Individual object conveying device

A technology for conveying devices and objects, which is applied in the direction of conveyor objects, transportation and packaging, and manipulators. It can solve problems such as energy loss and mechanical loss, reduce movement accuracy, and increase noise in the working environment, so as to reduce energy loss and mechanical damage. Loss, avoid swing and jitter, improve the effect of action accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

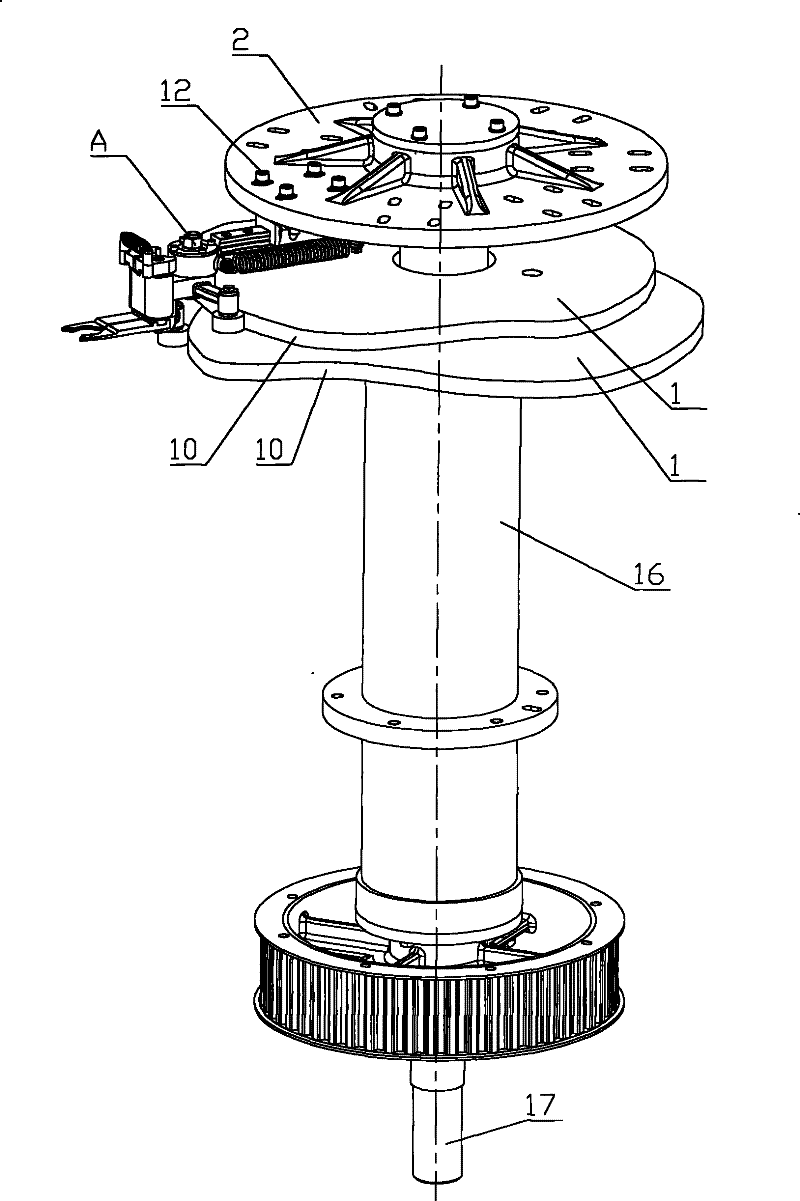

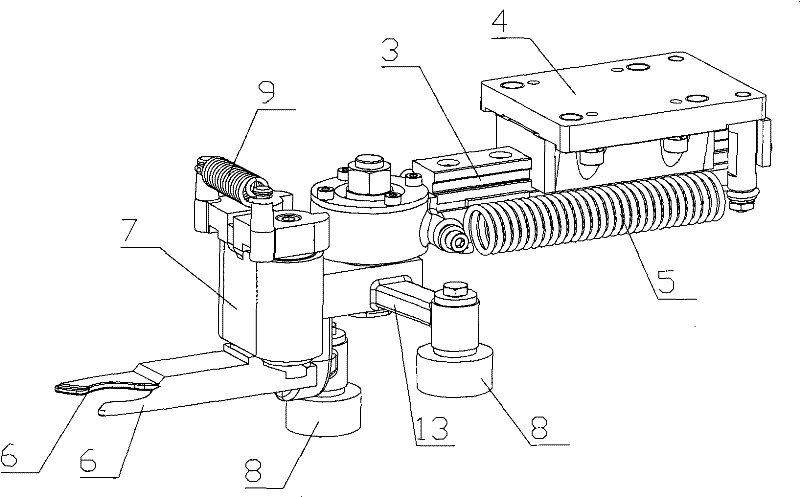

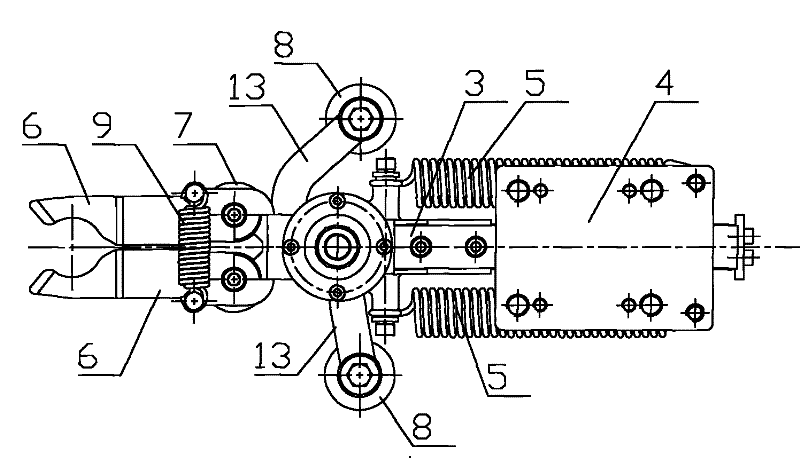

[0033] Such as Figure 1 to Figure 4 As shown, an individual object conveying device includes a cam disc 1, a rotating support 2, a sliding arm 3, a sliding arm seat 4, an elastic reset member, a claw 6, a claw seat 7 and two guide wheels 8, and the rotating support Seat 2 can rotate around its axis (i.e. vertical shaft 17), sliding arm seat 4 is fixed on the rotating support 2, and sliding arm 3 and sliding arm seat 4 slide and cooperate along the longitudinal direction of sliding arm 3, so that sliding arm 3 can rotate along the The bearing 2 reciprocates radially. The front end of the sliding arm 3 is provided with a claw seat rotating shaft 11, and the claw seat 7 is arranged on the front end of the sliding arm 3 through the claw seat rotating shaft 11 and can rotate around the claw seat rotating shaft 11. The gripping claw 6 is arranged on the claw seat 7, and the cam disc 1 is provided with two mutually independent cam curved surfaces 10, two guide wheels 8 are respecti...

Embodiment 2

[0044] Such as Figure 5 As shown, the claw seat 7 includes a front seat body 14 and a rear seat body 15, which are connected by a connector (screw 18) between the front seat body 14 and the rear seat body 15, and the claw 6 is arranged on the front seat body 14, and the side arm 13 is provided On the rear seat body 15. Because the claw seat 7 adopts a split structure, during manufacture, the front seat body 14 and the rear seat body 15 can be processed with different materials, such as the rear seat body 15 can be aluminum, light in weight, and the moment of inertia is small, while the front seat body 14 Other materials can be used to ensure its strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com