Thermostatic controlled valve

A thermostatic regulation, valve body technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of limited size design of cold and hot water inlets, inability to meet low pressure and large flow, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

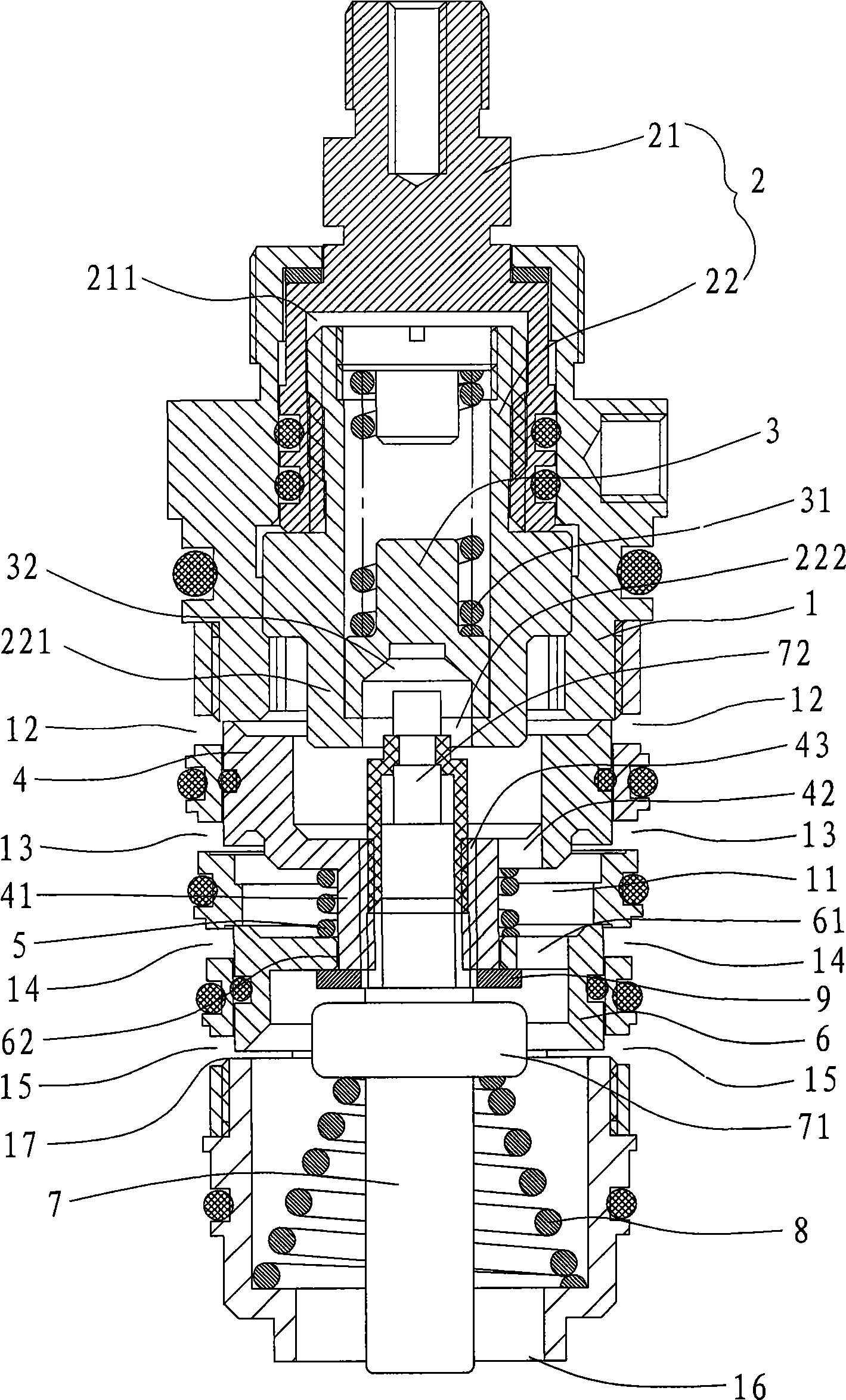

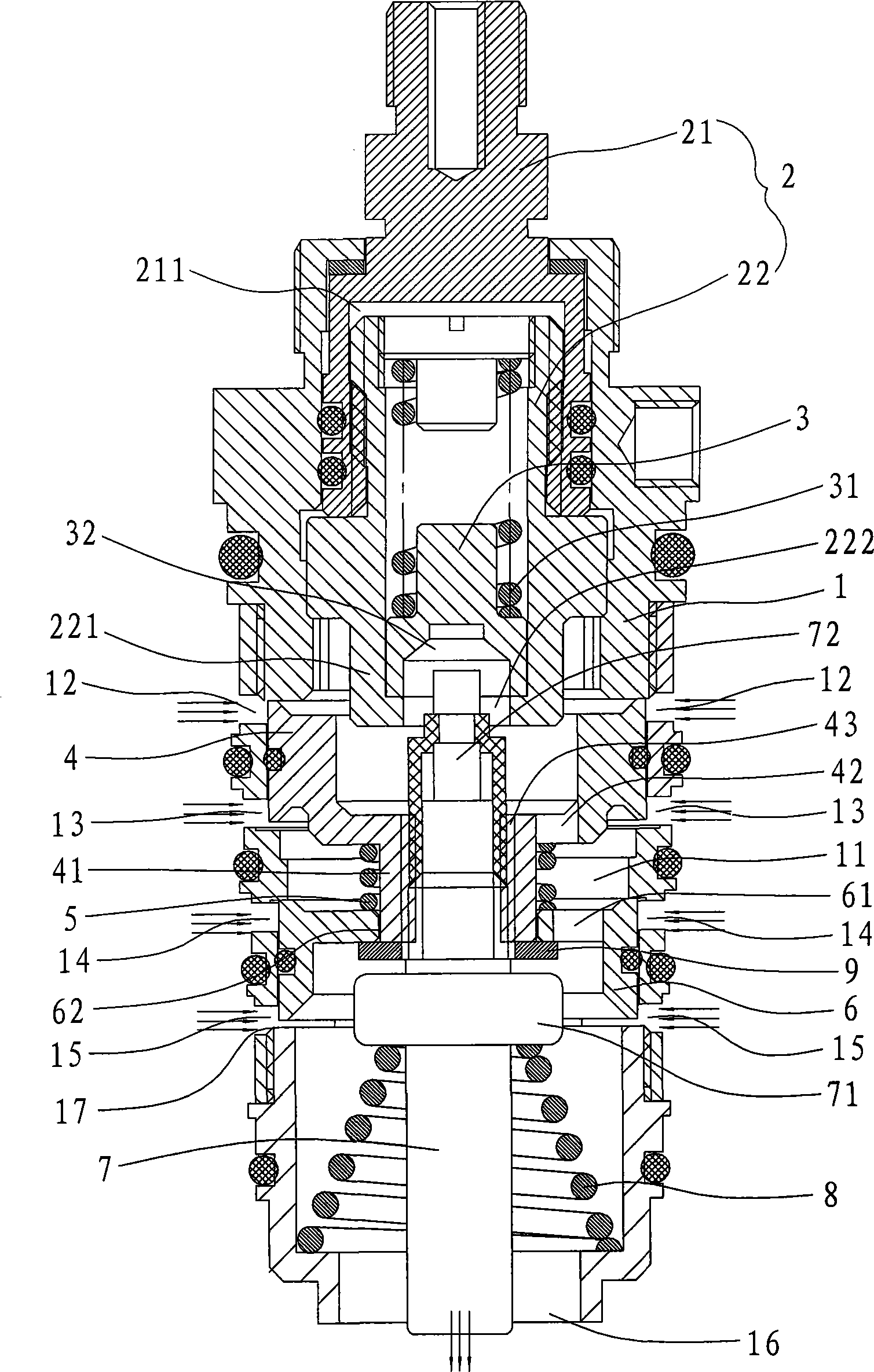

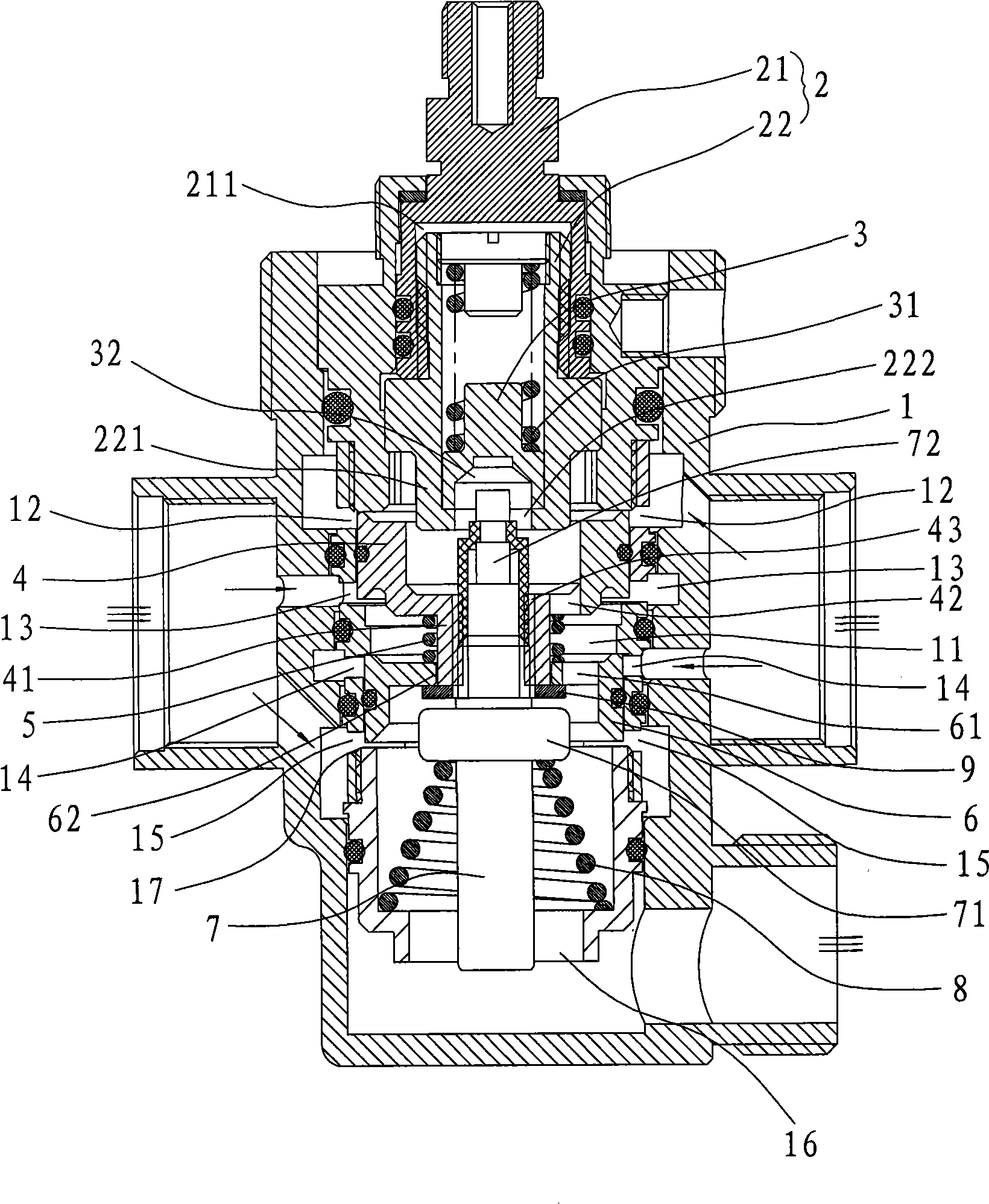

[0020] Such as figure 1 , 2 As shown, a constant temperature control valve provided by the present invention is applied to a hot and cold water supply system, and includes a valve body 1, an adjusting rod 2, a push rod 3, an upper piston 4, a transmission spring 5, a lower piston 6 and a heat sensitive element 7 .

[0021] The valve body 1 is axially formed with a valve cavity 11, and the upper cold water inlet 12 and the upper hot water inlet 13 are arranged on the side wall of the middle part of the valve cavity 11, and the two water inlets are arranged up and down, and on the side wall of the valve cavity 11 The upper hot water inlet 13 below is provided with lower cold water inlet 14 and lower hot water inlet 15 again, and equally two water inlets are arranged up and down; The bottom surface of valve body 1 is provided with outlet 16.

[0022] The adjusting rod 2 includes a rotating rod 21 and a sliding rod 22. The rotating rod 21 is sealed and arranged on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com