Patents

Literature

45results about How to "Short disassembly time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

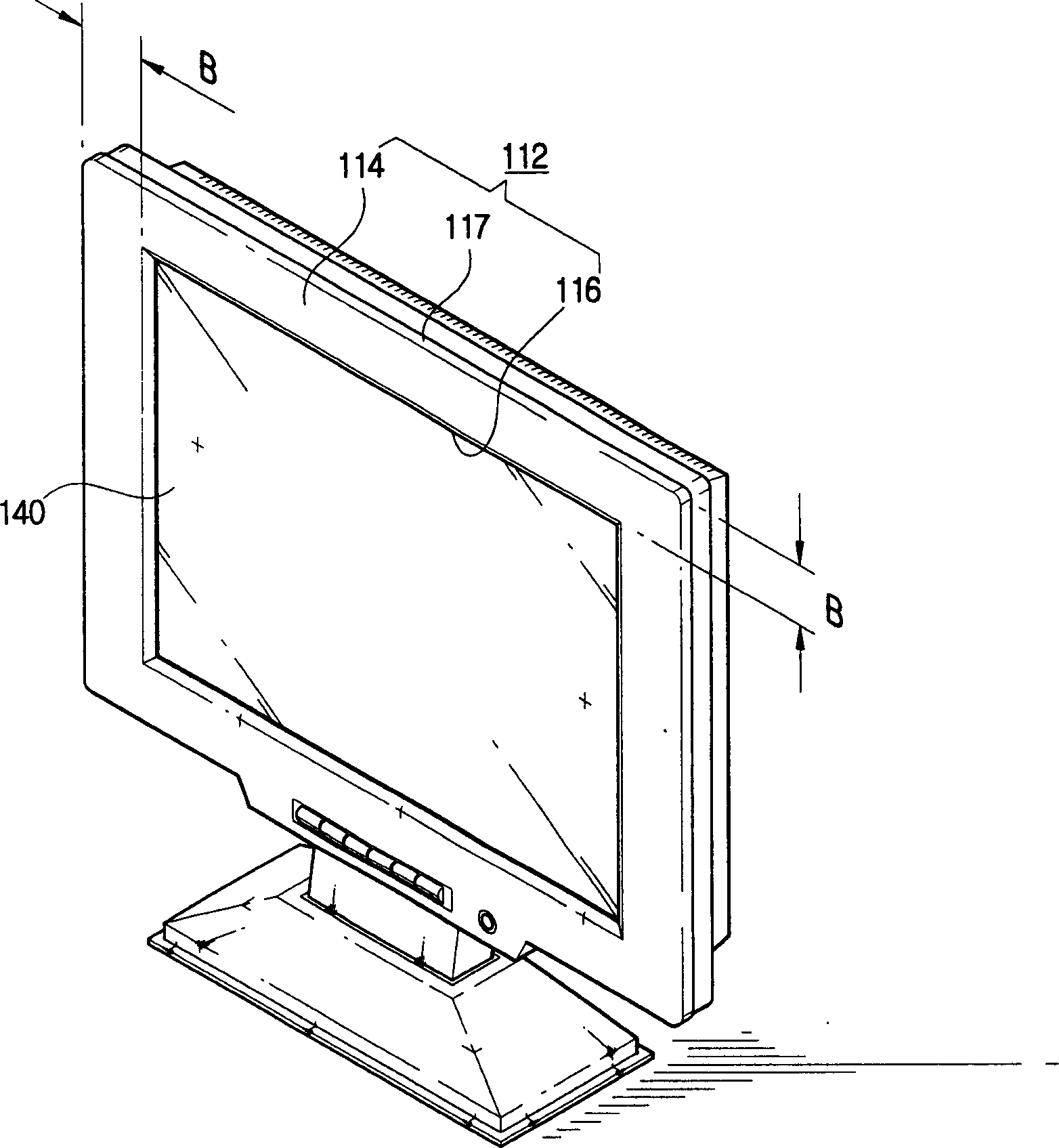

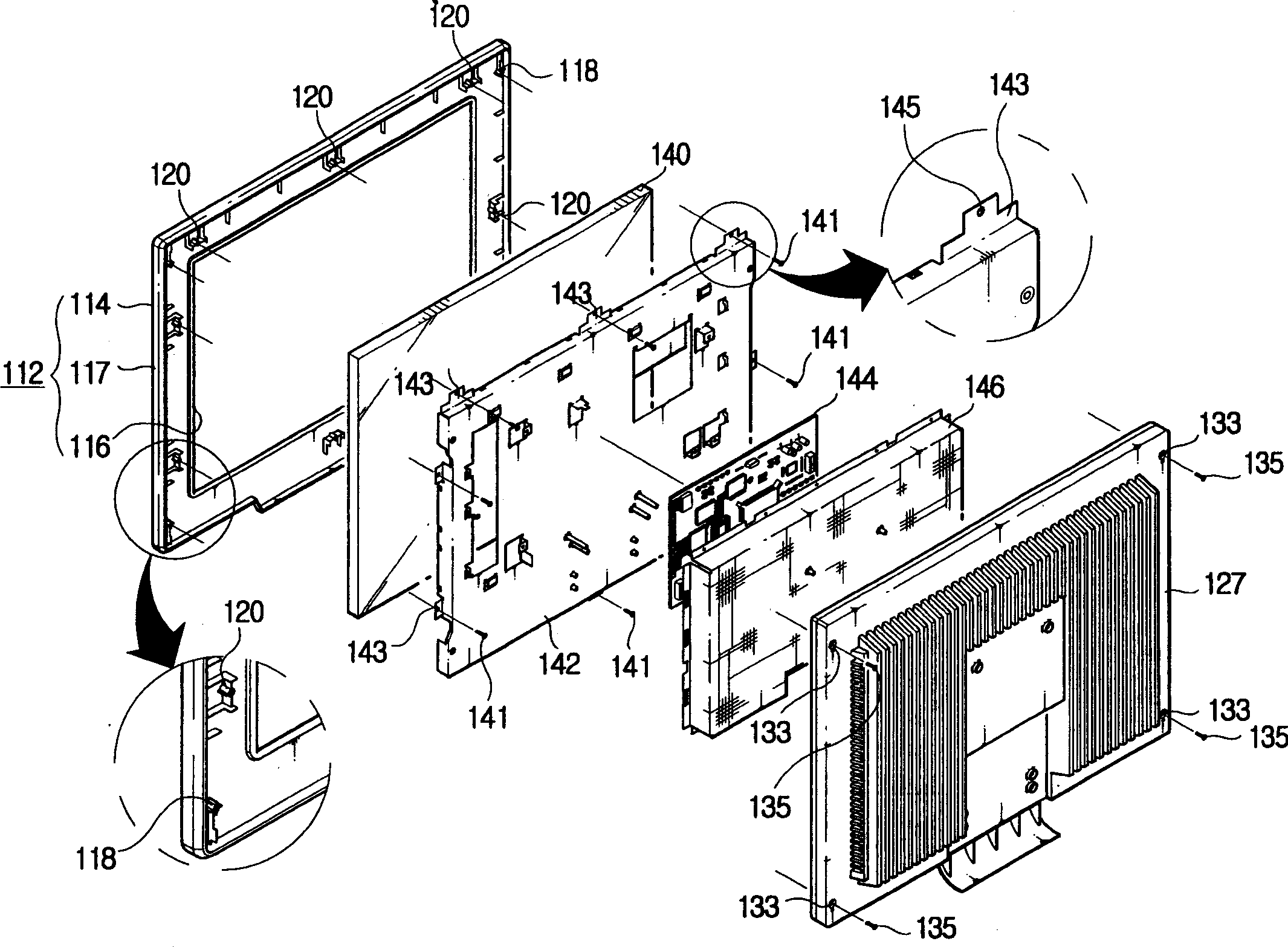

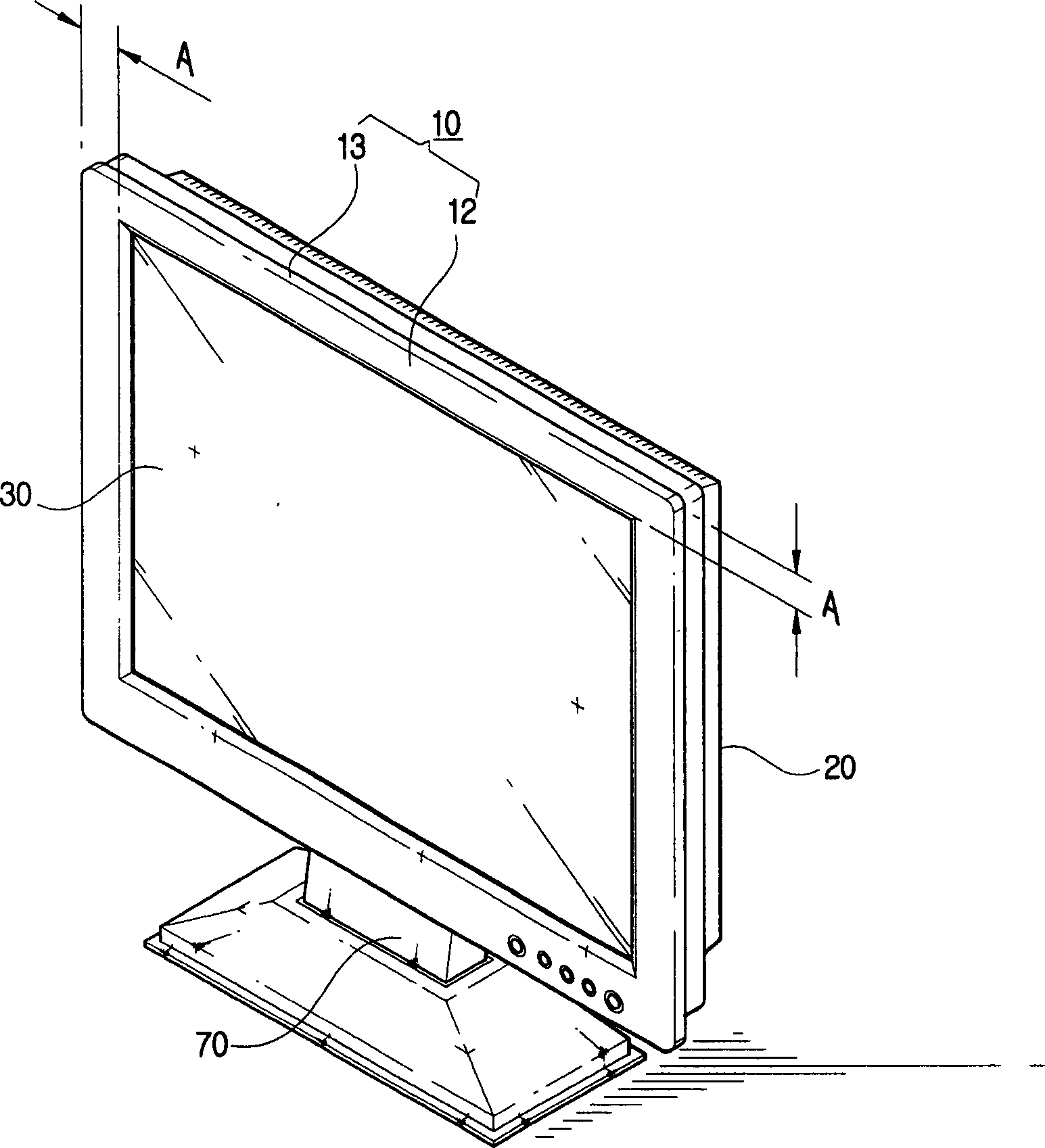

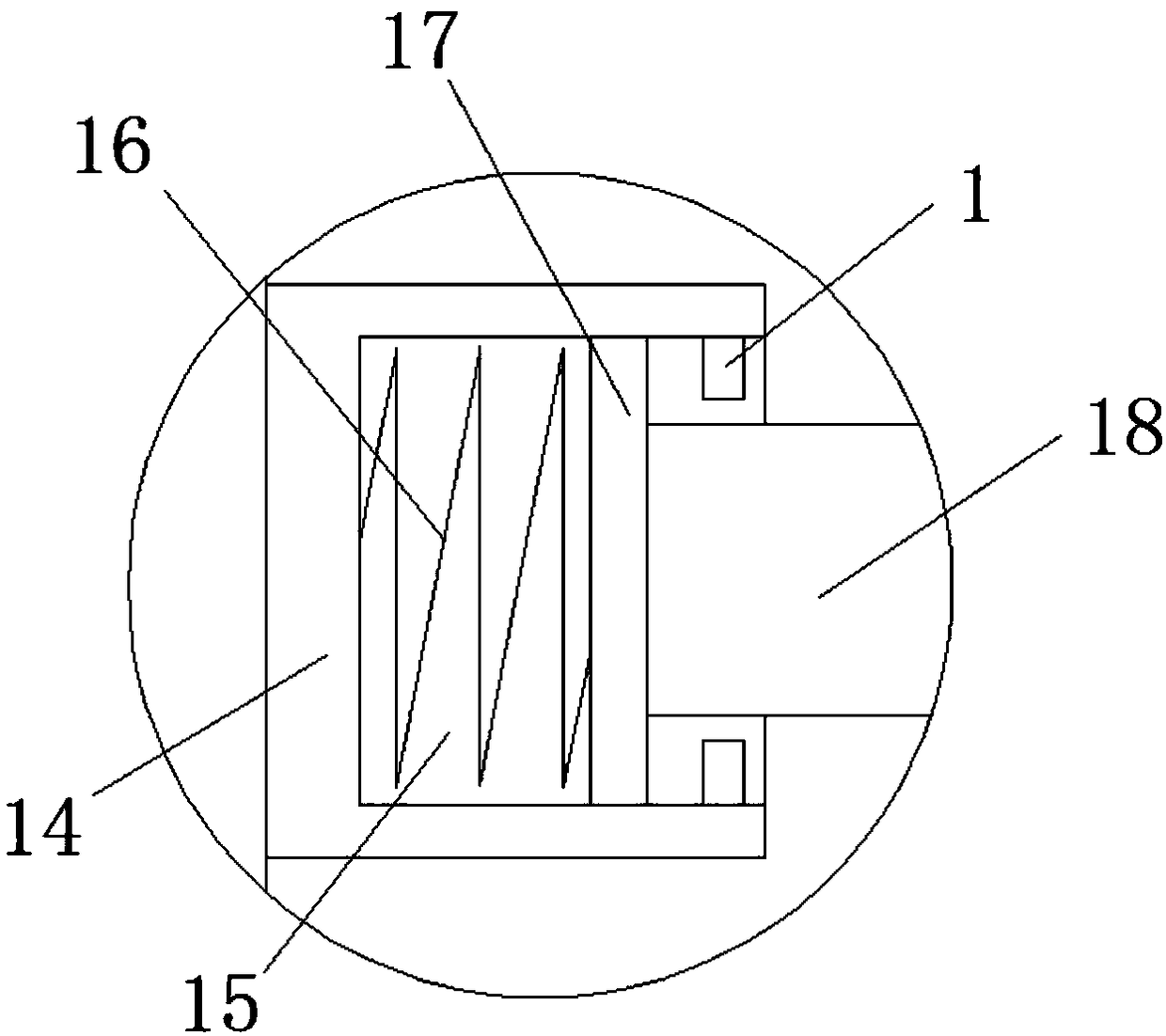

Display apparatus

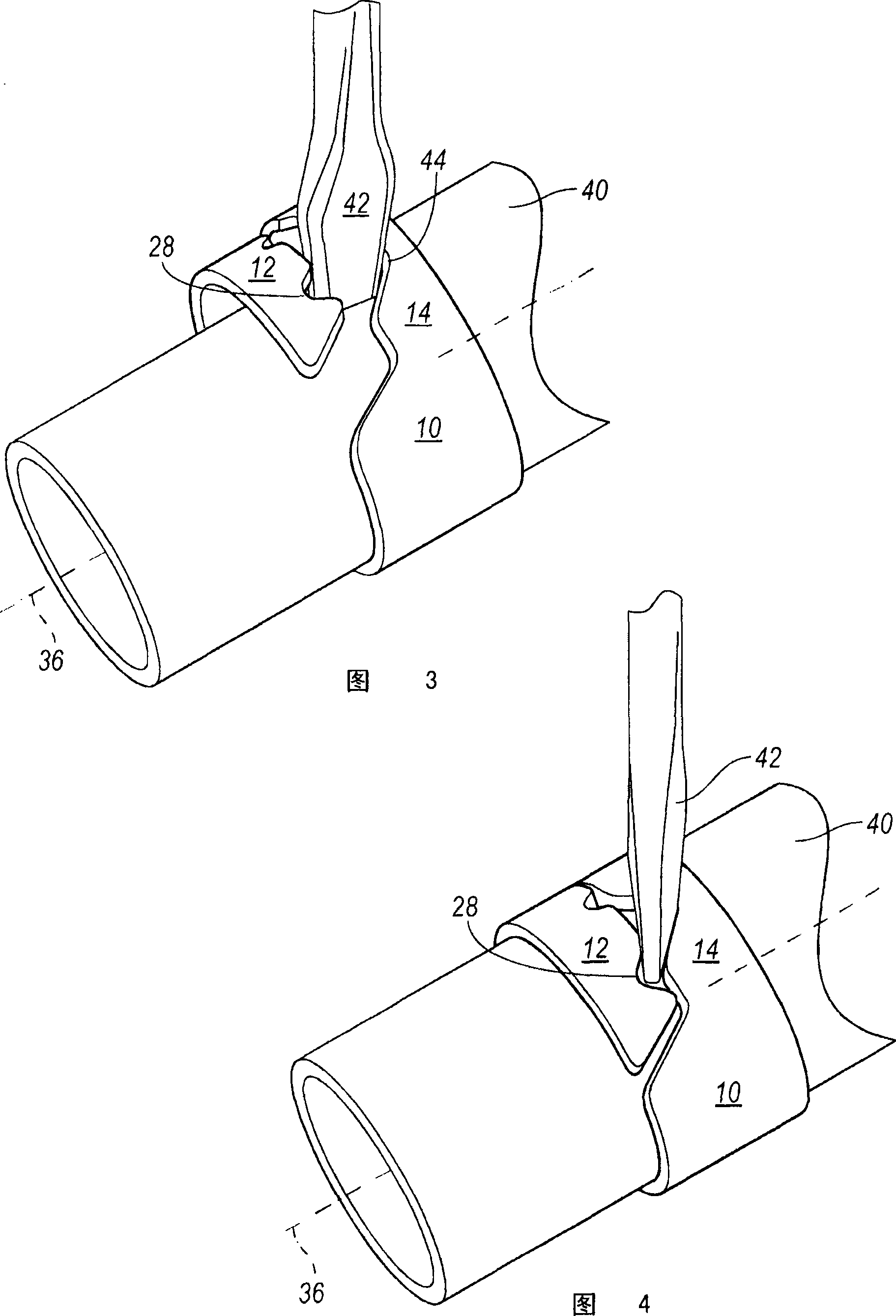

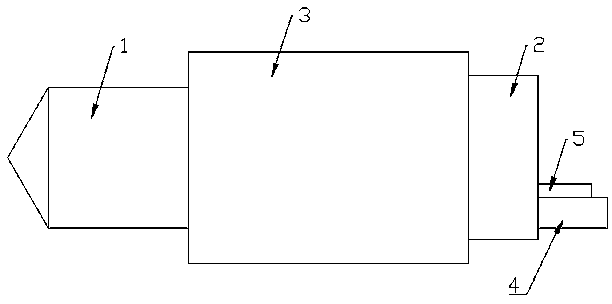

InactiveCN1467542AShort assembly timeShort disassembly timeTelevision system detailsCasings/cabinets/drawers detailsEngineeringFront edge

A display apparatus having an LCD panel, a front cover covering a front edge of the LCD panel, a panel supporting member connected to the front cover, with the LCD panel being disposed therebetween, and a rear cover disposed in back of the panel supporting member and connected to the front cover . The display also includes a first snap pin protruding from the rear of the front cover and having a first projection holder, a reinforcing member formed with an opening and having a projection engaging with the first projection holder of the first snap pin, and a flange part formed on the panel supporting member and having a first projection engaging with the opening of the reinforcing member. With this configuration, a display apparatus can be assembled or disassembled in relatively short time, has a slim and compact appearance, and has an improved EMI shielding effect.

Owner:SAMSUNG ELECTRONICS CO LTD

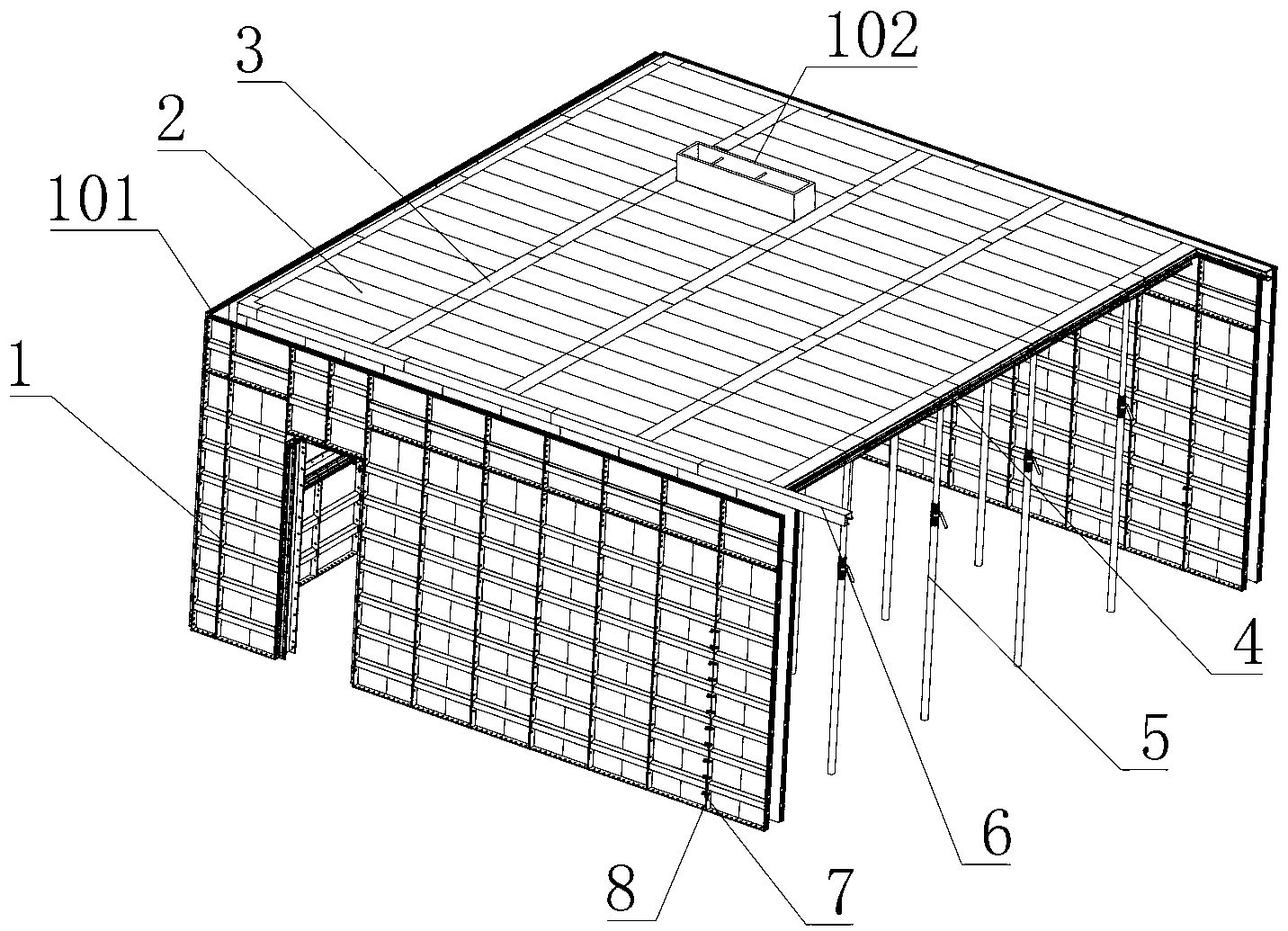

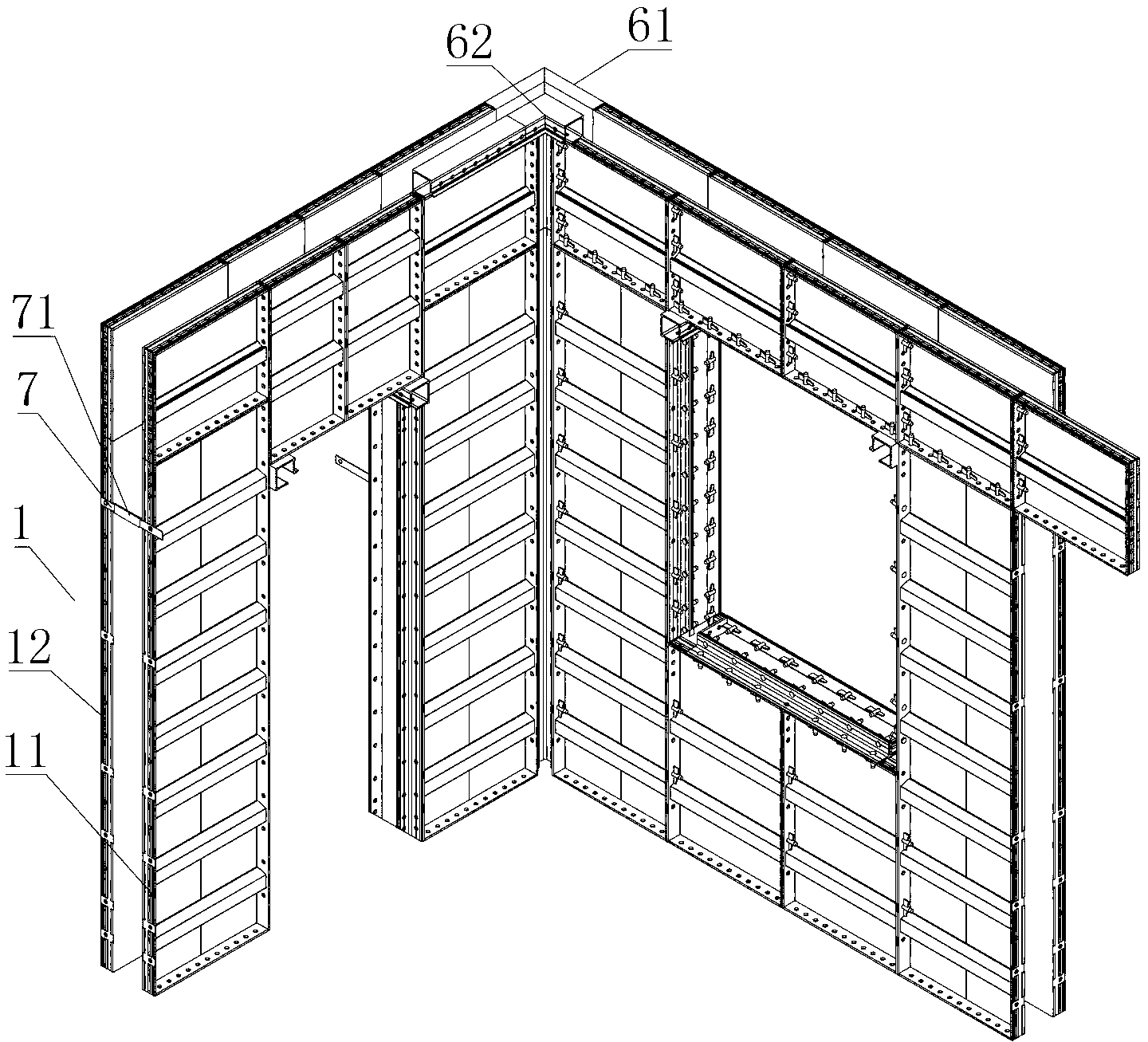

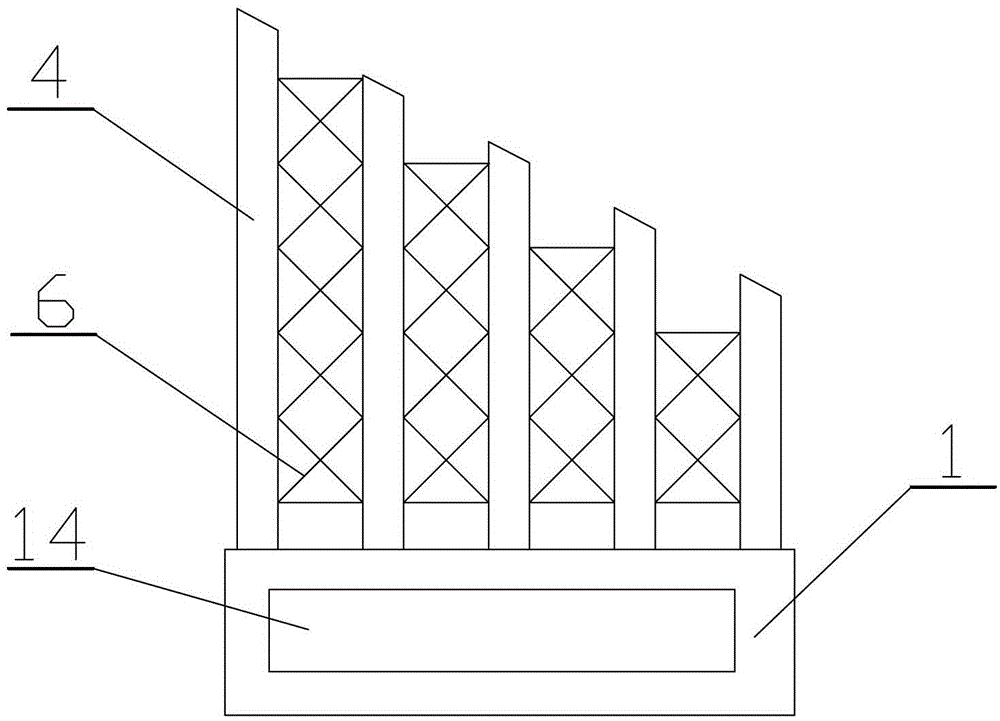

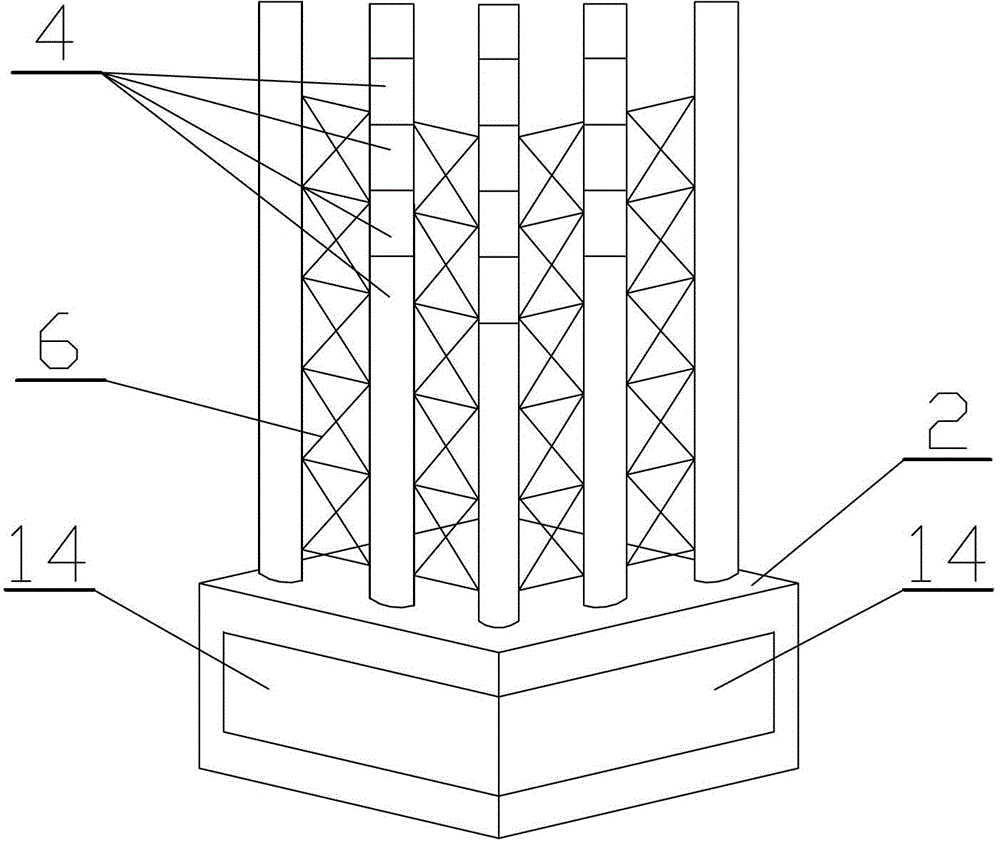

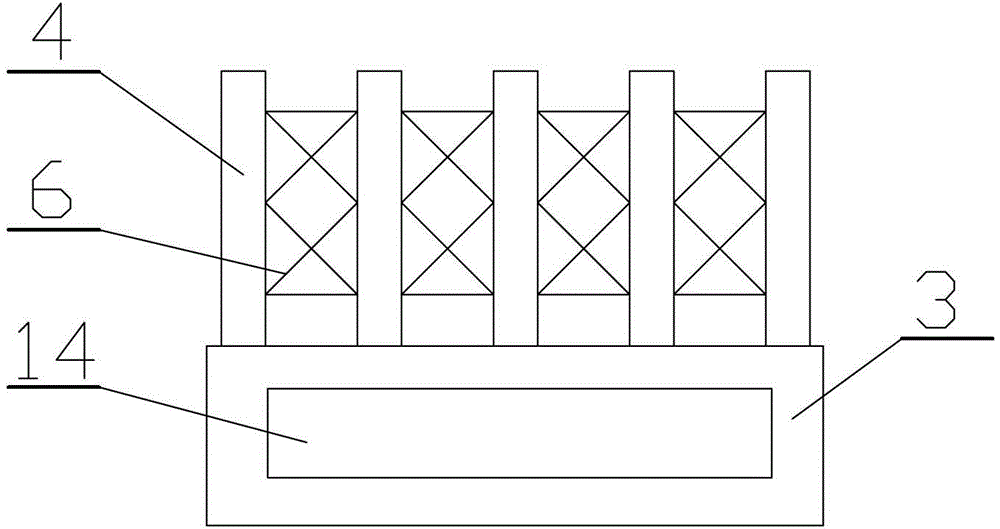

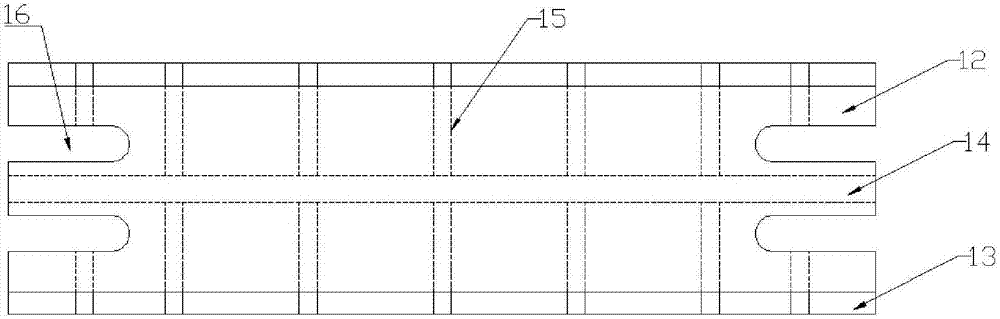

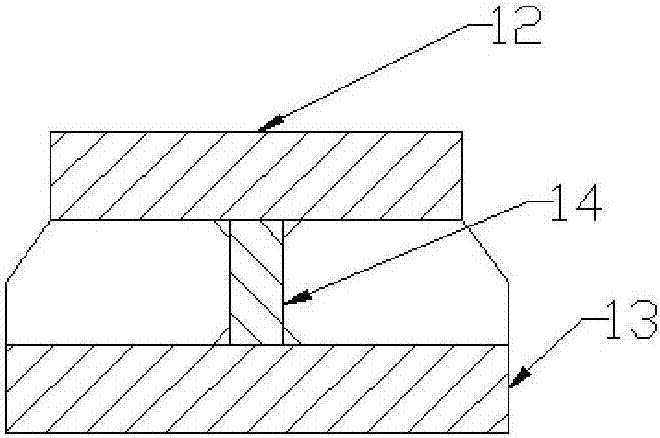

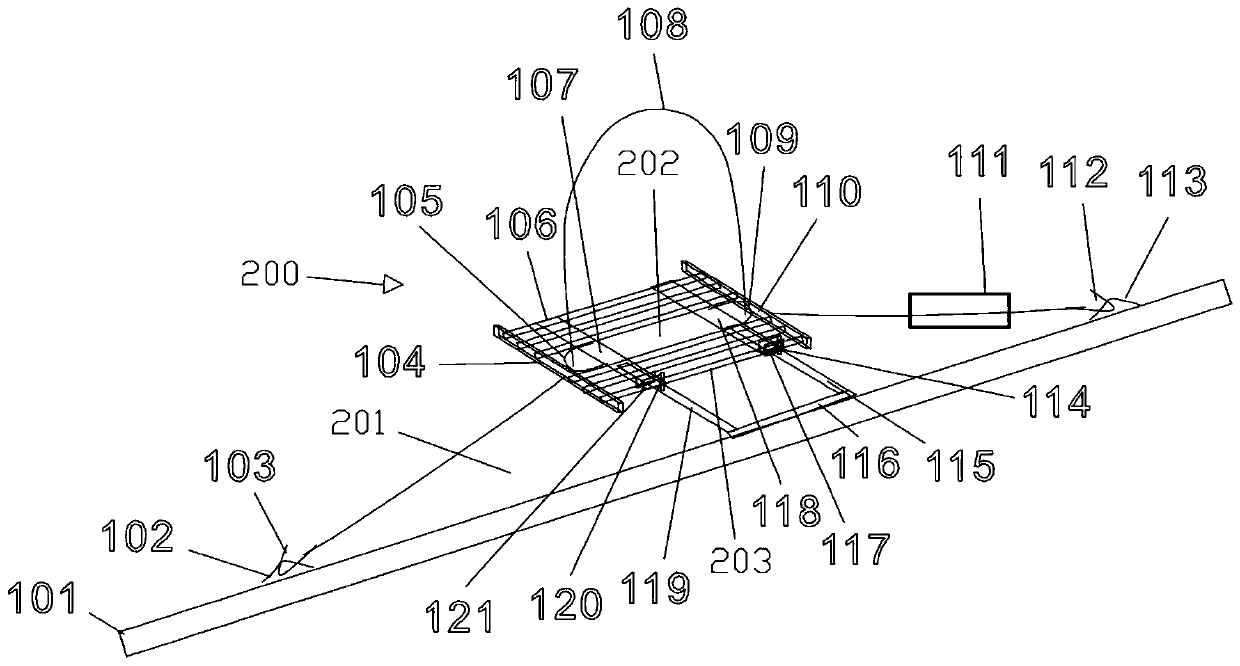

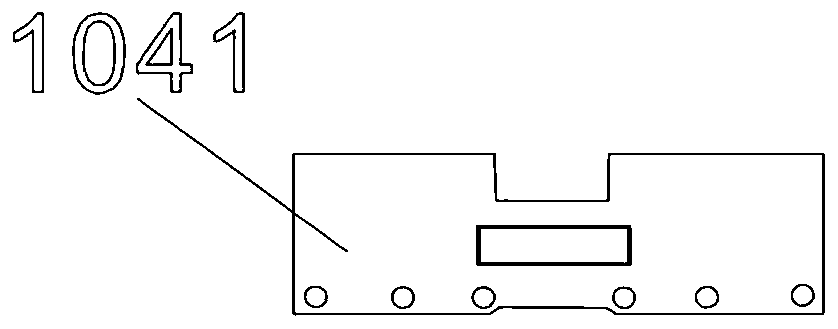

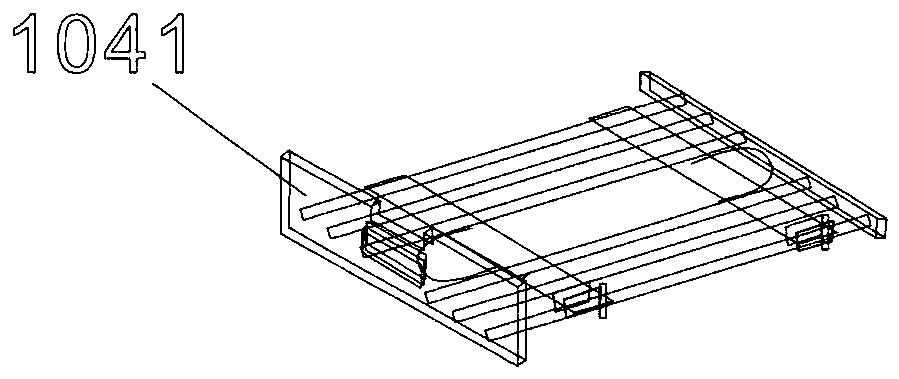

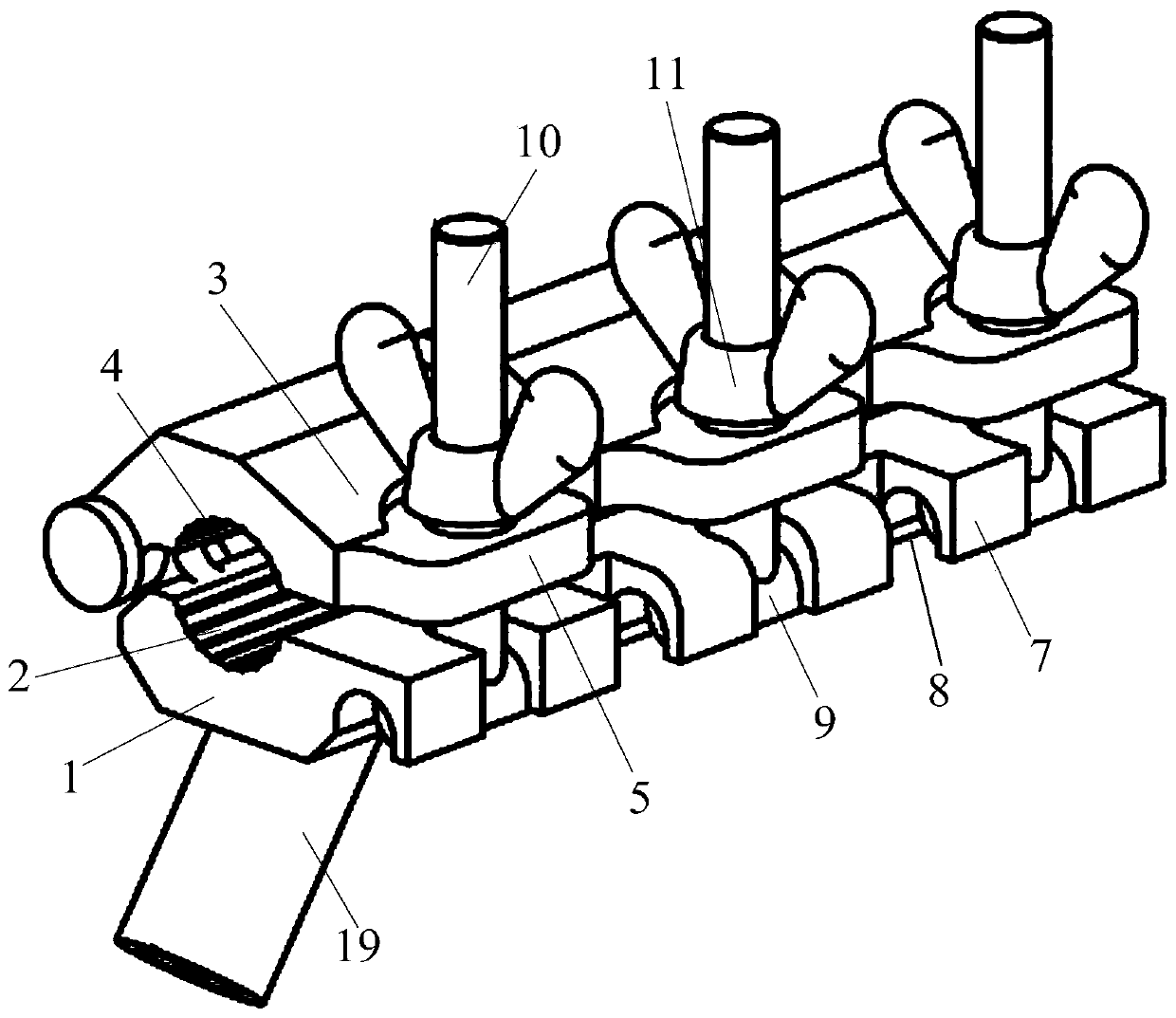

Aluminum template system for building

InactiveCN103276891AImprove turnover rateReduce construction costsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksUtilization rateBuilding construction

The invention belongs to the technical field of building construction and particularly discloses an aluminum template system for building. The system comprises wall boards, floor boards and supporting structures used for supporting the floor boards. The wall boards comprise inner wall boards and outer wall boards. The supporting structures comprise support columns, end beams and top head sleeves rotating at the top ends of the support columns and connected with the end beams. Quick locking and connection of adjacent templates are achieved through a bolt locking structure. Corner templates are arranged at the corner positions among the boards. Matching splicing of standard templates and non-standard templates is adopted in the system to form a building floor, then concrete is poured conveniently and quickly, the supporting structures adopt the mode that the end beams are separated from the support columns, the wall boards can be disassembled 12 hours after the concrete is poured, the floor boards and the end beams can be disassembled after 35 hours, template utilization rate is improved, the standard degree is high, construction cost is reduced, construction efficiency is improved, and the requirement for modern construction can be met.

Owner:GUANGDONG TAIAO SPECIAL ALUMINUM

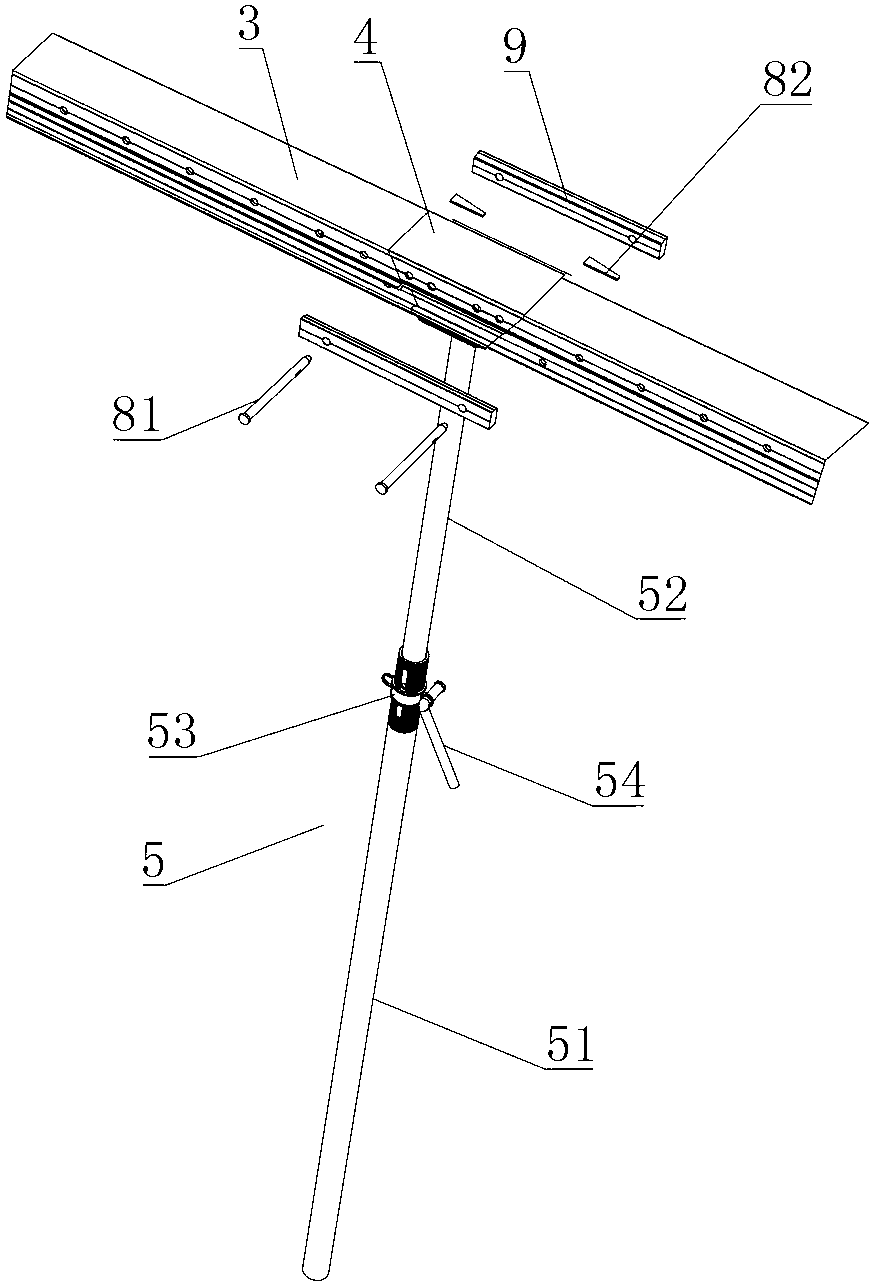

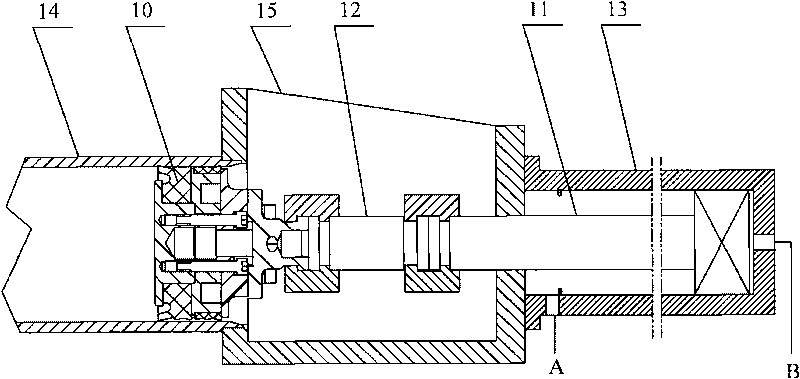

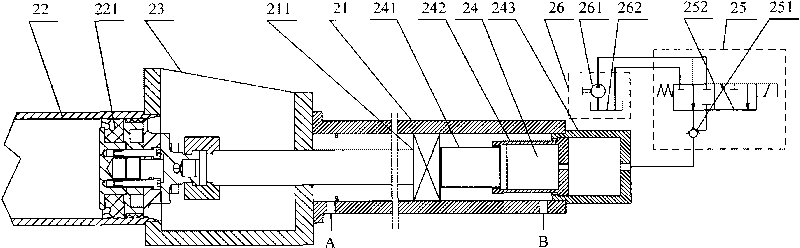

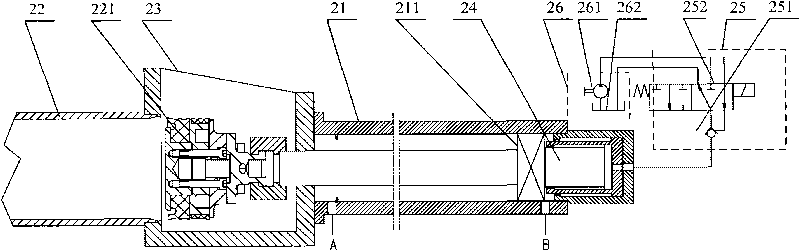

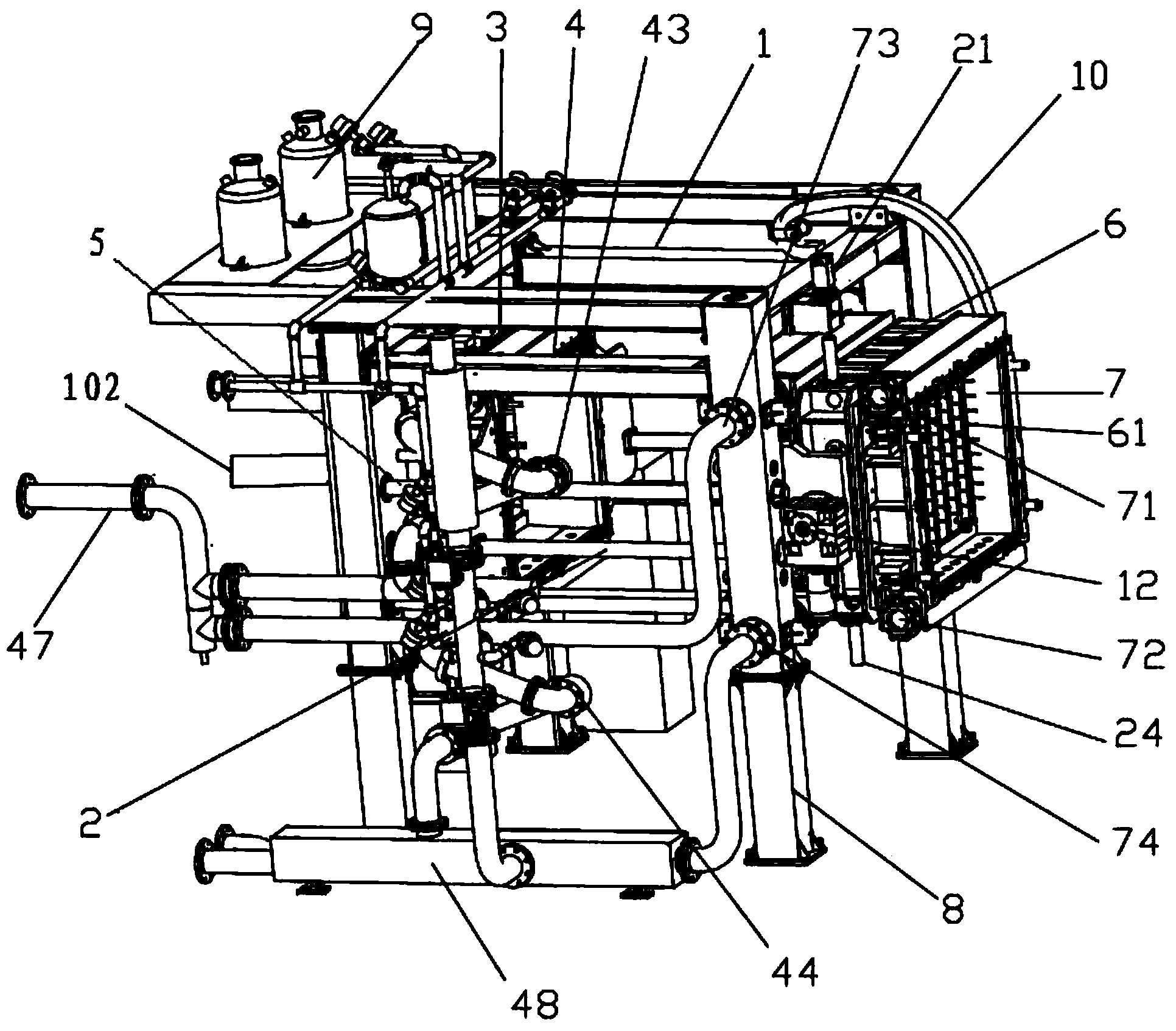

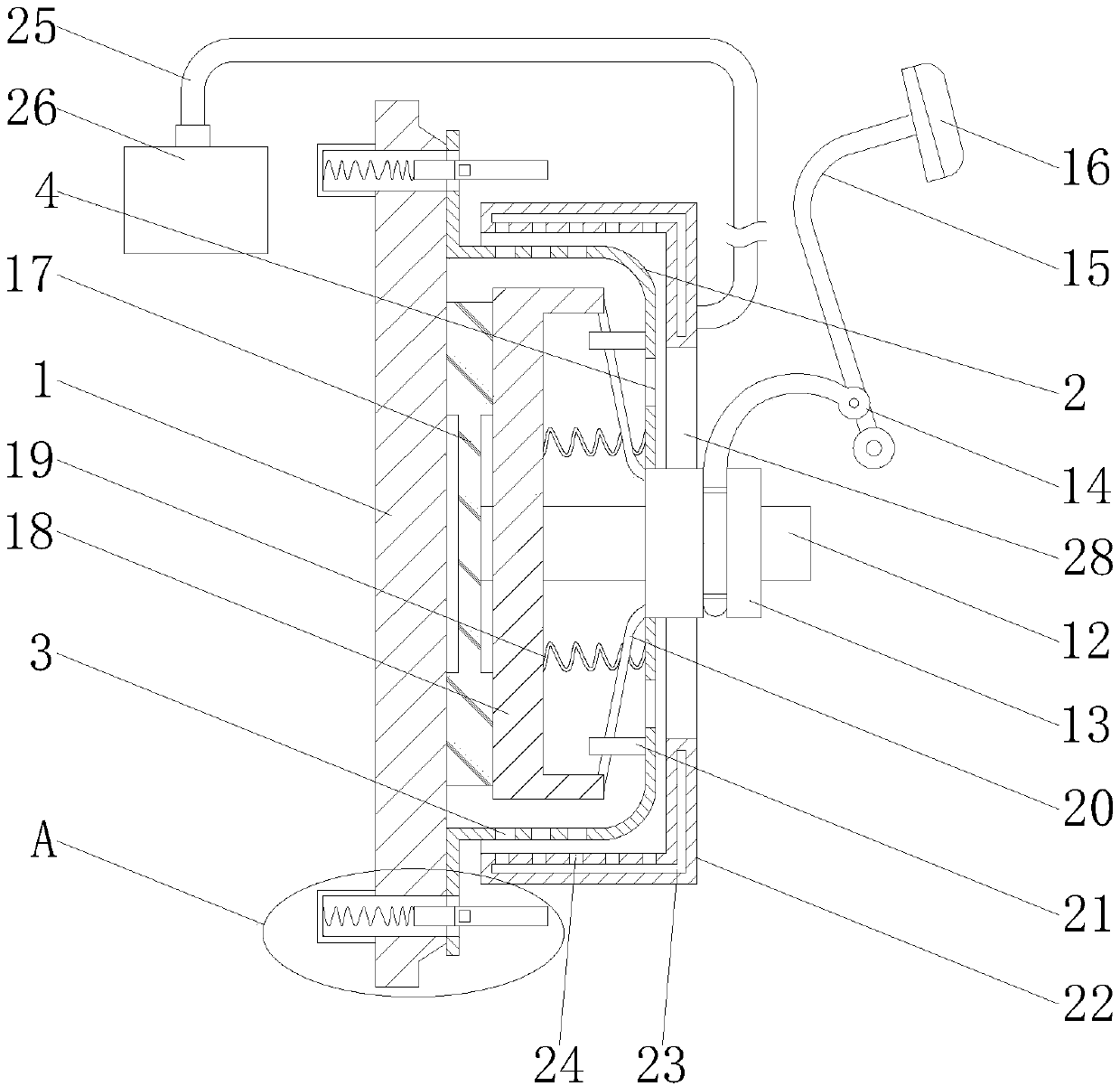

Concrete transfer pump

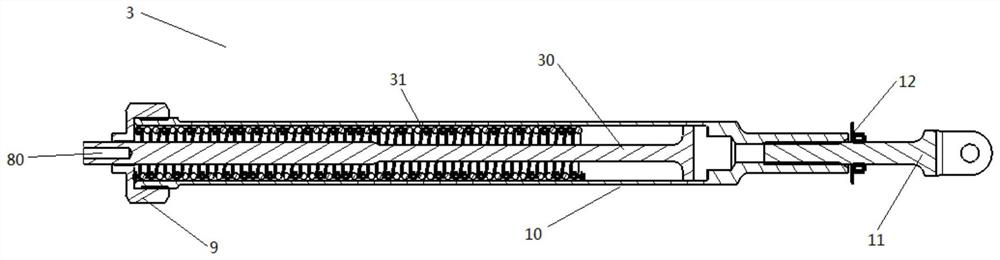

InactiveCN101705928AGuaranteed construction effectCompact structurePositive displacement pump componentsPump controlReciprocating motionStructural engineering

The invention discloses a concrete transfer pump comprising a main oil cylinder, a concrete cylinder and a water tank arranged between the main oil cylinder and the concrete cylinder; the main oil cylinder is internally provided with a main piston connected with a concrete piston arranged in the concrete cylinder through a main piston rod, and the main piston drives the concrete piston to do reciprocating motion under the action of hydraulic oil in the main oil cylinder; the end part of the main oil cylinder is also provided with a multi-stage oil cylinder which limits the motion stroke of the main piston by a way of supporting against the main piston; and the motion stroke of the main piston is shifted between a working stroke and a dismantling stroke through the protrusion or retraction of the multi-stage oil cylinder. In the embodiment, when the concrete piston of the concrete transfer pump is maintained, the concrete piston can be directly withdrawn to the water tank through retracting the multi-stage oil cylinder so as to be dismantled with simple process and short time; meanwhile, the concrete transfer pump has compact whole structure and small size.

Owner:BEIQI FOTON MOTOR CO LTD

Movable and quick-inflation rescue air cushion

The invention provides a movable and quick-inflation rescue air cushion, relates to a rescue air cushion, and solves the problem that the rescuing time is prolonged because a conventional rescue air cushion is long in inflation time, large in volume and hard to transport when being used. A plurality of tank bodies comprise at least one third tank body, a plurality of first tank bodies and a plurality of second tank bodies, wherein when the number of the third tank body is one or more, the plurality of first tank bodies and the plurality of second tank bodies are alternately attached to the periphery of the third tank body or the plurality of third tank bodies and connected to form a tank assembly, and a plurality of inflation hoses are fixedly connected to the upper end face of the tank assembly; the upper cavity in the tank assembly is a pipeline chamber, and the lower cavity of the tank assembly is a gas collection chamber; a plurality of gas inlet pipelines and a plurality of gas exhaust pipelines are arranged in the pipeline chamber; a plurality of rollers are arranged at the bottom of the tank assembly; a buffer face mesh is arranged on the plurality of inflation hoses; an inflation hose coating is coated on each inflation hose; and a plurality of reinforcing wires pass through the inflation hose coatings to form a reinforcing wire mesh. The movable and quick-inflation rescue air cushion is used in rescue work.

Owner:HARBIN INST OF TECH

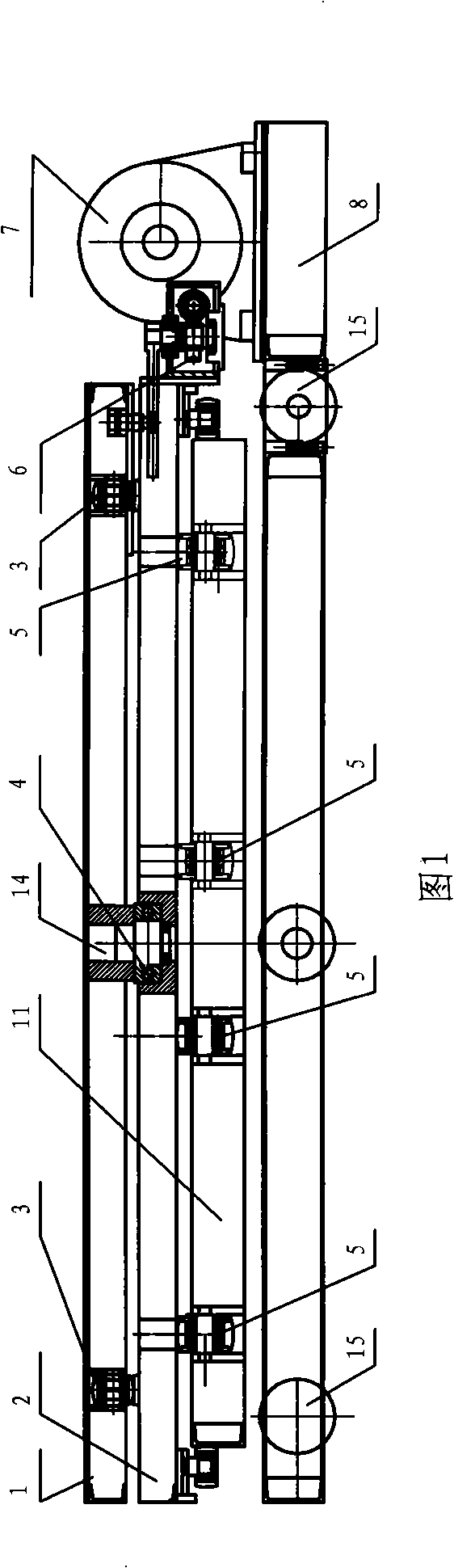

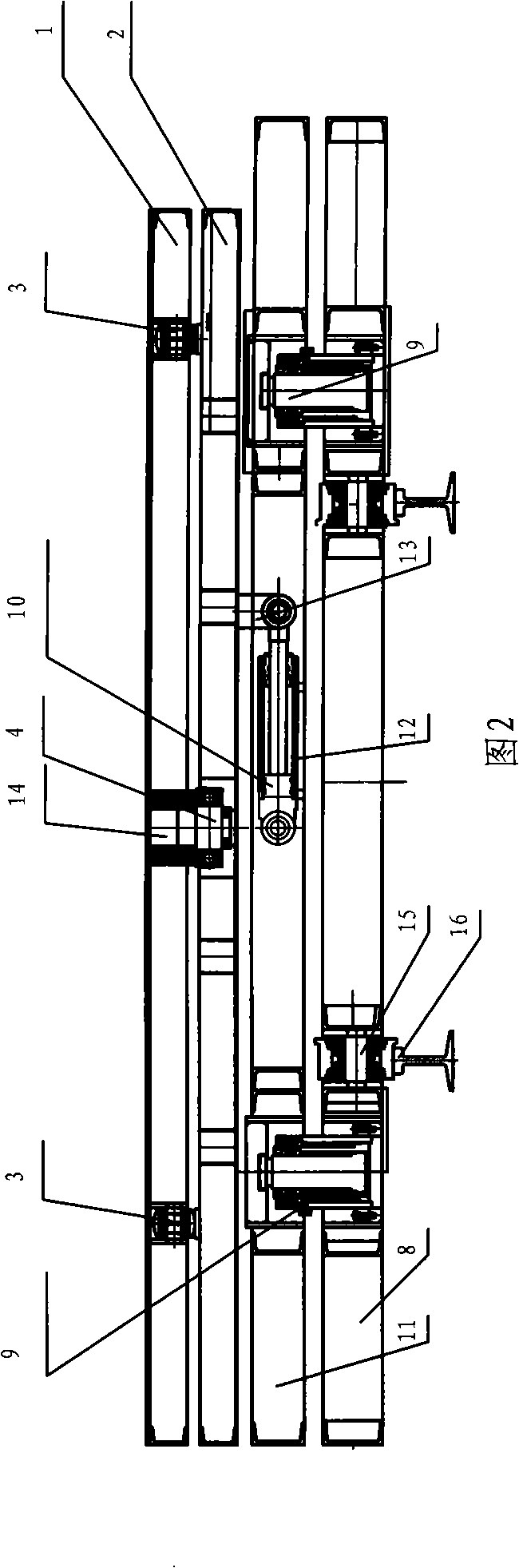

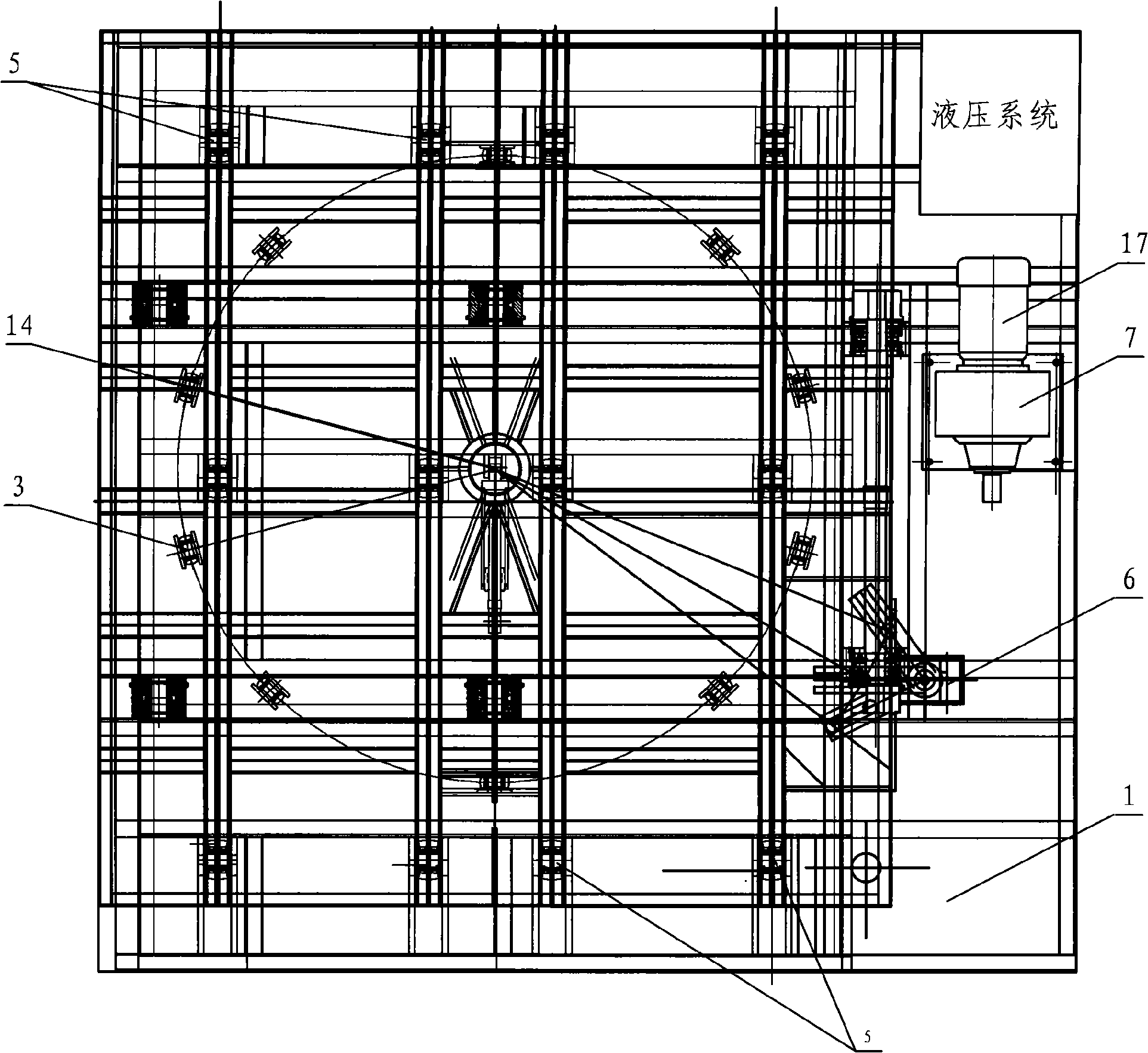

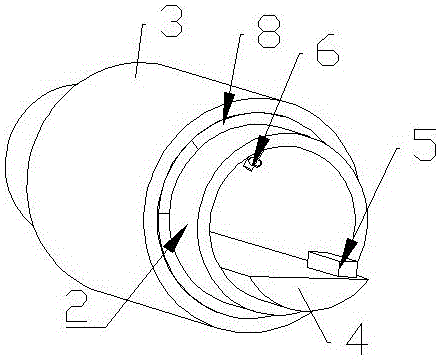

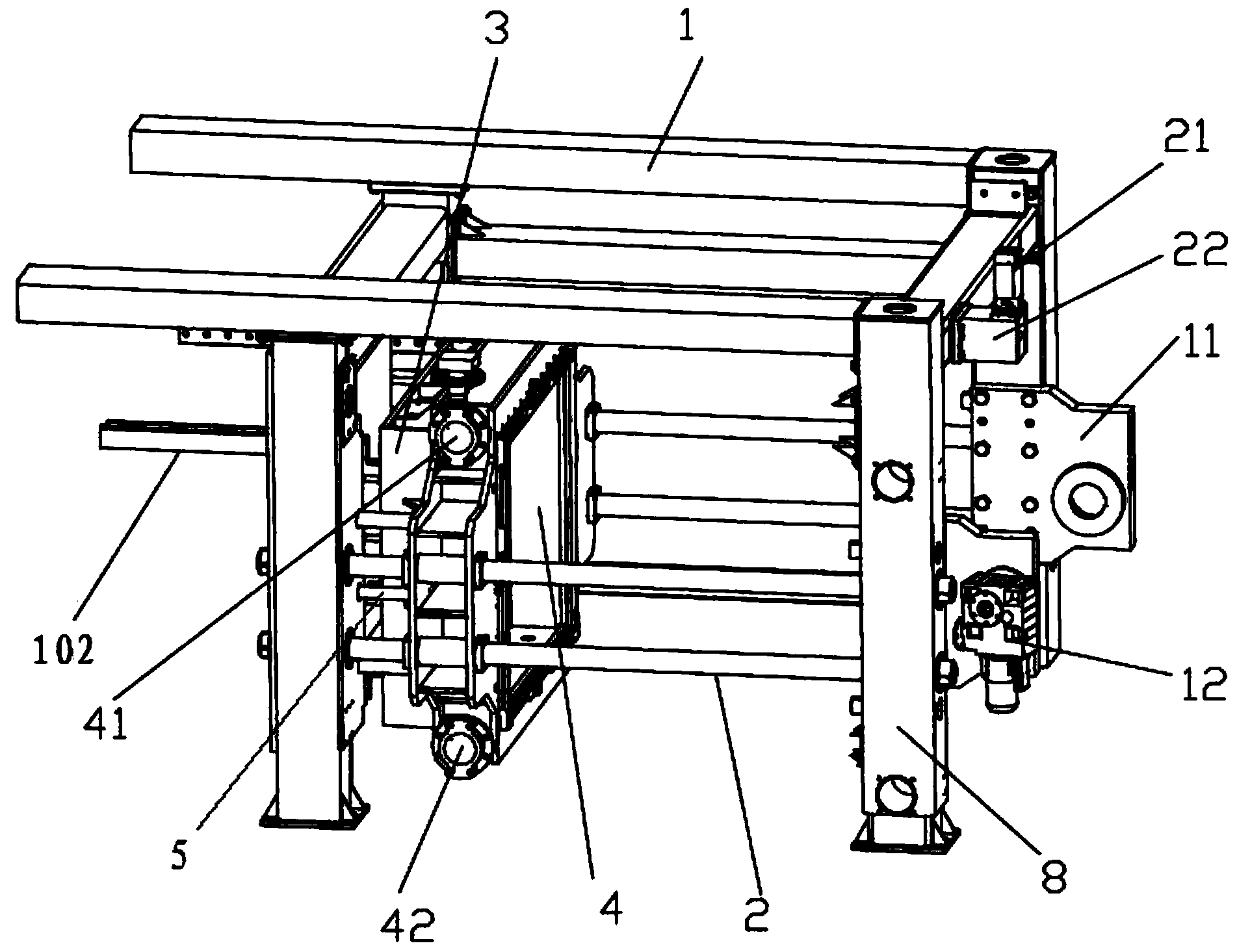

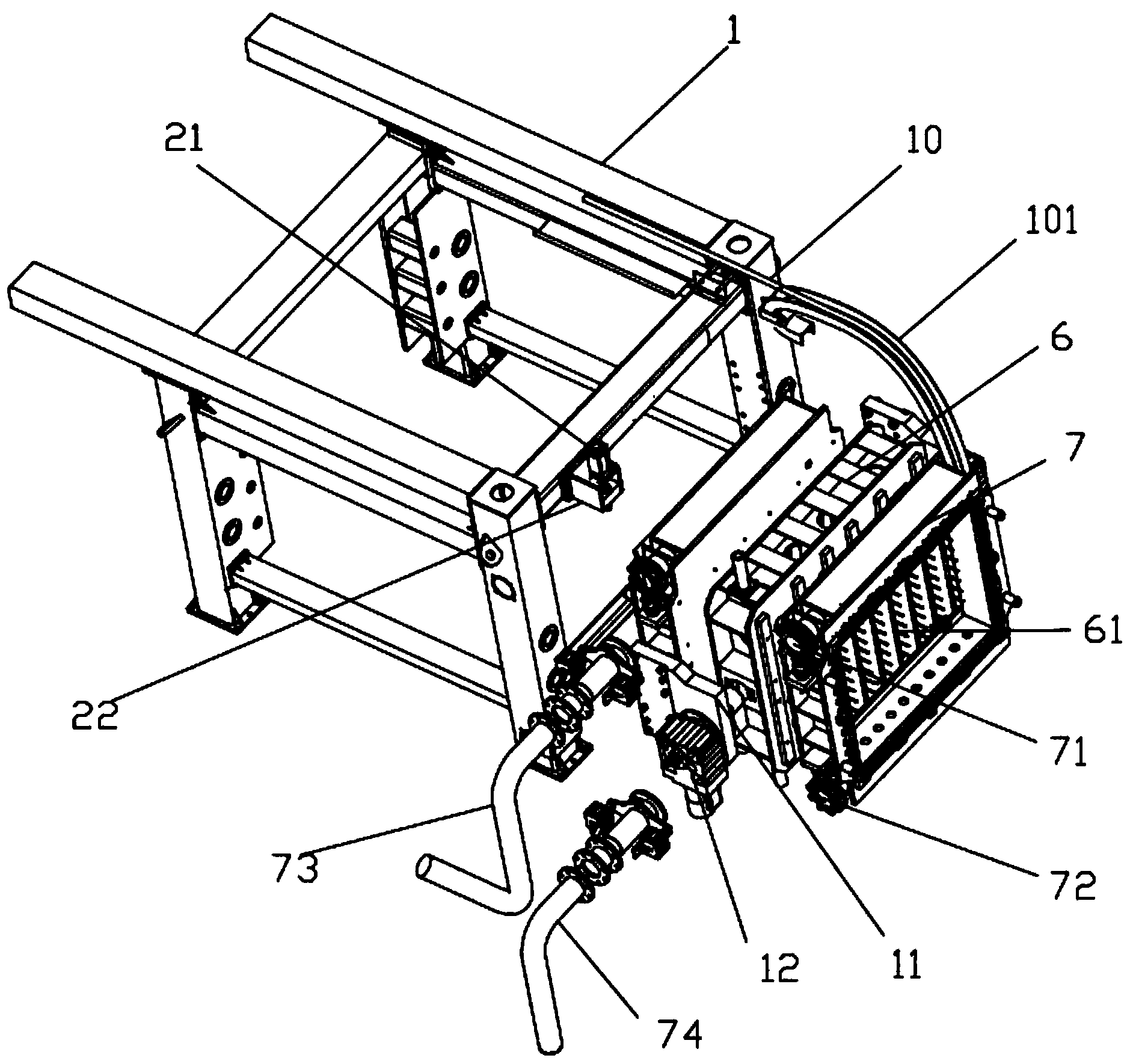

Installation platform of electric locomotive main transformer

The present invention belongs to the device which is used for repairing the electric locomotive in the railway factory, and in particular relates to a main transformer installation platform of the electric locomotive. In the technical proposal, a plane vehicle body of the running part is provided with a lifting platform, a side moving platform and a turntable; the lifting platform is connected with the plane vehicle body of the running part through a group of lifting oil cylinders; the side moving platform is arranged on the lifting platform; a side moving oil cylinder is arranged between the upper surface of the lifting platform and the lower surface of the side moving platform; the turntable is arranged on the side moving platform and rotates around the center of gyration. Because of the lifting, turning, translating and other functions, the application efficiency of the installation platform is improved by more than 6 times. Because of the reliable positioning accuracy, the main transformer can be accurately and safely installed, and is guaranteed to be complete; and the installation platform has the characteristics of time-saving, labor-saving and cost-saving capacities, excellent security, high degree of mechanization, convenient maintenance, and so on.

Owner:DALIAN TONGBAO HYDRAULIC CYLINDER

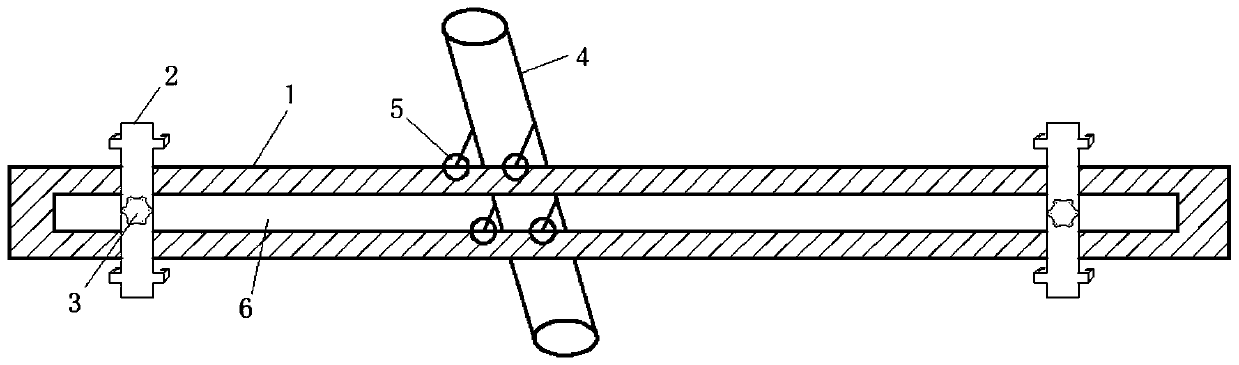

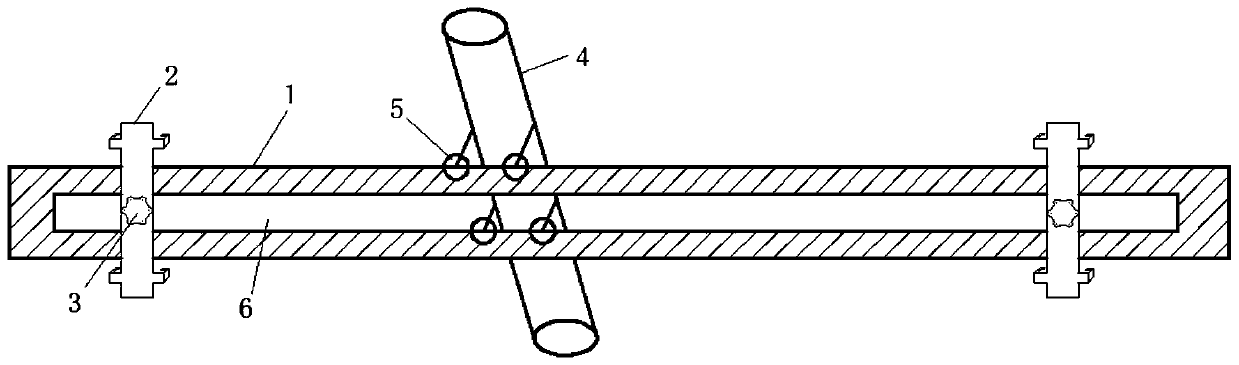

Grouting structure in tunnel driving process and grouting method matched with grouting structure

ActiveCN106761837AIncrease profitReduce grouting costsUnderground chambersTunnel liningSlurryUtilization rate

The invention relates to the technical field related to tunnel driving equipment, in particular to a grouting structure in the tunnel driving process and a grouting method matched with the grouting structure. The grouting structure in the tunnel driving process and the grouting method aim at solving the problem that in the prior art, filling a gap in the back portion of a segment cannot be achieved through synchronous grouting. The grouting structure in the tunnel driving process sequentially comprises a rock stratum and a segment stratum inwards from the inner wall of a tunnel, and accordingly a side-top arch, in unit of blocks, is formed. A support frame is arranged between the segment stratum and the rock stratum, and accordingly a hollow interlayer is formed. A base lining platform is arranged on the bottom of the side-top arch, and reserved grouting holes communicating with the hollow interlayer are formed in the positions, corresponding to the side-top arch blocks, of the top of the segment stratum. The reserved grouting holes are moveably connected with grouting pipes, and the other ends of the grouting pipes are connected with a grouting machine. The grouting structure in the tunnel driving process and the grouting method have the beneficial effects that the grouting cost is not increased, the grouting process is smooth, the utilization rate of the grout is high, the structure of equipment is simple, repairing and later maintenance are convenient, the assembling and disassembling time is short, grouting pressure can be monitored at any time, the grouting quality can be guaranteed, and a framework layer is formed on the contact surface between the grout and water glass so that flowing of the grout to a cutterhead can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

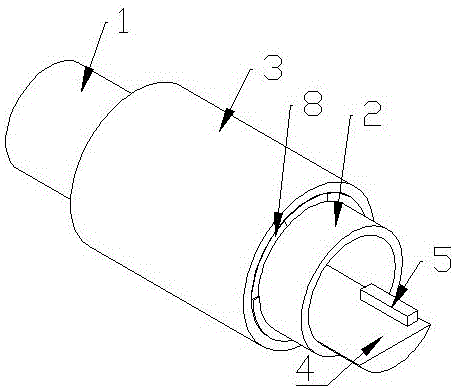

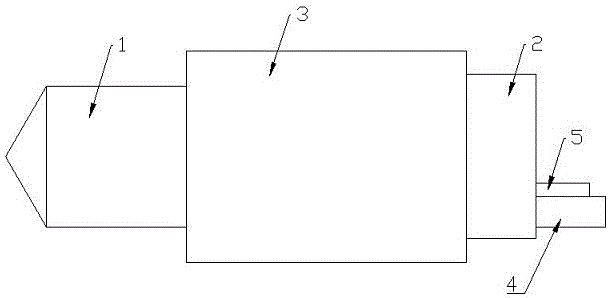

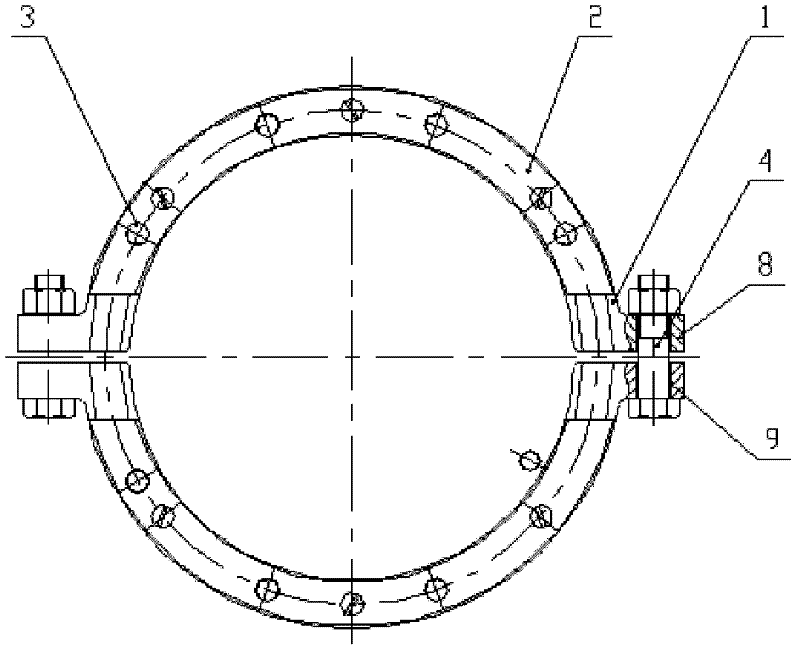

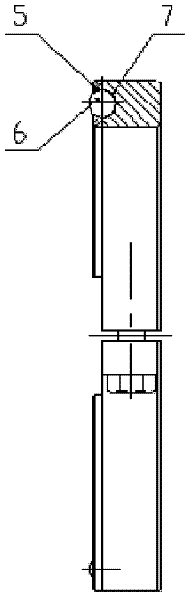

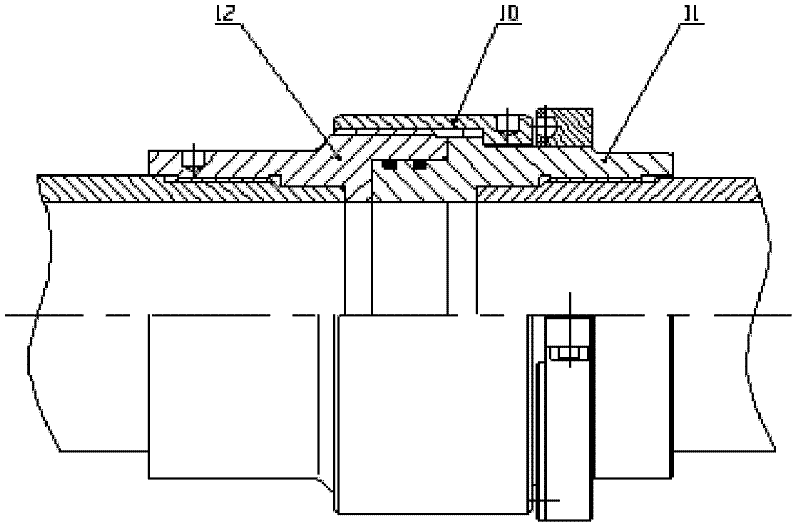

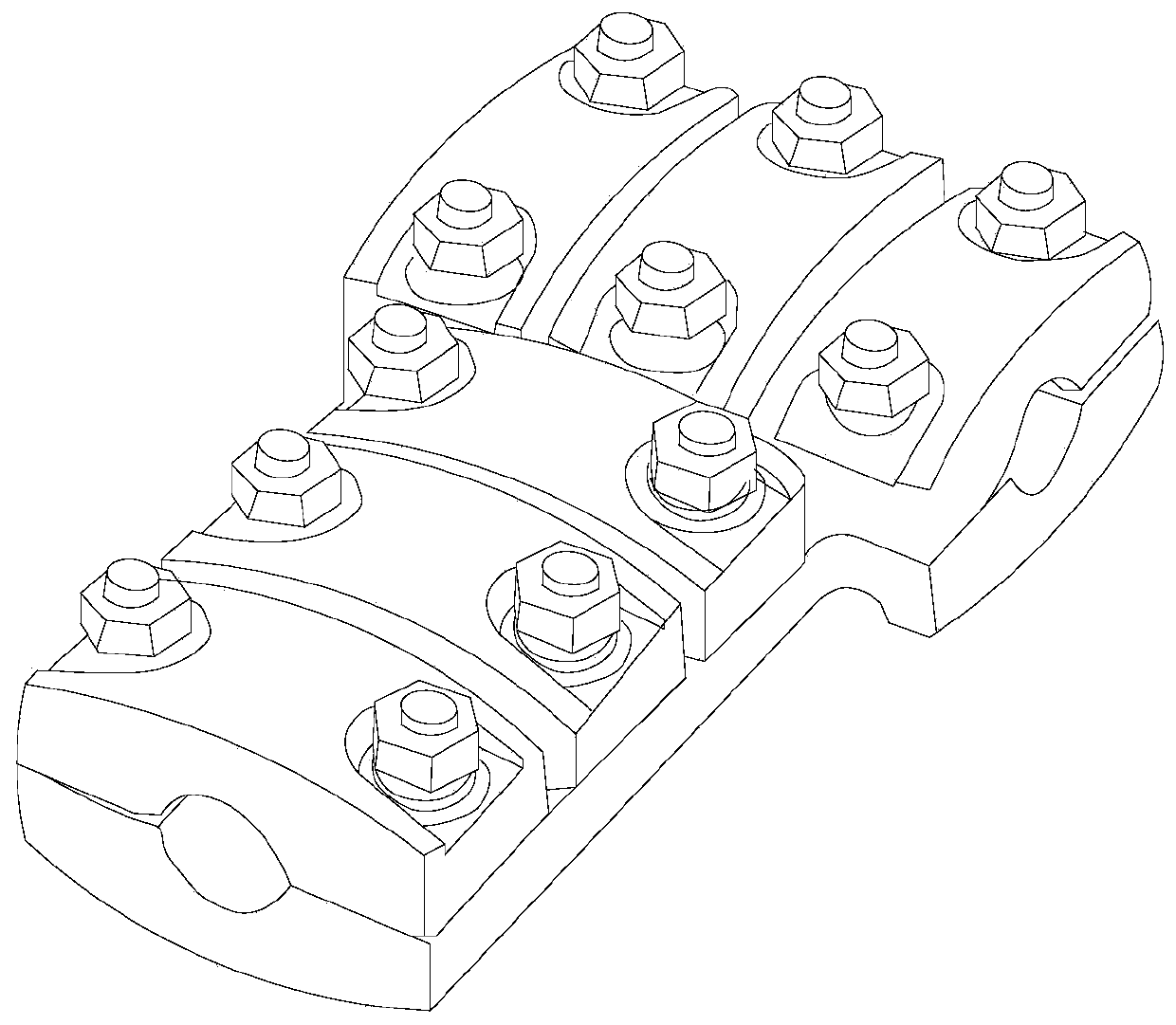

Union connection disassembling tool for blowout preventing device

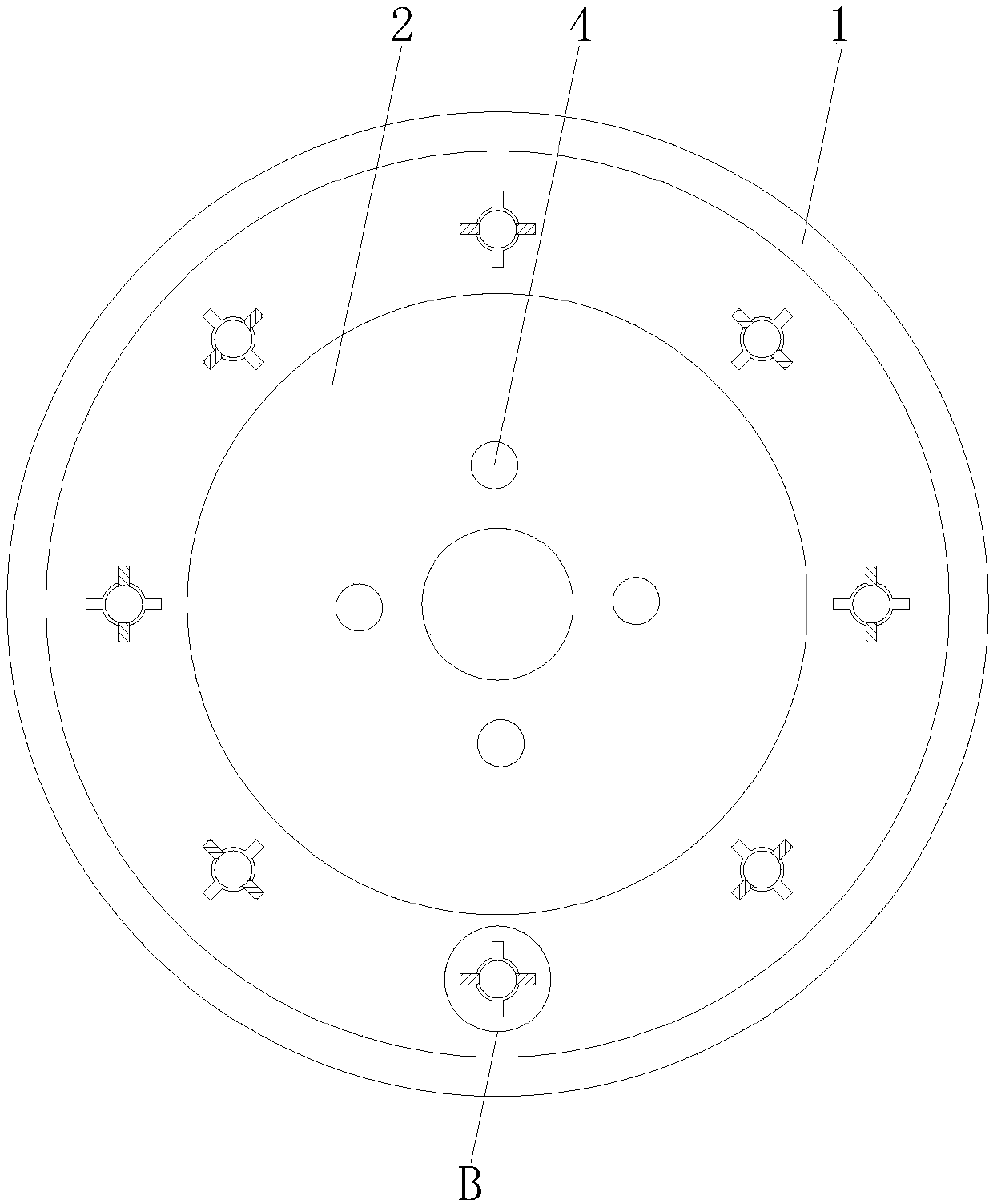

InactiveCN102416612AShort disassembly timeReduce operating costsMetal-working hand toolsEngineeringSteel ball

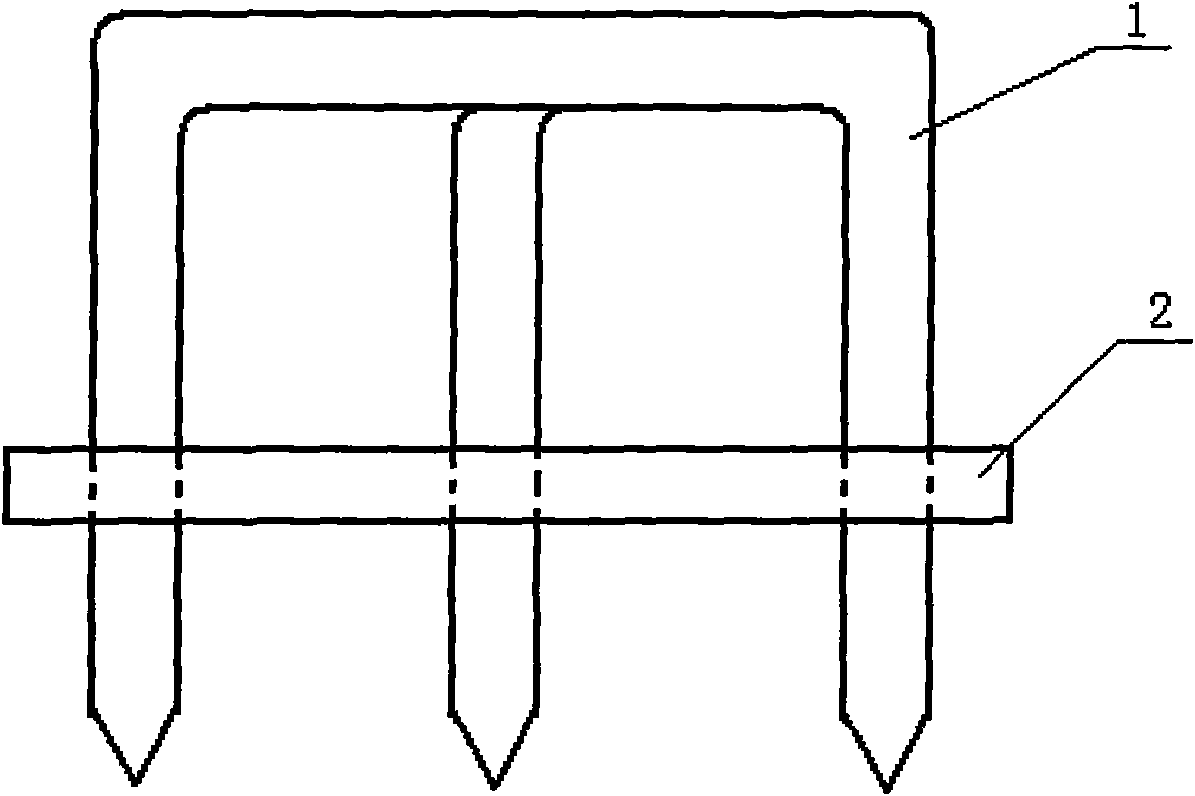

The invention relates to a union connection disassembling tool for a blowout preventing device. The tool consists of two semicircular clamping rings (1), two arc-shaped pressing plates (2) and steel balls (6), wherein the two semicircular clamping rings (1) are connected into a circular clamping ring through a bolt pair (4); semicircular grooves (7) are formed on the end faces of the two semicircular clamping rings (1) uniformly; circular through holes (5) are correspondingly formed on the two arc-shaped pressing plates (2); and the two arc-shaped pressing plates (2) are fixed on the two semicircular clamping rings (1) respectively to clamp the steel balls (6) between the semicircular grooves (7) and the circular through holes (5) and make the steel balls (6) partly protrude outside the arc-shaped pressing plates (2) and freely roll. By the tool, when a union nut is screwed off at one end of equipment to be disassembled by using an axial force effect generated by rotating the union nut, the two kinds of equipment connected by a thread pair can be separated; and the disassembly time is short, the operation cost is low, and the labor intensity is low. The structure of the tool is simple, the volume of the tool is small, the weight of the tool is light and the installation and use of the tool are convenient.

Owner:BAOJI SAIFU GASOLINEEUM MACHINERY

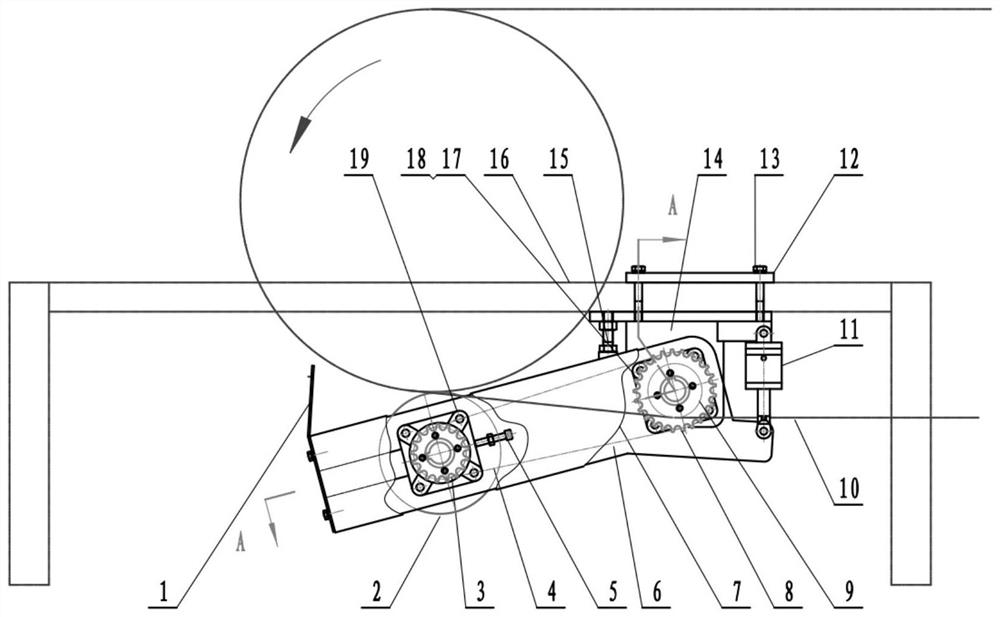

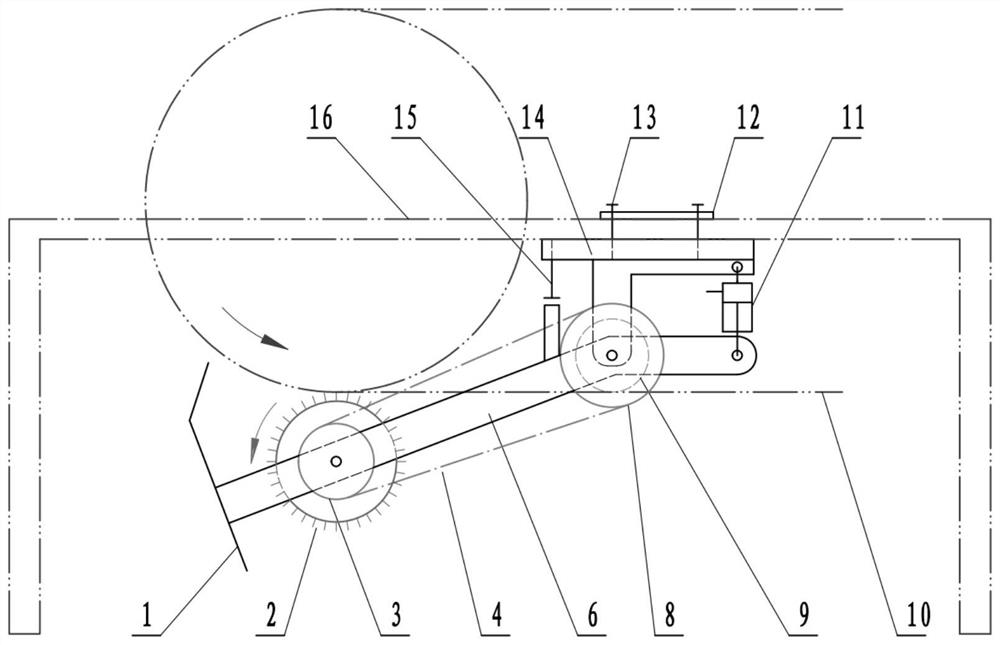

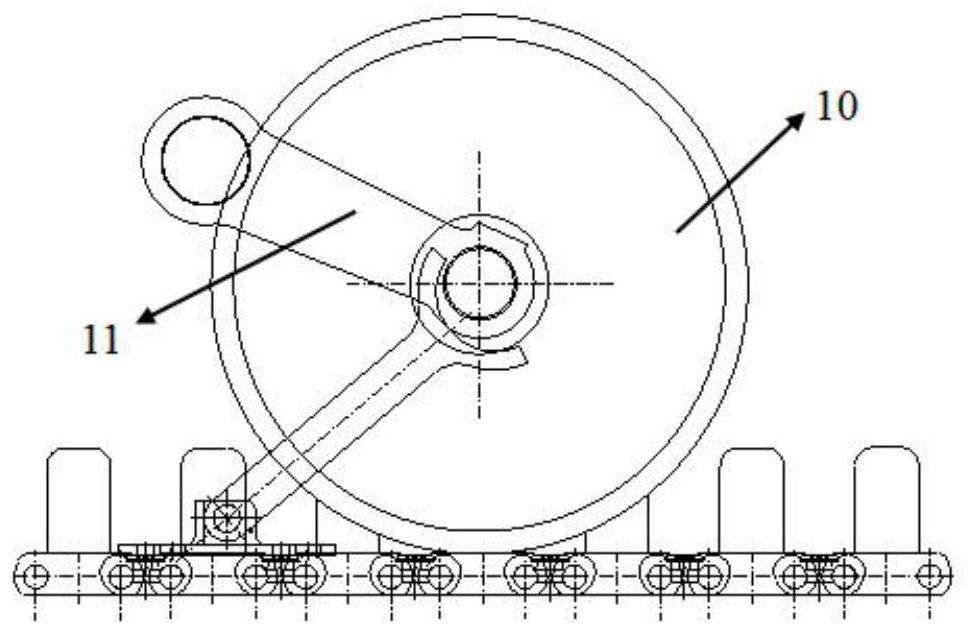

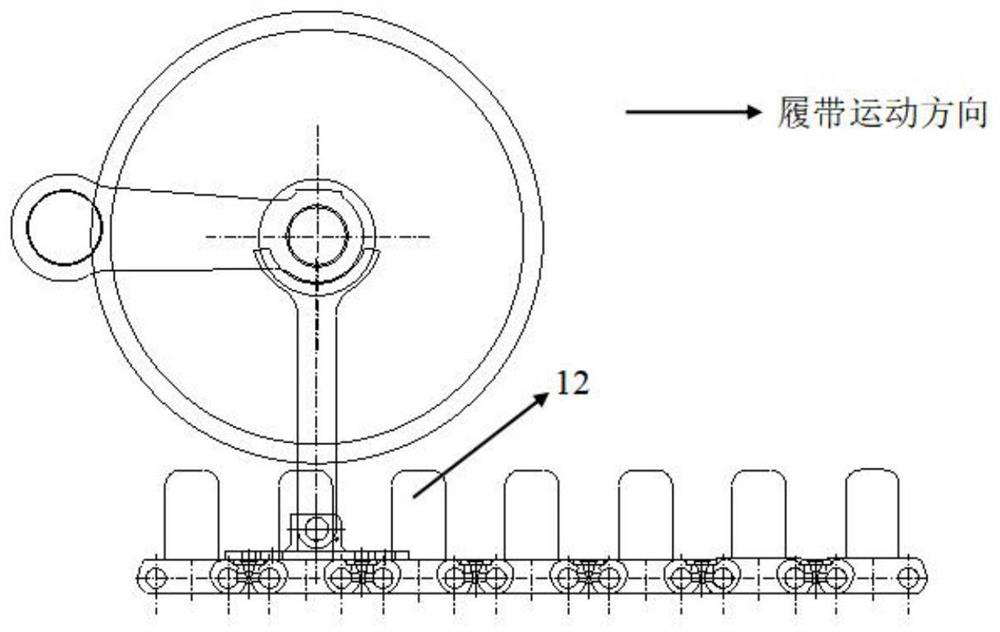

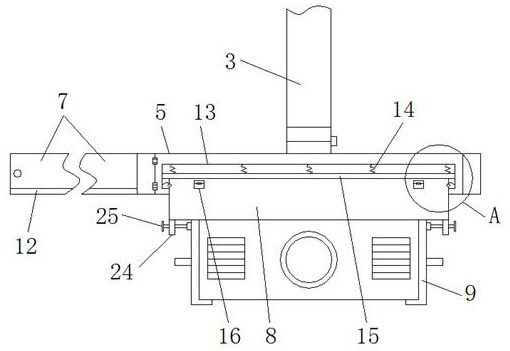

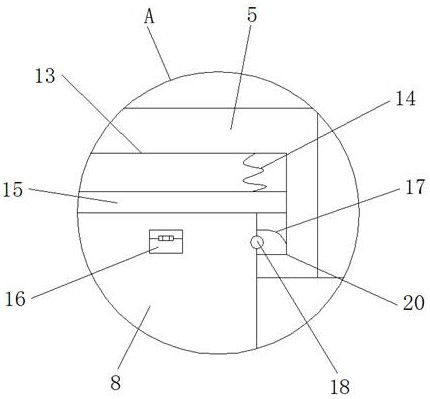

Unpowered belt sweeper

PendingCN112340394AGuaranteed transmission efficiencyReduce wear and runoutConveyorsCleaningSprocketEngineering

The invention relates to an unpowered belt sweeper which comprises a brush roller, a driven chain wheel, a chain, a swing arm, a driving chain wheel, a smooth roller, a pneumatic control system, a clamping plate, a support and a belt conveyor support. The support and the clamping plate are clamped to the belt conveyor support through fastening bolts, one end of the pneumatic control system is connected with the support, and the other end of the pneumatic control system is connected with the swing arm; a first mounted bearing is mounted on the support, and a second mounted bearing and third mounted bearings are mounted on the swing arm; the two ends of the smooth roller penetrate through the first mounted bearing and the second mounted bearing, and the smooth roller is pressed on a belt; the two ends of the brush roller penetrate through the third mounted bearings; and the driving chain wheel is locked at one end of the smooth roller, the driven chain wheel is locked at one end of the brush roller, and the chain is connected with the driving chain wheel and the driven chain wheel. According to the unpowered belt sweeper, on the premise that the external power consumption is not increased, the surface of the conveyor belt can be cleaned, and the service life of the brush roller can be prolonged.

Owner:GUANGXI HUAFENG FORESTRY

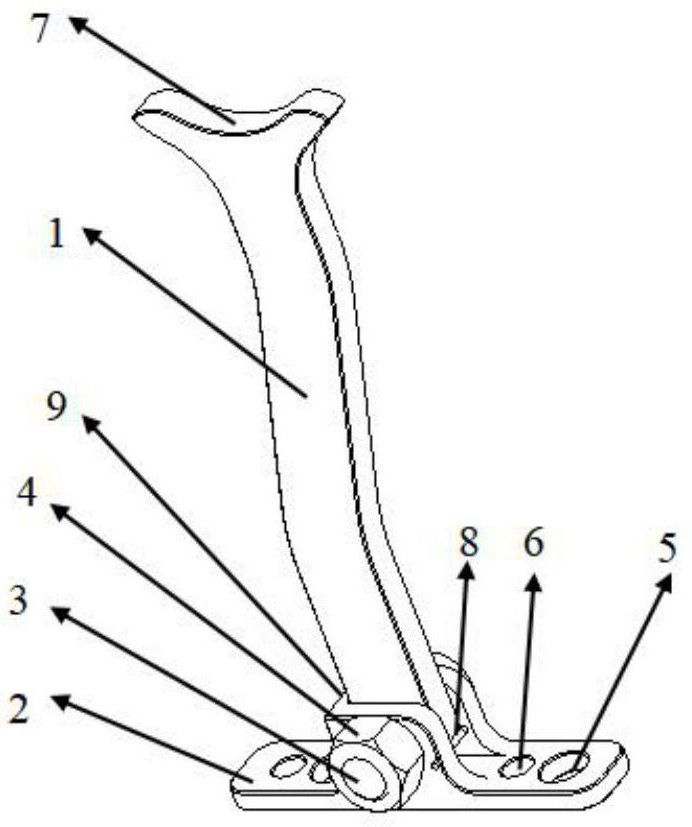

Tracked vehicle inner side loading wheel dismounting tool

PendingCN112550504AImprove maintainabilitySmooth connectionEndless track vehiclesControl theoryMechanical engineering

The invention provides a tracked vehicle inner side loading wheel dismounting tool which comprises a supporting arm, a base, a connecting bolt, a fixing nut and a positioning pin, the tool is fixedlyconnected with a track through the base, and the root of a balance elbow on the inner side of a loading wheel is supported by the supporting arm, so that the loading wheel is separated from the limitation of track guide teeth, and the loading wheel is smoothly dismounted. The tracked vehicle inner side loading wheel dismounting tool is simple in structure and small in size. After the tracked vehicle inner side loading wheel dismounting tool is adopted, the crawler belt does not need to be disconnected, the whole vehicle does not need to be hoisted, the tool can be reliably connected with the crawler belt without falling off, the disassembling time is short, the safety is high, the working efficiency of loading wheel disassembling is improved, and the maintainability of the vehicle is improved.

Owner:BEIJING NORTH VEHICLE GROUP CORP

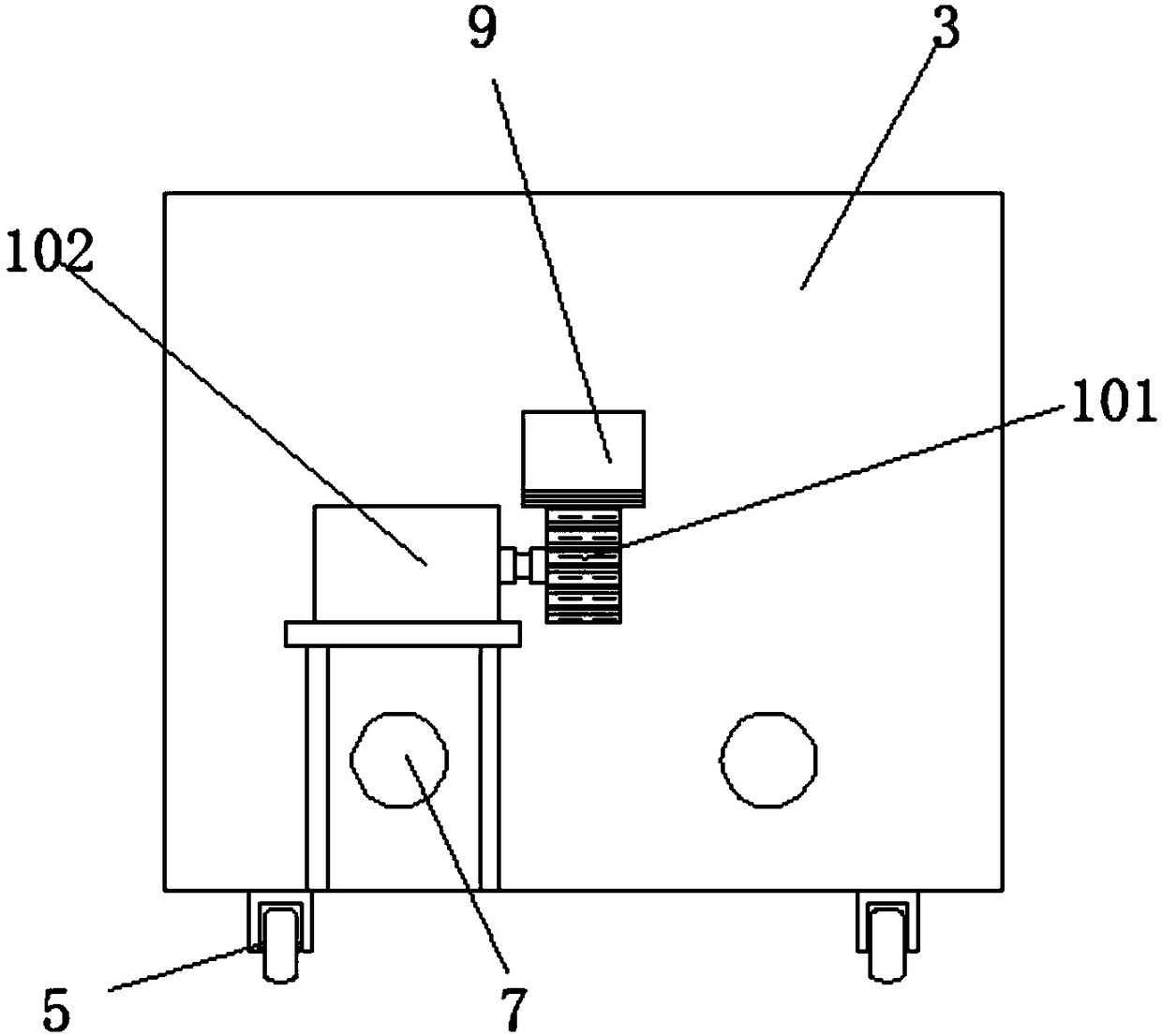

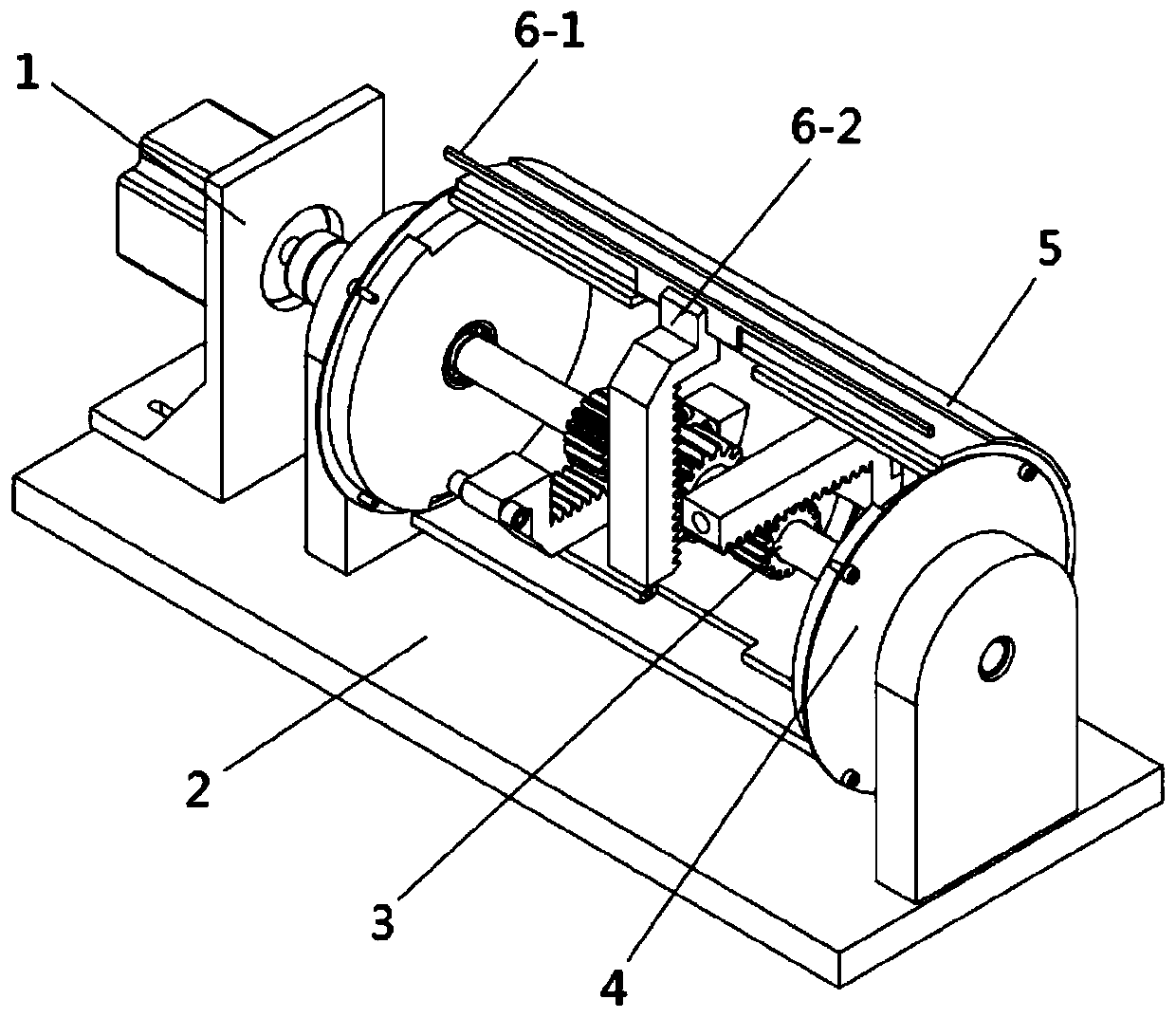

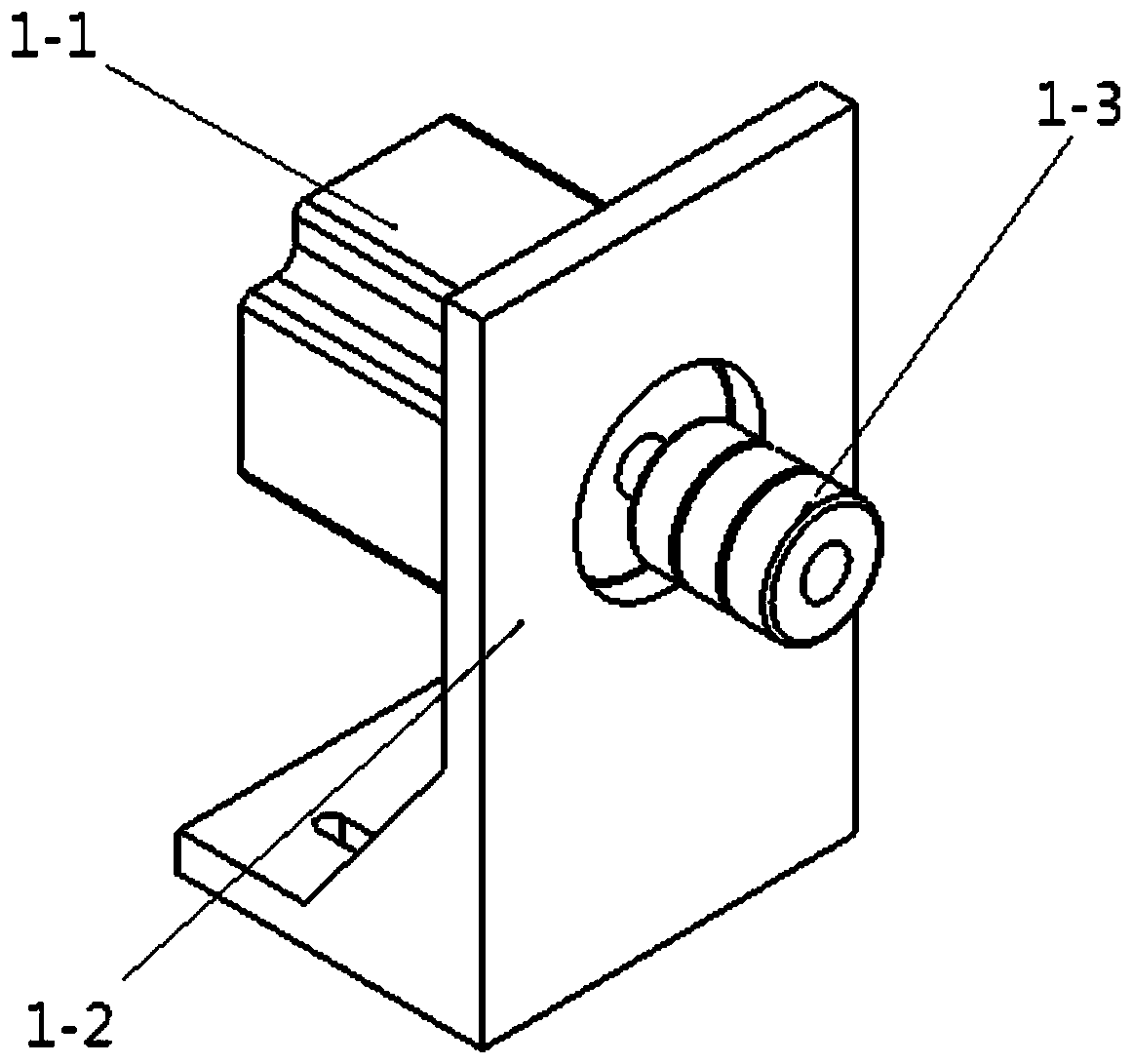

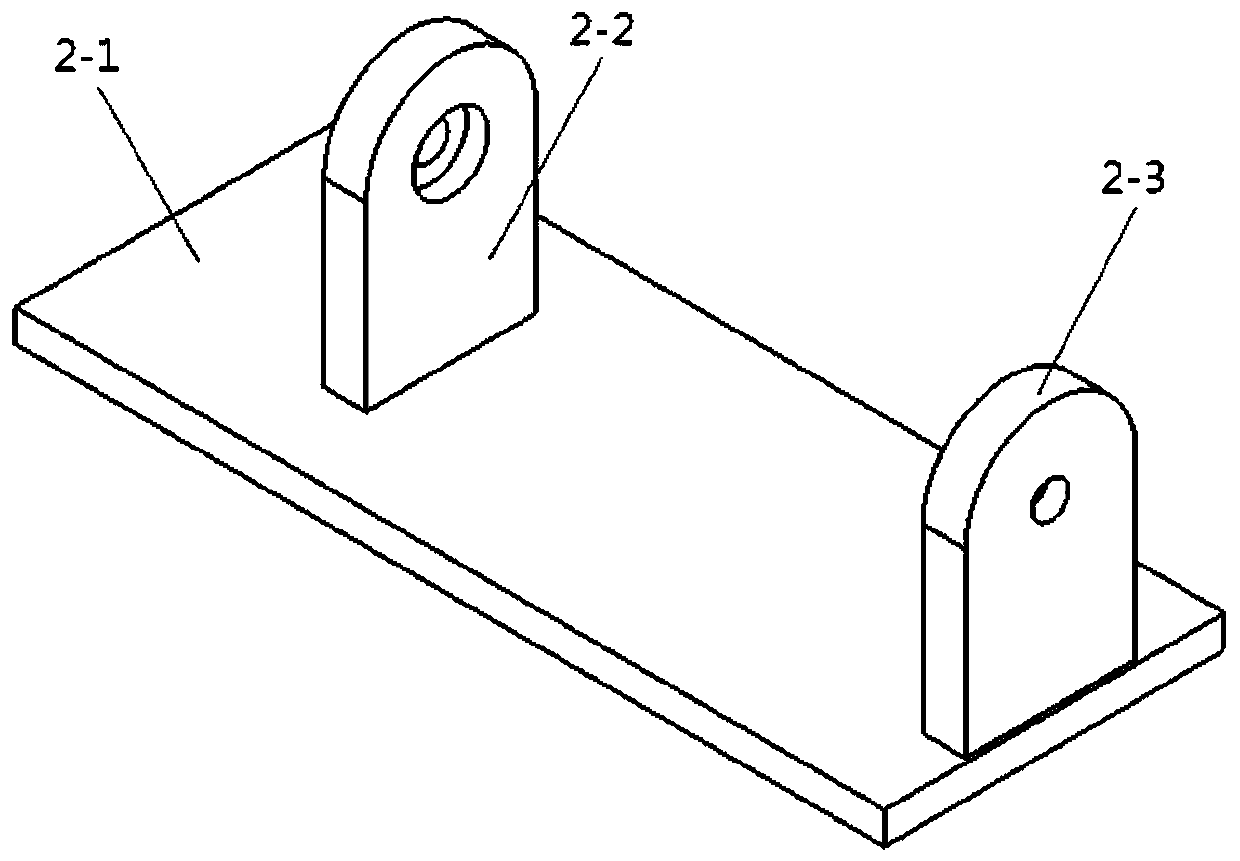

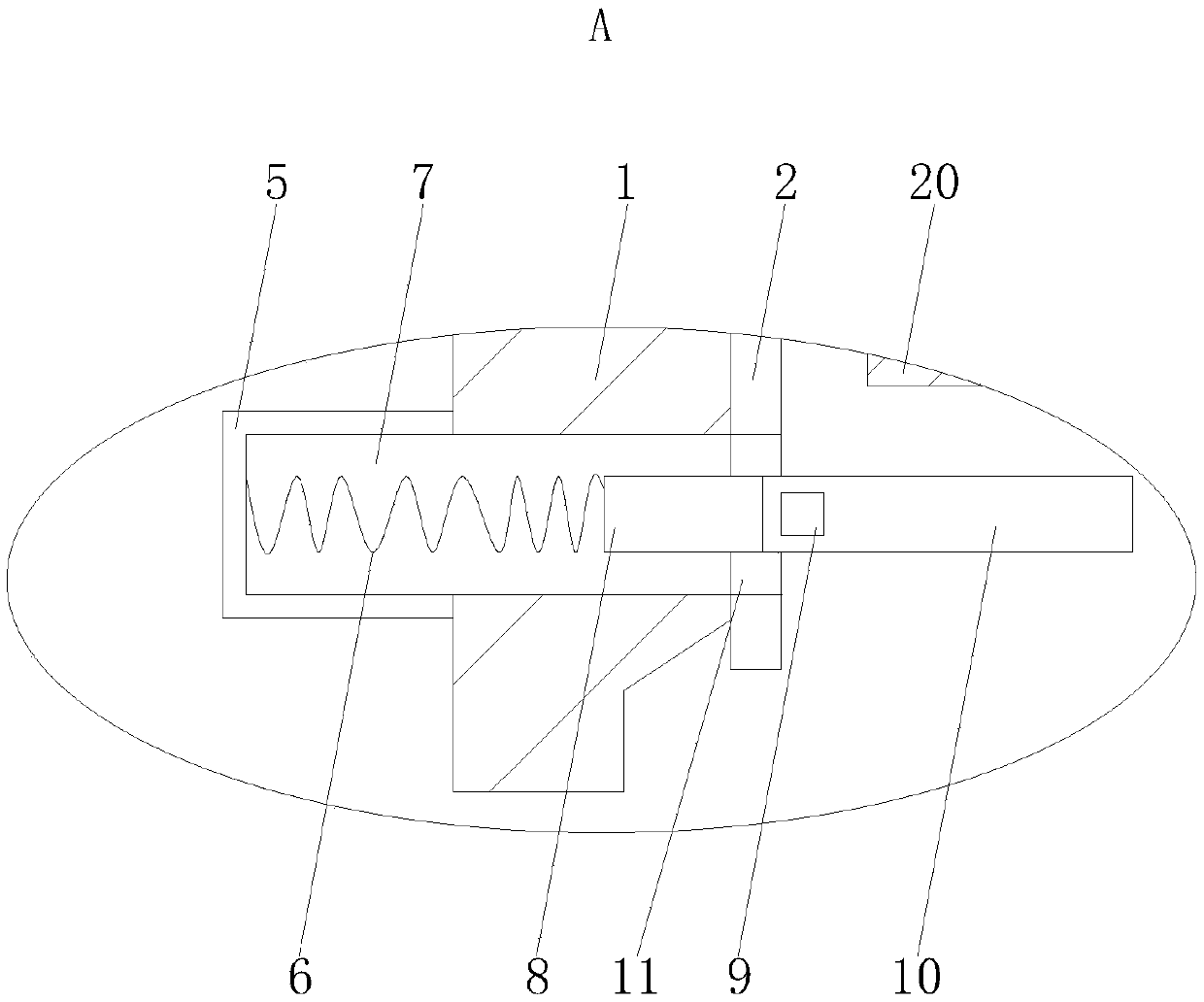

Fixing device for hardware processing

InactiveCN108527203ASimple stepsSimple structureWork holdersPositioning apparatusDrive motorEngineering

The invention discloses a fixing device for hardware processing. The fixing device for hardware processing comprises a fixed platform. A fixed plate is arranged on one side of the upper part of the fixed platform. A movable plate is arranged on the side, away from the fixed plate, of the fixed platform. Two groups of movable sliding grooves are formed in the fixed platform. Four groups of movablewheels are arranged at the bottom of the movable plate. The four groups of movable wheels are symmetrically arranged in the two groups of movable sliding grooves. Two groups of movable guide rails areconnected to the end, away from the fixed plate, of the movable plate. Two groups of fixed guide rings are arranged on the fixed platform. A spring is welded to one side of each movable guide ring. The ends, away from the corresponding fixed guide rings, of the springs are welded to one side of the movable plate. The movable guide rods are correspondingly sleeved with the springs. The fixing device for hardware processing is simple in structure, reasonable in design, capable of clamping and fixing hardware through a driving motor, easy to operate, short in disassembling and assembling time, convenient and fast to use and capable of effectively protecting the hardware in the clamping and fixing processes and preventing the hardware from being clamped and damaged.

Owner:马新佳

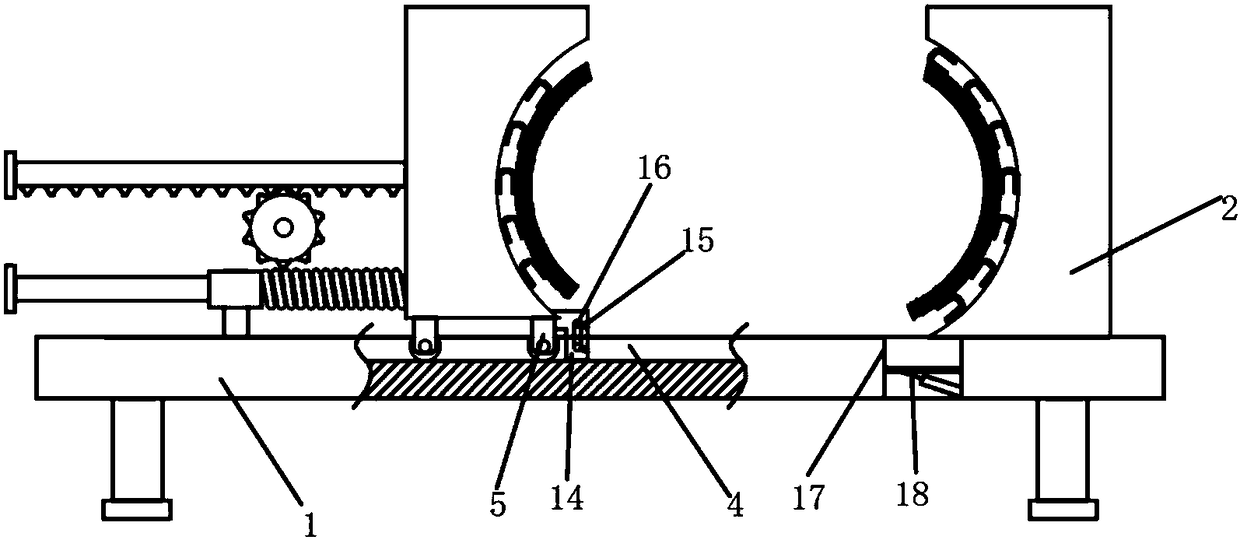

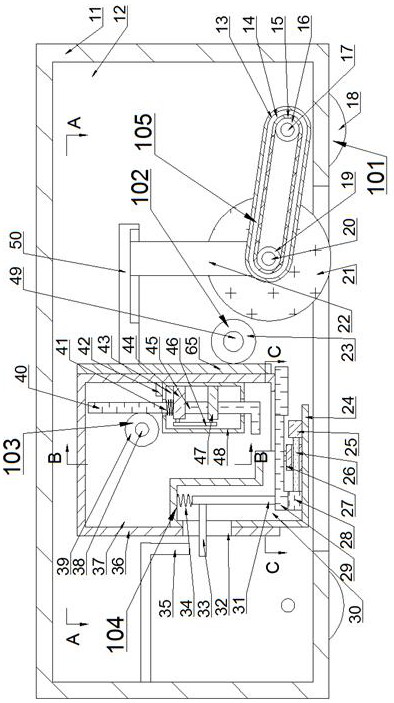

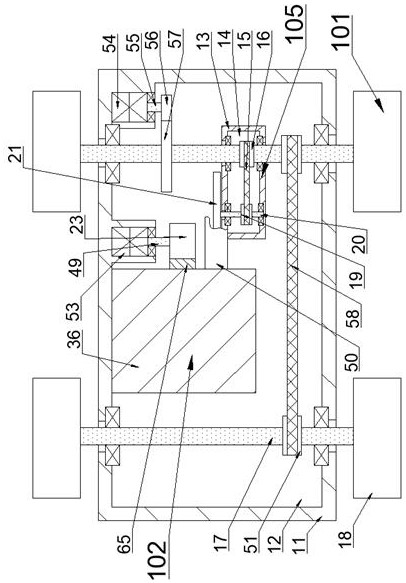

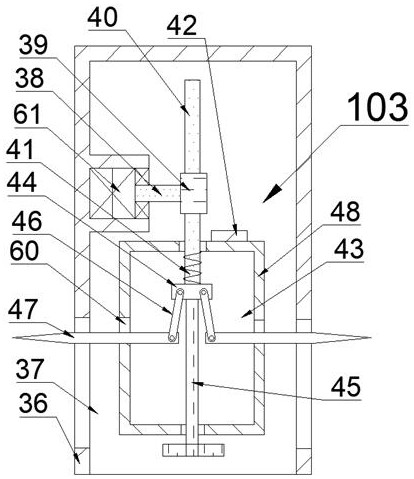

Waste water stop dissembling device for bridge expansion joint

ActiveCN110195407AImprove disassembly efficiencyShort disassembly timeBridge structural detailsBridge erection/assemblyCircular sawExpansion joint

The invention discloses a waste water stop dissembling device for a bridge expansion joint, which comprises a vehicle body. A main cavity with an opening facing downwards is formed in the vehicle body, left-right symmetric moving devices are arranged in the main cavity, a lifting device located at the symmetrical center of the moving devices is arranged in the main cavity, the lifting device is provided with a dissembling device, a guiding device located on the left side of the dissembling device is arranged in the lifting device, and the main cavity is provided with a cutting device located between the lifting device and the moving devices. According to the waste water stop dissembling device for the bridge expansion joint, a circular saw can be automatically moved down to a working position through the cutting device and cuts the water stop into two parts, the water stop dissembling mechanism is inserted into the cut water stop on both sides through a thrusting needle and pulls the water stop out from a steel beam clamping groove, a block pushing mechanism driven by the moving device to push the remaining undissembled water stop out from the steel beam clamping groove, so the waste water stop dissembling device for the bridge expansion joint can replace manual disassembly, the disassembly efficiency is high, disassembly time is short, and the labor cost is low.

Owner:中铁二十二局集团市政工程有限公司

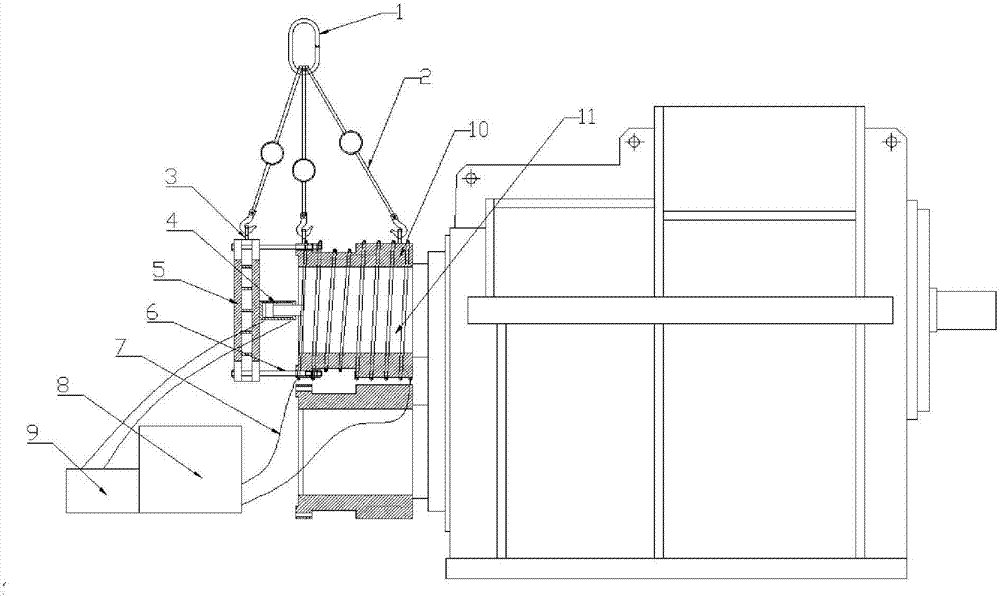

Rapid detaching method for large keyless connection coupler

InactiveCN107214471AReduce fatigueNot subject to external forceMetal working apparatusCouplingHydraulic pump

The invention provides a rapid detaching method for a large keyless connection coupler. The method comprises the following steps that a, a flange connection bolt of the coupler is detached; b, lifting rings are welded to the outer surface of the coupler and a detaching tool; c, a high-frequency winding wire of a high-frequency heater is uniformly wound on the outer surface of the coupler; d, the detaching tool and the coupler are connected together through a high-strength bolt; e, a 3T manual hand-drive block is made to hook the lifting rings on the detaching tool and the coupler; f, a hydraulic pushing-out cylinder is placed between the detaching tool and an output shaft, and a fixed nut on the high-strength bolt is screwed up; g, the hydraulic pushing-out cylinder and an electric hydraulic pump station are connected; h, the high-frequency heater is started, and heating is conducted for 10-20 min; and I, the electric hydraulic pump station is started, the hydraulic pushing-out cylinder extends, and the coupler is driven by the detaching tool to be dragged out and disengaged from an output shaft. According to the detaching method, rapid detaching and mounting on a site can be achieved, the method can be suitable for multiple models of couplers, and manpower and time are saved.

Owner:中重科技(天津)股份有限公司

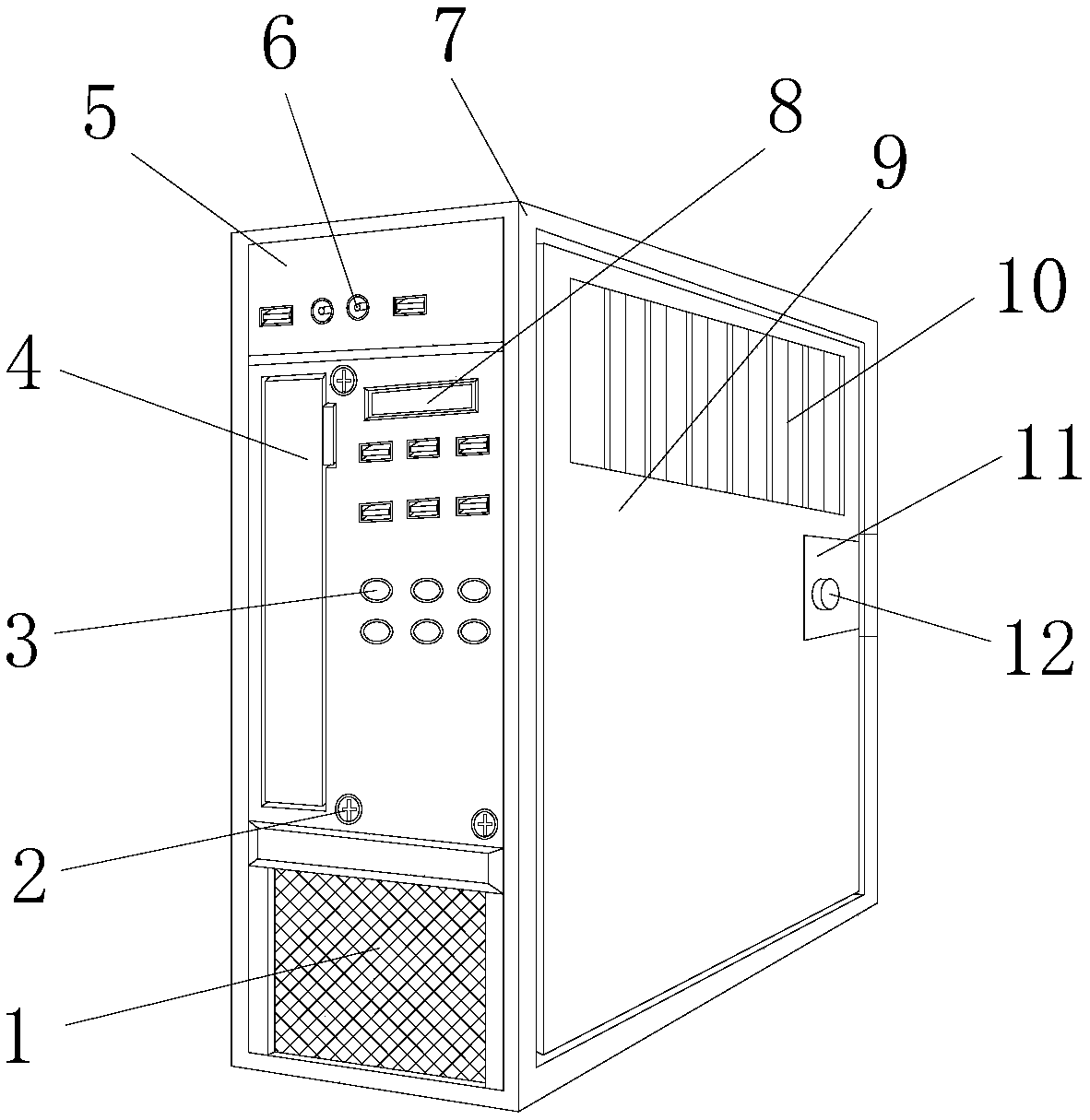

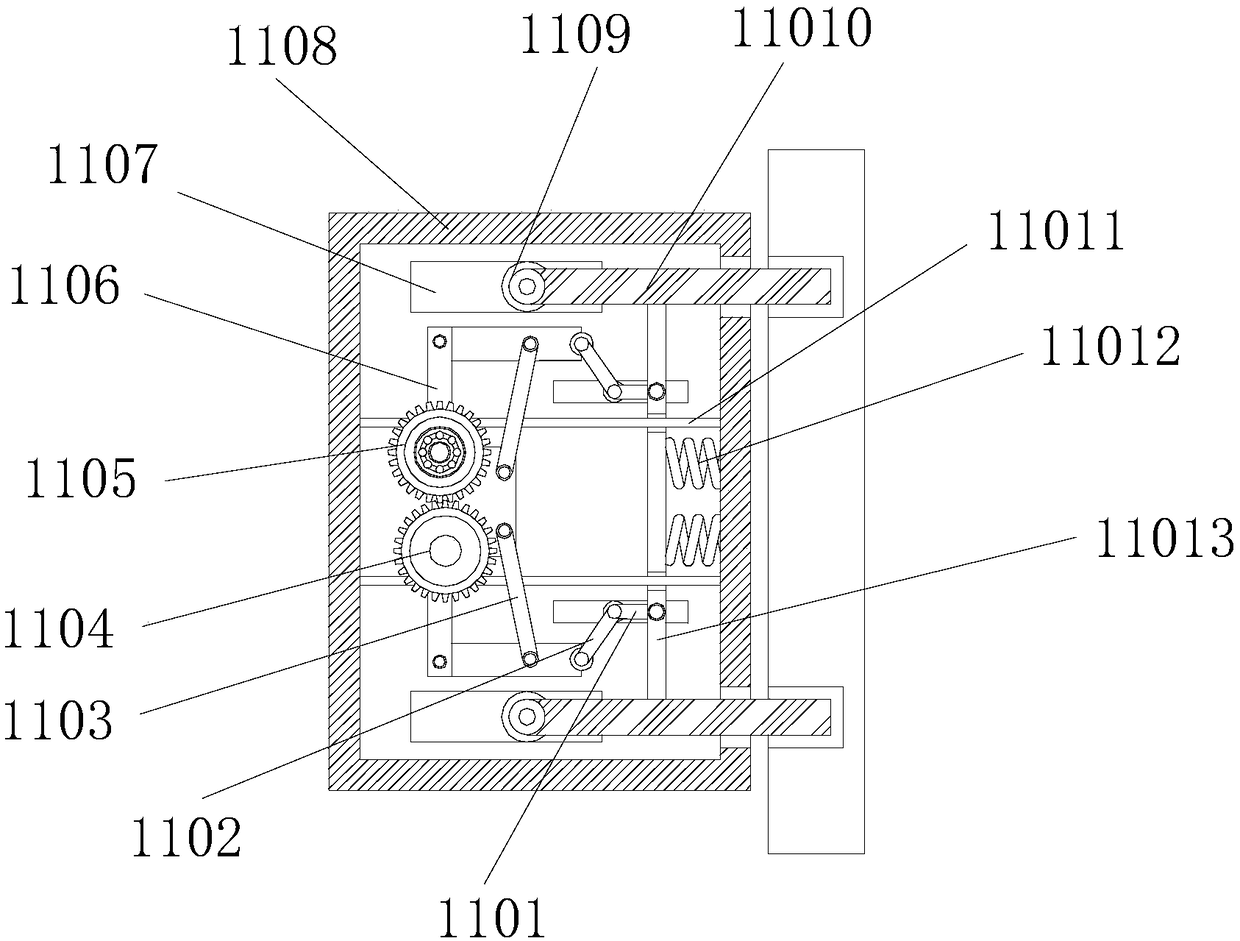

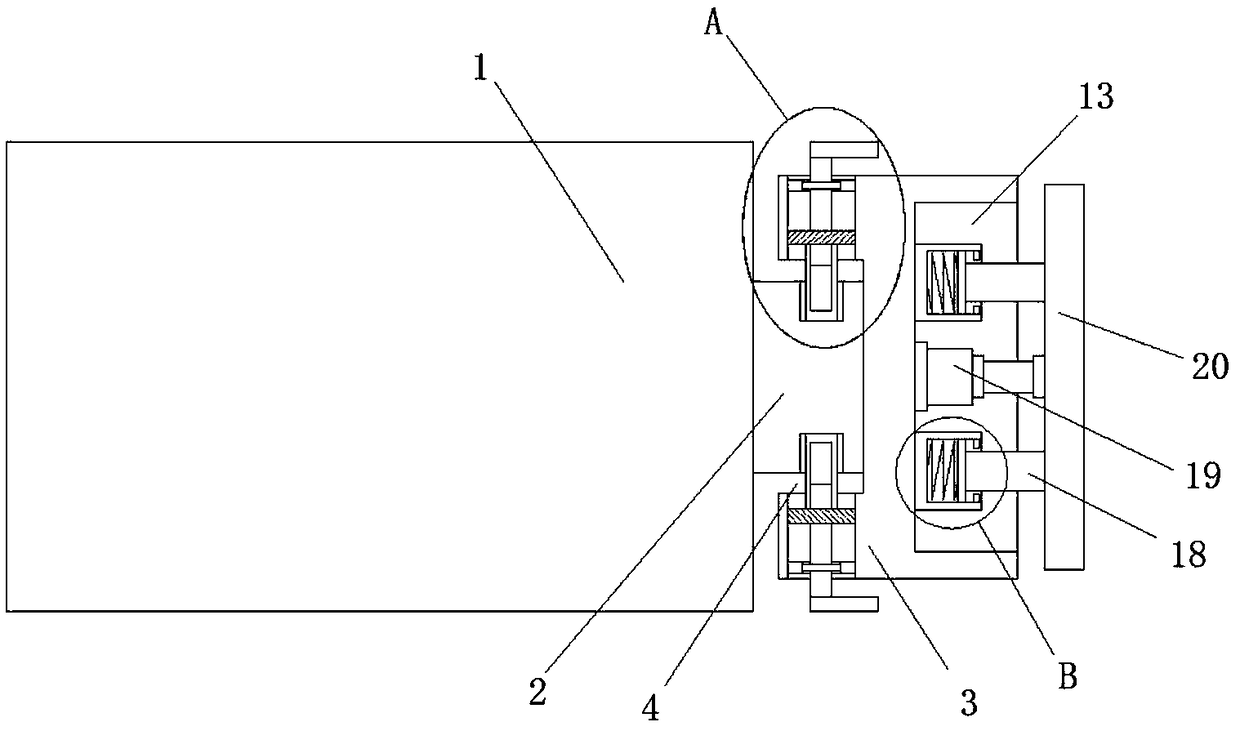

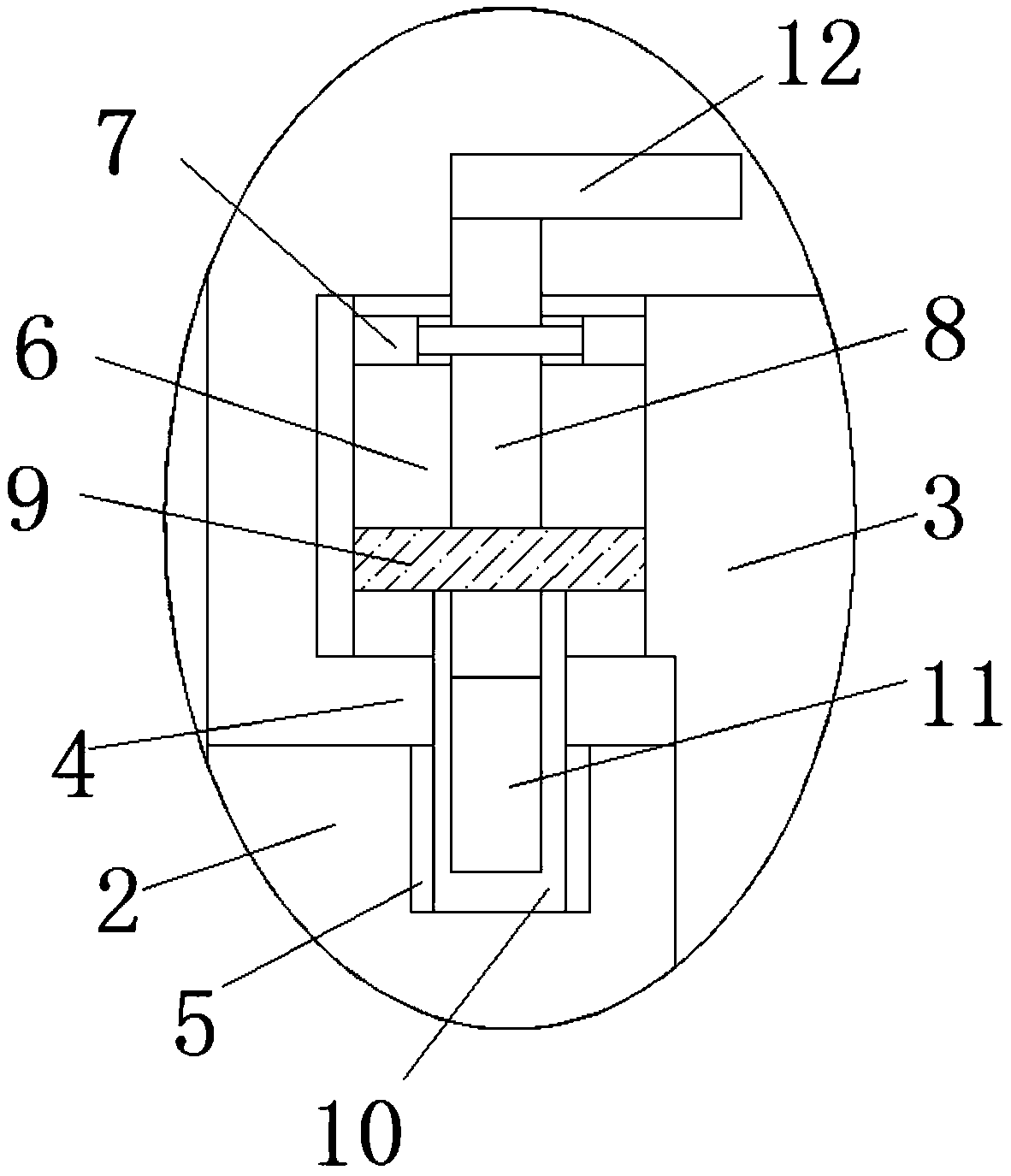

Computer external integrated device

InactiveCN108874069AEasy to disassembleShort disassembly timeDigital processing power distributionGear driveBroadcasting

The invention discloses a computer external integrated device. The structure comprises a broadcasting port, a screw, an indicator light, a data receiving disc, an operating panel, a connector, a body,a display, a removable door, a window, a removing device and a rotary knob. The indicator light is embedded in the front surface of the operating panel. The computer external integrated device provided by the invention is structurally provided with the removing device. The main gear inside the removing device is driven by the rotating of the rotary knob. The connecting gear is driven by the maingear. The connecting gear drives the mounting plate to move leftwards. By driving the mounting plate to move leftwards, the pushing rod is driven to move leftwards. The connecting rod is pulled by thepushing rod. The moving pushing plate is pulled to the left by the connecting rod. The fixed locking rod is driven to move leftwards by the moving pushing plate. The removable door is unlocked. The removing device makes removing easy. The removing time is shortened. The working speed becomes faster.

Owner:如皋蜗壳道场信息科技有限公司

High-strength bumper for new energy car

The invention discloses a high-strength bumper for a new energy car. The high-strength bumper comprises a car body. A mounting plate is fixedly mounted on one side of the car body. A bumper body is arranged on one side of the mounting plate. A mounting groove is formed in one side of the bumper body. The side, away from the car body, of the mounting plate extends into the mounting groove. Fixing grooves are formed in the top and the bottom of the mounting plate correspondingly. Fixing holes are formed in the top inner wall and the bottom inner wall of the mounting groove correspondingly. Moving plates are slidably connected to the side walls of the fixing holes. Fixing shafts are welded to the bottoms of the moving plates. The bottoms of the fixing shafts extend into the fixing grooves. Rotating grooves are formed in the tops of the fixing shafts. The high-strength bumper is simple in structure, the bumper body can be protected by an anti-collision plate, damage to the bumper body dueto direct collision is prevented, the bumper body can be easily dismounted by rotating a rotating shaft, the dismounting time is short, the efficiency is high, and using is convenient and fast.

Owner:HEFEI DONGSHENG AUTO PARTS CO LTD

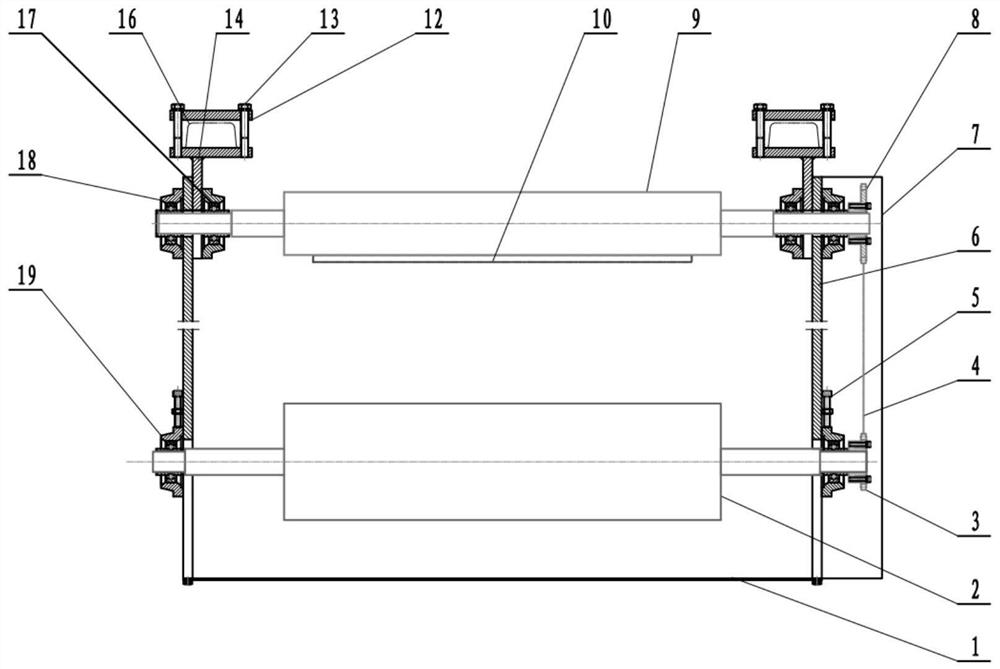

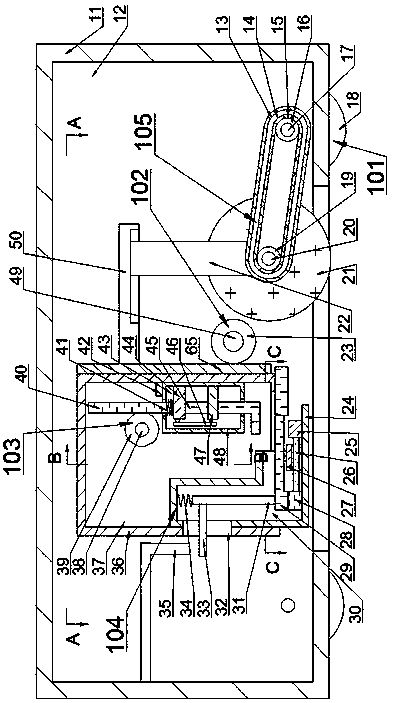

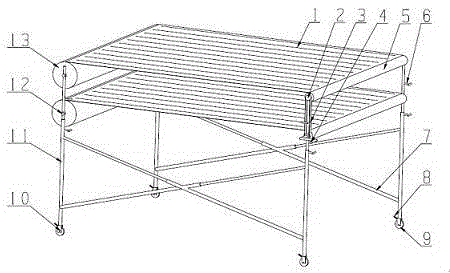

EPP overturned molding machine

The invention discloses an EPP overturned molding machine. The machine comprises a rack, a plurality of transverse sliding rods are arranged in the rack, the sliding rods are provided with a sliding seat, a female die fixing frame is arranged at one side of the sliding seat, a push rod is arranged at the rear end of the sliding seat, a rotating seat is arranged at the outer end of the rack on the sliding rods, male die fixing frames are respectively arranged at two sides of the rotating seat, the two male die fixing frames are symmetrically distributed relative to the rotating seat, the rotating seat is in rotary connection with support columns of the rack, a material storage pot is arranged at the upper end of the rack, the material storage pot is communicated with the die cavity of a female die through a material tube, and the rack is also provided with a steam heating mechanism. The machine has the advantages of convenient skeleton installation, convenient dismounting of the molded skeleton, short installation and dismounting time, great improvement of the work efficiency of an apparatus, almost no wait time in the whole working process of the apparatus, high activation rate of the apparatus, and high skeleton molding efficiency.

Owner:上海古汉汽车饰件模具有限公司

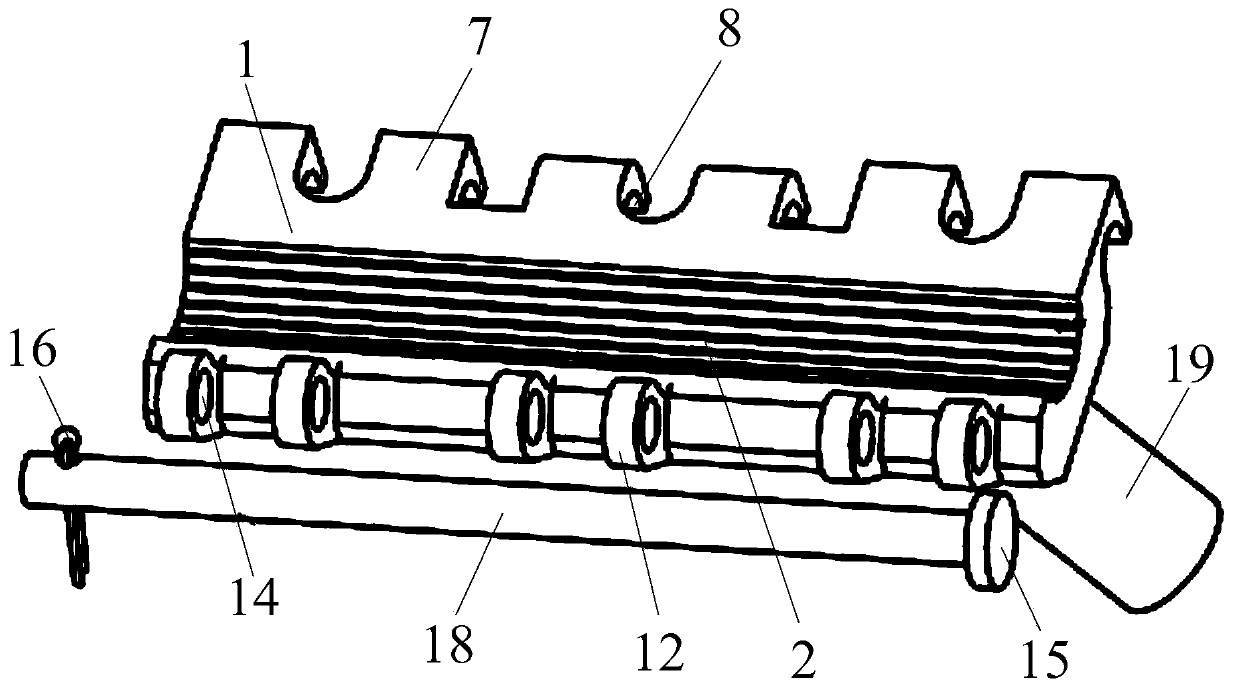

Cotton fiber roll automatic dismounting device

ActiveCN109926807AGentle disassembly processShort disassembly timeMetal working apparatusGramEngineering

The invention provides a cotton fiber roll automatic dismounting device, and belongs to the technical field of textile detection equipment. The cotton fiber roll automatic dismounting device comprisesa machine frame assembly, a cotton lifting-apart mechanism, a cotton discharging mechanism and a power mechanism, wherein the cotton shifting mechanism is used for shifting cotton fiber roll, the cotton shifting mechanism comprises a tip plate and a first execution element which is arranged on the frame assembly and is used for driving the tip plate to move in the first direction; the cotton discharging mechanism is arranged on the frame assembly and is used for allowing the cotton fiber rolls winding and used for expanding the cotton fiber rolls in second direction; and the power mechanism is used for providing power for the cotton shifting mechanism and the cotton discharging mechanism. According to the device, the cotton shifting mechanism and the cotton discharging mechanism are driven by the power mechanism to shift the cotton fiber rolls and expand the cotton fiber rolls towards the two sides, so that the expanded cotton fiber rolls fall down due to self weight, the cotton fiberrolls can be automatically disassembled, disassembling process is soft, the cotton fiber is small in damage and is not easy to lose, disassembling time is short, the efficiency is high, and convenience is provided for subsequent sample preparation and detection processes; the device relates to an instrument for textile material detection, and the device is suitable for disassembling of a small amount with 2.5-20 grams of cotton fiber rolls.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

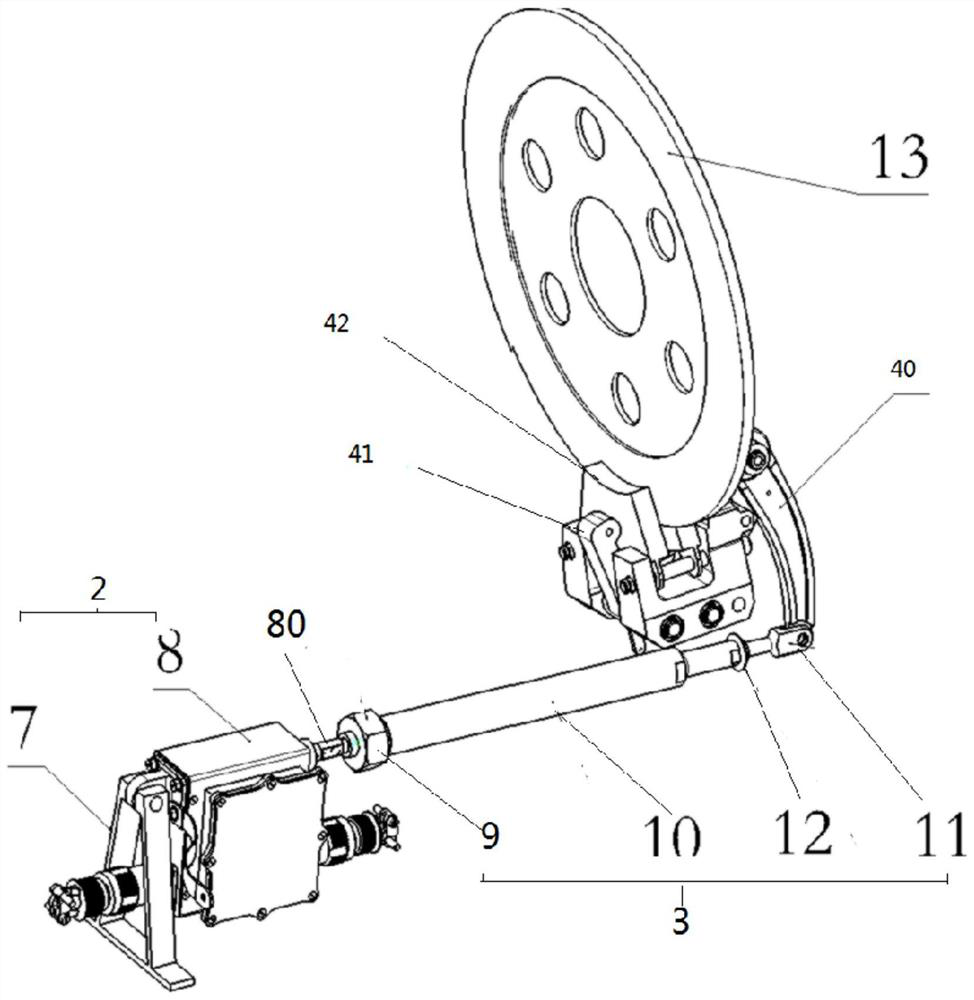

Clutch for vehicle

PendingCN109654129AReduce labor intensityShort installation and removal timesFriction clutchesClutchFlywheel

The invention belongs to the technical field of clutches, and particularly relates to a clutch for a vehicle. The clutch comprises a flywheel, a shell, a first ventilation hole, a second ventilation hole, a fixing sleeve, a first spring, a cavity, a movable rod, a depression bar, a rotating pull rod, a strip-shaped groove, a rotating shaft, a slider, a connecting arc strip, a connecting strip, a pedal, a friction plate, a pressure plate, a second spring, a spring piece, a guide groove strip, an air blowing cover, a cavity, a through hole, a connecting pipe, an air pump, a circle hole and a round slot. The clutch is reasonable in structure; an installation structure is arranged so that the shell can be installed on and detached from the flywheel; in the installing process, only the rotatingpull rod needs to be pulled and rotated for achieving installation; compared with the traditional manner of connection through bolts and screws, the labor intensity is low, and the installation and detachment time is short; through cooperation effects of a heat dissipation structure, the first ventilation hole and the second ventilation hole, components inside the shell can be cooled, damage caused by overheating of the friction plate and the pressure plate is avoided, and the service life of the friction plate and the pressure plate can be prolonged.

Owner:王志伟

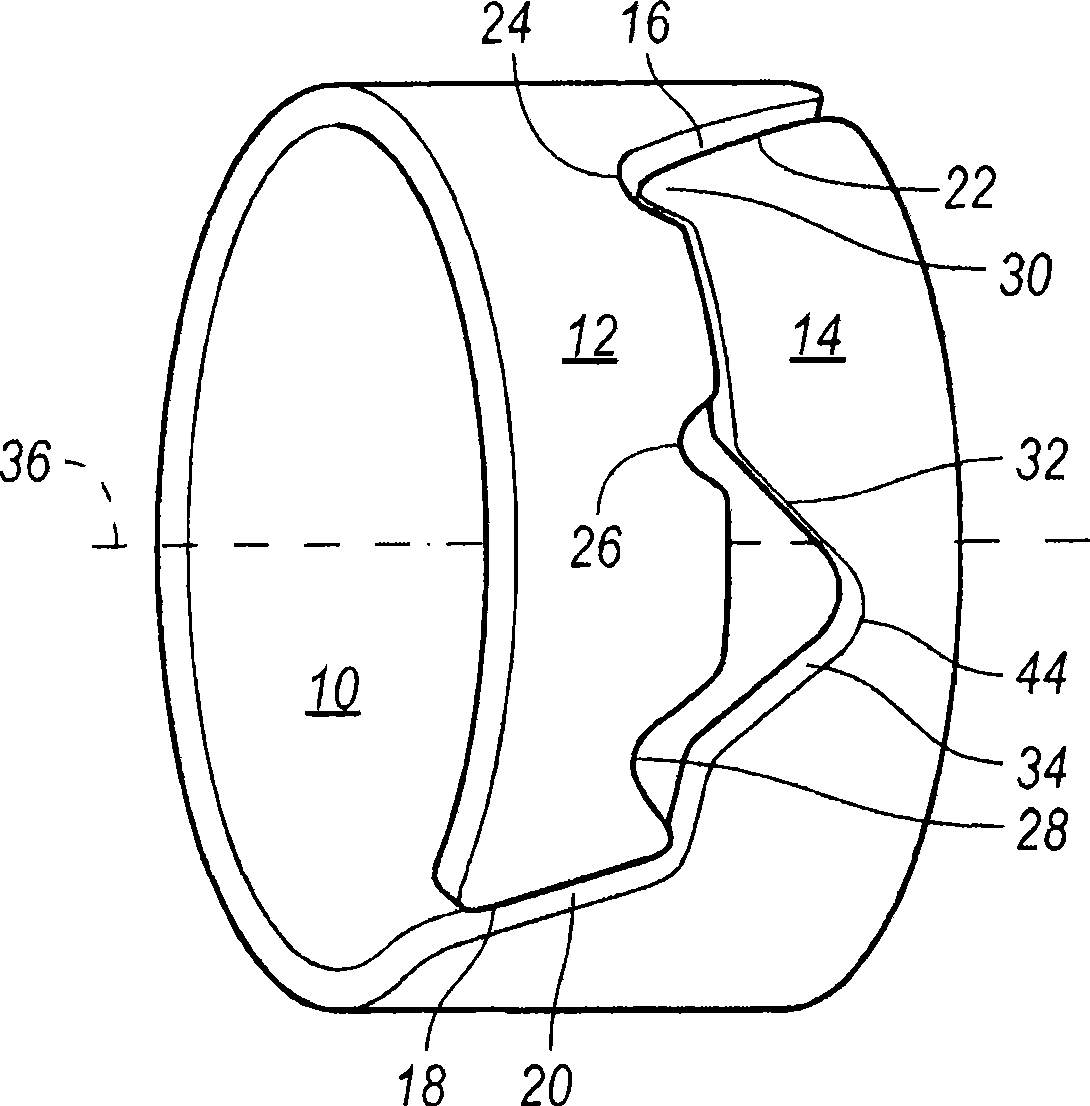

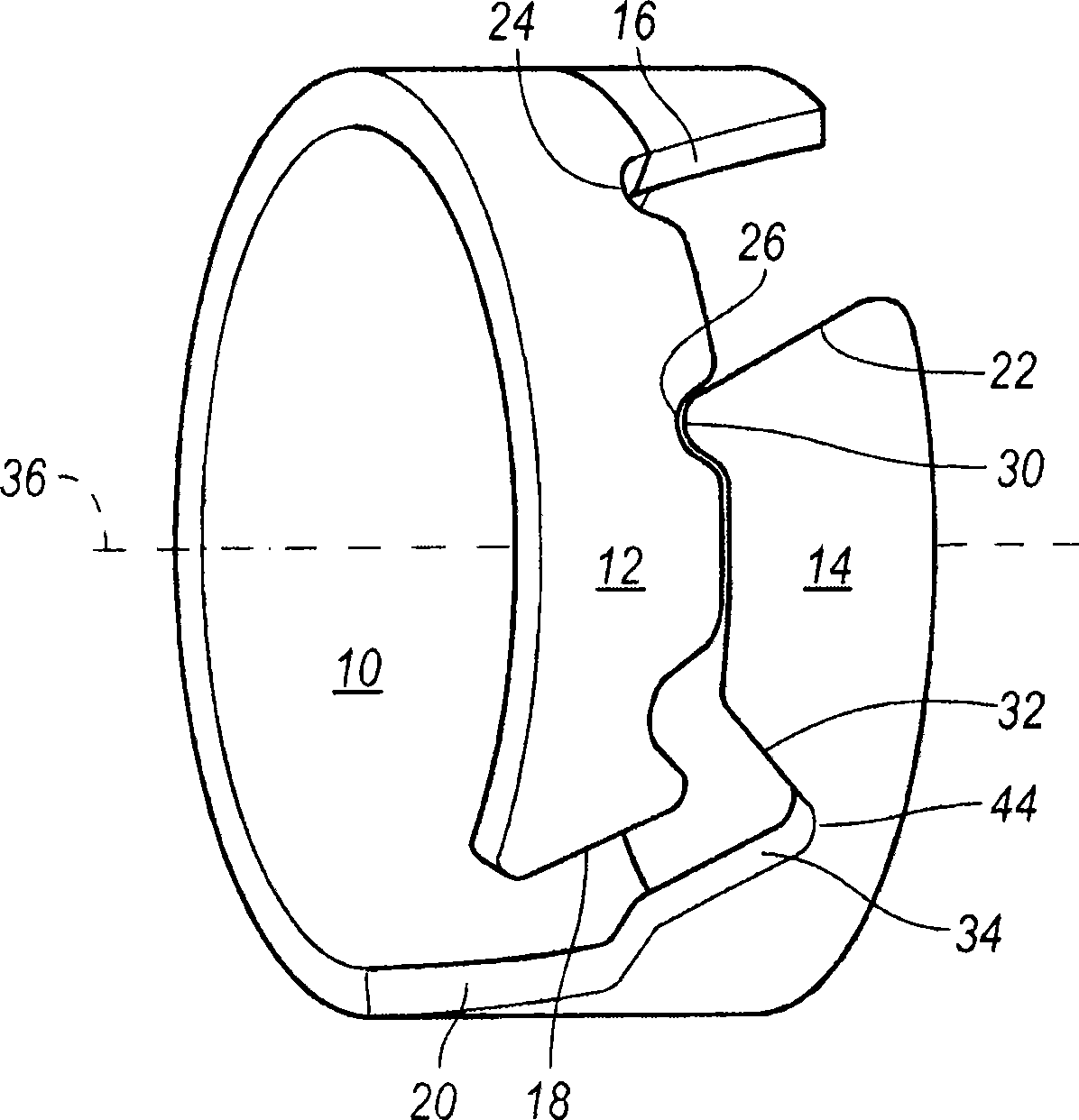

Hose clamp

InactiveCN101498392ARealize functionSmall footprintLighting and heating apparatusSpace heating and ventilation detailsBiomedical engineeringHose clamp

A hose clamp for securing a hose to a component includes a first band of uniform thickness that extends angularly about an axis and includes an engagement surface, and a second band having the uniform thickness and formed in one piece with the first band, extending angularly about the axis, offset axially from the first band, and including a latch surface engageable with the engagement surface, the clamp having an open state in which the first band and the second band are elastically urged angularly about the axis toward contact with the hose, said engagement maintaining an elastically resilient load between the first band and the second band.

Owner:GM GLOBAL TECH OPERATIONS LLC

Tunnel steel frame foot-locking anchor rod guiding and positioning device

PendingCN110017160AEasy to control the angleMake fastDirectional drillingAnchoring boltsSheet steelSteel frame

The invention relates to a tunnel steel frame foot-locking anchor rod guiding and positioning device which comprises a steel plate, an opening is formed in the middle of the steel plate, two sliding clamps are installed on the steel plate, elastic nuts are arranged at the positions, matched with the opening, of the sliding clamps, a guiding pipe is arranged on the steel plate through a pulley, andthe angle of the guiding pipe is consistent with the angle of a foot-locking anchor rod. By applying the device, the tunnel primary support steel frame foot-locking anchor rod can be rapidly, efficiently and accurately constructed, and the construction quality of the primary support steel frame support is guaranteed.

Owner:THE FIRST ENG OF CHINA RAILWAY 16TH CONSTR BUREAU GROUP

High-altitude falling lifesaving device easy and convenient to use

The invention discloses a high-altitude falling lifesaving device easy and convenient to use. The device mainly comprises four parts of a buffer mechanism, a supporting support, a synchronous reeling and unreeling mechanism and a moving mechanism. The buffer mechanism is composed of four parts of canvas strips, rotary rods, fixing rods and volute spiral springs. The supporting support is composed of three parts of locating screws, hydraulic buffer damping rods and telescopic supports. The synchronous reeling and unreeling mechanism is composed of three parts of chain wheels, chains and rotary hand wheels. The moving mechanism is composed of three parts of fixing switches, movable trundles and fixed trundles. The high-altitude falling lifesaving device easy and convenient to use is mainly applied in emergency rescue and has the beneficial effects of being small in size, easy to carry, suitable for various terrains, easy and convenient to assemble, short in rescue preparation time, capable of playing an important role in high-altitude falling emergency rescue and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Automobile fixing device

The invention discloses an automobile fixing device. The automobile fixing device comprises a first connecting piece, a second connecting piece, a fixing piece and a rope, the first connecting piece is fixed on one side of the lower portion of the inner wall of a container, the second connecting piece is fixed on one side of the lower portion of the inner wall of the container, moreover, a gap isarranged between the second connecting piece and the first connecting piece, the fixing piece is located in the middle of the gap, and abuts against the inner wall of the container, one end of the rope is detachably connected with the first connecting piece, and is wound around an automobile tire, the other end of the rope is detachably connected with the second connecting piece so that the automobile tire can be fixed. The fixing piece is located in the middle of the gap, and abuts against the inner wall of the container, one end of the rope is detachably connected with the first connecting piece, and is wound around the automobile tire, the other end of the rope is detachably connected with the second connecting piece so that the automobile tire can be fixed, then a wood floor of the container is not damaged, the fixing effect is good, then the damage of an automobile is avoided, and the binding time and the dismounting time are short.

Owner:GUANGXI HAIBEN TECH CO LTD

A quick loading and unloading short-circuit clamp and its short-circuit method

ActiveCN109119853BShorten the duration of altitude stayReduce in quantityCoupling device connectionsFlangeElectrical and Electronics engineering

Owner:国网四川省电力公司技能培训中心 +2

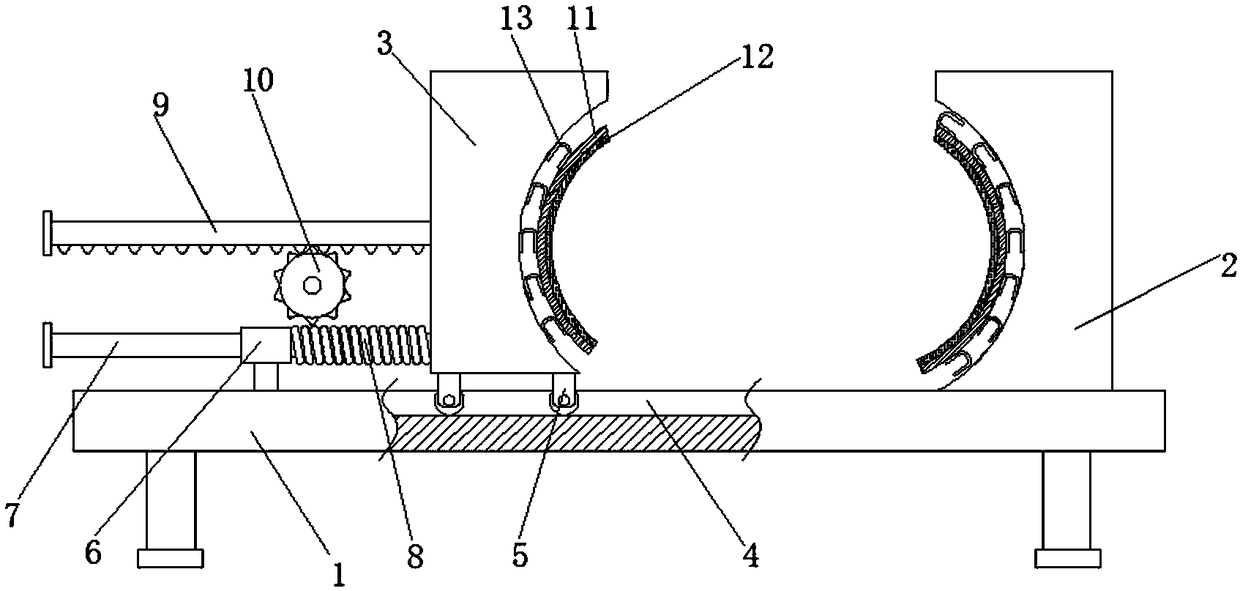

An electronically controlled electric rotor brake system

ActiveCN110701215BReduce weightSave construction spaceAxially engaging brakesBrake actuating mechanismsControl systemRotor (electric)

Owner:哈尔滨哈飞航空工业有限责任公司

A device for dismantling waste waterstops of bridge expansion joints

ActiveCN110195407BImprove disassembly efficiencyShort disassembly timeBridge structural detailsBridge erection/assemblyWater stopCircular saw

The invention discloses a waste water stop dissembling device for a bridge expansion joint, which comprises a vehicle body. A main cavity with an opening facing downwards is formed in the vehicle body, left-right symmetric moving devices are arranged in the main cavity, a lifting device located at the symmetrical center of the moving devices is arranged in the main cavity, the lifting device is provided with a dissembling device, a guiding device located on the left side of the dissembling device is arranged in the lifting device, and the main cavity is provided with a cutting device located between the lifting device and the moving devices. According to the waste water stop dissembling device for the bridge expansion joint, a circular saw can be automatically moved down to a working position through the cutting device and cuts the water stop into two parts, the water stop dissembling mechanism is inserted into the cut water stop on both sides through a thrusting needle and pulls the water stop out from a steel beam clamping groove, a block pushing mechanism driven by the moving device to push the remaining undissembled water stop out from the steel beam clamping groove, so the waste water stop dissembling device for the bridge expansion joint can replace manual disassembly, the disassembly efficiency is high, disassembly time is short, and the labor cost is low.

Owner:中铁二十二局集团市政工程有限公司

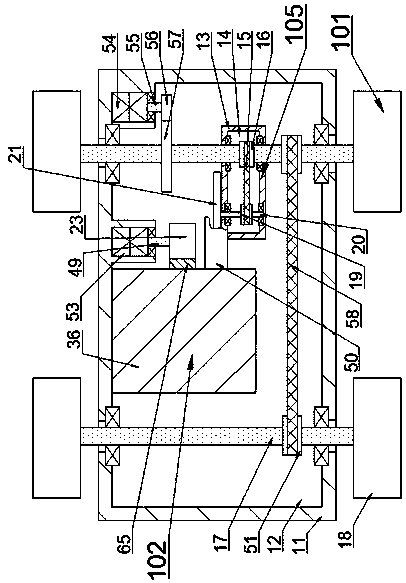

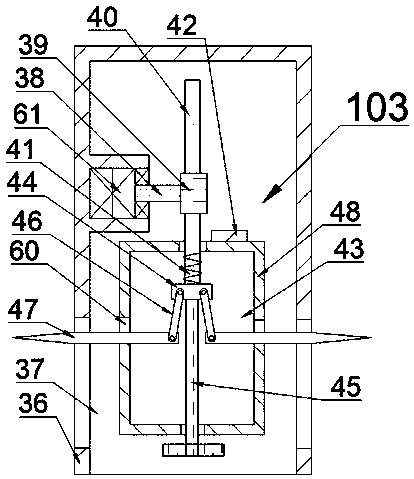

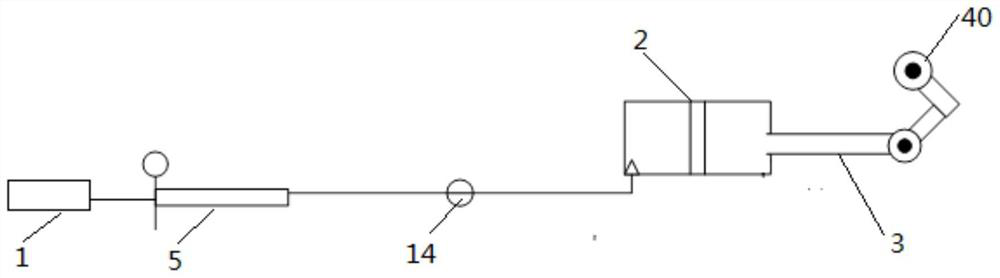

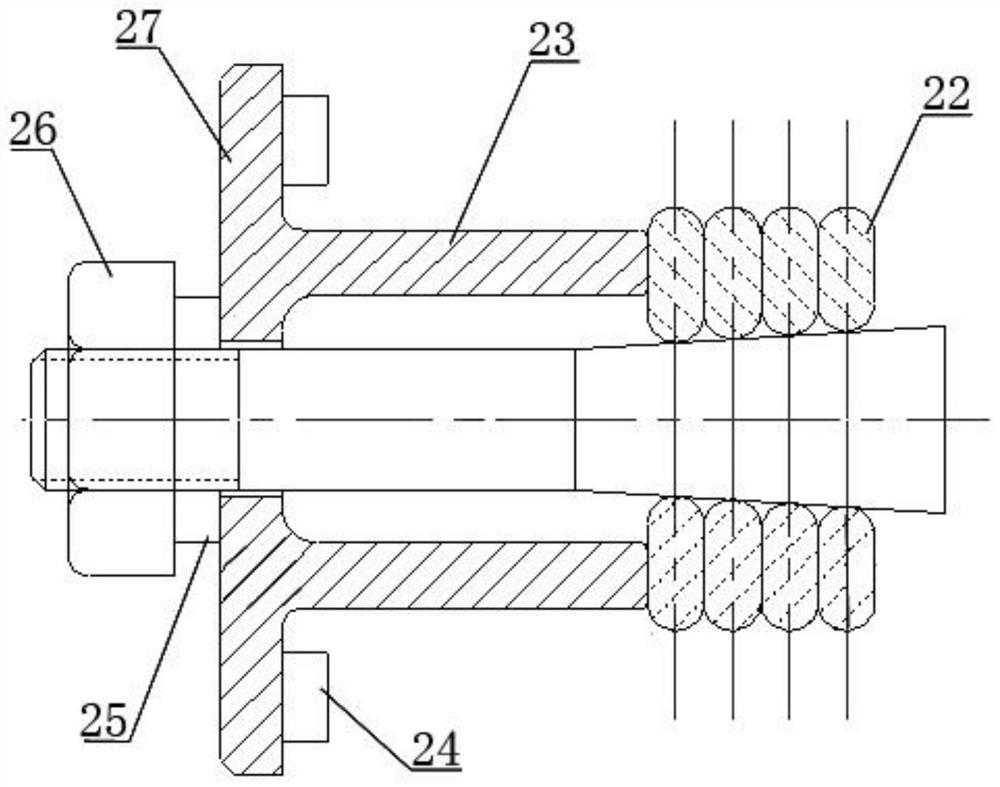

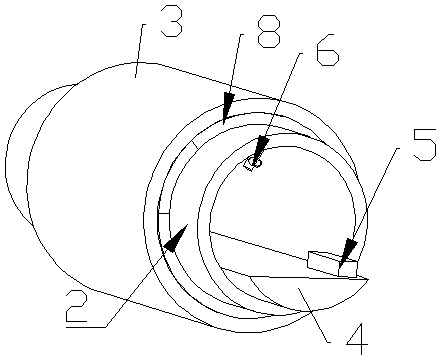

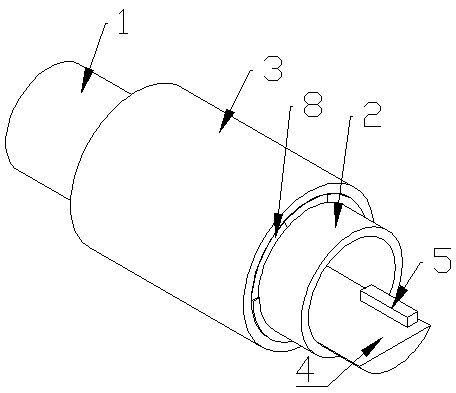

Heat exchange pipe plugging device, plugging tool, plugging system and plugging method

ActiveCN112629311AWill not cause crackingNo damageHeat exhanger sealing arrangementMetal-working hand toolsThermodynamicsEngineering

The invention belongs to the technical field of pipeline construction, and relates to a pipeline end plugging device, system and method. The heat exchange pipe plugging device comprises a tensioning rod, a sealing ring and a pipe end sleeve. The tensioning rod is arranged in the pipe end sleeve, the sealing ring is arranged on the outer portion of the tensioning rod in a sleeving manner, the inner ring of the sealing ring is attached to the outer wall of the tensioning rod, and thte outer ring of the sealing ring is attached to the inner wall of the pipeline. The tensioning rod acts on the sealing ring through rotation and self-tightening to achieve pipe end sealing. According to the heat exchange pipe plugging device, plugging tool, plugging system and plugging method, construction is easy and convenient, plugging is reliable, high-risk operation such as welding and electricity utilization is not needed, sealing stress acts on the pipeline in a pipe plate, cracking of a pipeline welded junction of the pipe plate cannot be caused, the anticorrosive coating of the pipe plate is not stressed, damage to the anticorrosive coating cannot be caused, plugging and dismounting time is short, and working efficiency is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

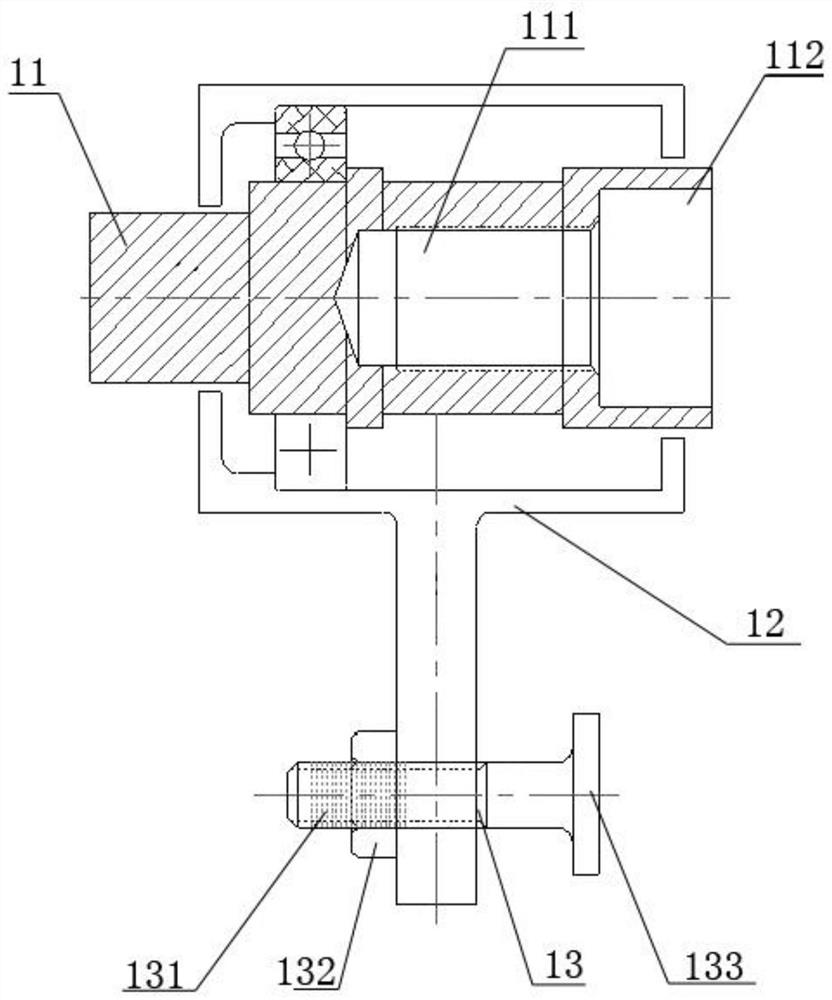

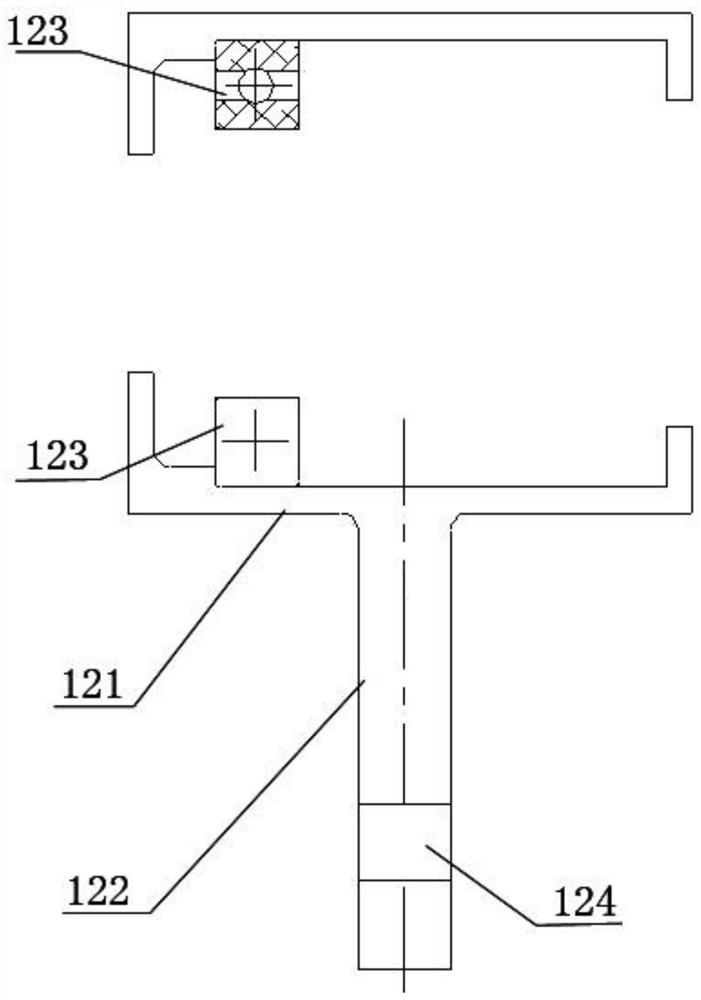

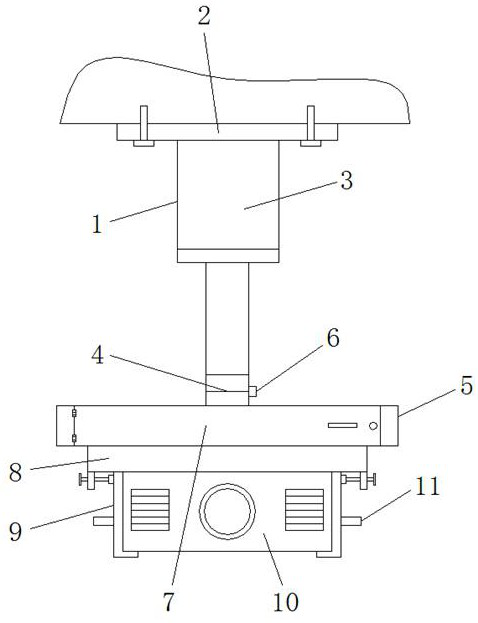

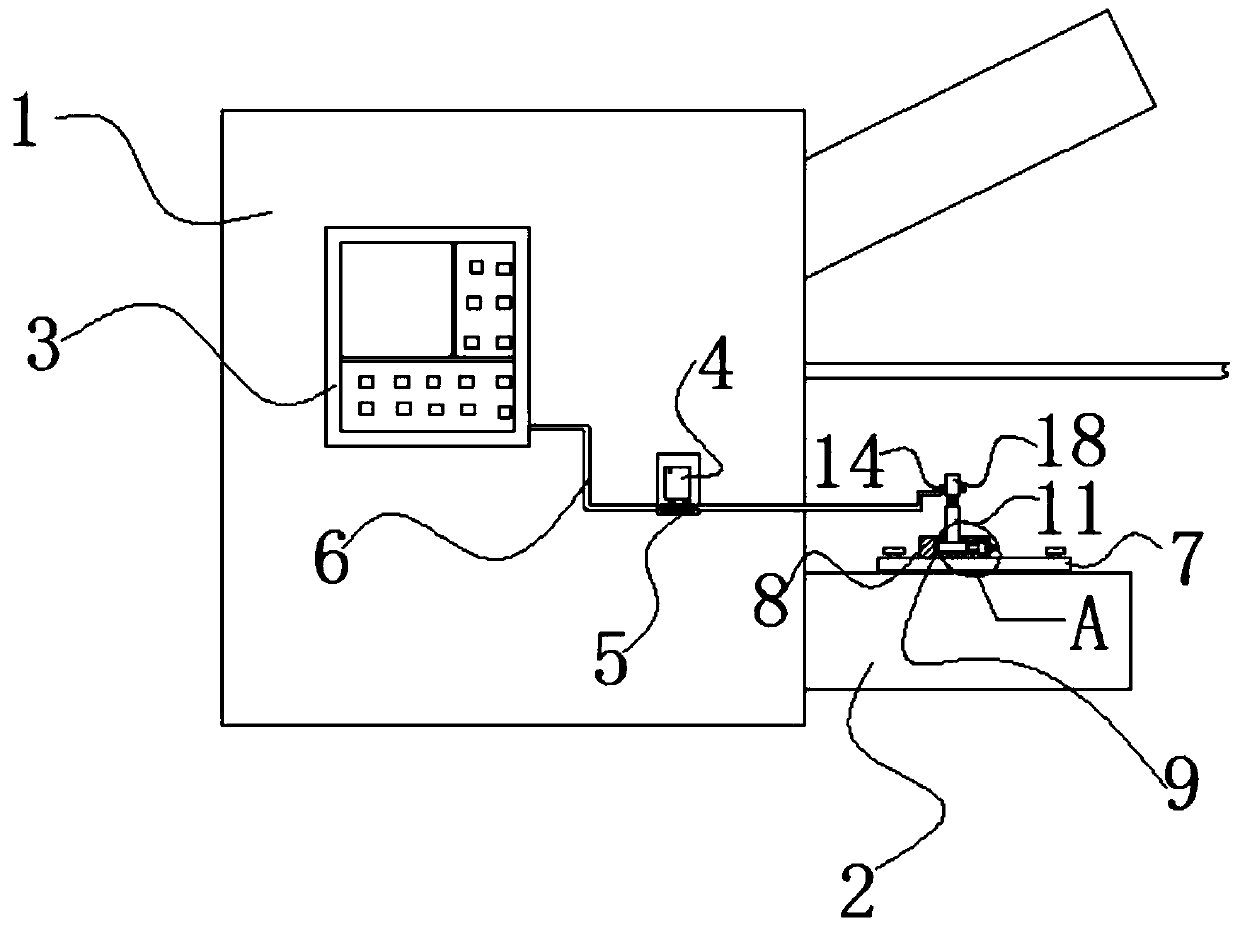

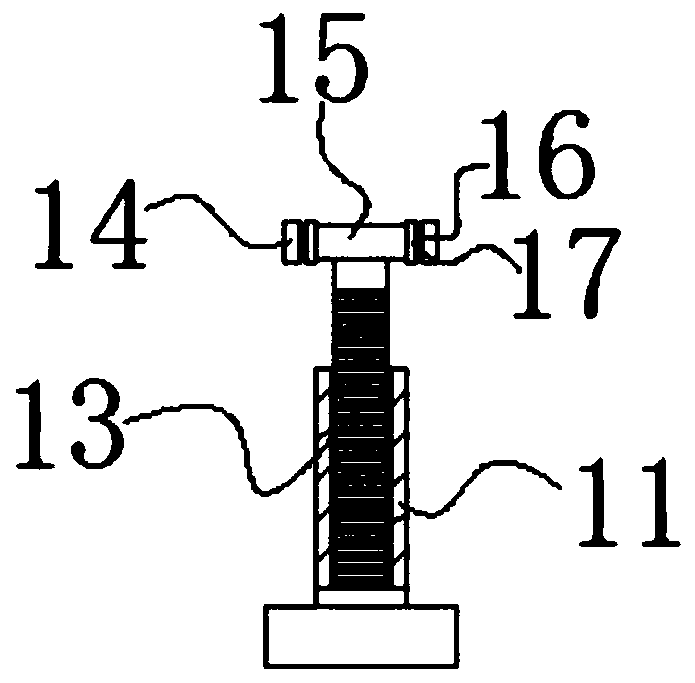

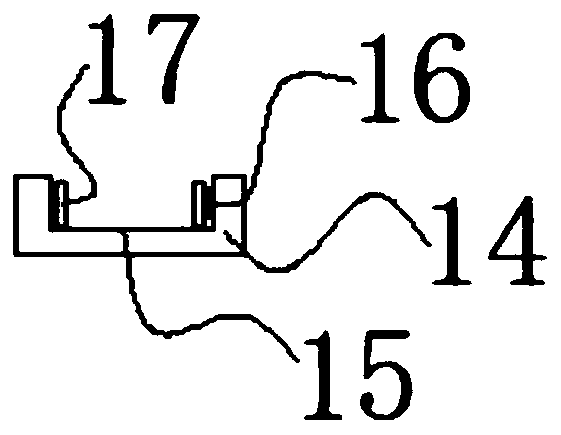

A projection equipment mounting bracket capable of quick disassembly and lifting control

ActiveCN110878885BQuick installationQuick disassemblyProjectorsStands/trestlesStructural engineeringMechanical engineering

The invention discloses a projection setting mounting bracket capable of quick disassembly and lifting control, comprising a mounting bracket main body, an electric telescopic device, a rotating shaft, a tightening nut, projection equipment, a handle, a reset rotating shaft and bolts, the mounting bracket The top of the main body is provided with a fixed seat, and an electric telescopic device is provided under the fixed seat, and the lower end of the electric telescopic device is connected with the mounting frame through a rotating shaft, and a tightening nut is arranged on the rotating shaft at the same time, and the front of the mounting frame The side is provided with a fixed plate, and the lower part of the inner side of the fixed plate is provided with a support block, the inner side of the installation plate is connected with the projection equipment through bolts, and the lower end surface of the installation frame is provided with an installation port. The projection setting installation bracket that can realize quick disassembly and lifting control can realize the rapid installation of projection equipment on the installation frame, and does not need to dismantle a large number of bolts, the disassembly time is short, and different types of projection equipment can be installed and fixed , strong versatility.

Owner:深圳市云杰科技文化有限公司

Grouting structure and matching grouting method during tunnel excavation

The invention relates to the technical field related to tunnel driving equipment, in particular to a grouting structure in the tunnel driving process and a grouting method matched with the grouting structure. The grouting structure in the tunnel driving process and the grouting method aim at solving the problem that in the prior art, filling a gap in the back portion of a segment cannot be achieved through synchronous grouting. The grouting structure in the tunnel driving process sequentially comprises a rock stratum and a segment stratum inwards from the inner wall of a tunnel, and accordingly a side-top arch, in unit of blocks, is formed. A support frame is arranged between the segment stratum and the rock stratum, and accordingly a hollow interlayer is formed. A base lining platform is arranged on the bottom of the side-top arch, and reserved grouting holes communicating with the hollow interlayer are formed in the positions, corresponding to the side-top arch blocks, of the top of the segment stratum. The reserved grouting holes are moveably connected with grouting pipes, and the other ends of the grouting pipes are connected with a grouting machine. The grouting structure in the tunnel driving process and the grouting method have the beneficial effects that the grouting cost is not increased, the grouting process is smooth, the utilization rate of the grout is high, the structure of equipment is simple, repairing and later maintenance are convenient, the assembling and disassembling time is short, grouting pressure can be monitored at any time, the grouting quality can be guaranteed, and a framework layer is formed on the contact surface between the grout and water glass so that flowing of the grout to a cutterhead can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Infrared fault induction based automatic shutdown device

InactiveCN111155229ASolve the installationShort disassembly timeLoomsKnittingTextileControl engineering

The invention discloses an infrared fault induction based automatic shutdown device, and belongs to the technical field of textile machinery fault protection. The device comprises a machine box, a supporting table and a controller, wherein one end of the bottom of the machine box is fixedly connected with the supporting table; one side of the outer wall of the machine box is in interference fitting connection with the controller; the input end of the controller is electrically connected with an external power source; a lead wire is detachably connected between the output end of the controllerand the input end of a relay; the relay is installed on the outer wall of one side of the machine box; and a lead wire is detachably connected between the output end of the relay and the input end ofan infrared sensor. A clamping seat, a rectangular groove, a spring and a contact piece are arranged, the infrared sensor is directly embedded in the rectangular groove, the spring in the rectangulargroove clamps the infrared sensor by the contact piece through taking the inner wall of the rectangular groove as supporting force, and when being detached, the infrared sensor can be detached only bylifting upwards, so that the problem of long detaching time of the infrared sensor of existing textile equipment is solved.

Owner:潜山金诚永泰服装有限公司

Tool for disassembling yellow phosphorus furnace break electric pole

InactiveCN101549489AEasy to disassembleNot easy to hurtMetal-working hand toolsEngineeringMechanical engineering

The present invention provides a tool for disassembling a yellow phosphorus furnace break electric pole which includes a four-foot fork and a fixing plate. The four-foot fork is crosswise welded by two reverse U shape steels, the four-foot fork is fixed on the fixing plate. The above structure only needs opening four holes with suitable interval on the electric pole when the yellow phosphorus furnace break electric pole is disassembled, then the four-foot fork is inserted into the four holes, a level turns the four-foot fork for turning the break electrode down. The tool can disassemble the yellow phosphorus furnace break electric pole, does not damage the electric pole thread port and human and has short disassembling time.

Owner:HUBEI XINGFA CHEM GRP CO LTD

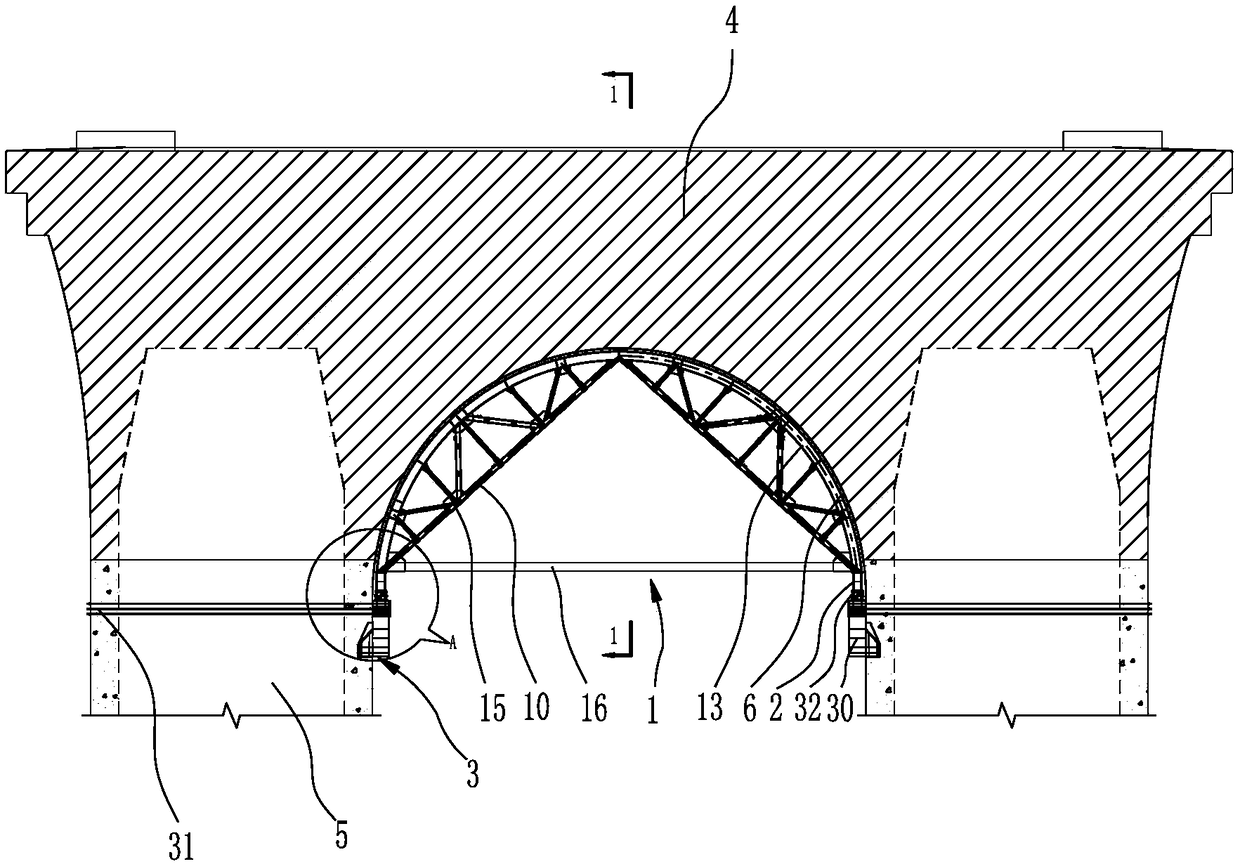

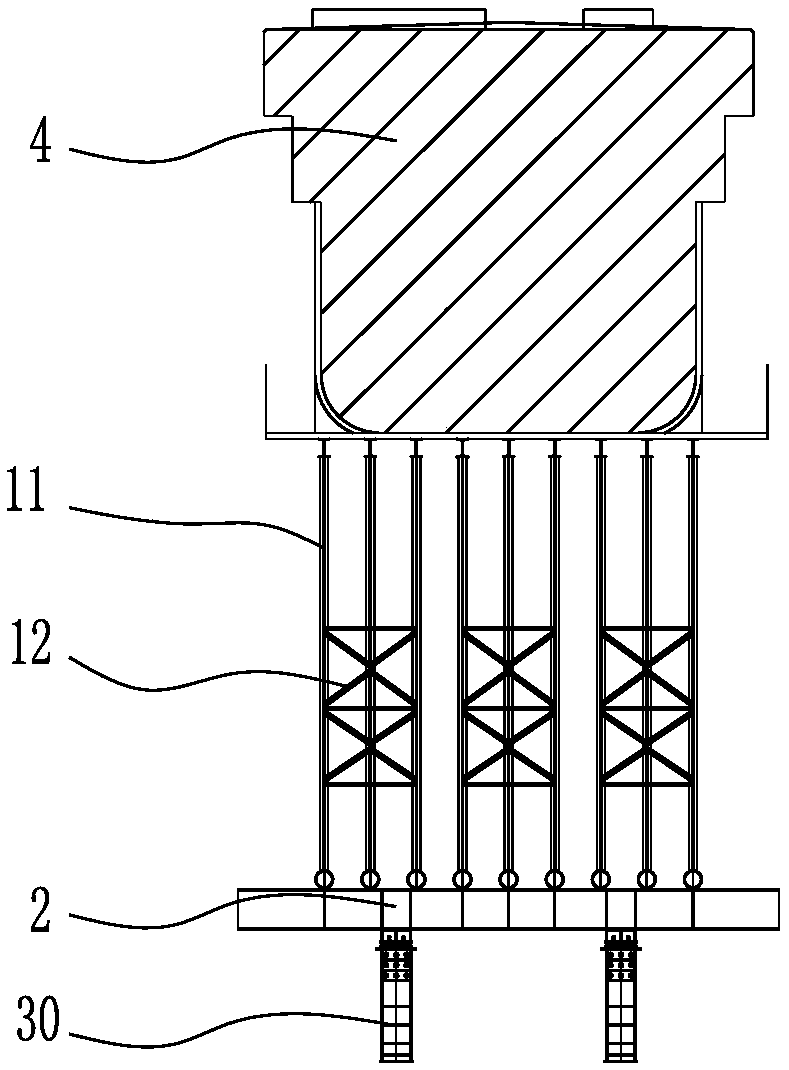

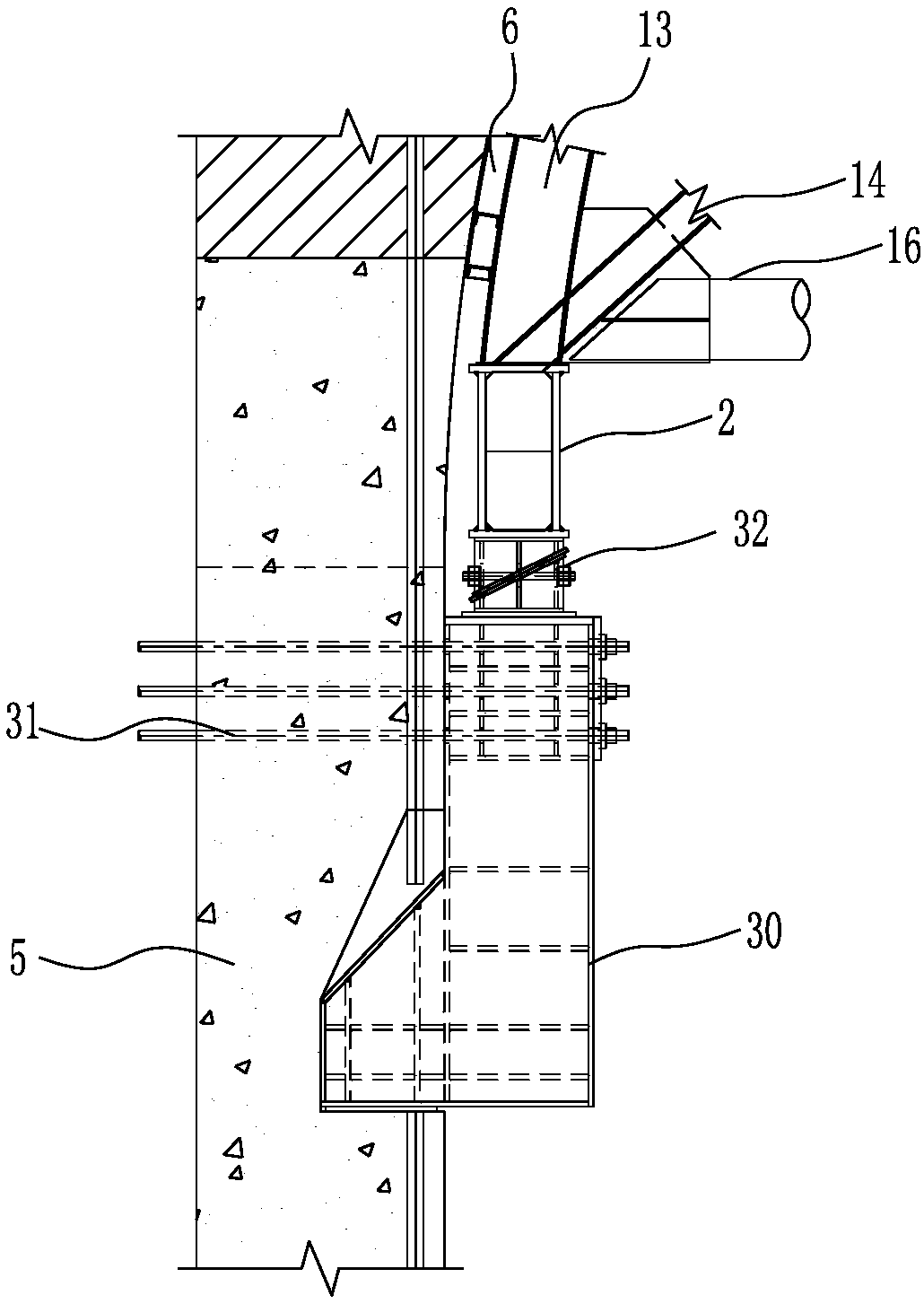

Arc-shaped pier cap construction arch support assembly and arc-shaped pier cap construction method

ActiveCN106758855BSimple structureSmall amount of on-site installation and disassemblyBridge structural detailsBridge erection/assemblyUtilization rateArch supports

The invention discloses an arched support assembly used for the arc-shaped pier cap construction and an arc-shaped pier cap construction method, and relates to the technical field of bridge construction. The arched support assembly includes an upper support, a base and a supporting structure, wherein the upper support includes a number of arched support bodies and tie systems, the arched support bodies are connected through the tie systems, the upper surface of the upper support is provided with an arc-shaped construction surface adapted to an arc-shaped pier cap, the upper support is installed on the base, the supporting structure is used for supporting and fixing the base. The arched support assembly is used in the arc-shaped pier cap construction process, arched support bodies are assembled in a construction site and then hoisted integrally, risks brought by high-altitude support assembling are reduced, in the arched support body disassembly process, the supporting structure is disassembled, then the upper support with an arc-shaped pier cap formwork and the base are integrally placed on a platform or the ground, the number of times of the disassembly is small, the high-altitude operation time is short, the arc-shaped pier cap construction efficiency is improved, the whole bridge construction speed is improved, and the cyclic utilization rate of the arched support assembly is high.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com