Post-processing apparatus for printing medium, image forming apparatus and post-processing method for printing medium

A post-processing device and technology for printing media, applied to electrical recording technology using charge graphics, equipment and instruments using electrical recording technology using charge graphics, etc., capable of solving the problems of delay in discharge of printing media stacks, deflection in the discharge direction, and interference discharge And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

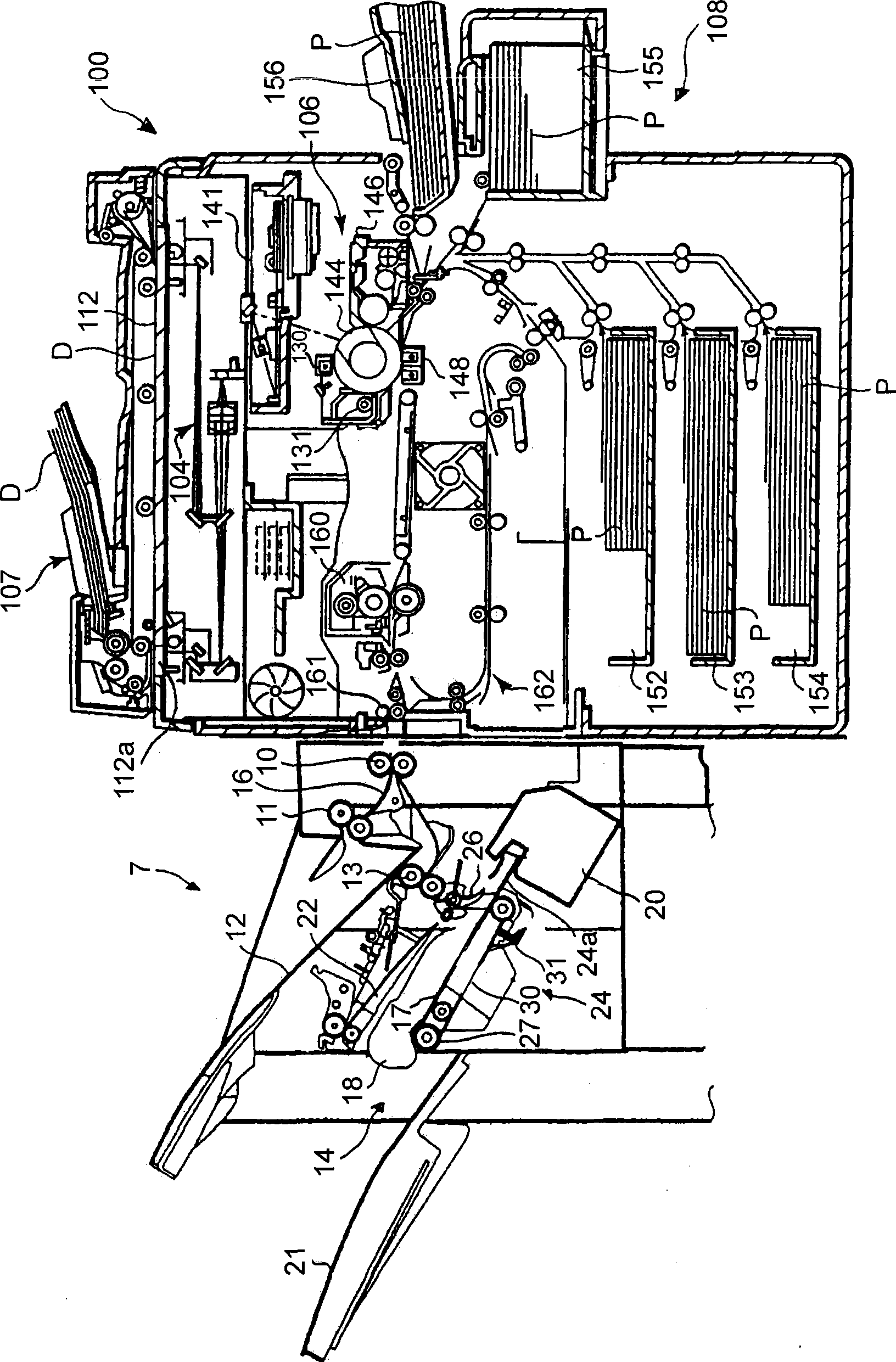

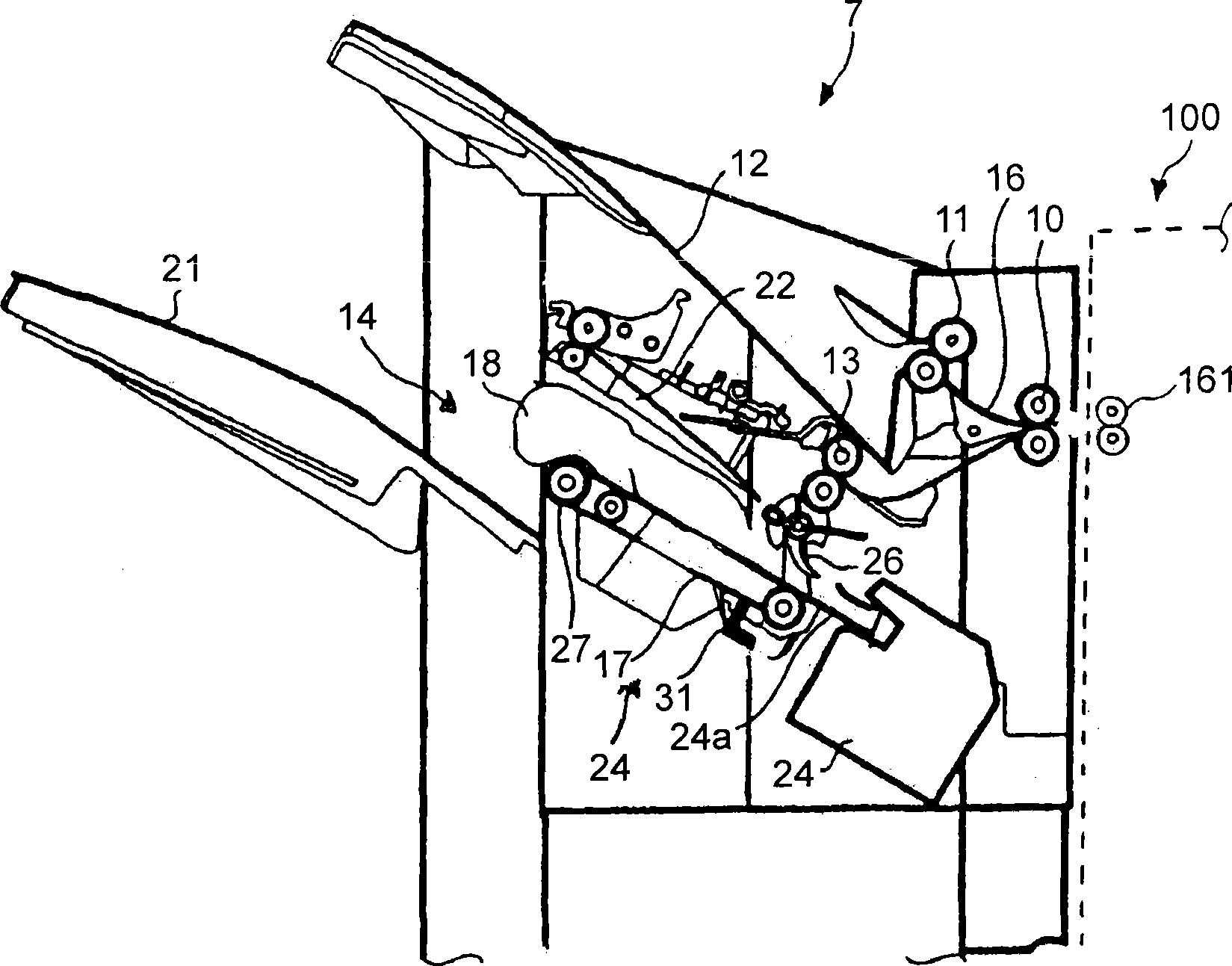

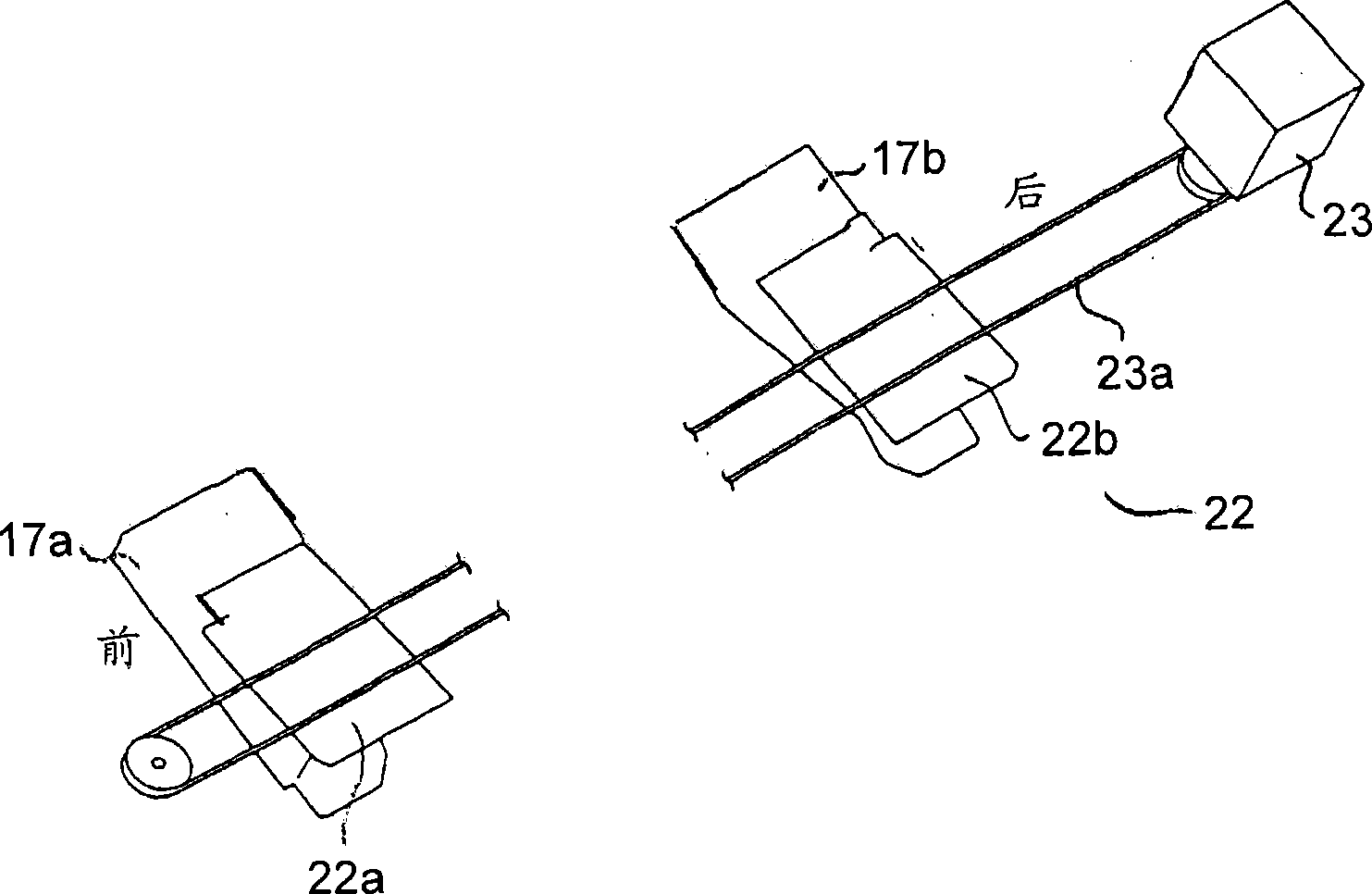

[0030] Hereinafter, the first embodiment will be described in detail by taking the drawings as examples. figure 1 It is a schematic configuration diagram showing a copier 100 as the image forming apparatus according to the first embodiment, and a finishing unit 7 as a print medium post-processing device connected to the copier 100 . The copying machine 100 has a mounting table 112 for a document D on its upper surface. An automatic document feeder (ADF) 107 for feeding a document D to the mounting table 112 is arranged on the upper surface of the mounting table 112 . The document D is set on the automatic document feeder 107, and image forming conditions (for example, presence or absence of stapling processing, content of stapling processing, number of copies, print medium size, etc.) are set. Next, when the copying operation is started, the document D is moved to the read glass 112 a of the stage 112 by the automatic document feeder 107 , and the image is read by the scanner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com