Arc-shaped pier cap construction arch support assembly and arc-shaped pier cap construction method

A construction method and arc-shaped technology, which is applied to bridge parts, erection/assembly of bridges, buildings, etc., can solve the problems of increasing the difficulty of support design and engineering volume, many high-altitude operations, and high-risk operations, etc., to improve The effect of construction speed and safety, small amount of installation and dismantling, and time reduction for high-efficiency work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

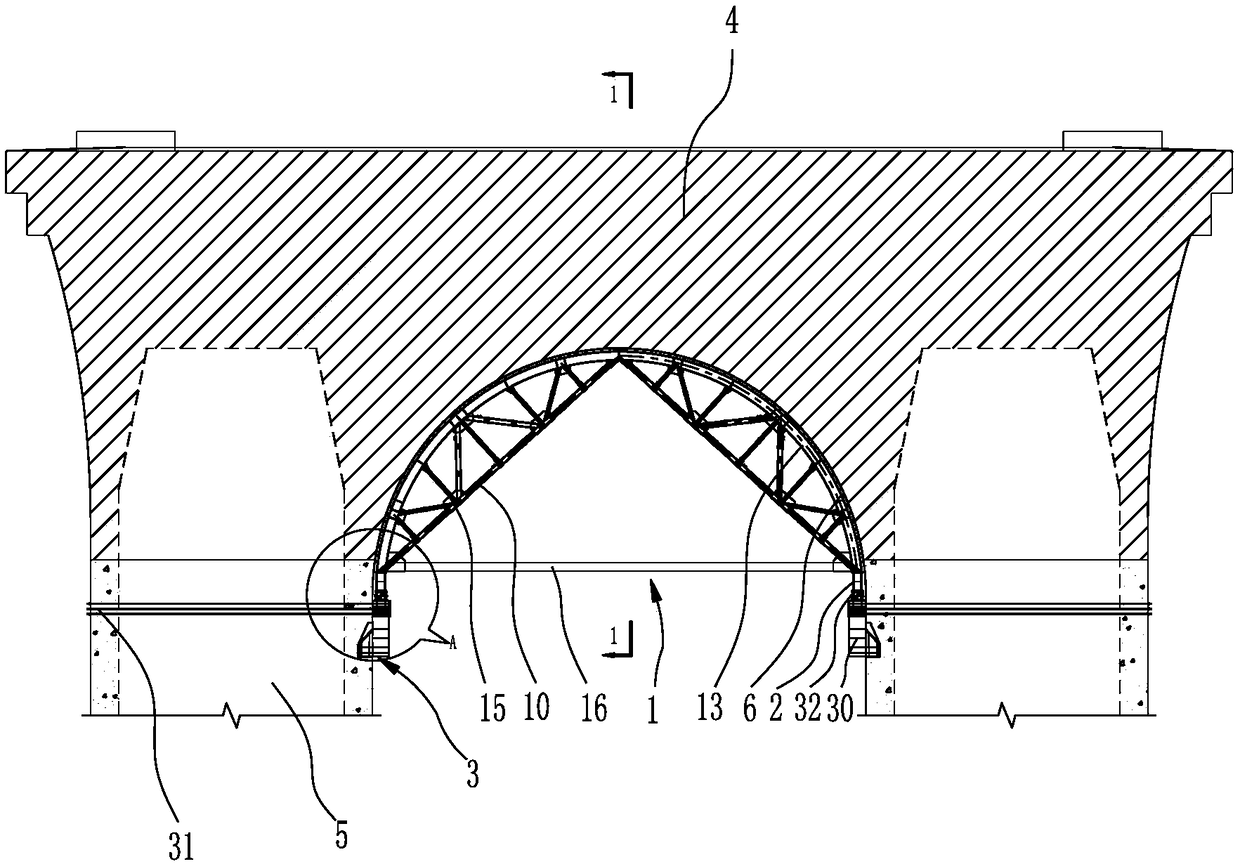

[0033] see figure 1 As shown, the embodiment of the present invention provides an arch bracket assembly for arc-shaped pier cap construction, including:

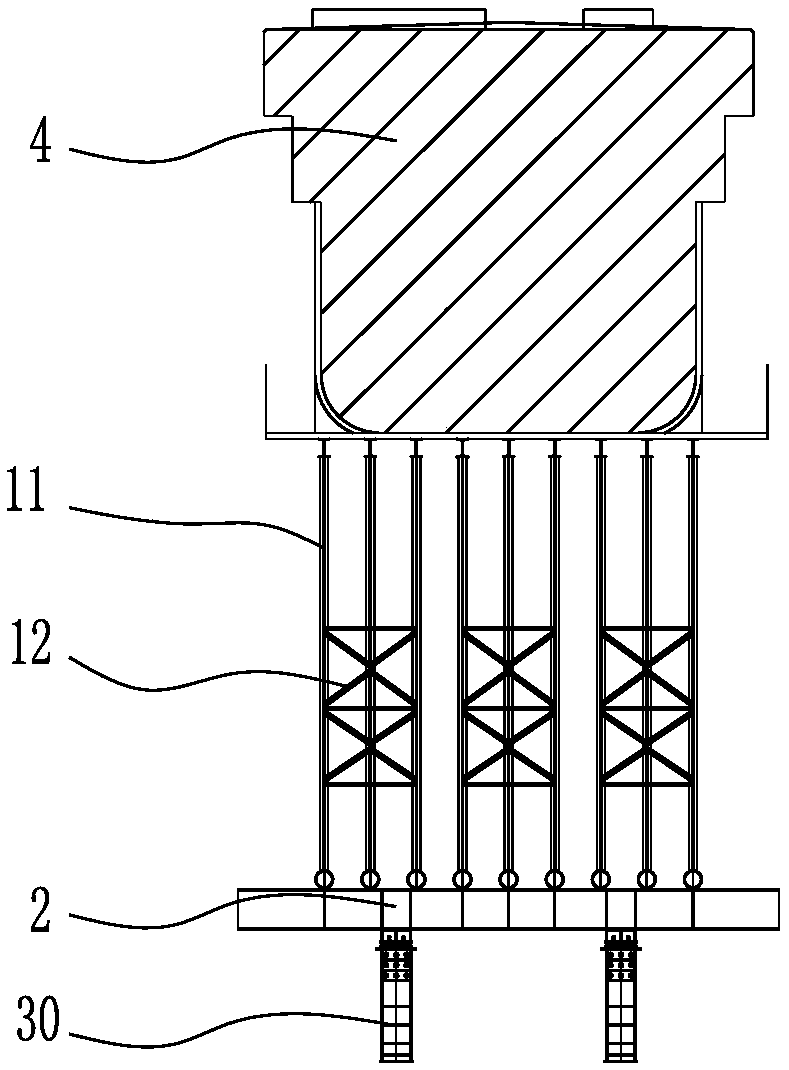

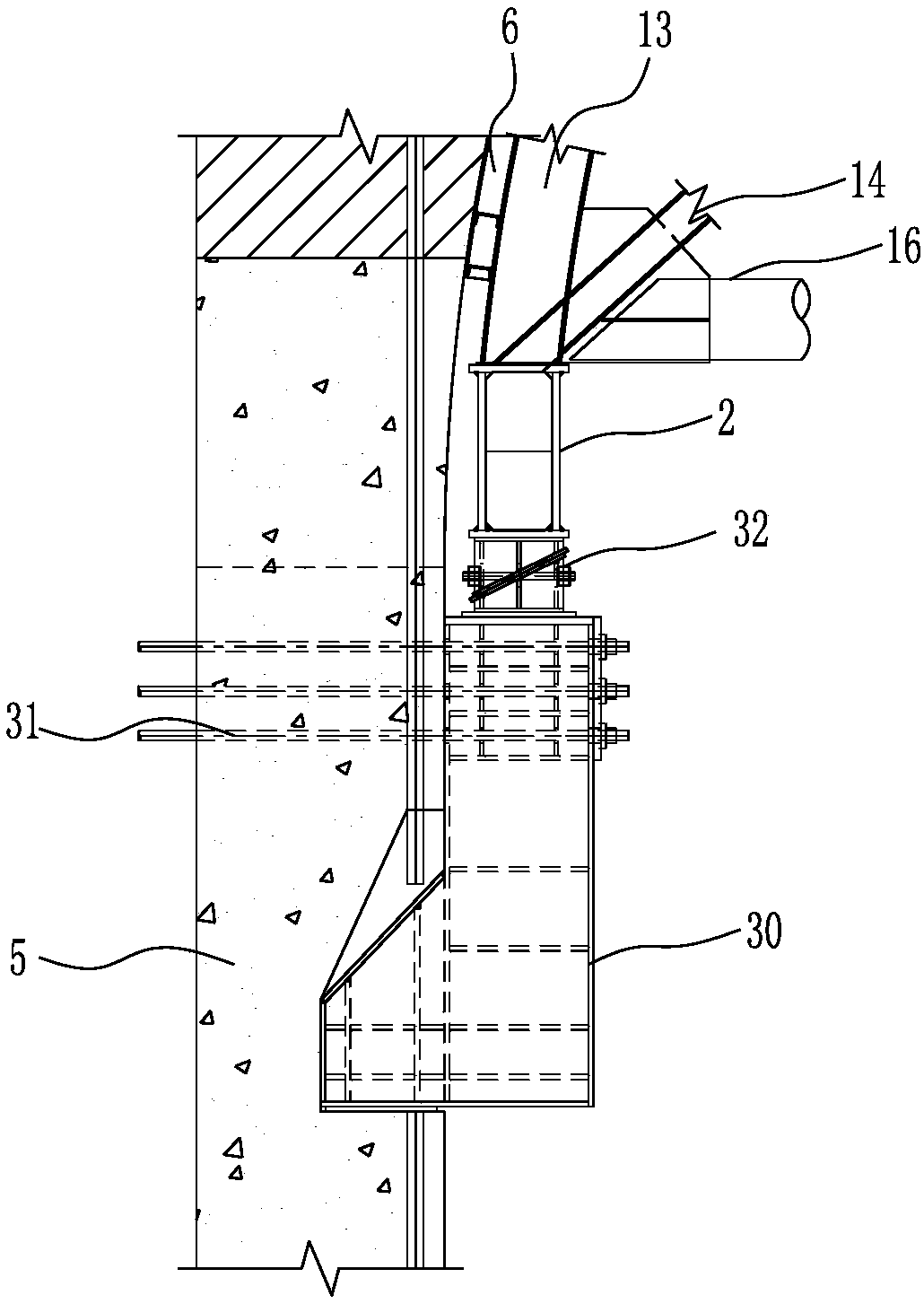

[0034] see figure 2 As shown, several upper brackets 1 include several arched brackets 11 and coupling systems 12, and multiple arched brackets 11 are connected into upper brackets 1 through coupling systems. A single arc-shaped pier cap can be constructed with one or more upper brackets 1, Several upper brackets 1 are arranged side by side along the direction of the bridge, and the upper surfaces of the upper brackets 1 are spliced to form an arc-shaped construction surface suitable for arc-shaped pier caps. The arched bracket 11 includes two prefabricated half brackets 10 and a tie rod 16, and the two half brackets 10 are butted through the tie rod 16, the size is small, and the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com