Two stage damping axial flow type check valve with adjustable closure time

A technology of closing time and damping shaft, which is applied in the field of axial flow check valve and can solve problems such as water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

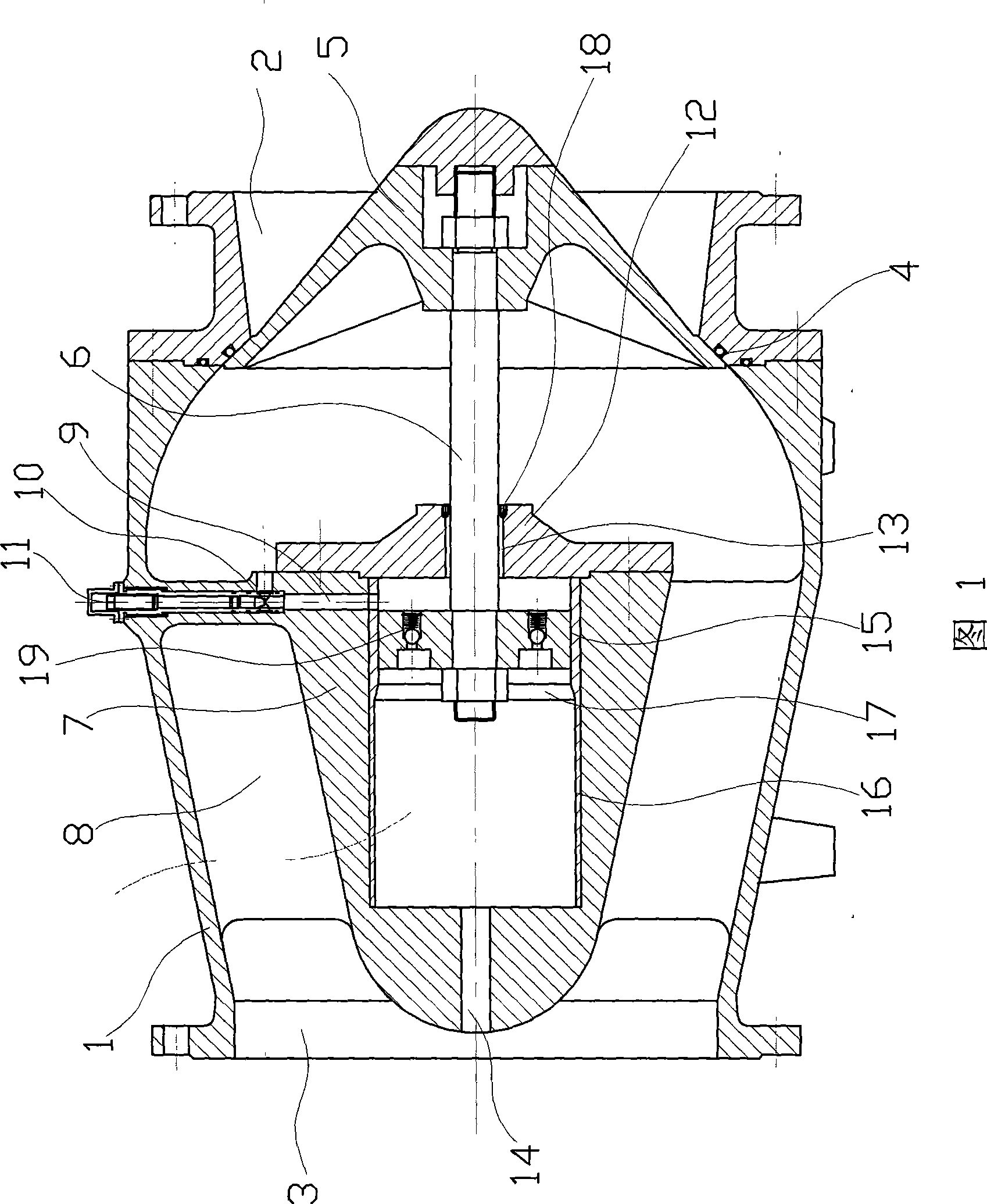

[0012] In Fig. 1, the two-stage damping axial flow check valve with adjustable closing time has a cylindrical valve body 1, and the front and rear ends of the valve body respectively have inlet and outlet ports 2 and 2 whose axes are on the same line as the axis of the valve body. 3. On the front side of the valve body, there is a valve seat 4 whose axis is on the same line as the axis of the cylindrical valve body. There is a valve core 5 matching the valve seat in the valve body. The center behind the valve core is connected with the axis of the valve core. On the valve shaft 6 on the same straight line, there is a damping cylinder 7 whose axis is on the same straight line as the axis of the cylindrical valve body in the valve body. The front end of the valve body has a lateral pipe 9 communicating with the valve body, and in the lateral pipe is a throttle valve 10 connecting the cylinder cavity and the valve body, the handle 11 of the throttle valve is outside the valve body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com