An electronically controlled electric rotor brake system

A brake system and rotor technology, applied in the direction of brake type, brake actuator, axial brake, etc., can solve the problems of multiple acquisition signals, complex structure design, high operating cost, etc., achieve short disassembly time, convenient installation and maintenance, The effect of improving system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

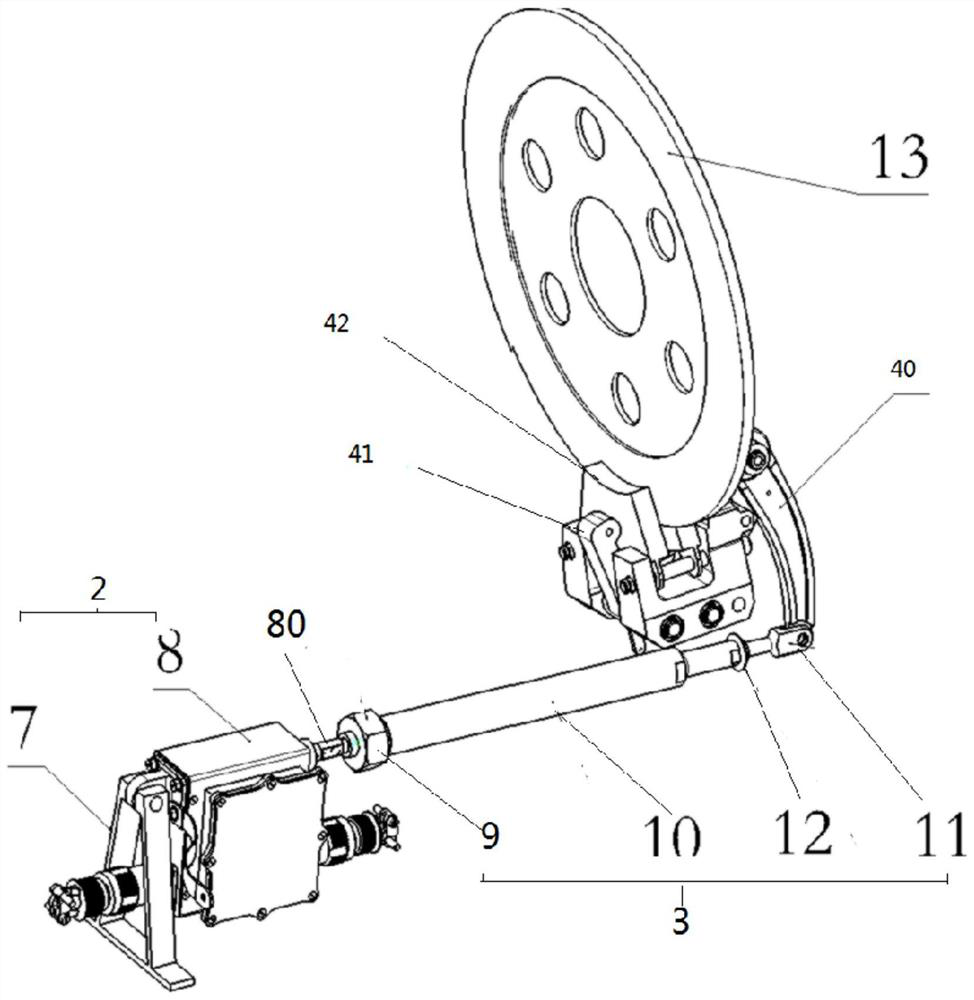

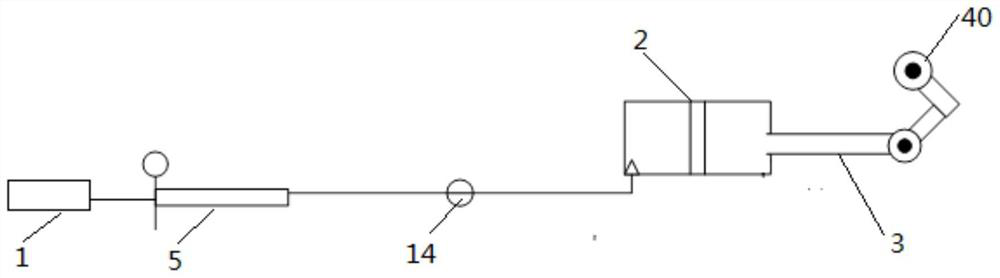

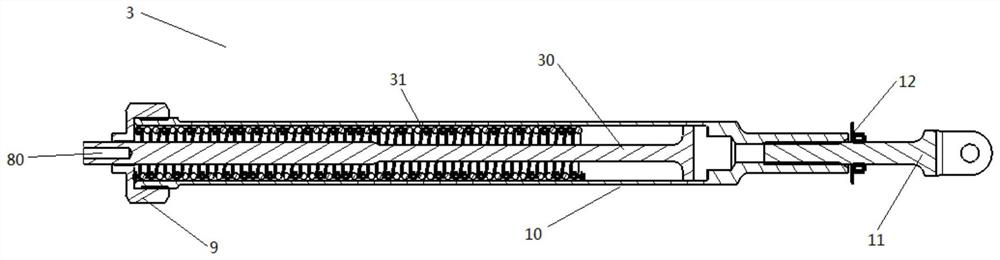

[0034] figure 1 It is an axonometric view of the electric mechanism assembly, connection assembly and rotor brake stop mechanism connection mode in the electronically controlled electric rotor brake system of this embodiment, figure 2 It is a schematic diagram of the working principle of the electronically controlled electric rotor brake system of this embodiment, combined with figure 1 and figure 2 As shown, this embodiment provides an electronically controlled electric rotor brake system for helicopter rotor brakes. The brake system includes a control system 1, an electric mechanism assembly 2, a connection assembly 3, and a rotor brake stop mechanism. The motor mechanism assembly 2 includes a driving mechanism 8 , and the connecting assembly 3 includes a connecting pipe 10 .

[0035] like figure 2 As shown, the control system 1 is electrically connected with the driving mechanism 8 for controlling the movement of the driving mechanism 8 . like figure 1 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com