Lath laser for implementing Z shape light path by reflecting glass

A technology of slab laser and reflective glass, used in lasers, laser parts, phonon exciters, etc., can solve the problems of reduced total reflection efficiency and poor beam quality, and achieve reduced total reflection efficiency, simple processing, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

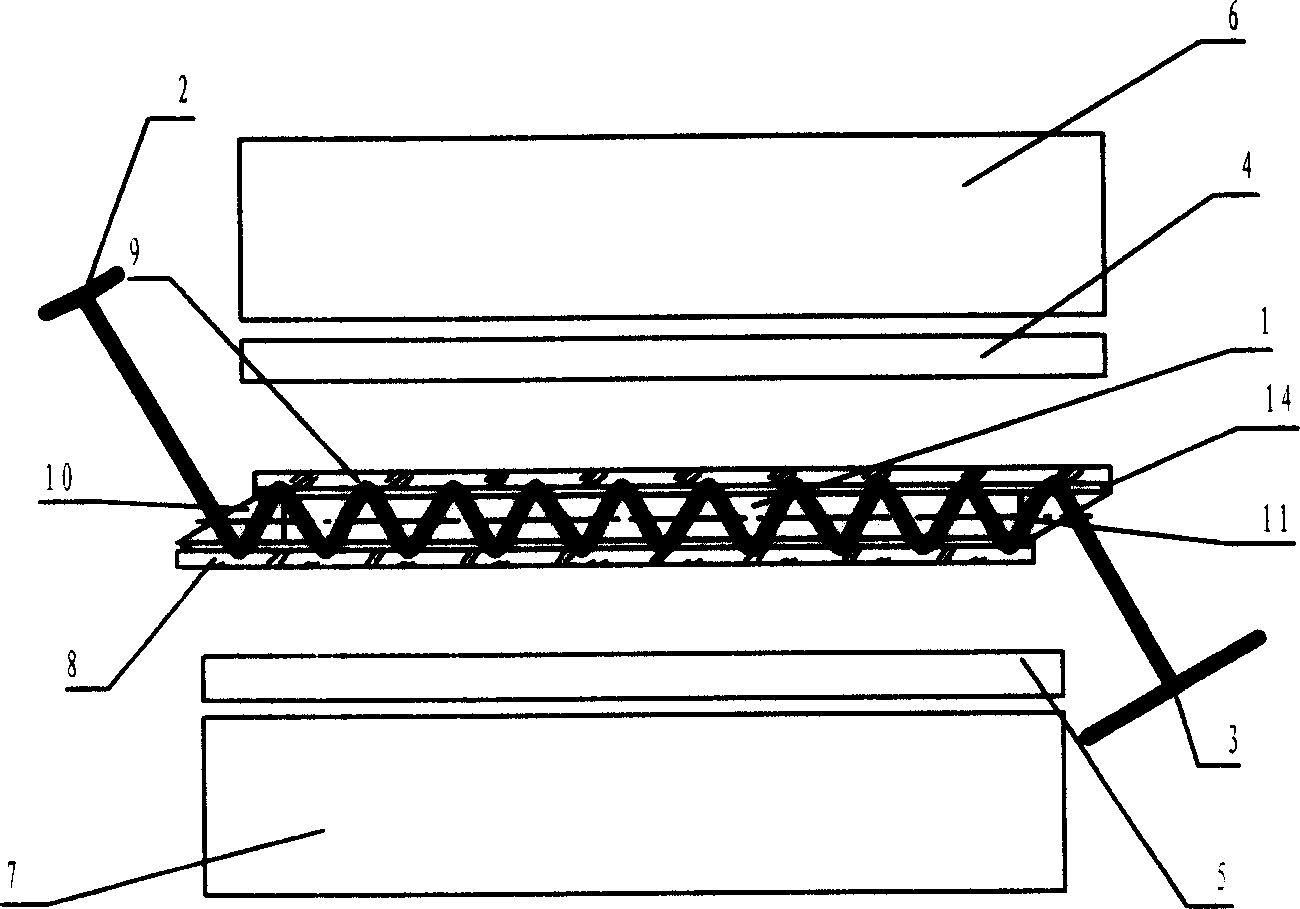

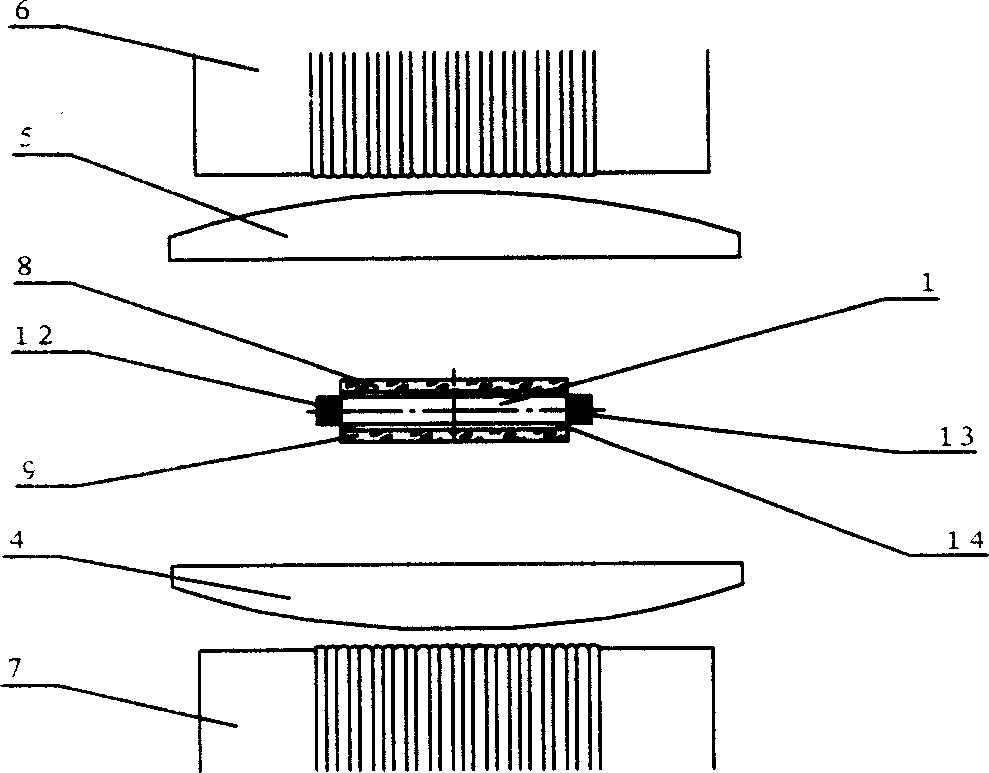

[0022] see figure 1 and figure 2 ,Depend on figure 1 , figure 2 It can be seen that the reflective glass of the present invention realizes the slab laser of the Z-shaped optical path, including a laser medium, a pump source, and a pump light coupling system located between the rear cavity mirror 2 and the front cavity mirror 3, and its characteristics are:

[0023] The laser medium is a rectangular parallelepiped thin-slice laser crystal slab 1, and a pair of reflective glasses 7, 8 of the laser wavelength are respectively provided in parallel outside the left and right two large surfaces of the thin-slice laser crystal slab 1 through a sealing element 14. An absorber 12, 13 is provided on the upper and lower sides of the thin laser crystal slab 1, and the cooling water channel is between the thin laser crystal slat 1 and the reflective glass 7, 8;

[0024] The pumping source is composed of double column laser diode arrays 6, 7, cylindrical coupling lenses 4, 5 are betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com