Number checking device

A counting machine and counting technology, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of easy counting errors, low efficiency, inaccurate product packaging quantity, etc., and achieve low cost, simple operation and accurate counting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples.

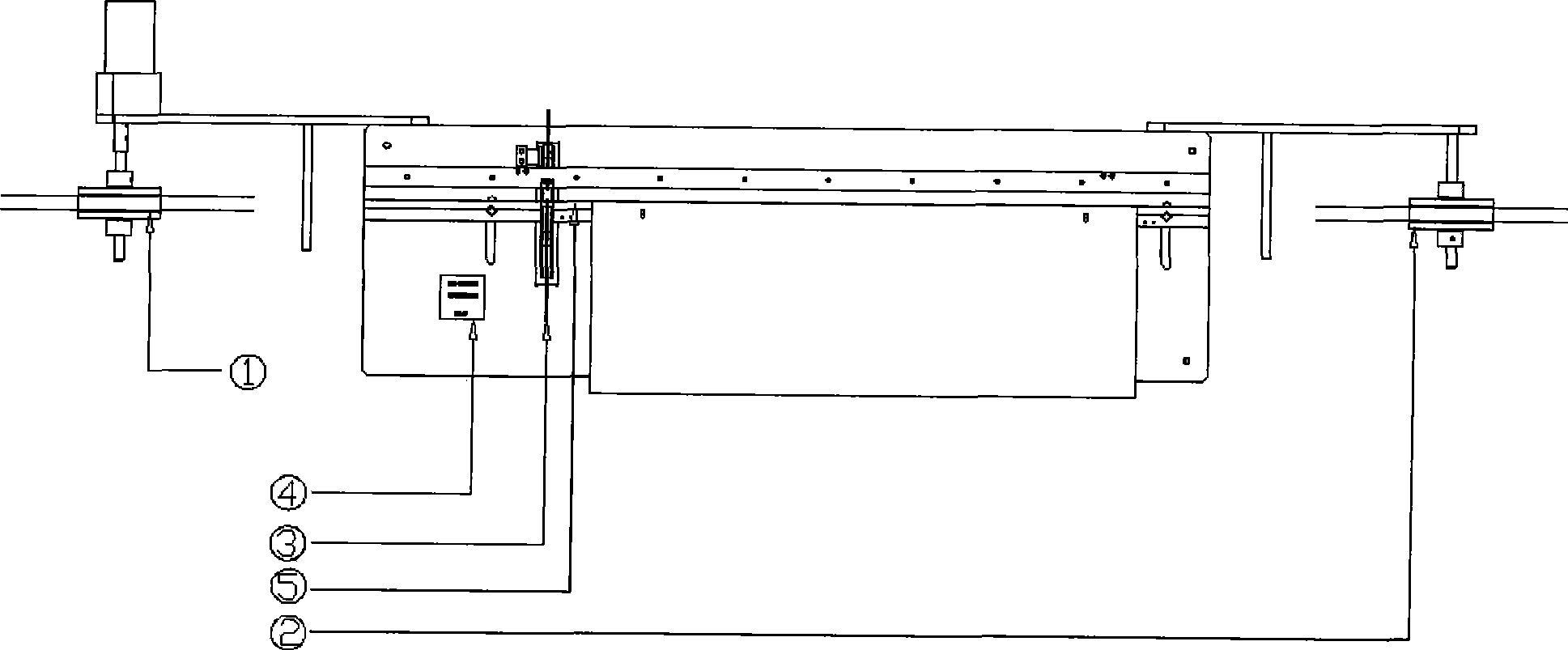

[0012] like figure 1 As shown, the counting machine is mainly composed of a feeding device 1, a receiving device 2, an infrared counting device 3, a counting device 4 and a product track 5. Its working process is to put the carrier tape loaded with products on the product track 5, set the standard quantity of products to be counted, and then press the start button, and the receiving device 2 starts to rotate to drive the carrier tape to move in the product track 5. When the infrared counting device 3 receives the light according to the gap between two adjacent products on the carrier tape, a signal is given to the counting device 4 whenever a gap is encountered, and the counting device 4 counts a number. When the number is equal to the set standard quantity, the material receiving device 2 will stop automatically, so that a roll of products will be automatically counted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com