Improvements in or relating to joining stretchable fabric portions to one another

A fabric structure and fabric technology, applied to the seams of textile materials, textiles, papermaking, clothing, etc., can solve the problems of reducing the degree of bonding of two pieces of fabrics and the fragmentation of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

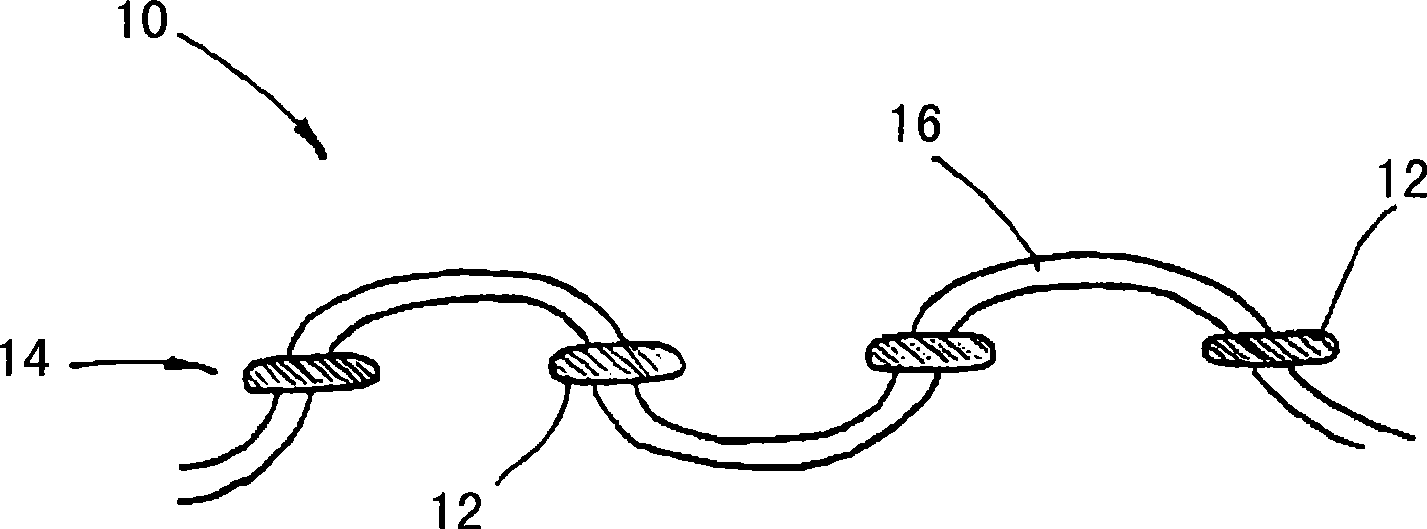

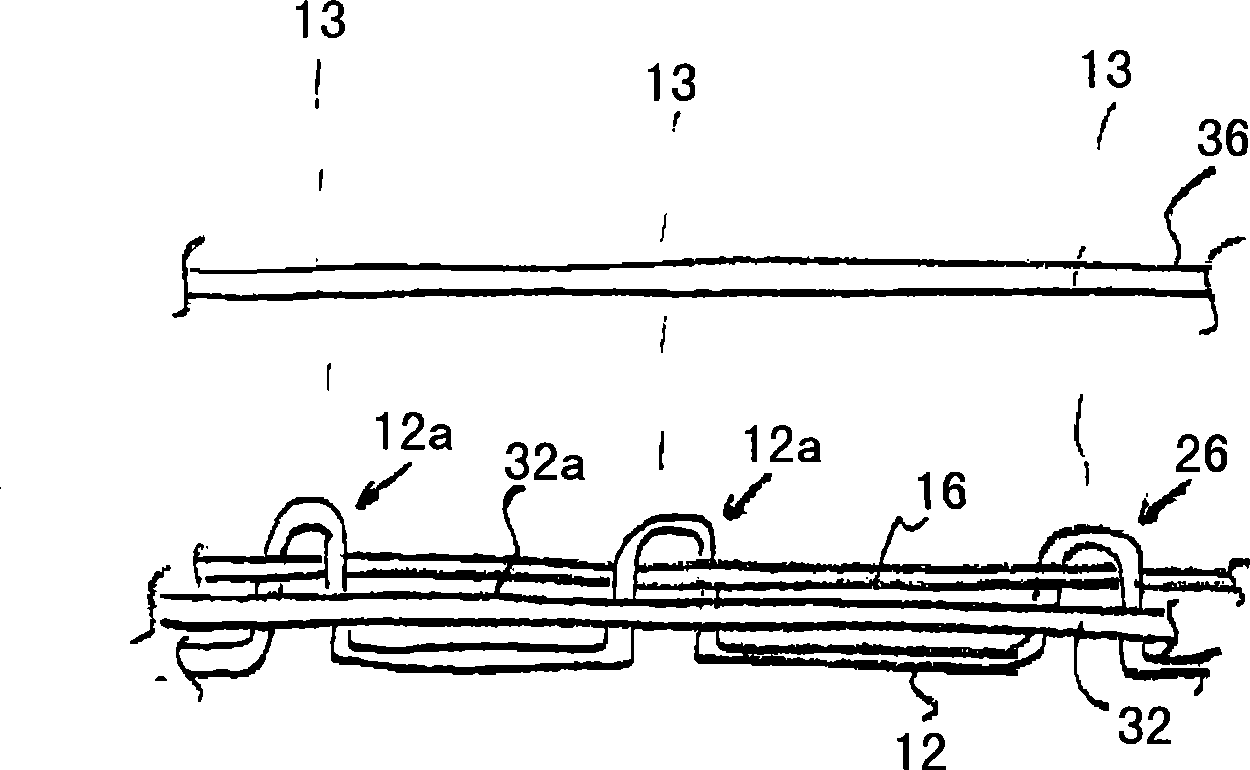

[0056] As shown schematically in FIG. 1( a ), the suture structure formed by the method according to the first embodiment of the present invention is mainly indicated by reference numeral 10 .

[0057] The first seaming structure 10 is a simple double-stitched seam formed by sewing the infusible first thread 12 (FIG. 1(b)) through the first stretchable fabric portion 32 to define forming a first stitch formation (stitch formation) 14; and by looping the second fusible thread 16 in the first stitch formation 14, so that the first thread 12 and the second fusible thread 16 overlap each other. This is shown more clearly in Figure 1(b), it is to be noted that the second thread 16 extends across (across) the surface 32a of the first fabric portion 32 and is in face contact with said surface 32a, The first line 12 is formed as bridge formations 12 a at a plurality of discrete locations 13 along the second line 16 , each bridge formation spanning over the second line 16 in a bridging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com