Double wind chamber medium air-out type wind uniformly-distributing grate based on wind chambers

An air-out type, double-air chamber technology, which is applied to the grate of the solid grate, the grate, and the air/fuel supply for combustion, can solve the problems of reducing fuel heat conversion efficiency, affecting fuel combustion effect, and wasting energy. , to improve the combustion effect, overcome the lack of static pressure, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

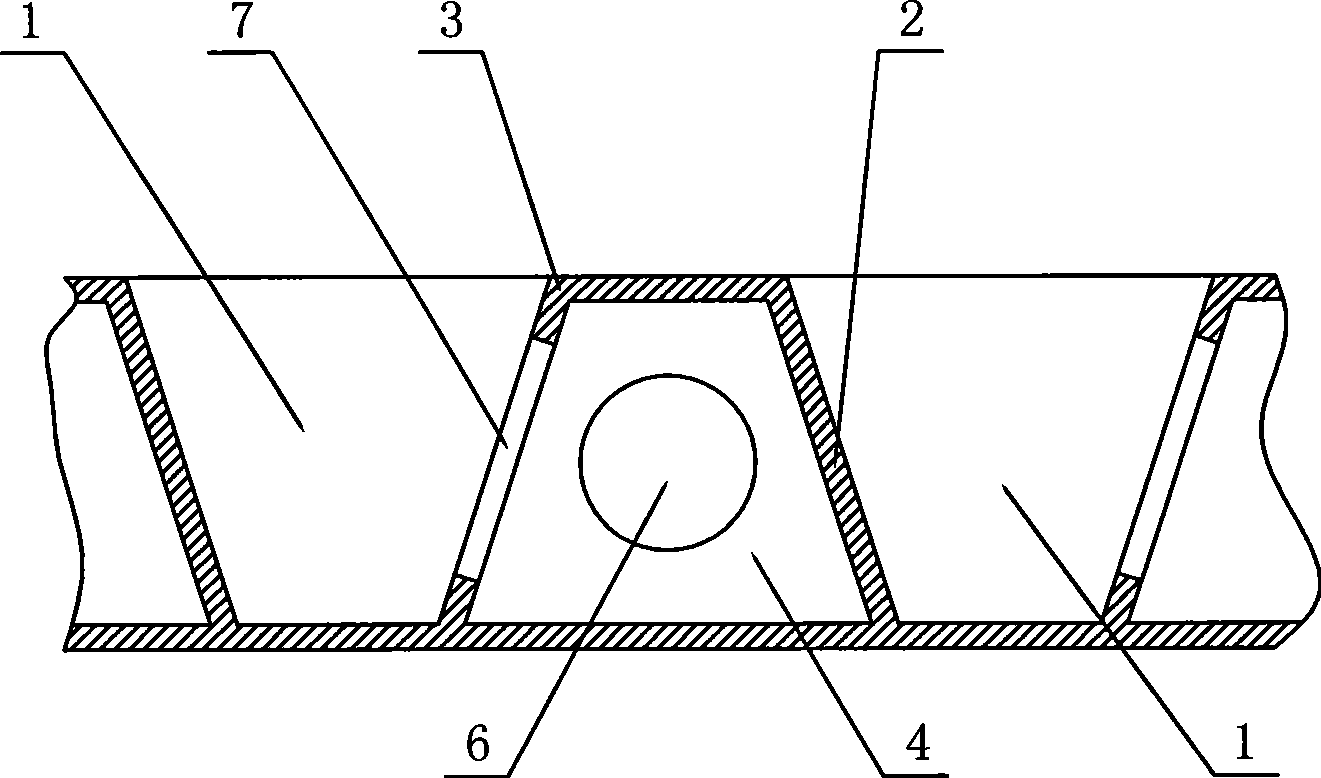

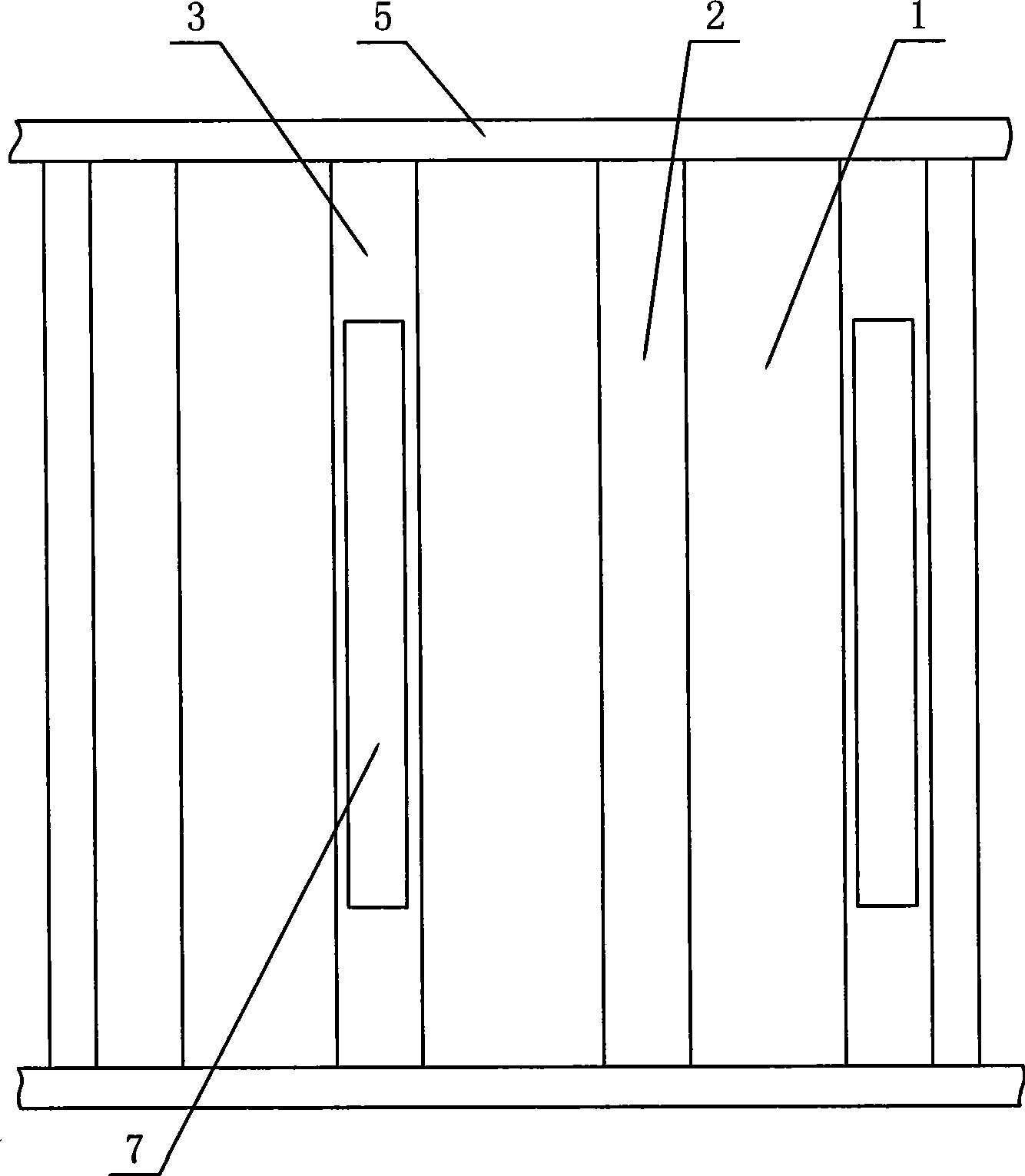

[0009] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like figure 1 Shown: a fire grate with double air chambers with middle air outlet type air distribution chamber for uniform air distribution, with a plurality of main air chambers 1 arranged in the longitudinal direction, and between two adjacent main air chambers 1 there are partitions 2 The auxiliary air chamber 4 formed by , 3 is respectively provided with an air inlet 6 on the opposite side wallboards 5 of the auxiliary air chamber 4, and is respectively provided with an air guide port 7 on the partition plate 2 or partition plate 3, and the air guide port 7 Space is arranged between wallboard 5.

[0010] When air supply is required, the air supply fan sends the air from the two air inlets 5 into the auxiliary air chamber 4, and then enters the main air chamber 1 through the air guide port 6. The air supply is uniform, which can significa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com