Female connection element and quick connection including such an element

A female element and connector technology, applied in the field of quick connectors, can solve the problems of increasing the cost of connector manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

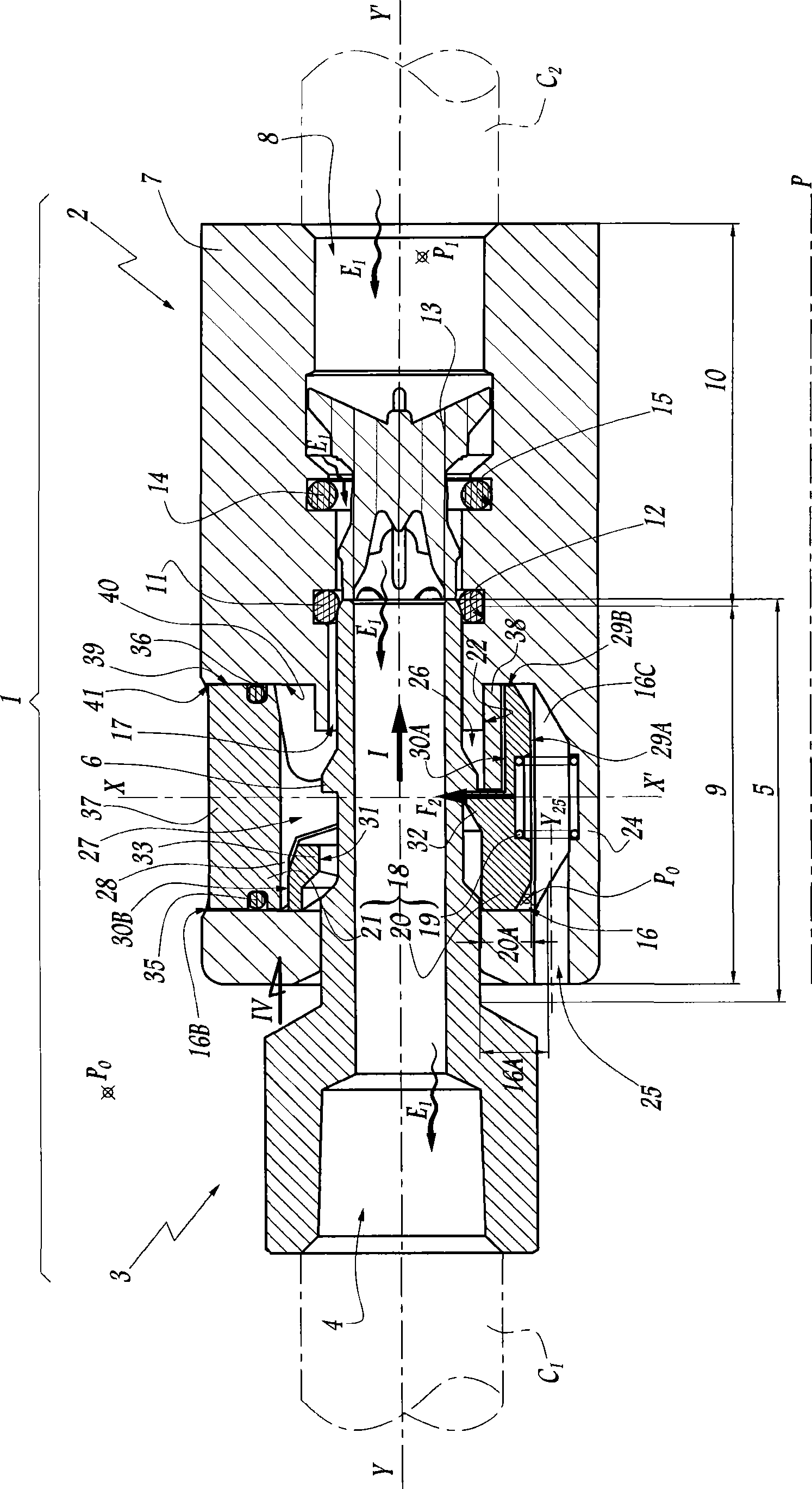

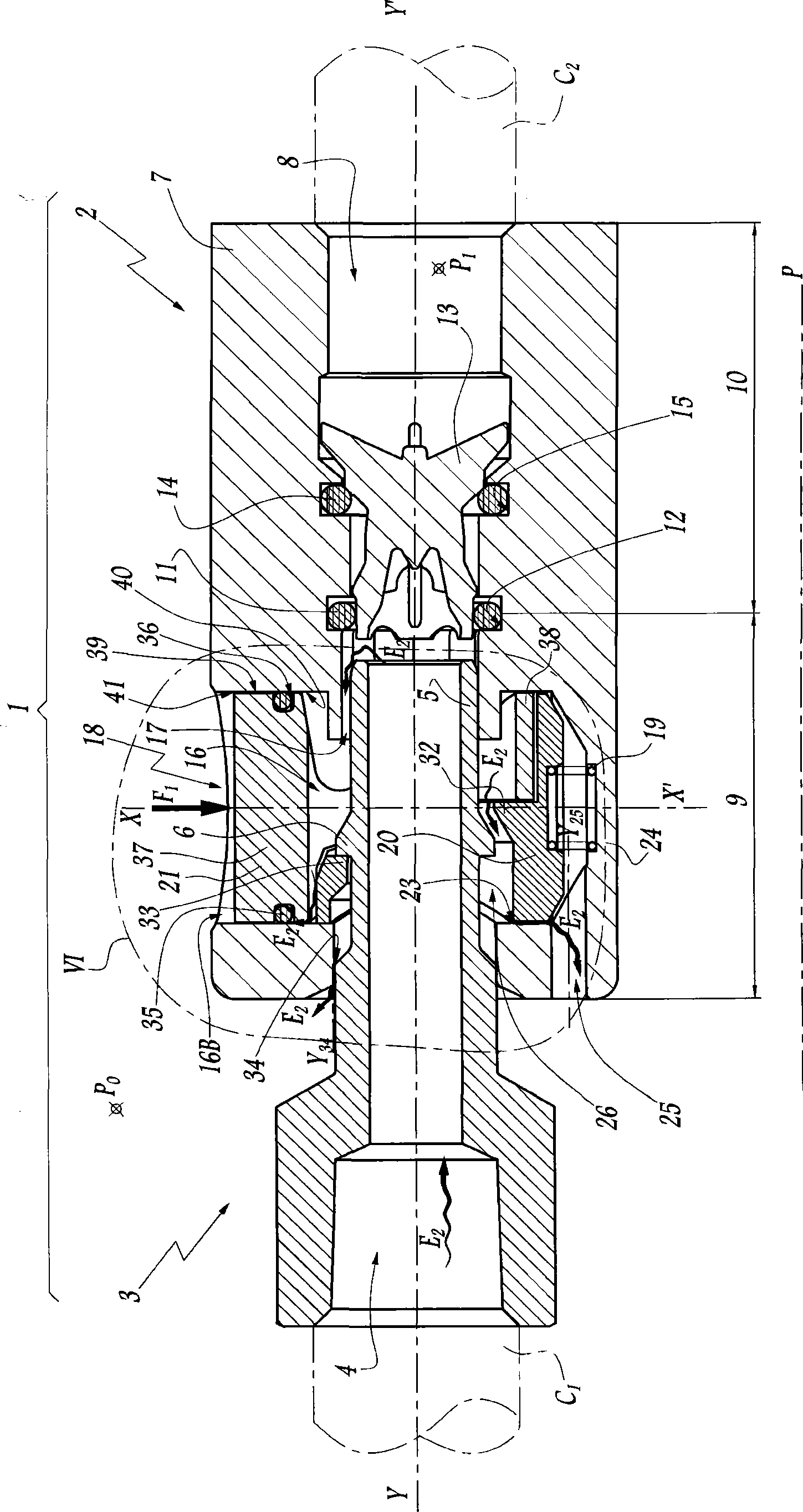

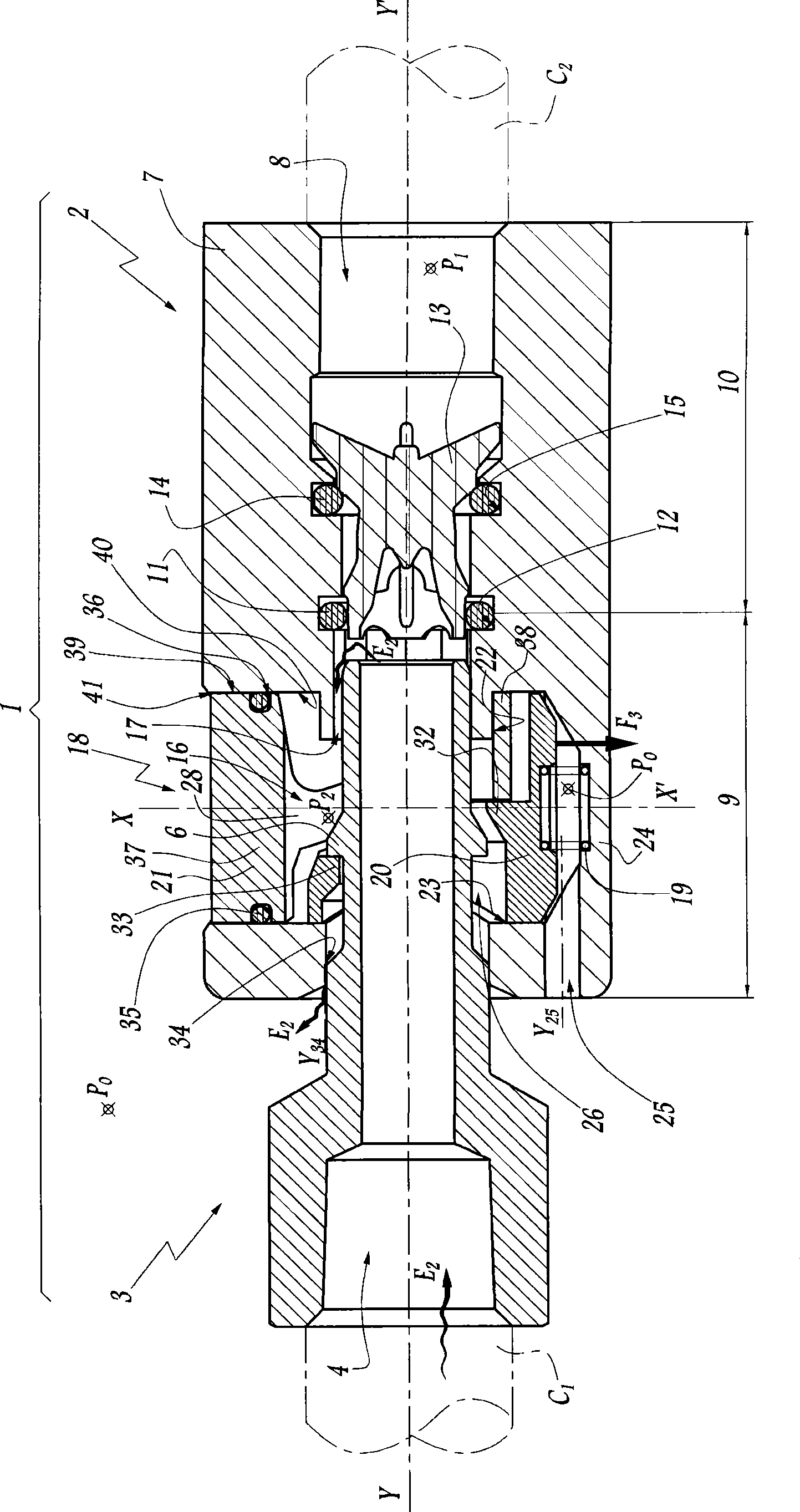

[0026] Figures 1 to 3 Quick connector 1 is shown for two pipes C that will deliver pressurized fluid 1 and C 2 connected. In this specification and the appended claims, "upstream", "downstream" and similar terms refer to the direction of flow of pressurized fluid through the connector 1 in the figure 1 Arrow E 1 express.

[0027] The connector 1 comprises a female element 2 and an associated male part, which in this first embodiment is constituted by a male element 3 . The elements 2 and 3 are designed to engage one in the other in the direction of the axis Y-Y', said axis Y-Y' being the longitudinal axis common to the elements 2 and 3 .

[0028] Within the scope of the invention, the proximal part of one of the elements 2 or 3 is facing or close to the tube C to which said element is connected. 1 or C 2 and the distal portion is the portion of the elements facing each other and facing or close to another element when ready for engagement.

[0029] An axial channel 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com