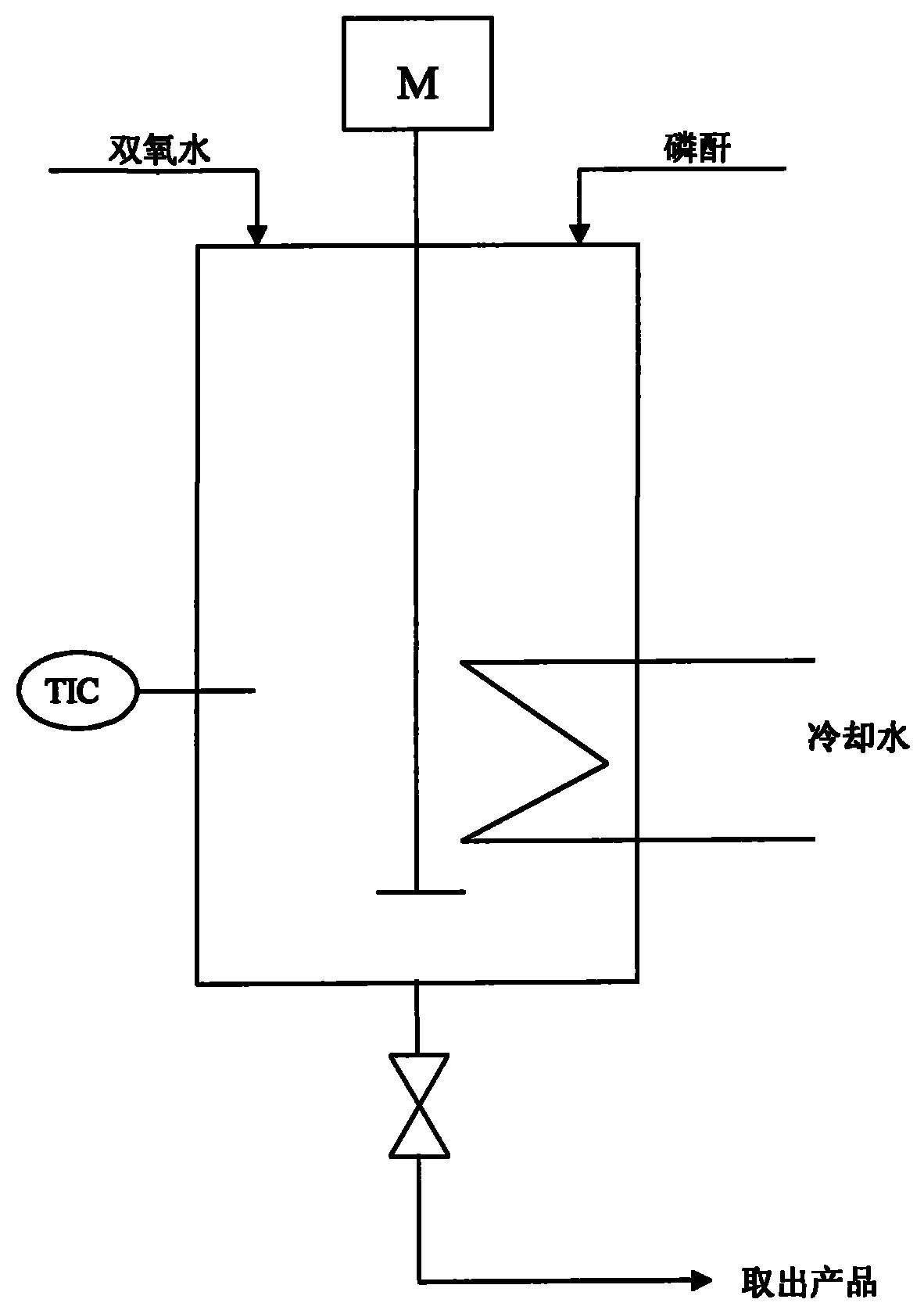

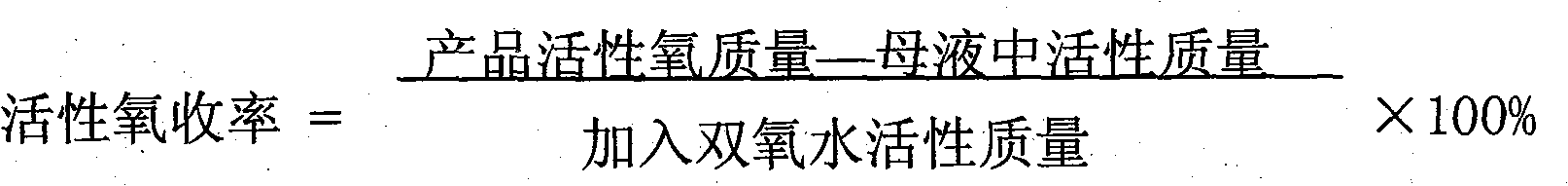

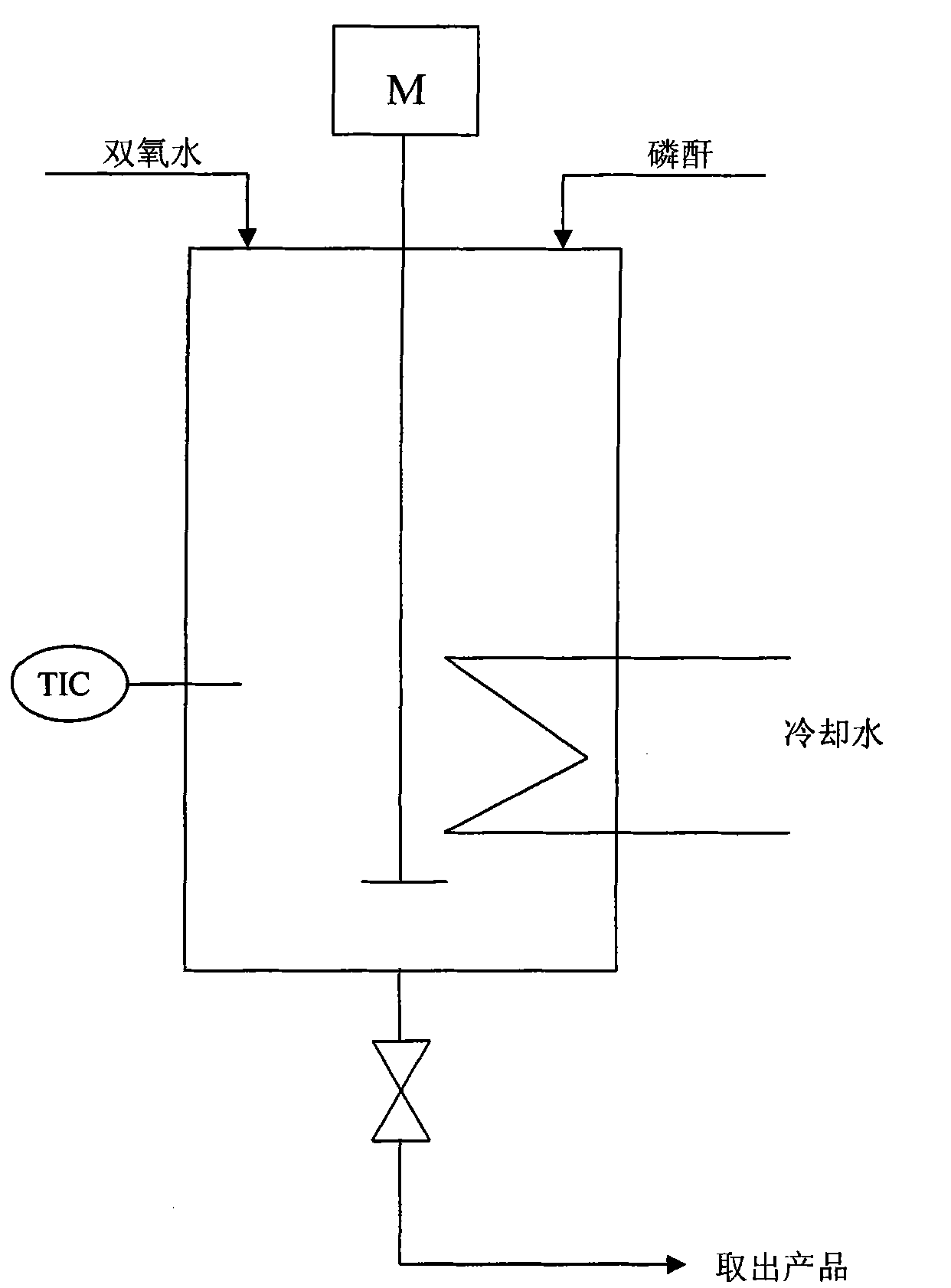

In order to solve the shortcomings of the above-mentioned production of peroxyphosphoric acid with phosphoric anhydride and hydrogen peroxide as raw materials, the hydrogen peroxide active oxygen yield is low and the heat transfer cost is high. The invention provides a method for preparing peroxyphosphoric acid, comprising the following steps:

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for preparing a peroxide phosphoric acid, belongs to the chemical technical field of phosphorus, and relates to an improved method for producing peroxide phosphoric acid (H3PO5). The method adopts phosphoric acid anhydride and hydrogen peroxide aqueous solution as raw materials and comprises the following steps: (1) resolving phosphoric acid anhydride in a peroxide phosphoric acid mother solution, and (2) adding a hydrogen peroxide aqueous solution for hydrolyzing the product to get peroxide phosphoric acid. Part of peroxide phosphoric acid is taken out as products, and the rest serves as mother solution to circulate in step 1. The method is easy to control, has low active oxygen loss and is easy to realize industrialized production.

Description

A kind of preparation method of peroxyphosphoric acid technical field The invention belongs to the technical field of phosphorus chemical industry and relates to a production method of peroxyphosphoric acid. Background technique Similar to peroxysulfuric acid and peroxynitric acid, peroxyphosphoric acid (H3PO5) is an inorganic peroxyacid. According to "B.Elver, S.Hawkins, G.schulz, 'Peroxocompounds, Inorganic'inullmannEncyclopediaofIndustrialChemistry, 19A, P177-197 (1991)" ("Inorganic peroxide" "Ullmann Encyclopedia of Industrial Chemistry") description, peroxy Phosphoric acid is a strong oxidizing agent. Unlike peroxysulfuric acid and peroxynitric acid, because phosphoric acid is a non-volatile acid, peroxyphosphoric acid has high stability, and it is involved in the application of peroxyphosphoric acid in many industries. Literature "Springer, E.l., 'Delignification of wood and kraftpulp with peroxymonophosphoricacid', J.pulpandpap.sci., Vol.23NO.12, P582-584 (1997)" ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B15/16

Inventor 万荣惠后雪松王斌饶志臻马兴良

Owner YUNNAN JIANGLIN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com