Heat exchange pipe plugging device, plugging tool, plugging system and plugging method

A technology for plugging devices and heat exchange tubes, which is applied to heat exchanger sealing devices, manufacturing tools, heat exchange equipment, etc., and can solve problems such as damage to anti-corrosion coatings, cracking and leakage of heat exchange tube nozzles, and safety incidents , to achieve the effect of improving work efficiency, short disassembly time, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

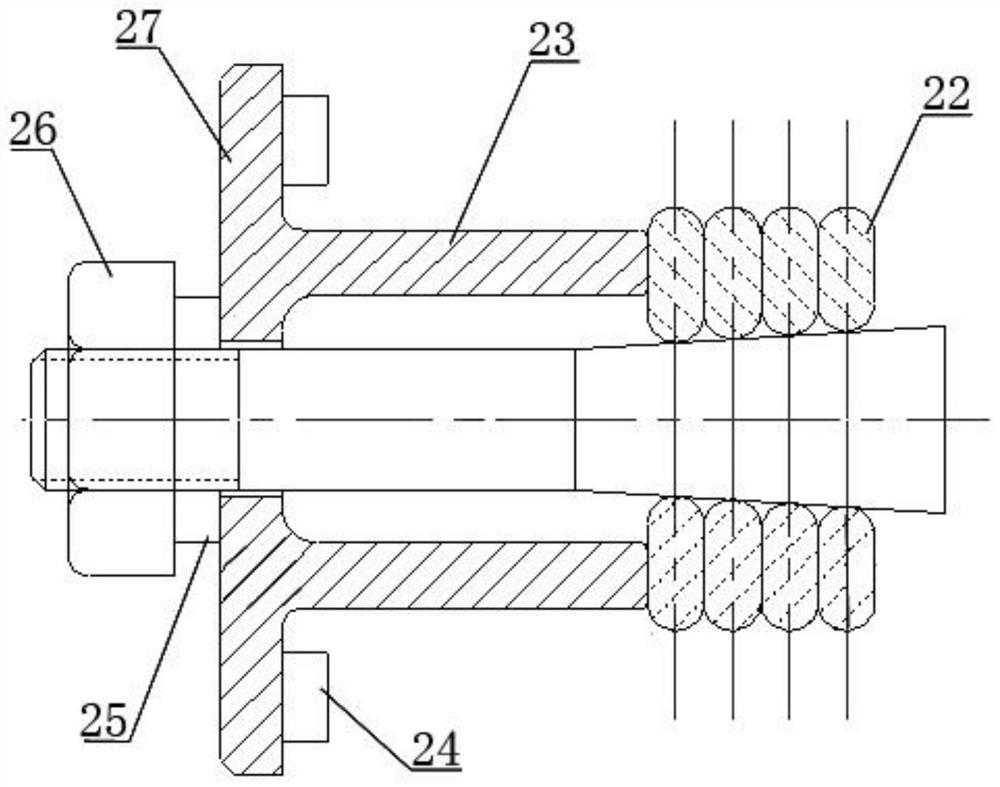

[0036] Embodiment 1 This embodiment provides a heat exchange tube plugging device, the structure of which is as follows figure 1 As shown, it mainly includes: tension rod 21 , sealing ring 22 , pipe end sleeve 23 and nut 26 . Wherein, one end of the tension rod 21 is provided with an external thread, and the other end is a tapered body. The sealing ring 22 is sleeved on the outside of the cone.

[0037] The radius of the conical body of the tension rod 21 increases successively, and the radius of the bottom surface is slightly smaller than the inner diameter of the heat exchange tube 4, so that the axial force on the bottom surface of the conical body of the tension rod 21 is much greater than that received by the other surfaces of the tension rod after sealing. Axial force generated by pressure. There are more than two groups of sealing rings 22 set outside the conical body of the tension rod 21. The diameters of the outer rings of all the sealing rings are equal, and the d...

Embodiment 2

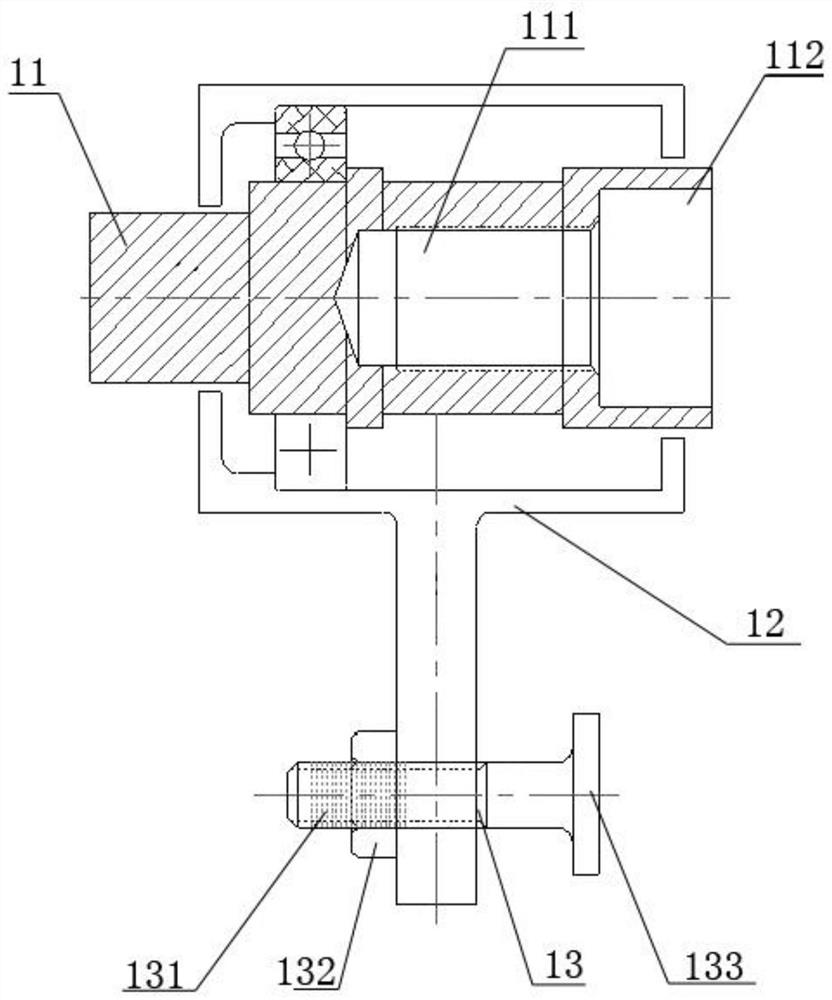

[0043] Embodiment 2 This embodiment provides a heat exchange tube sealing tool for cleaning the heat exchange tube and installing a heat exchange tube sealing device, such as figure 2 As shown, the plugging tool includes a sleeve 11 , a positioning device 12 and a preload setting rod 13 .

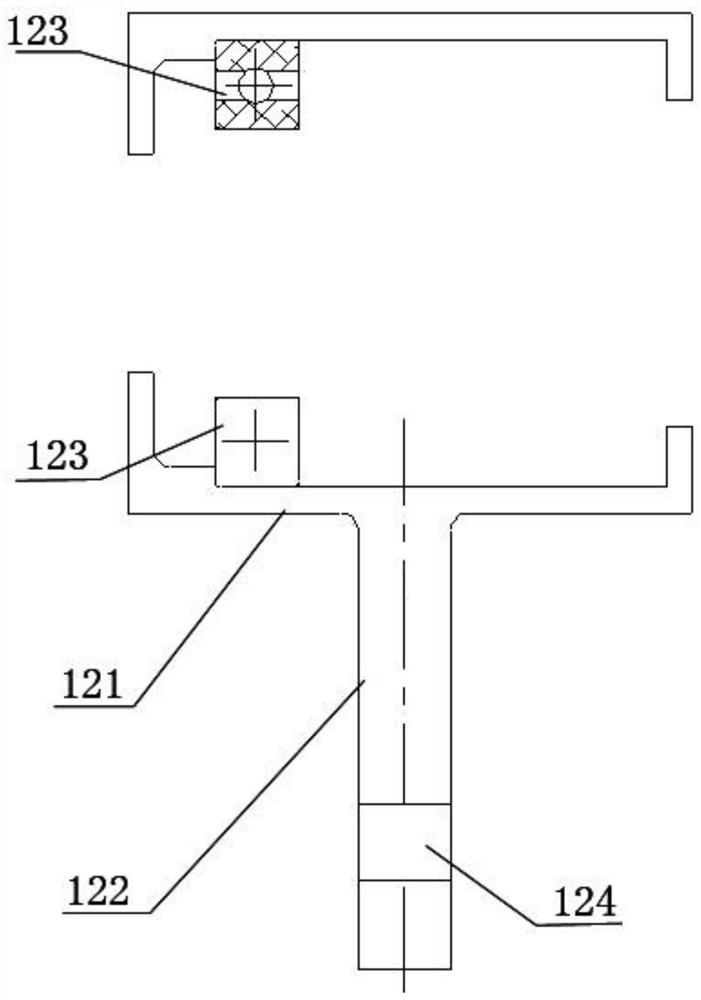

[0044] Such as image 3 As shown, the positioning device 12 includes a sleeve frame 121, which is square or rectangular. Two opposite openings are arranged on both sides of the sleeve frame, one of which is slightly larger than the other. When the sleeve 11 is placed in the sleeve frame 121 , the two ends of the sleeve 11 are respectively at two opening positions, and slightly protrude from the ends of the openings. The sleeve 11 can rotate around its own long axis in the sleeve frame 121 . A pair of bearings 123 are arranged in the frame, and the outer peripheral surface of the bearings 123 is in contact with the outer wall of the sleeve 11 to provide support for the rotation of the sl...

Embodiment 3

[0048] Embodiment 3 This embodiment provides a rapid plugging system for heat exchange tubes, such as Figure 4 As shown, the system includes the heat exchange tube sealing tool 1 and the heat exchange tube sealing device 2 described above. The heat exchange tube sealing device 2 is used for sealing the heat exchanger tube sheet 3 and the heat exchange tube pipe. The heat exchange tube plugging tool 1 is used for installation and disassembly of the heat exchange tube plugging device 2, and at the same time, it can also be used to clean the inside of the heat exchange tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com