Bullet-proof holster and ballistic pouch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

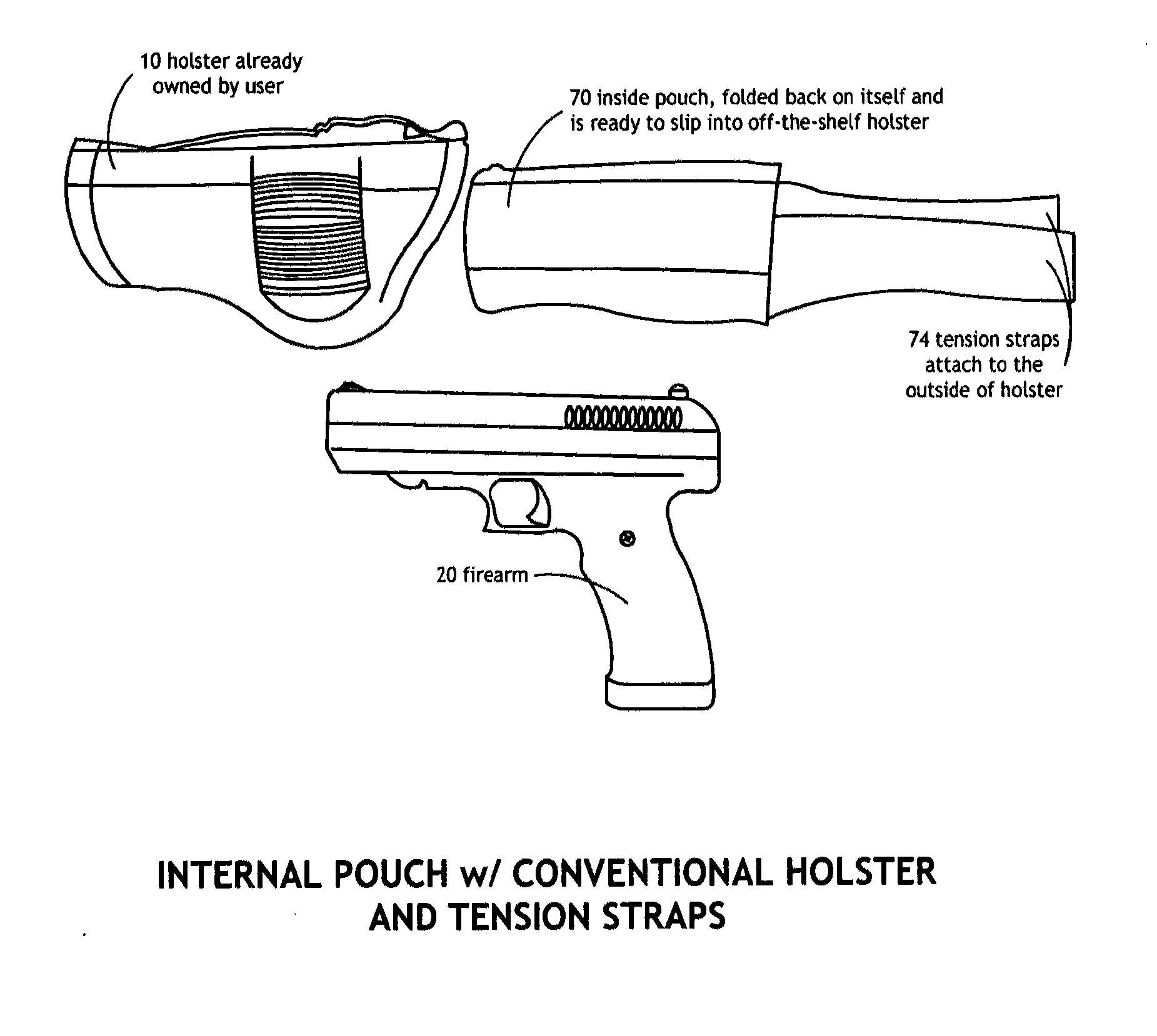

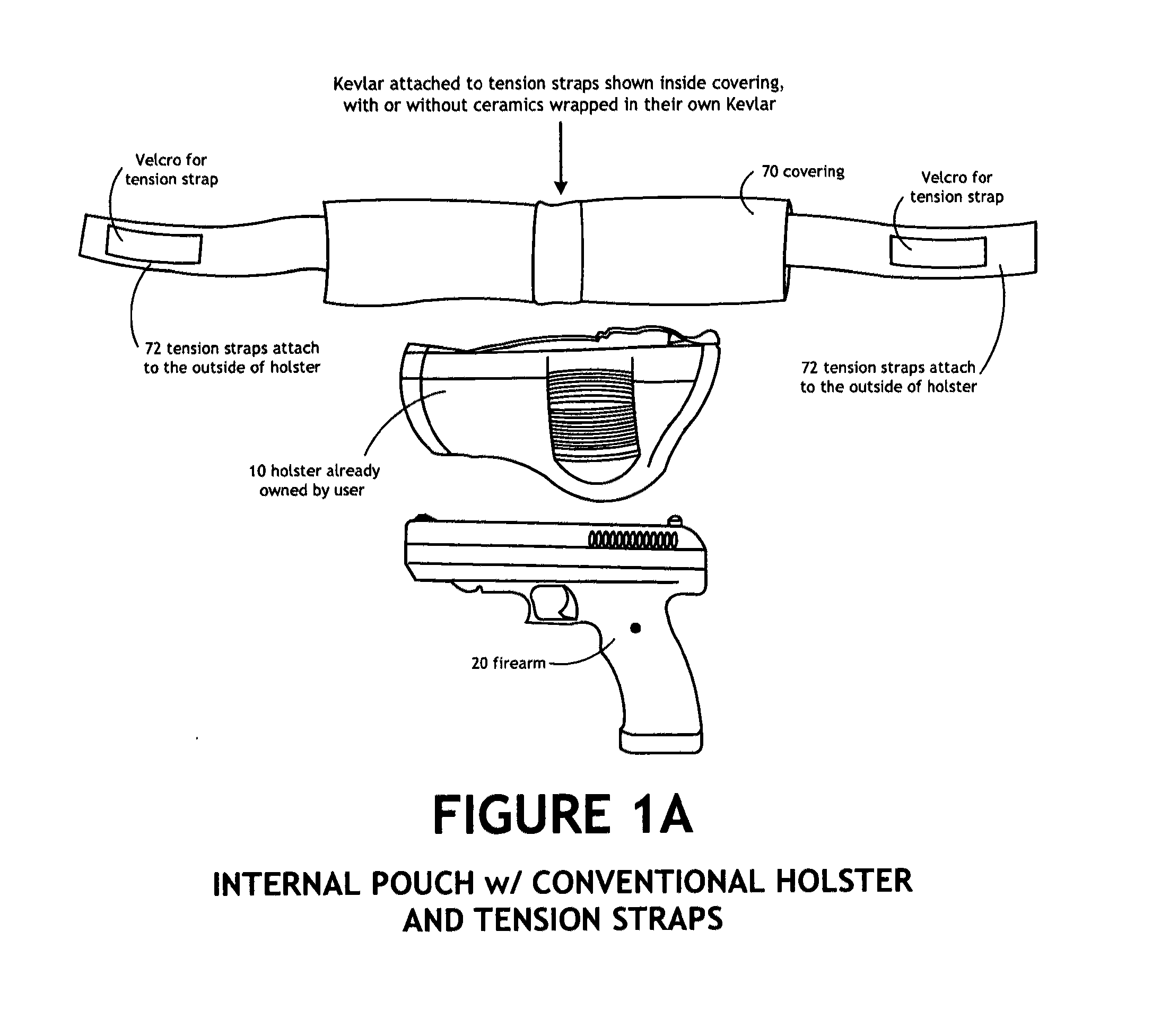

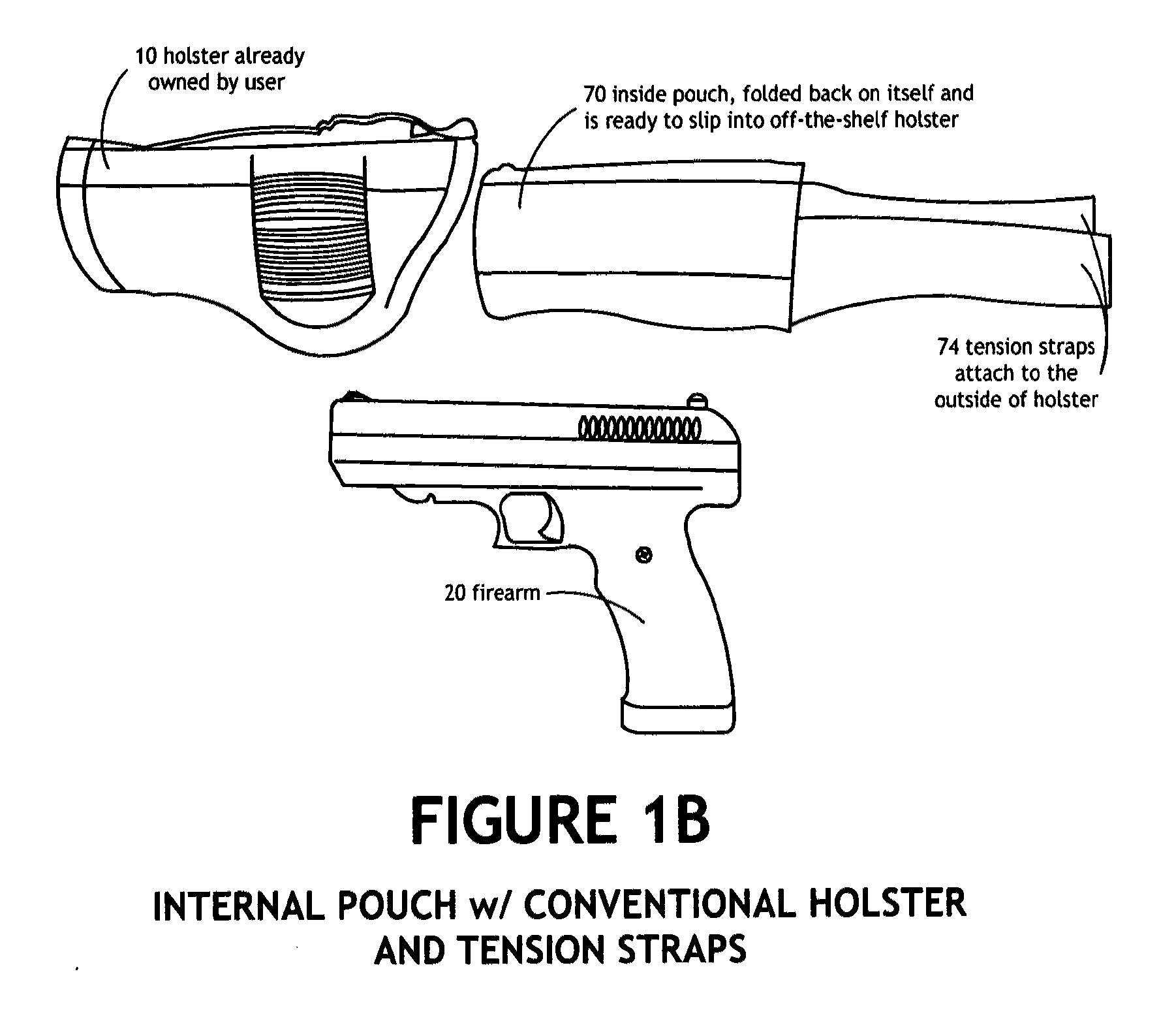

[0044]Referring now to the drawings, FIGS. 1A through 1D (an internal pouch) and FIGS. 2A through 2D (external pouch), two different preferred embodiments of the bullet-proof ballistic pouch of the present invention are disclosed. FIGS. 1A through 1D disclose the ballistic pouch being mounted internally into a conventional holster 10; and FIGS. 2A through 2D disclose the ballistic pouch being mounted externally onto the conventional holster 10. In both examples, the high tensile strength material with the optional ceramics are built into the holster 10, in such a way as to insure that the high tensile strength material is in tension during the time the bullet is being caught. This can be done by sewing tension straps to the high tensile strength material and sewing them to the holster 10, or by just sewing the Kevlar to the holster material. High tensile strength sewing thread should be used, such as Tenara or many sewing lines of standard high strength standard sewing thread.

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com