A bag type dust collector, a bag cage and a manufacturing method of the bag cage

A technology of bag filter and manufacturing method, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of complex manufacturing process, large welding volume, and uneven surface of the welding place, and achieve simple process, Guaranteed service life and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

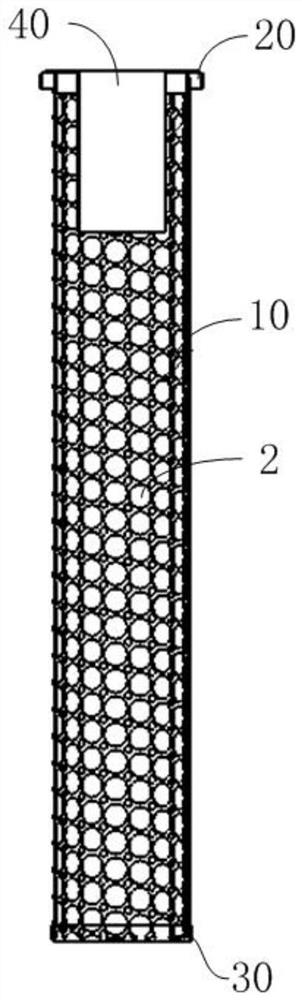

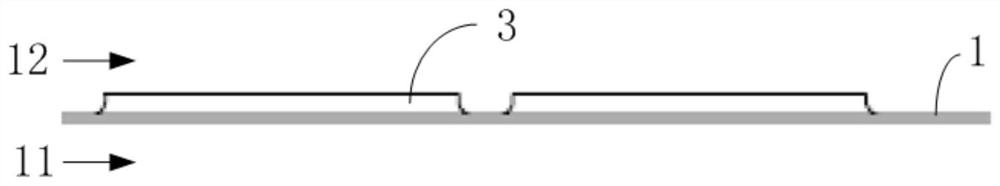

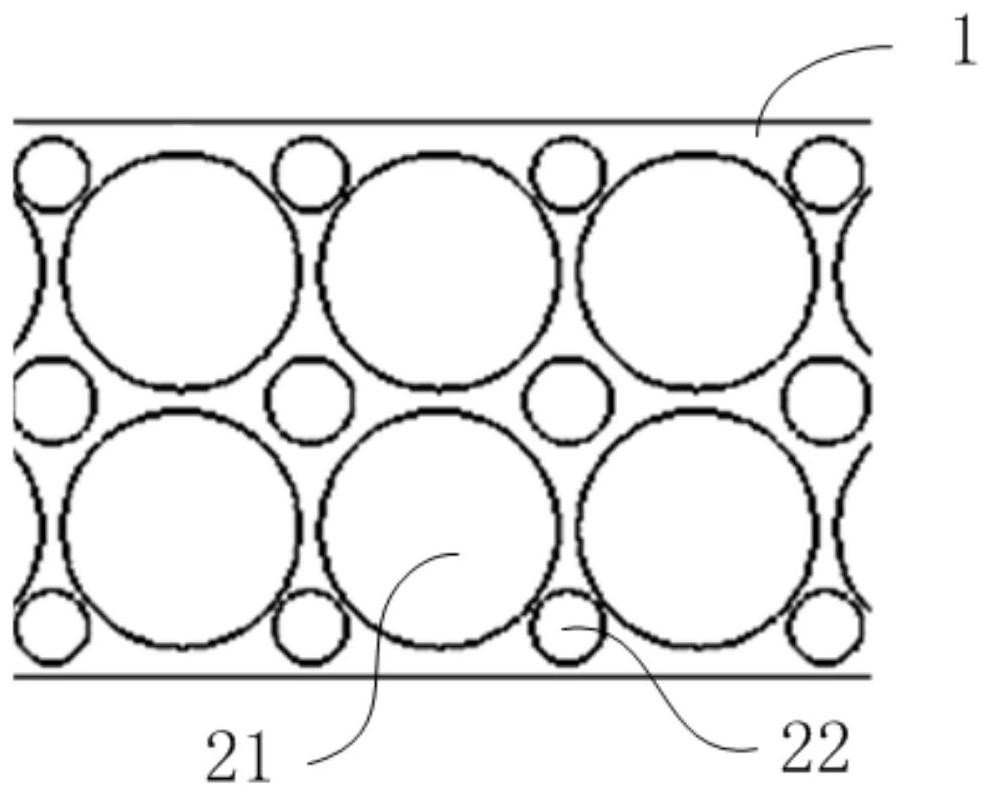

[0038] Please refer to Figure 1-4 , figure 1 It is a structural schematic diagram of the bag cage provided by the embodiment of the present invention; figure 2 is the side view of the steel plate; image 3 It is a structural schematic diagram when the filter hole of the steel plate includes the first hole and the second hole; Figure 4 It is a schematic diagram of the structure when the filter holes of the steel plate include square holes.

[0039] An embodiment of the present invention provides a method for making a bag filter, a bag cage, and a bag cage, wherein the bag filter includes a dust filter bag and a bag cage. Specifically, when in use, the dust filter bag is sleeved On the outside, the bag cage is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com