Ultrasonic wave automatic cleaning machine for eyeglasses

An automatic cleaning machine, ultrasonic technology, applied in the direction of glasses/protective glasses, glasses/goggles, cleaning and flexible items, etc., can solve the problems of unclean cleaning, bacterial cross-infection, unsanitary, etc. The effect of preventing bacterial cross infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

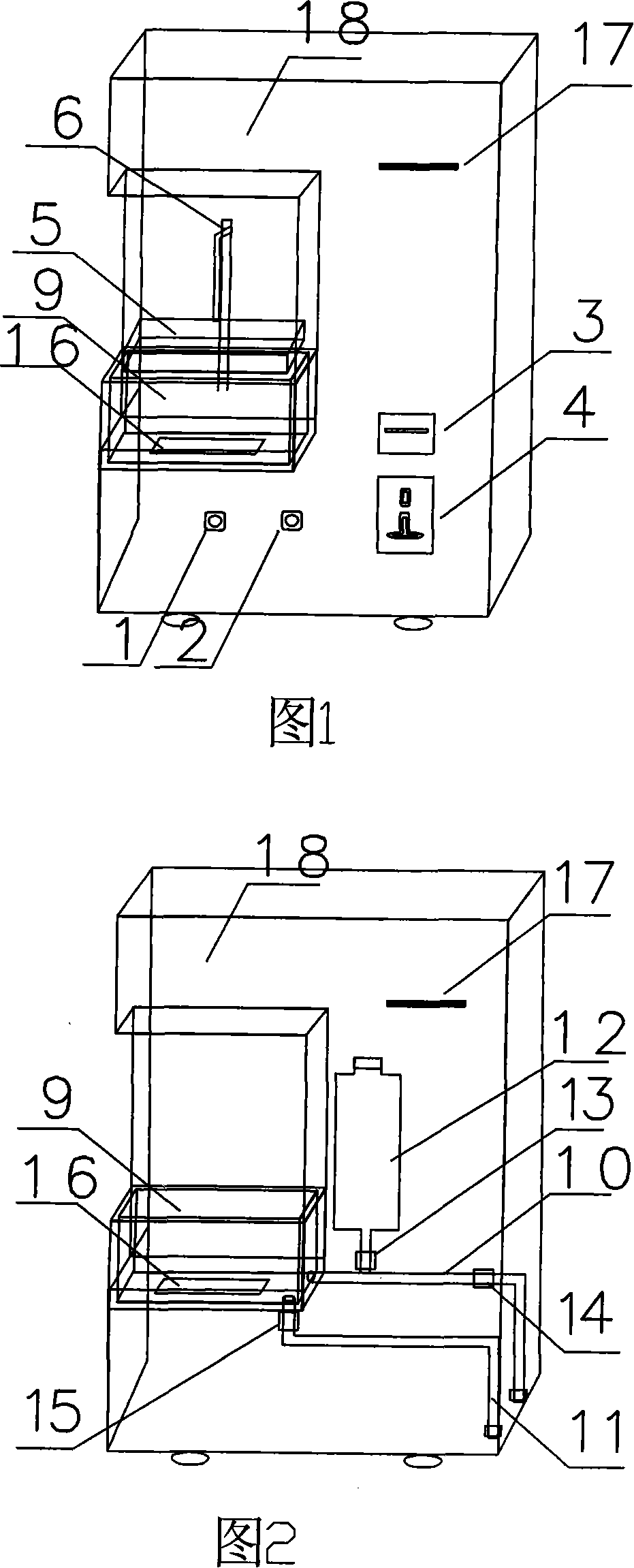

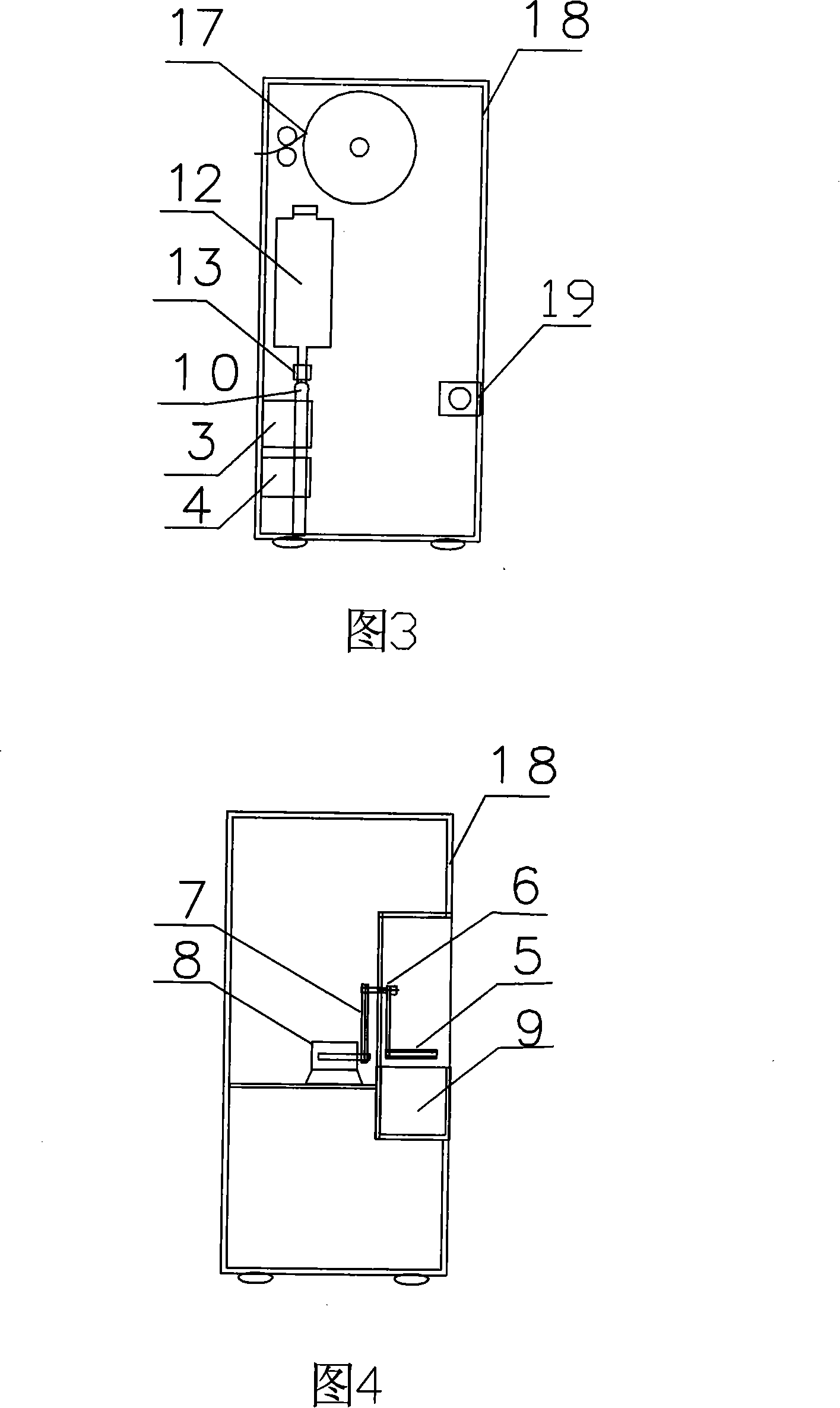

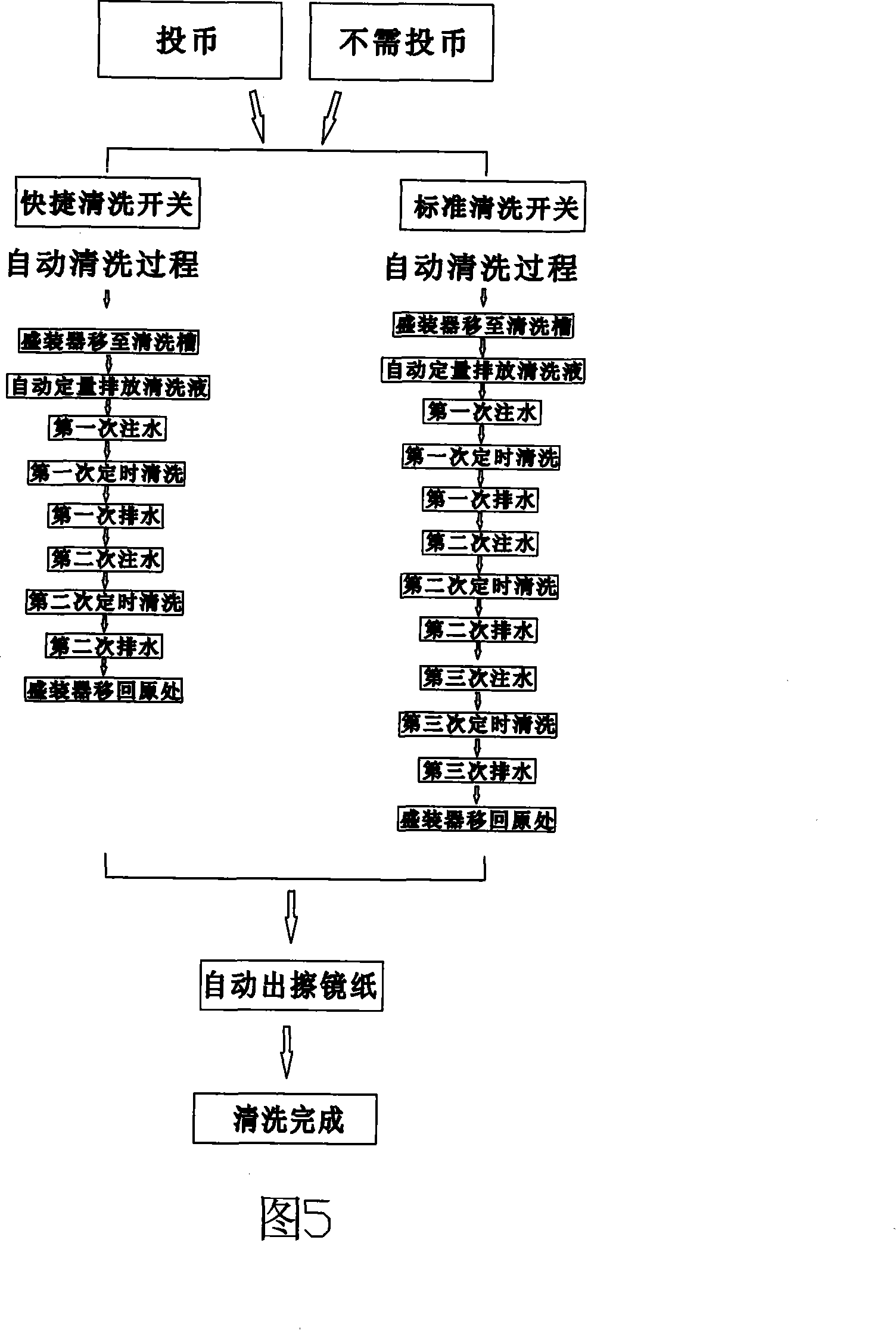

[0012] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention includes a vertical box 18, a control circuit, a cleaning tank 9, a container 5, an ultrasonic generator 16 positioned at the bottom of the cleaning tank 9, and one side of the cleaning tank 9 is connected with a water inlet pipe 10 respectively. , the drain pipe 11, the water inlet pipe 10 and the drain pipe 11 are respectively provided with a water inlet control solenoid valve 14 and a drain control solenoid valve 15, and the end of the water inlet pipe 10 near the cleaning tank 9 is connected with a cleaning liquid container 12 , the cleaning liquid container 12 is equipped with a cleaning liquid discharge control electromagnetic valve 13, the back of the cleaning tank 9 is provided with a decelerating motor 8, and a guide rail 7 is installed between the decelerating motor 8 and the cleaning tank 9. The device 5 is suspended on the connecting rod 6, the other end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com