Isotonic constant-pressure compensator

A compensator and isotonic technology, applied in buildings, piping systems, water supply devices, etc., can solve the problems of high maintenance costs, large consumption of air bags and diaphragms, and small adjustment volume, so as to save floor space and buildings The effect of height and easy maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

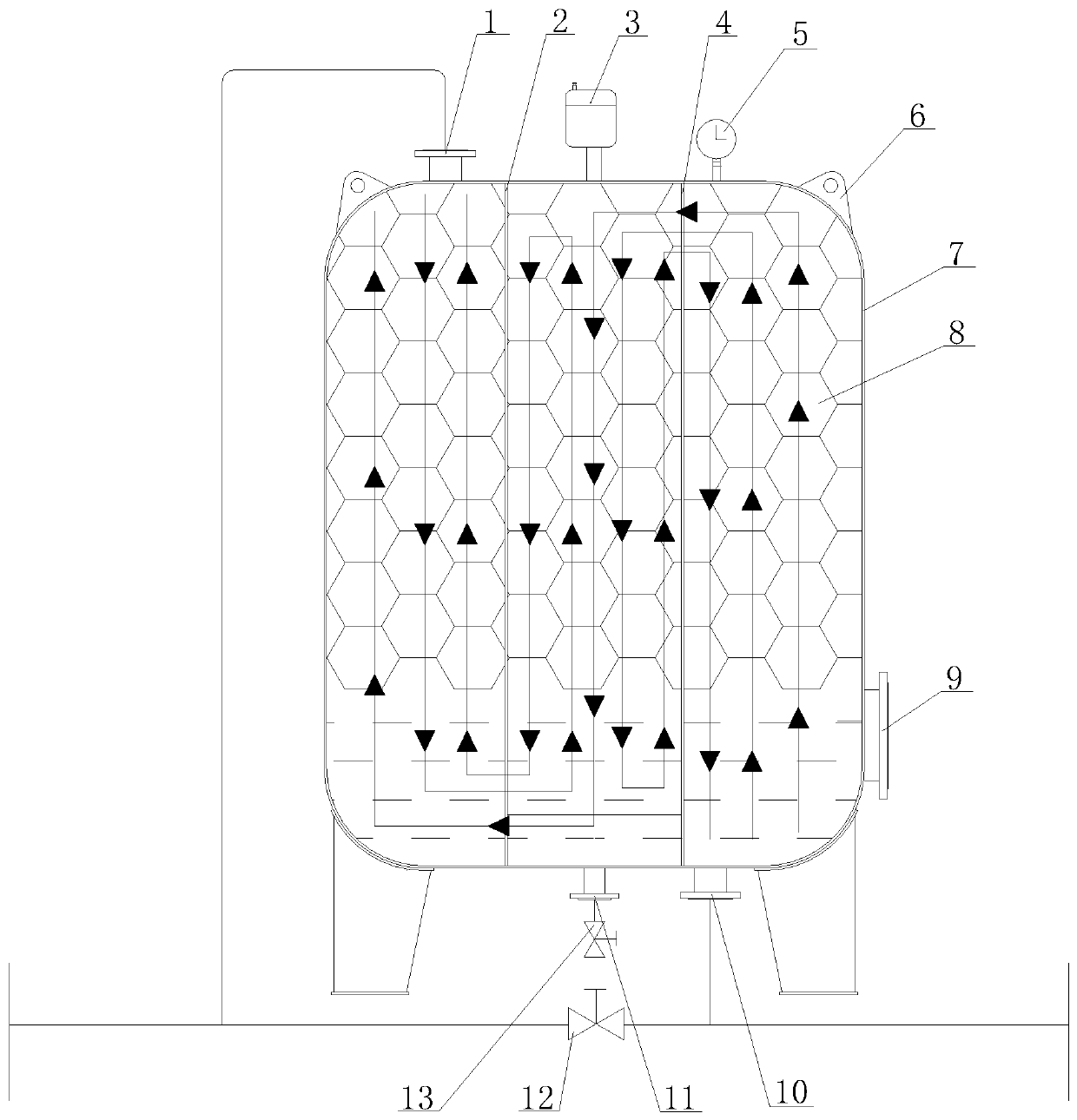

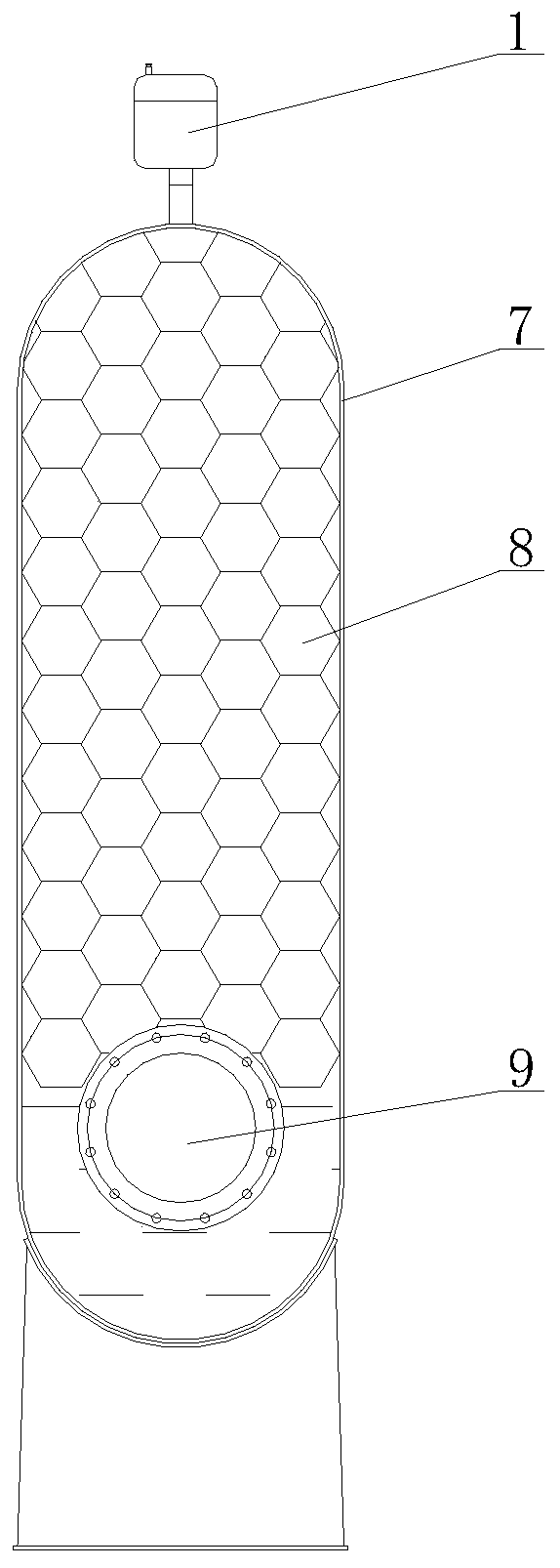

[0019] Such as Figure 1~4 As shown, the isotonic constant pressure compensator of this embodiment is composed of the second inlet and outlet pipe 1, left baffle 2, exhaust pipe 3, right baffle 4, pressure gauge 5, lifting lug 6, expansion tank 7, isotonic expansion Ball 8, filling isotonic expansion ball inlet 9, the first water inlet and outlet pipe 10, sewage outlet 11, drainage valve 12, sewage valve 13, and connection form.

[0020] An exhaust pipe 3 and a pressure gauge 5 are installed on the top of the expansion tank 7. The inside of the expansion tank 7 is subjected to flexible anti-corrosion treatment such as plastic spraying. The inner surface of the expansion tank 7 is not easily oxidized. Lifting lugs 6 are installed on both sides of the top of the expansion tank 7 . One side of the expansion tank 7 is installed with an isotonic expansion ball inlet 9, which is used for filling the isotonic expansion ball 8 and personnel inspection. The left baffle plate 2 is inst...

Embodiment 2

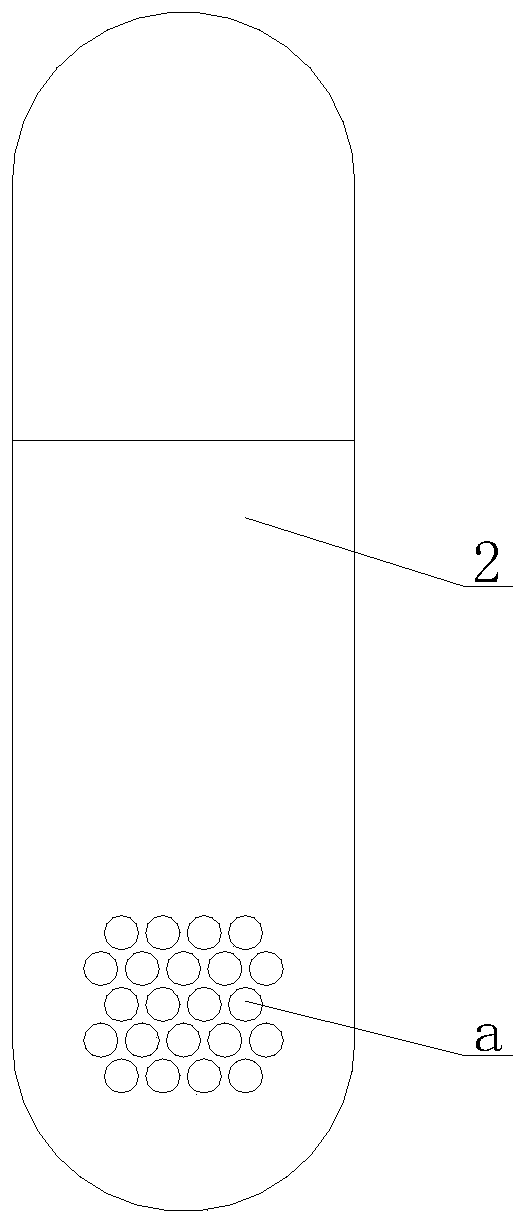

[0022] An exhaust pipe 3 and a pressure gauge 5 are installed on the top of the expansion tank 7 , and lifting lugs 6 are installed on both sides of the top of the expansion tank 7 . One side of expansion tank 7 is equipped with filling isotonic expansion ball inlet 9, left baffle plate 2 is installed on the left side of expansion tank 7, right baffle plate 4 is installed on the right side, left baffle plate 2, right baffle plate 4 will expand tank 7 It is divided into the left area of the expansion tank, the middle area of the expansion tank, and the right area of the expansion tank. The bottom of the left baffle 2 is processed with a diversion hole a, and the upper part of the right baffle 4 is processed with a diversion hole a. The diameter of the diversion hole a is 50mm. The arrangement order of the diversion holes a processed on the left baffle 2 and the right baffle 4 is: the diameters of the diversion holes a are the same, and a row of diversion holes a is alterna...

Embodiment 3

[0025] An exhaust pipe 3 and a pressure gauge 5 are installed on the top of the expansion tank 7 , and lifting lugs 6 are installed on both sides of the top of the expansion tank 7 . One side of expansion tank 7 is equipped with filling isotonic expansion ball inlet 9, left baffle plate 2 is installed on the left side of expansion tank 7, right baffle plate 4 is installed on the right side, left baffle plate 2, right baffle plate 4 will expand tank 7 It is divided into the left area of the expansion tank, the middle area of the expansion tank, and the right area of the expansion tank. The bottom of the left baffle 2 is processed with a diversion hole a, and the upper part of the right baffle 4 is processed with a diversion hole a. The diameter of the diversion hole a is 130mm. The arrangement order of the diversion holes a processed on the left baffle 2 and the right baffle 4 is: the diameters of the diversion holes a are the same, and a row of diversion holes a is altern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com