Fuel delivery unit

A technology of conveying unit and fuel oil, which is used in transportation and packaging, engine components, liquid fuel feeders, etc., can solve the problem of high cost of filter components, and achieve the effect of simple installation and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

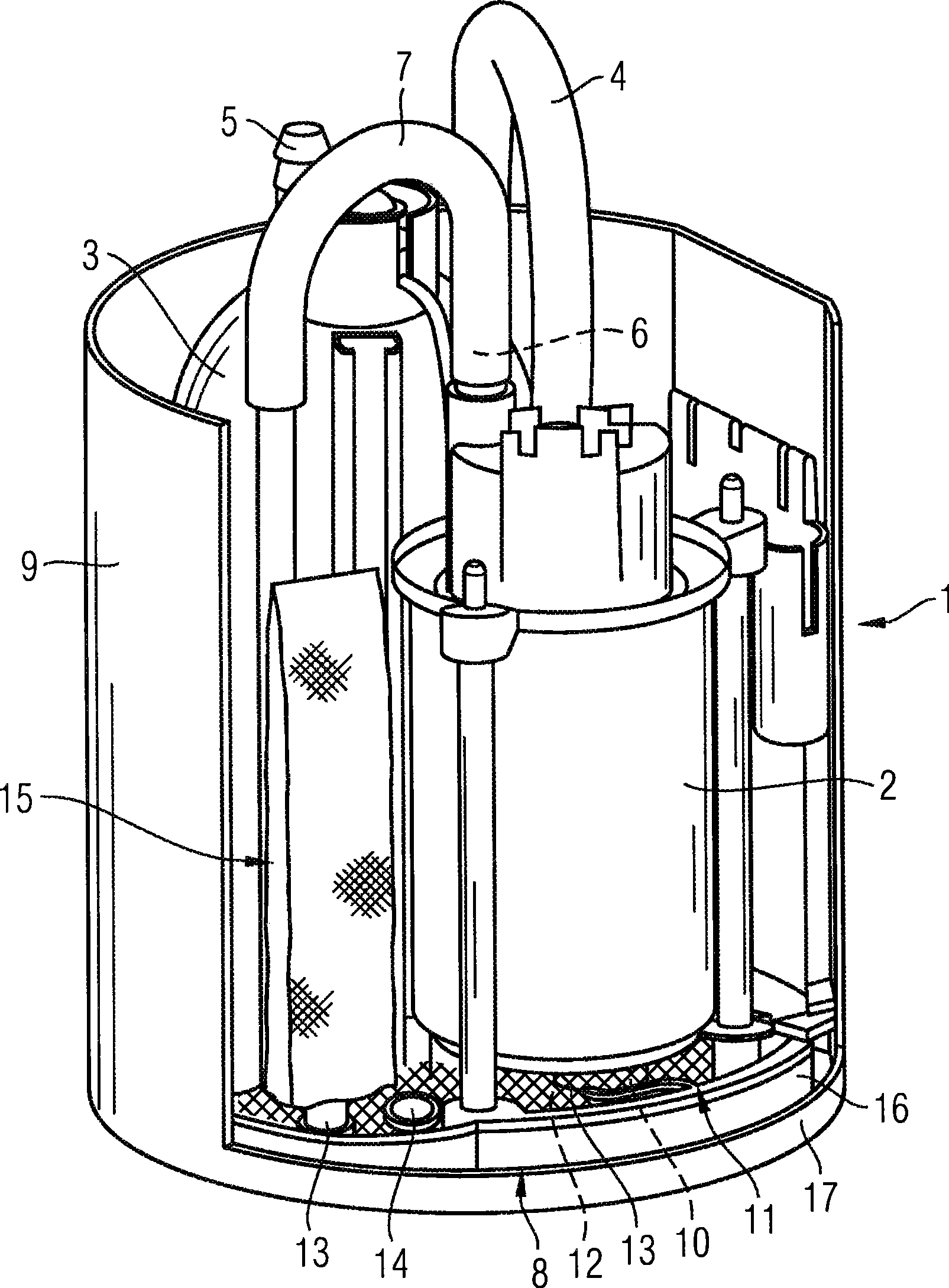

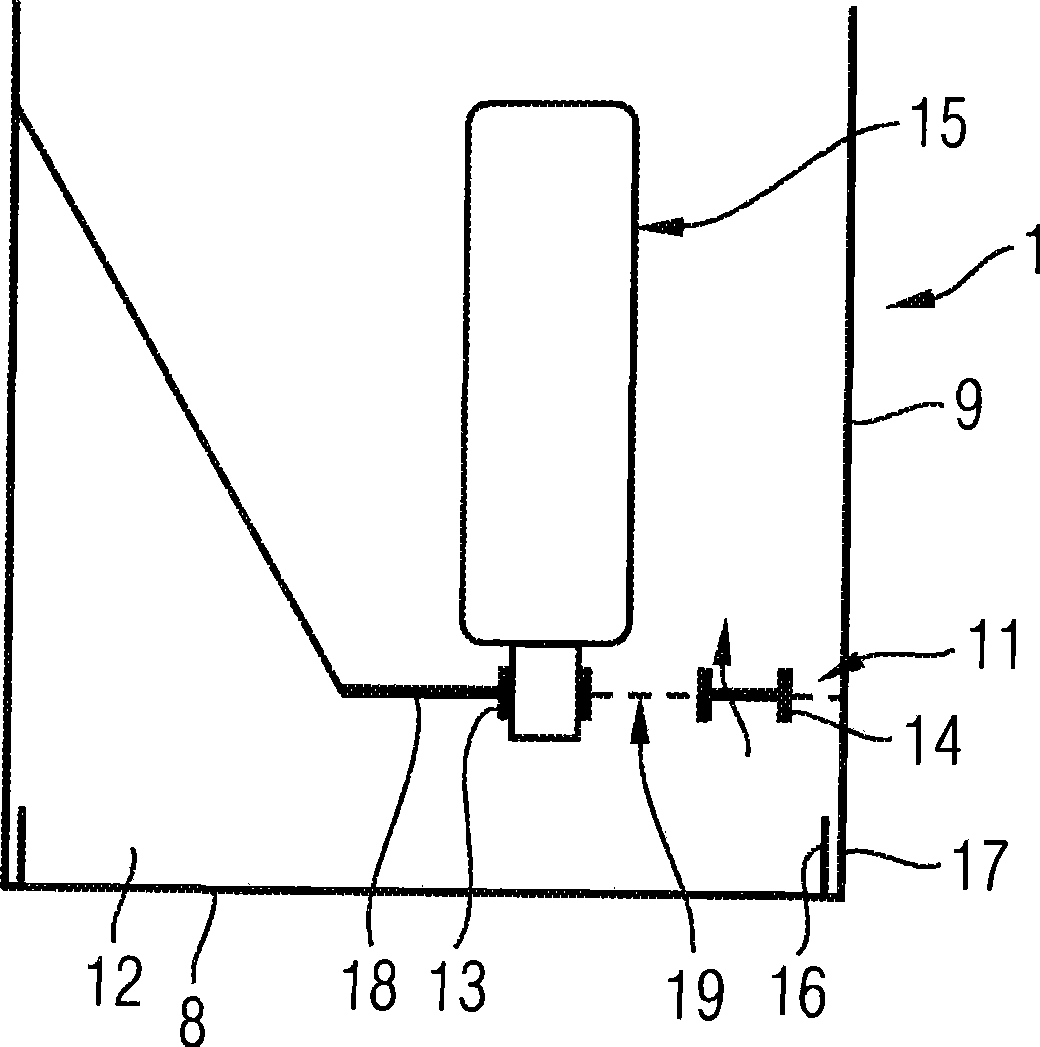

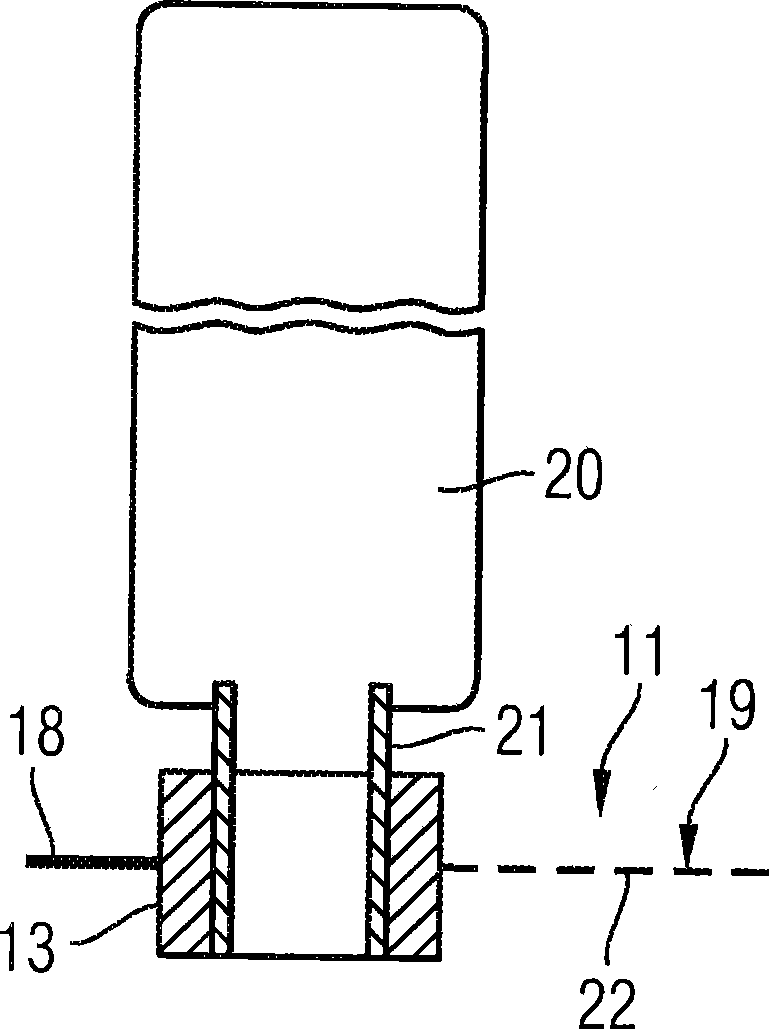

[0018] figure 1 Shown is a feed unit arranged in a fuel tank (not shown) of the motor vehicle, which feed unit is used to feed fuel to an internal combustion engine (also not shown) of the motor vehicle. The delivery unit has an electrically driven fuel pump 2 and a fine filter 3 arranged in a swirl pot 1 . The fine filter 3 is also arranged in the swirl pot 1 and is connected to the fuel pump 2 via a fuel line 4 . Furthermore, the fine filter 3 has a drain connection 5 for the drain of the internal combustion engine leading to the fuel tank. A line 7 for a suction injection pump (not shown) is connected to the connection 6 of the fuel pump 2 . The suction jet pump sucks in fuel from the surrounding environment of the swirl pot 1 and delivers it into the swirl pot 1 . The swirl pot 1 serves to collect fuel and has a bottom plate 8 and a housing 9 connected to the bottom plate 8 in a sealing manner. A suction connection 10 of the fuel pump 2 protrudes through a prefilter 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com