Screw rod positioning device of elevator

A technology of positioning mechanism and hoist, applied in the direction of hoisting device, etc., can solve the problems of affecting the service life, poor positioning effect, poor jacking efficiency, etc., and achieves the effect of easy manufacture, labor-saving operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

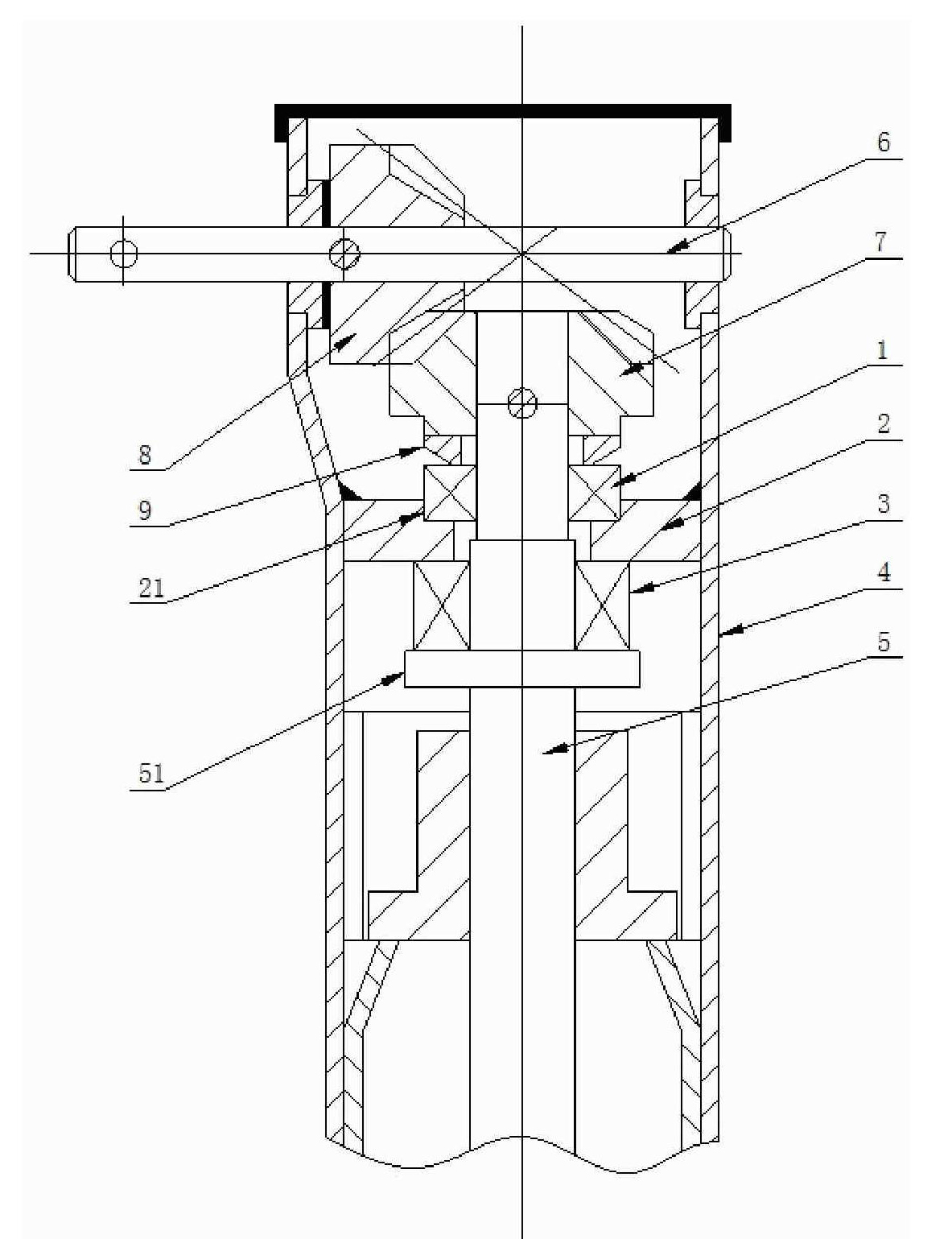

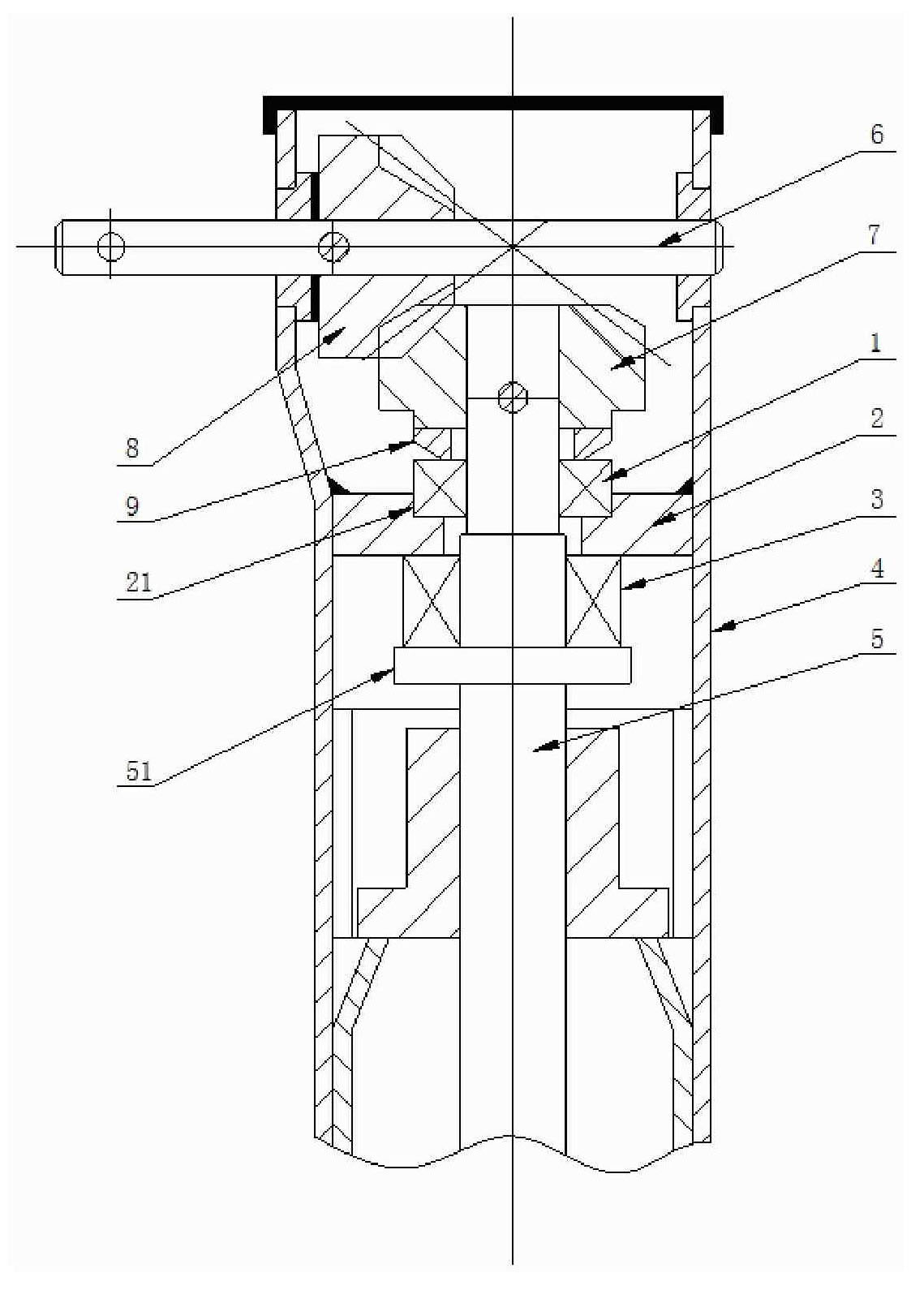

[0011] Embodiment: A screw positioning mechanism of a hoist, including a hollow pipe body 4 and an input shaft 6 and a screw 5 arranged thereon. The input shaft 6 and the screw 5 are perpendicular to each other and are driven by a pair of bevel gears 7 and 8. connection, the pipe body 4 is fixed with a support plate 2, the middle part of the support plate 2 is provided with a through hole and is sleeved outside the screw rod 5 through the through hole; The connected centripetal bearing 1, the other side is a plane and is provided with a planar bearing 3 that is rotationally connected with the boss 51 on the screw 5; The plane bearings 3 on both sides, the radial bearing 1 and the gear 7 constitute axial positioning. The fixing method of the support plate 2 and the pipe body 4 is welding. The support plate 2 is provided with a groove 21 for installing the radial bearing 1 . A washer 9 is arranged between the radial bearing 1 and the end face of the gear 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com