Automatic lubrication device of vertical type pump bearing

An automatic lubrication and bearing technology, applied in non-variable displacement pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of low operation reliability, difficult for lubricating oil to ascend, and poor oil supply effect. , to achieve high operational reliability, good lubrication effect and good oil supply effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

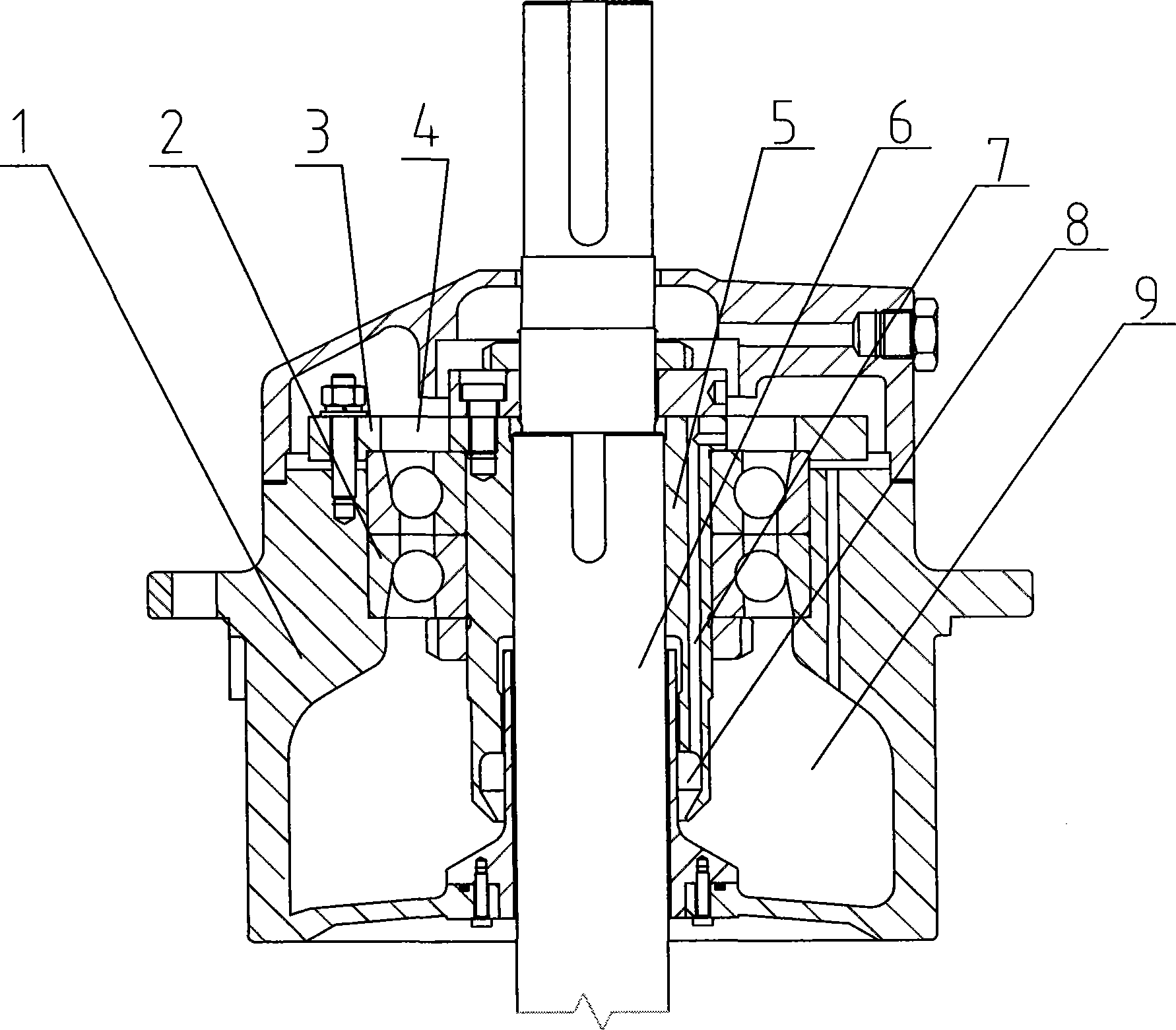

[0007] As shown in the vertical pump bearing automatic lubrication device, the bearing body 1 is provided with a bearing 2, and the outer casing of the bearing 2 is fixed in the bearing body 1 through the bearing outer casing gland 3. A main shaft 6 is arranged inside the bearing 2, and a lubricating oil chamber 9 is arranged under the bearing 2. There is a lubricating body 5 between the bearing 2 and the main shaft 6, the inner sleeve of the bearing 2 is fixed on the main shaft 6 through the lubricating body 5, and an annular oil storage tank 4 is formed between the bearing cover gland 3 and the lubricating body 5, and the annular oil storage tank 4 can be stored lubricating oil. The outer side of the lower end of the lubricating body 5 is a cone, and the inner diameter of the lower end of the lubricating body 5 is provided with an annular oil storage chamber 8, which can store lubricating oil. An oil supply hole 7 is arranged above the annular oil storage chamber 8 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com