Damping and sealing tube joint

A sealing tube and sealing ring technology, applied in the field of pipe joints, can solve problems such as unsatisfactory sealing effect, many parts, troublesome installation, etc., and achieve the effects of increasing compression resistance, convenient opening/closing, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

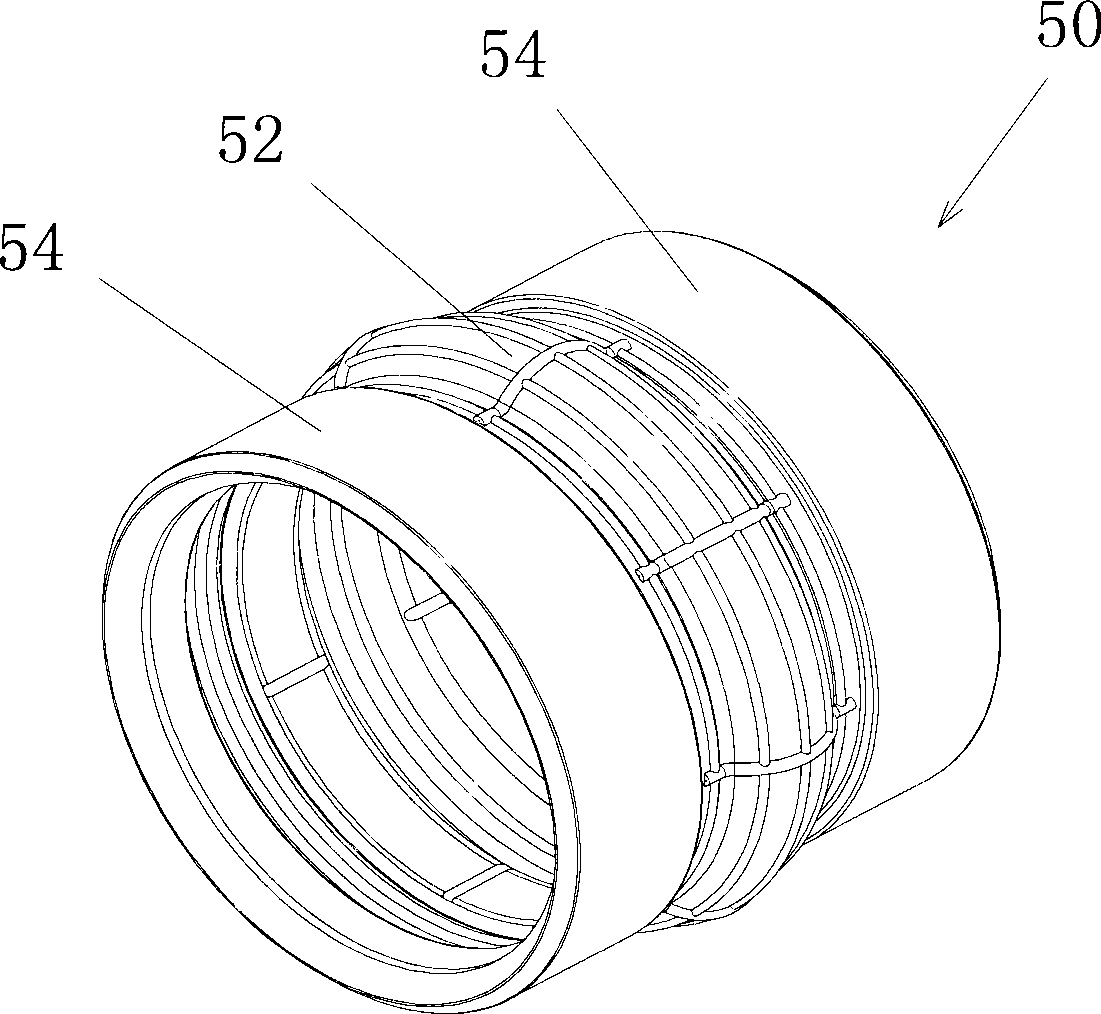

[0024] The present invention In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings. The pipe joint in the preferred embodiment of the present invention includes a connecting device and a sealing device, a toothed entrainment belt, a triangular steel belt, and a stainless steel wire ring.

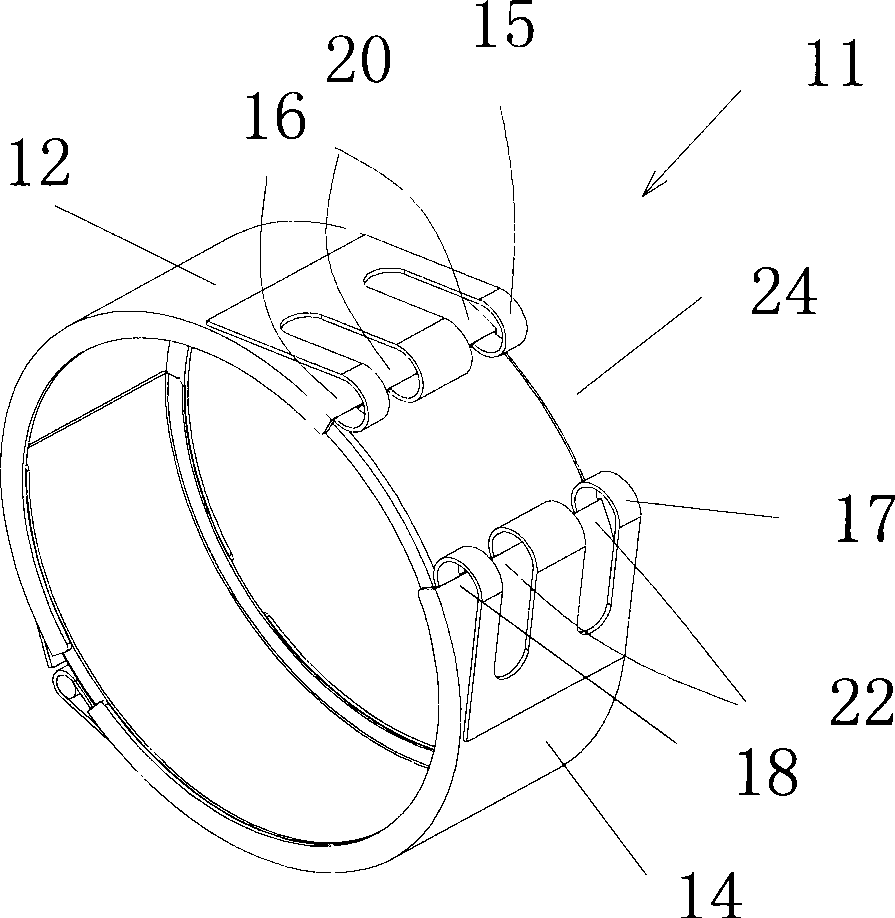

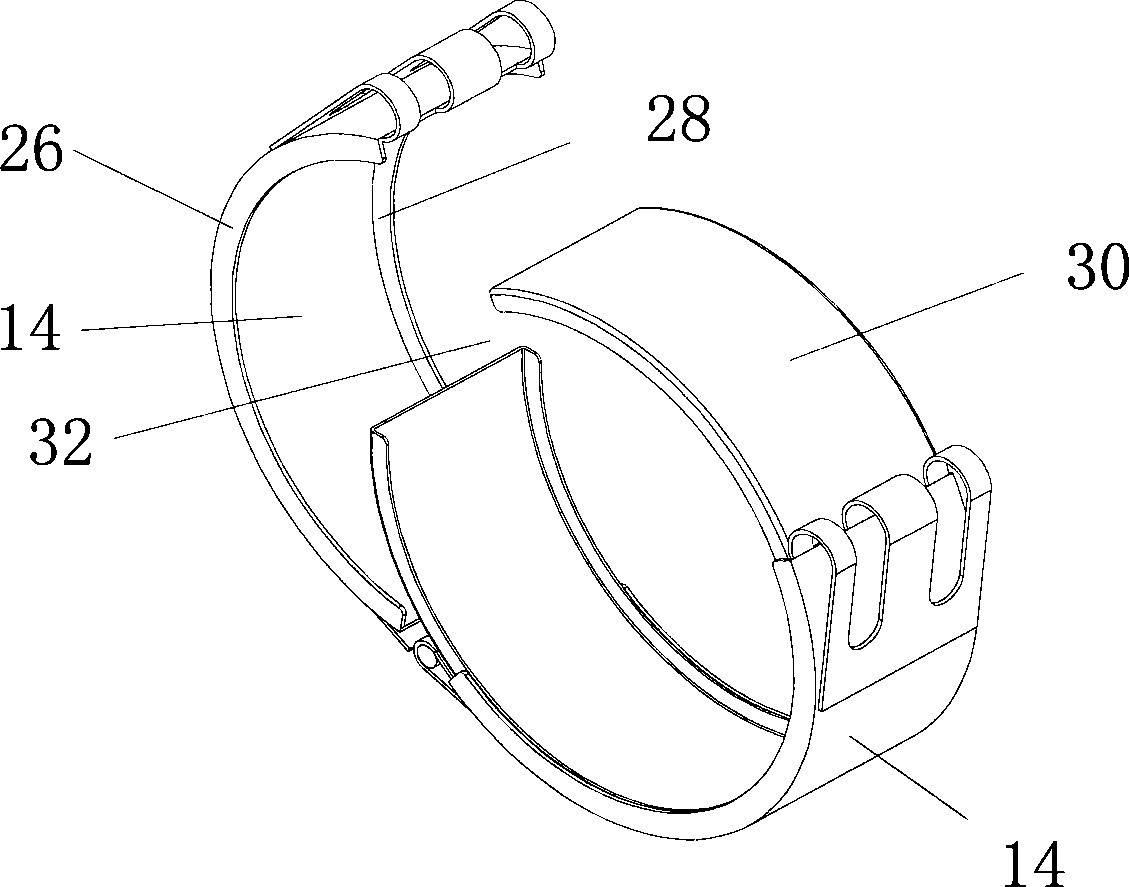

[0025] see figure 1 and figure 2 As shown, the connection device 10 of the preferred embodiment of the present invention includes an open annular shell 11 with a certain axial width and a clamping device 13 for clamping the shell 11 (such as Figure 6 shown). The shell 11 is formed by hinge connection of a first arc-shaped shell 12 and a second arc-shaped shell 14 . The free ends of the first housing 12 and the second housing 14 are respectively bent outwards to form lugs 15, 17 with axial through holes 16, 18, and lugs 15, 17 are also provided with axially spaced holes. A plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com