Process for manufacturing integral molding epoxy glass fibre laminated insulating joint pad

A technology of epoxy glass fiber and insulating joints, which is applied in the direction of household components, applications, household appliances, etc., can solve the problem of loss of insulation of insulating gaskets, failure to meet electrical insulation, mechanical strength, surface shape and position tolerance, leakage resistance, and sealing failure and other problems to achieve the effect of satisfying electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Integral molded epoxy glass fiber laminated insulating joint gasket manufacturing process, the steps are as follows:

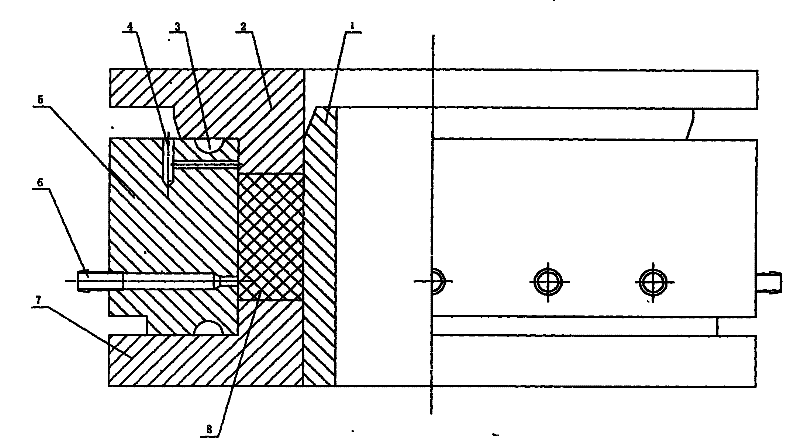

[0016] 1) Manufacture mold: the mold is composed of positioning guide pillars, upper mold, middle mold, and lower mold. On the upper surface of the middle mold, there are resin overflow grooves, 8 evenly distributed exhaust holes, and 16 resin injection holes. channel, install the positioning guide post in the middle hole of the lower mold, install the middle mold on the lower mold, install the upper mold on the middle mold and the positioning guide post; 16 resin injection channels form the resin with the resin resin storage tank and injection equipment Injection system; the mold is designed according to the size of the insulating joint gasket;

[0017] 2) Cut the fibers of each layer: cut according to the size of the inner cavity of the mold;

[0018] 3) Apply mold release agent: use polyvinyl alcohol and silicone oil, when the temperature of the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com