Trigger mechanism capable of implementing automatic popup of main lock tongue

An automatic pop-up and trigger mechanism technology, which is applied in building locks, building structures, building fastening devices, etc., can solve the problem of door side strip damage, affecting the sound of closing the door, the appearance of the door side strip, and the collision and friction of the door side strip and other issues to achieve the effect of simple trigger structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

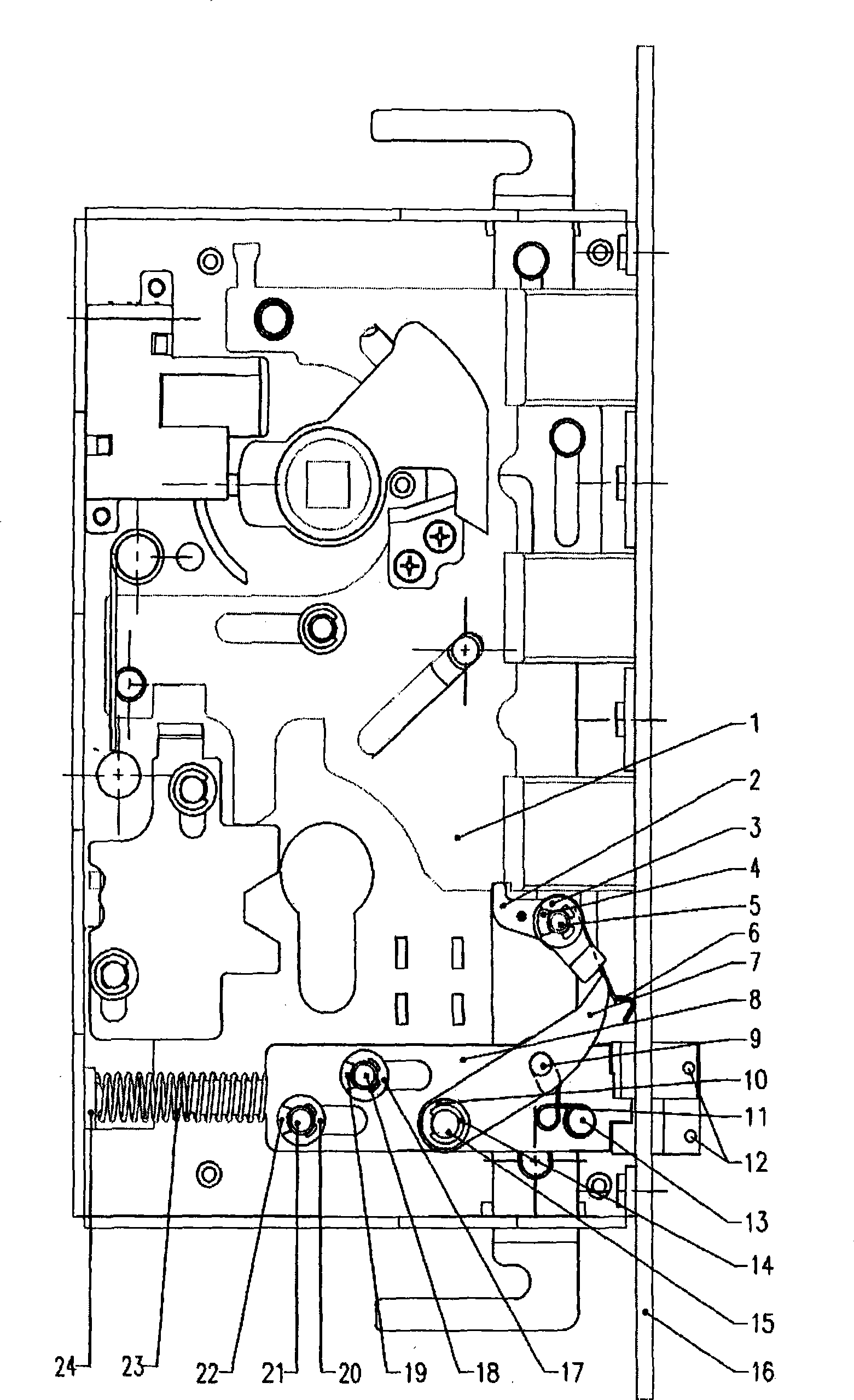

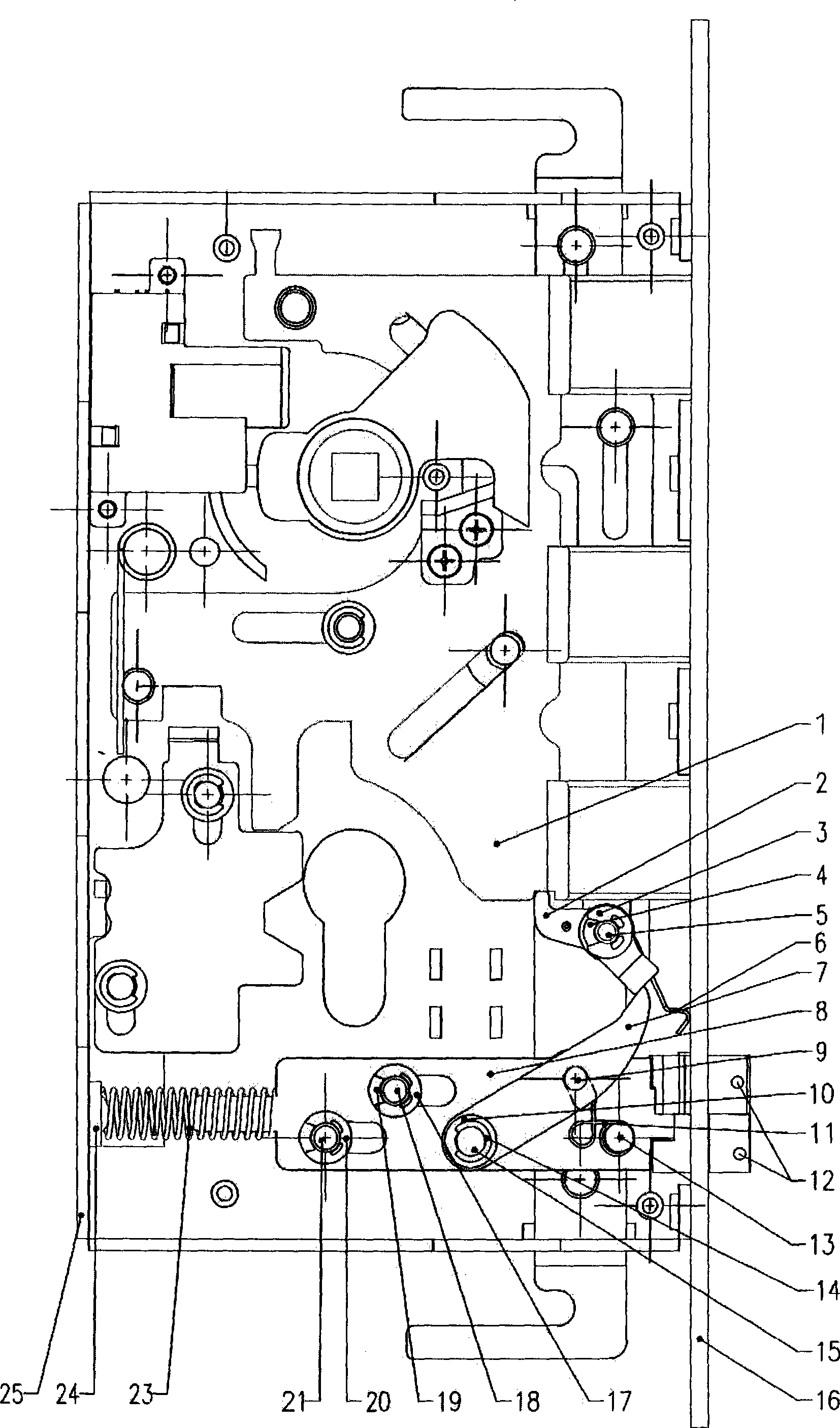

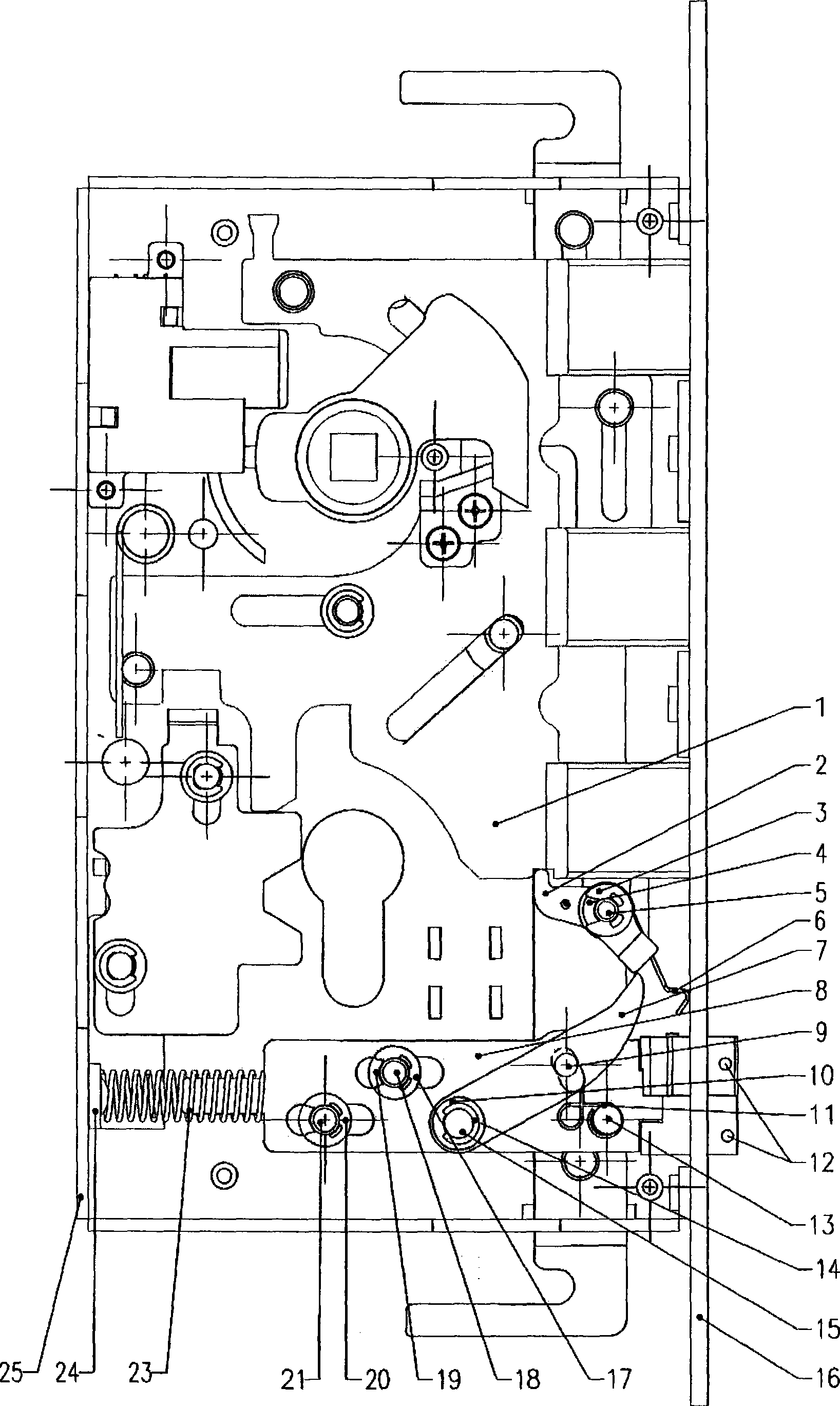

[0016] Such as figure 1 As shown, a trigger mechanism for the automatic ejection of the main tongue of the lock body described in this embodiment includes the main bolt plate 1, the No. 1 paddle 2, the No. 1 column 5, the No. 1 torsion spring 6, the No. 2 paddle 7, Two-way tongue connecting plate 8, No. 2 column 9, No. 2 torsion spring 11, two-way tongue 12, No. 3 column 13, No. 4 column 15, edge bar 16, No. 5 column 18, No. 6 column 21, spring 23, spring seat 24. The anti-lock plate 26 is characterized in that the No. 1 column 5 is riveted in the housing 25, the No. 1 paddle 2 is installed on the No. 1 column 5, and the No. 1 torsion spring 6 is also installed on the No. 1 column 5. One end of the torsion spring 6 is set in the No. 1 paddle 2 hole, the other end of the No. 1 torsion spring 6 presses the side bar 16, and the No. 1 gasket 4 and the No. 1 opening retaining ring 3 are installed on the No. 1 column 5; No. 5 column 18 and No. 6 column 21 are riveted on the top, No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com