Dispersion strip forming method

A technique of scattering strips and together, applied in the field of resolution enhancement, can solve problems affecting the quality of lithography patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

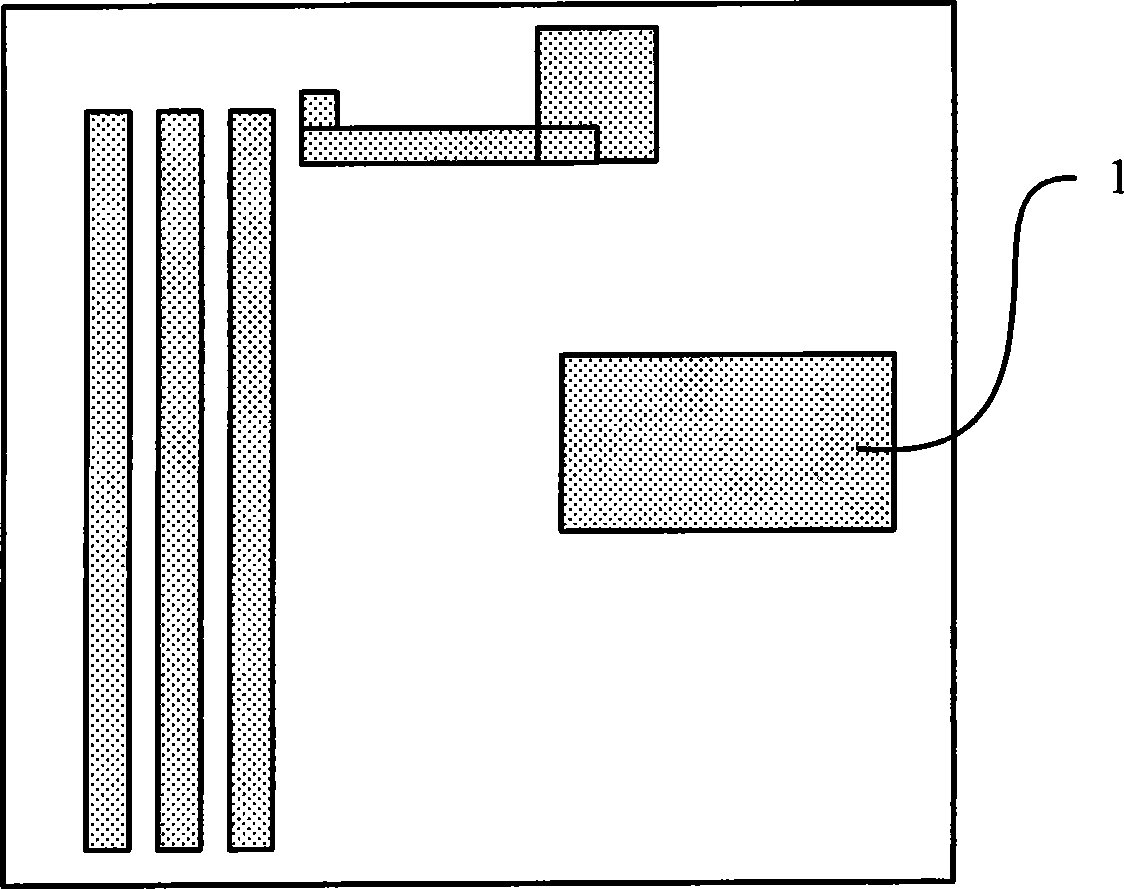

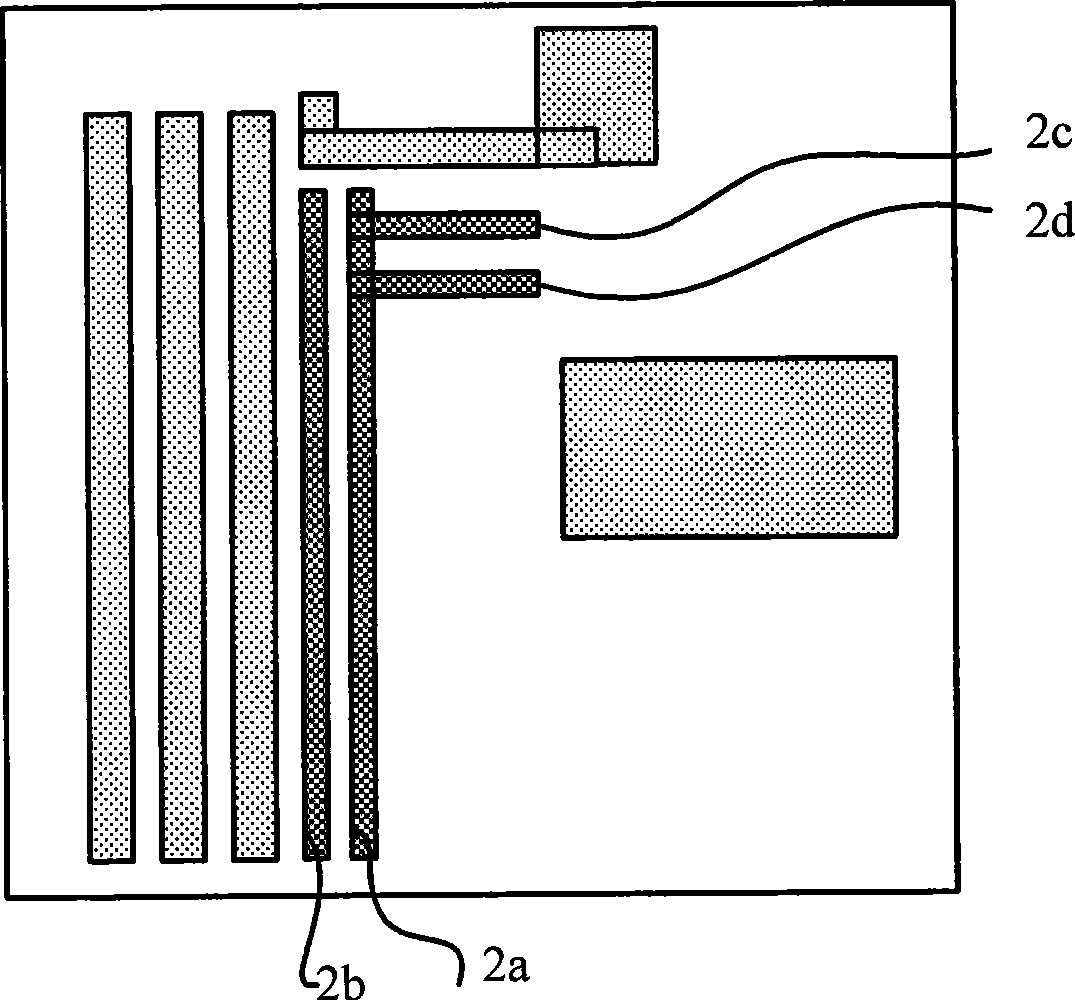

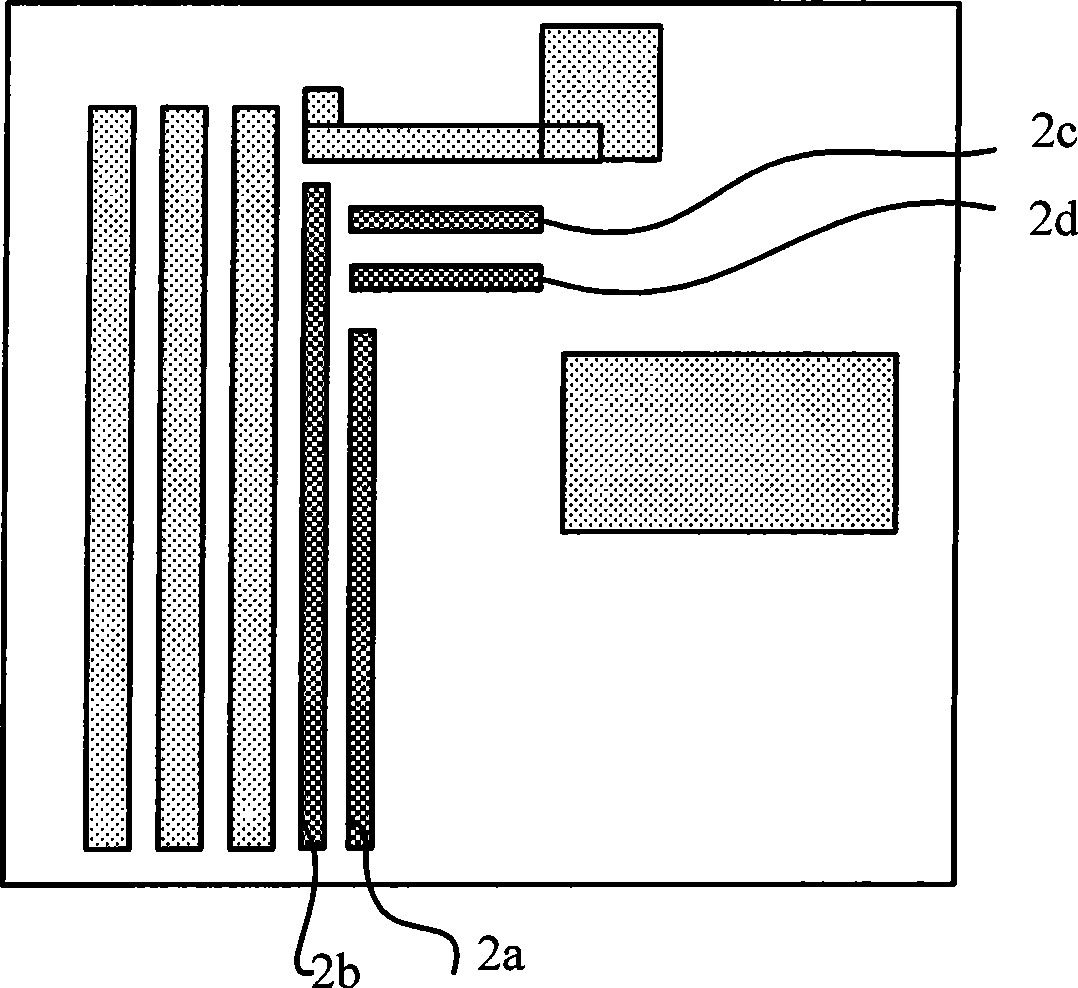

[0014] When the main pattern is placed on the lithography isolation or semi-isolation photomask, it is necessary to insert scattering bars in the main pattern to improve the resolution of the lithography pattern. see figure 1 , figure 1 The filling pattern in 1 is the same as the main pattern of the photomask template. Taking the main pattern shape of the photomask as an example, the method of generating the scattering strips is described. First, insert the scattering bars with preset parameter values in the main graphics of the photomask template, such as figure 2 The scattering bars shown in 2a, 2b, 2c and 2d, from figure 2 It can be seen in 2c and 2d that the scatter strips bridge with the scatter strip 2a. Next, the influencing factors of the bridged scattering bars 2c, 2d and 2a are determined, and the influencing factors of the scattering bars are sorted by size. The influence factors of the scattering bars 2c, 2d and 2a are determined by calculating the normaliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com