Hose clamp

A clip and hose technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, heating method, etc., can solve the problems of high clip weight and cost, influence, and high cost of clip tools, and achieve light weight and low cost. Cost, effect of short installation or removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

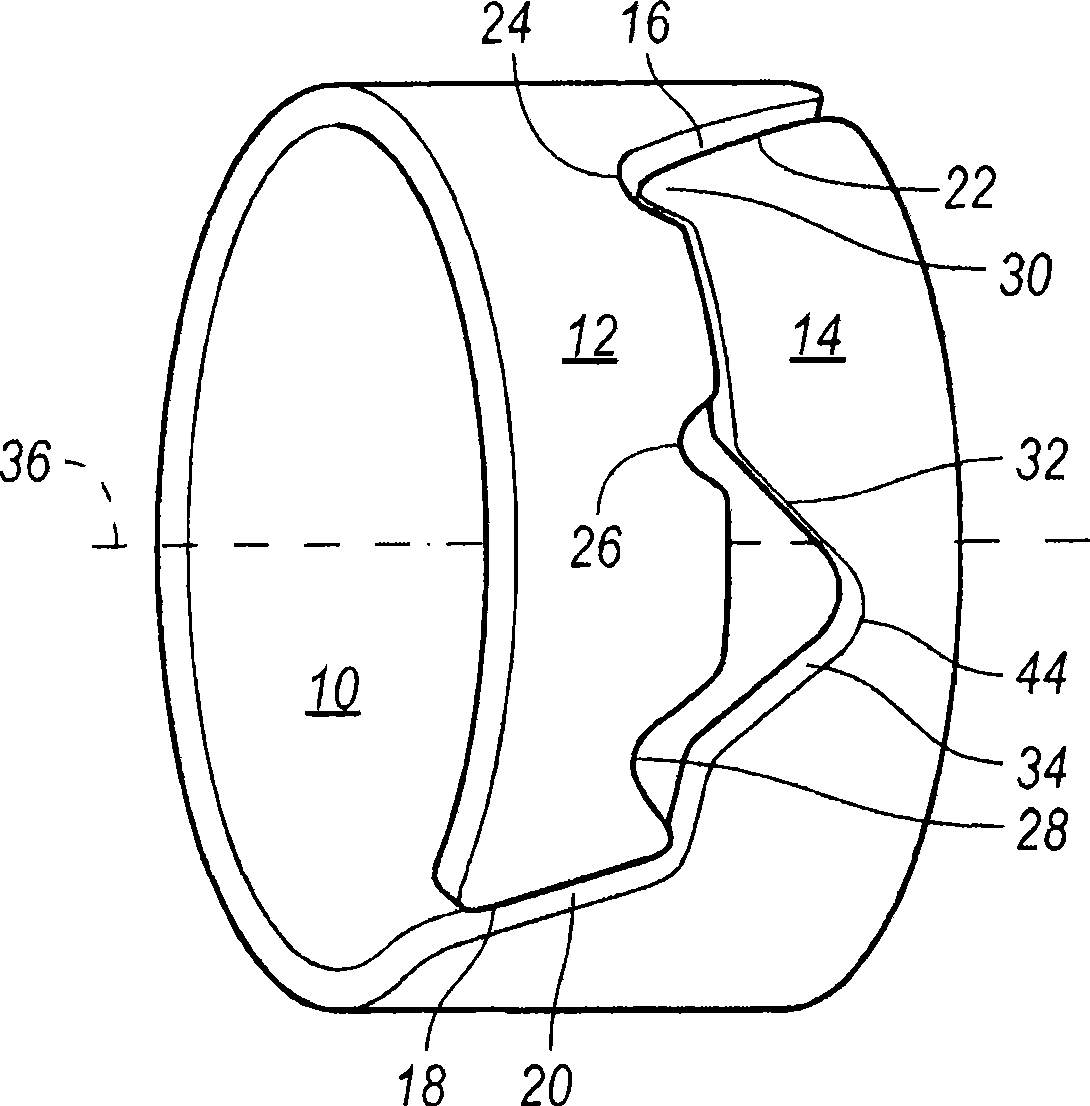

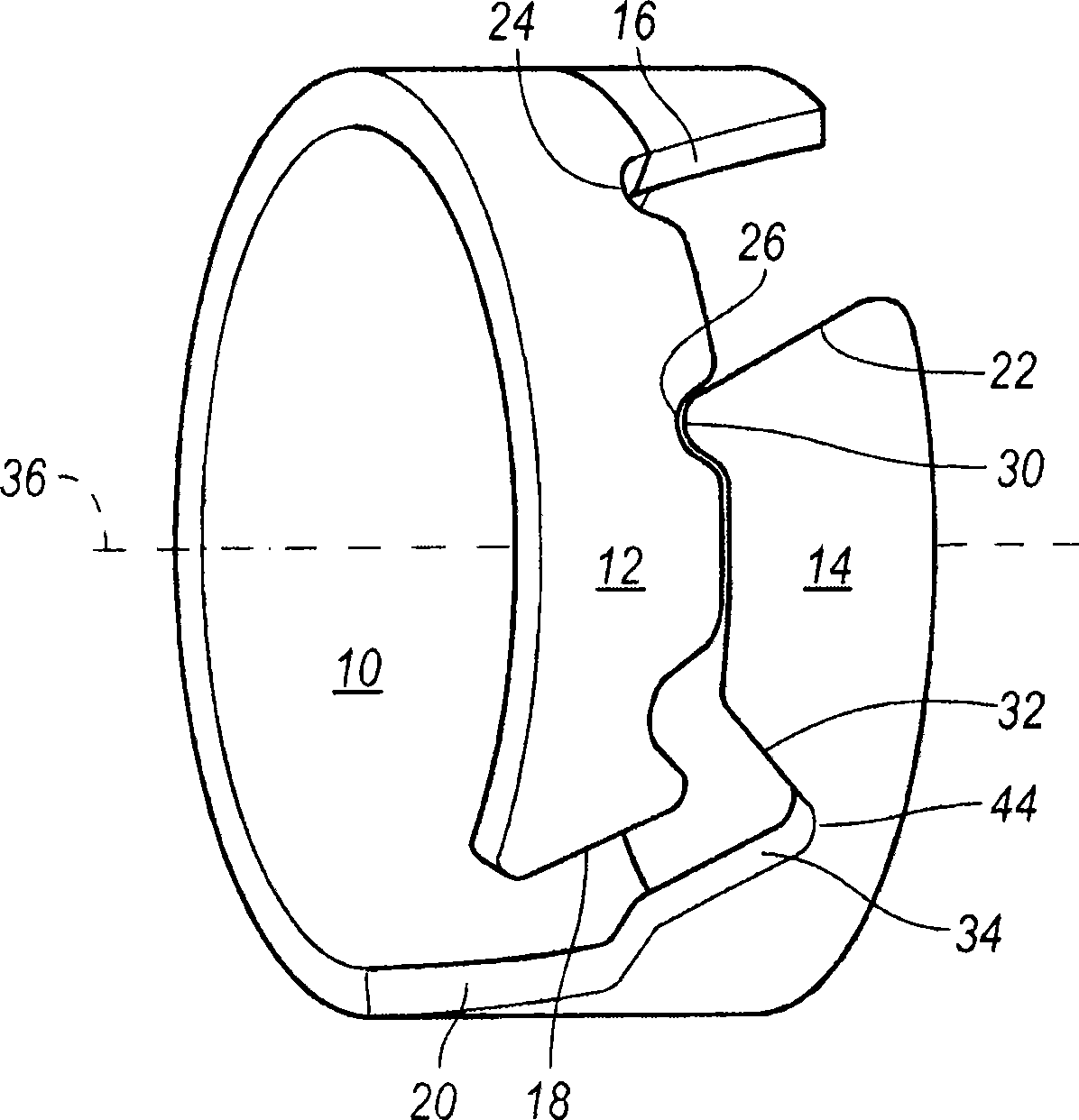

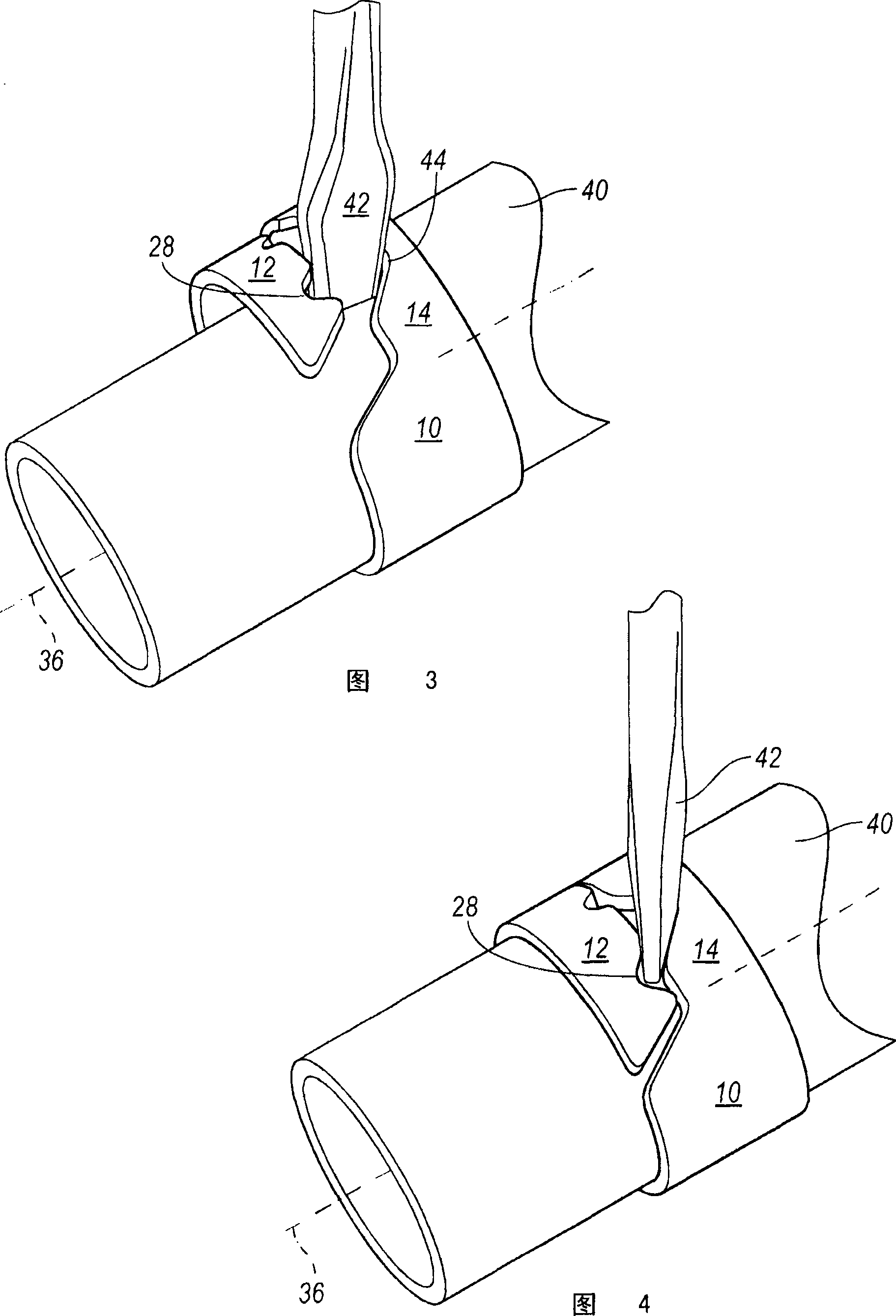

[0022] first reference figure 1 , the first hose clamp 10 is formed from a resilient material, preferably steel, as a round, open ring of uniform thickness. figure 1 The clip 10 is shown in its closed state. figure 2 The clip 10 is shown in its open state, wherein the clip creates and maintains a resilient preload tending to return the clip to its closed state.

[0023] The clip 10 includes first and second mutually parallel strips 12 , 14 extending around the circumference of the clip, each strip extending axially along a portion of the width of the clip 10 . The first transition surface 16 leads to the strip 12 and its open end 18 . The second transition surface 20 leads to the band 14 and its open end 22 facing and spaced from the surface 16 . Similarly, end 18 faces and is spaced from transition surface 20 .

[0024] The band 12 is formed with recesses 24 , 26 , 28 circumferentially spaced from each other. The strap 14 is formed with a protrusion 30 capable of engagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com