Magnetic disk device and head stack assembly

A technology of a magnetic disk device and a magnetic head group, which is applied in the directions of the magnetic head, magnetic recording, and head configuration relative to the rotating disk, can solve the problems of increasing the production cost of the actuator, and achieve the effect of ensuring the positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

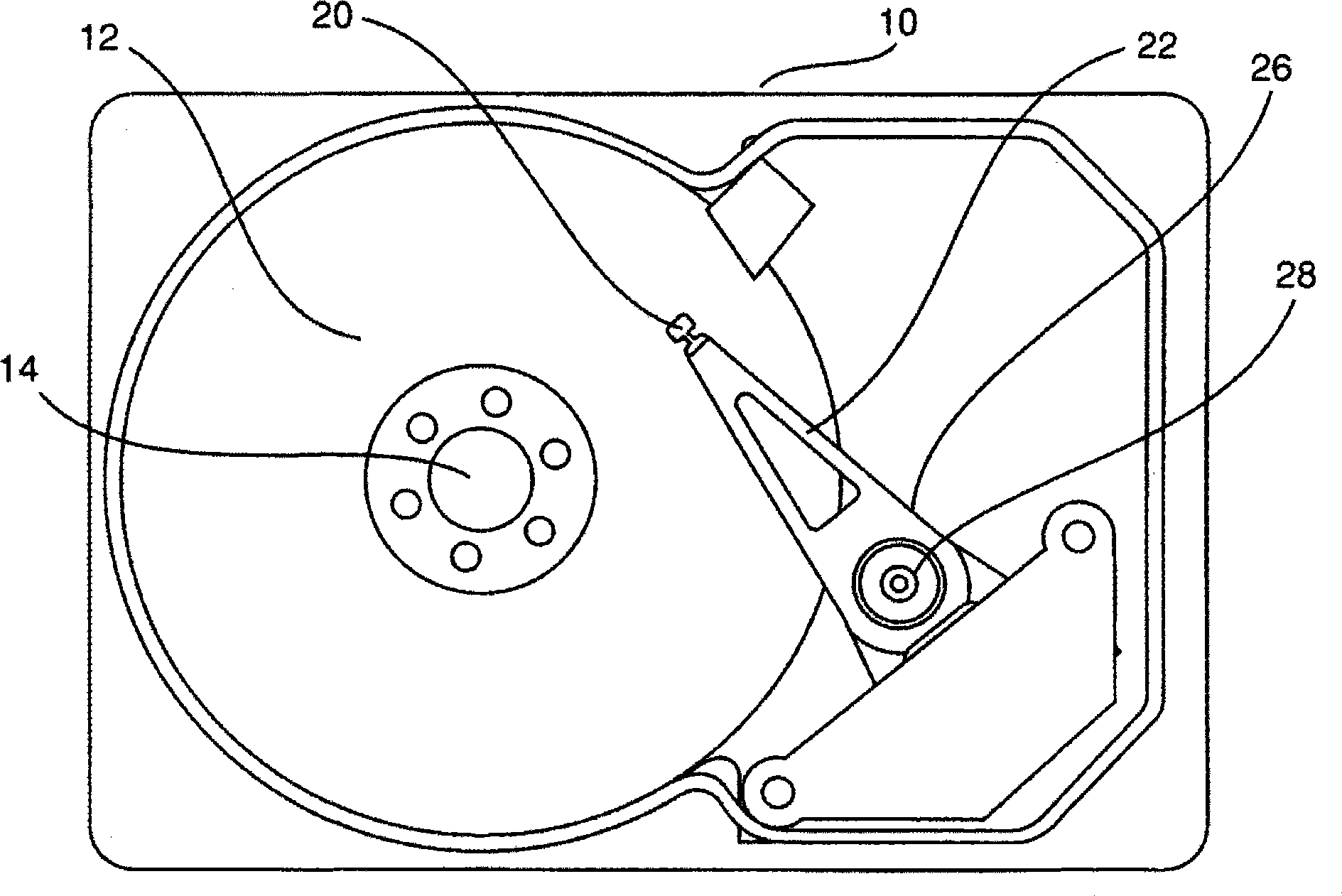

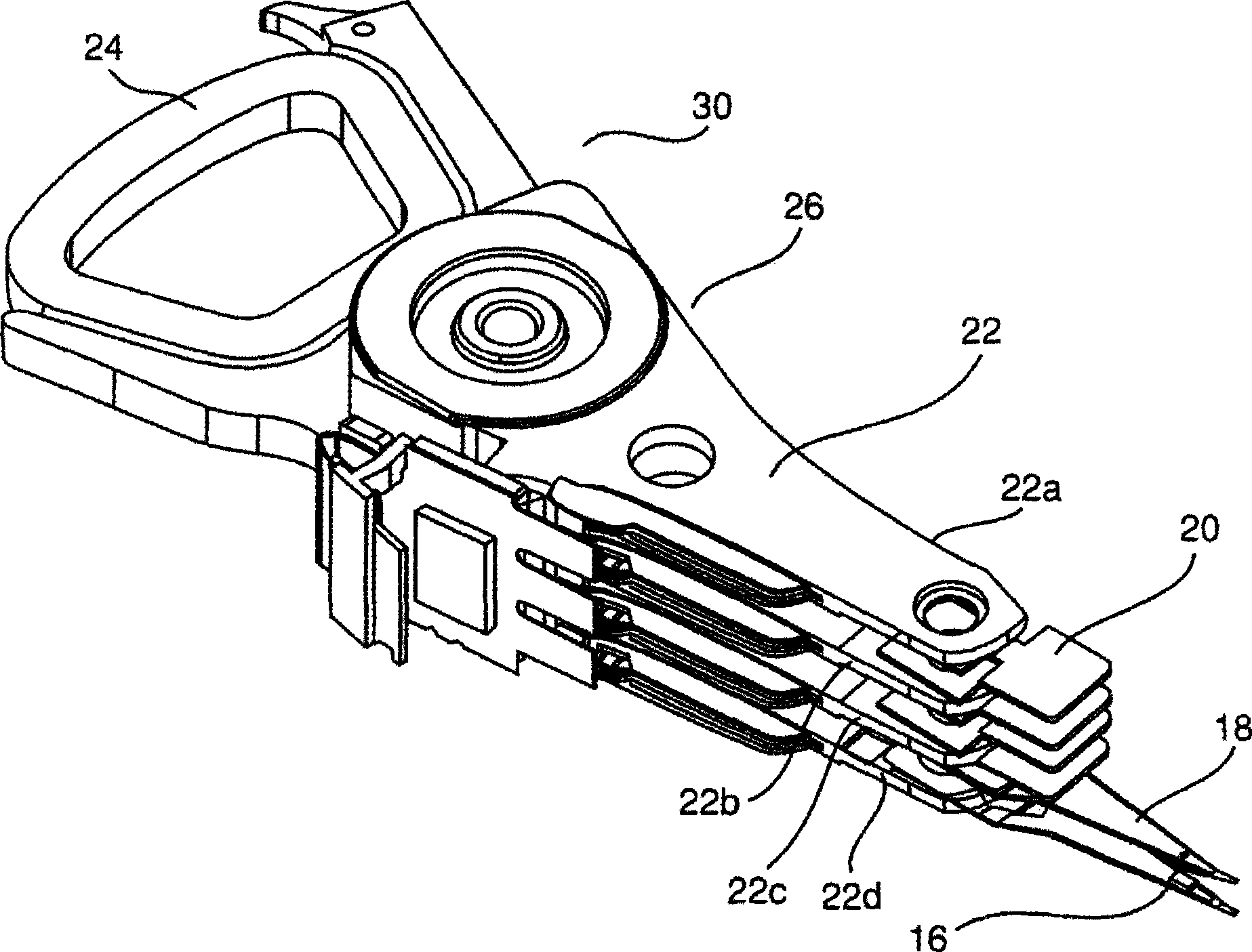

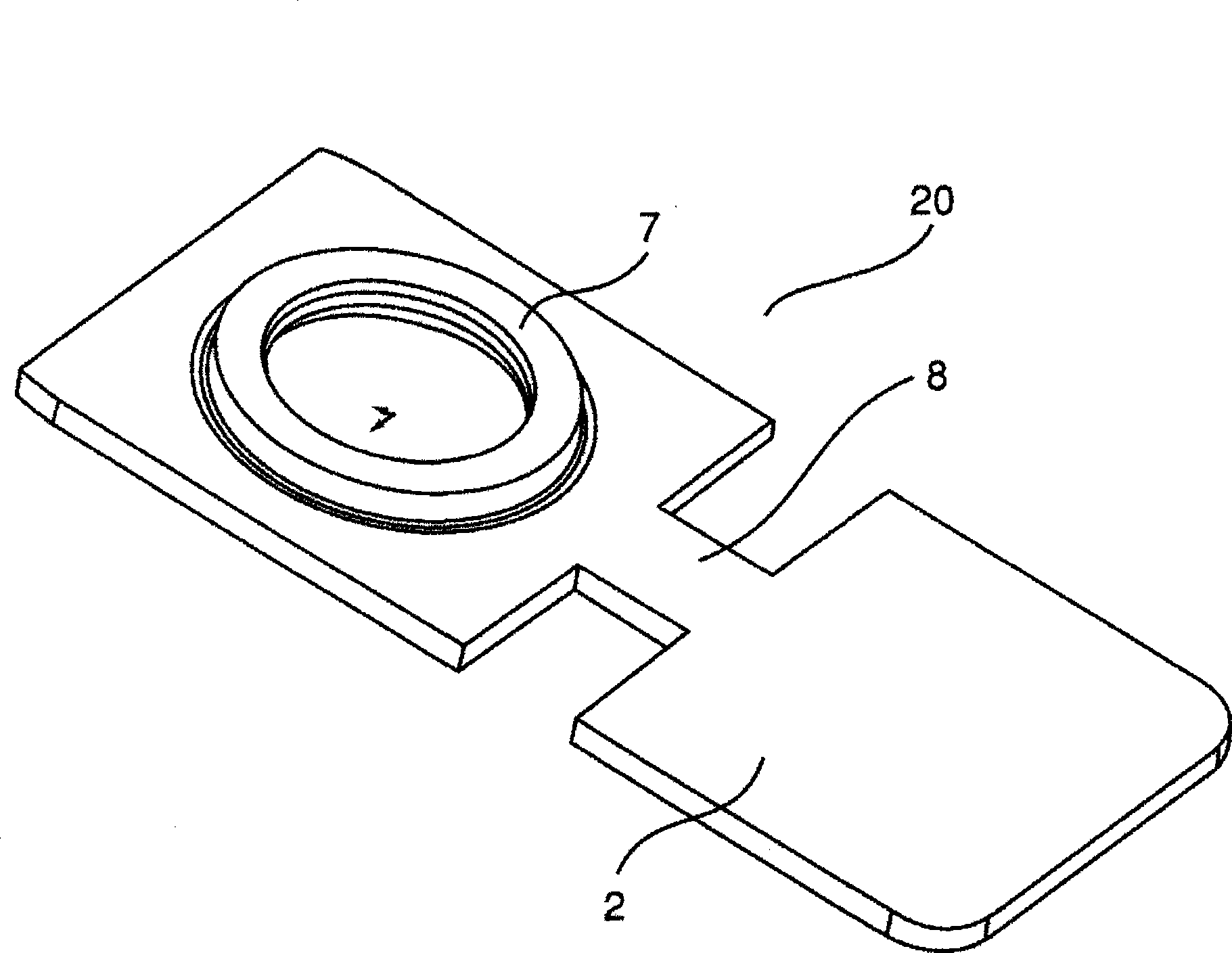

[0027] figure 1 is a plan view showing the schematic configuration of the magnetic disk device according to Embodiment 1, and figure 2 is a perspective view of the actuator. One or more magnetic disks 12 for recording information are placed in a magnetic disk device 10, which includes: a spindle motor 14 for rotating the magnetic disks 12; A slider 16 for the magnetic head; a suspension 18 for supporting the slider 16 ; an actuator 26 having a plurality of arms 22 to which the suspension 18 or plate 20 is attached; and a voice coil 24 . The actuator 26 is rotatably supported with respect to the rotary shaft 28 and can move the slider 16 in the radial direction of the magnetic disk 12 via the suspension 18 . The suspension 18 applies a predetermined load to the slider 16, and the slider 16 floats above the disk when the load is balanced by the lift force from the viscose laminar flow generated by the rotation of the disk 12. here, as figure 2 The structure shown is referr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com