Combined type variable-pressure exhaust passage structure

An exhaust duct and combined technology, applied in the direction of vertical pipes, building components, building structures, etc., can solve the problems of unfavorable mass production, inconvenient use, inconvenience, etc., and achieve easy use and transportation, easy standardization, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

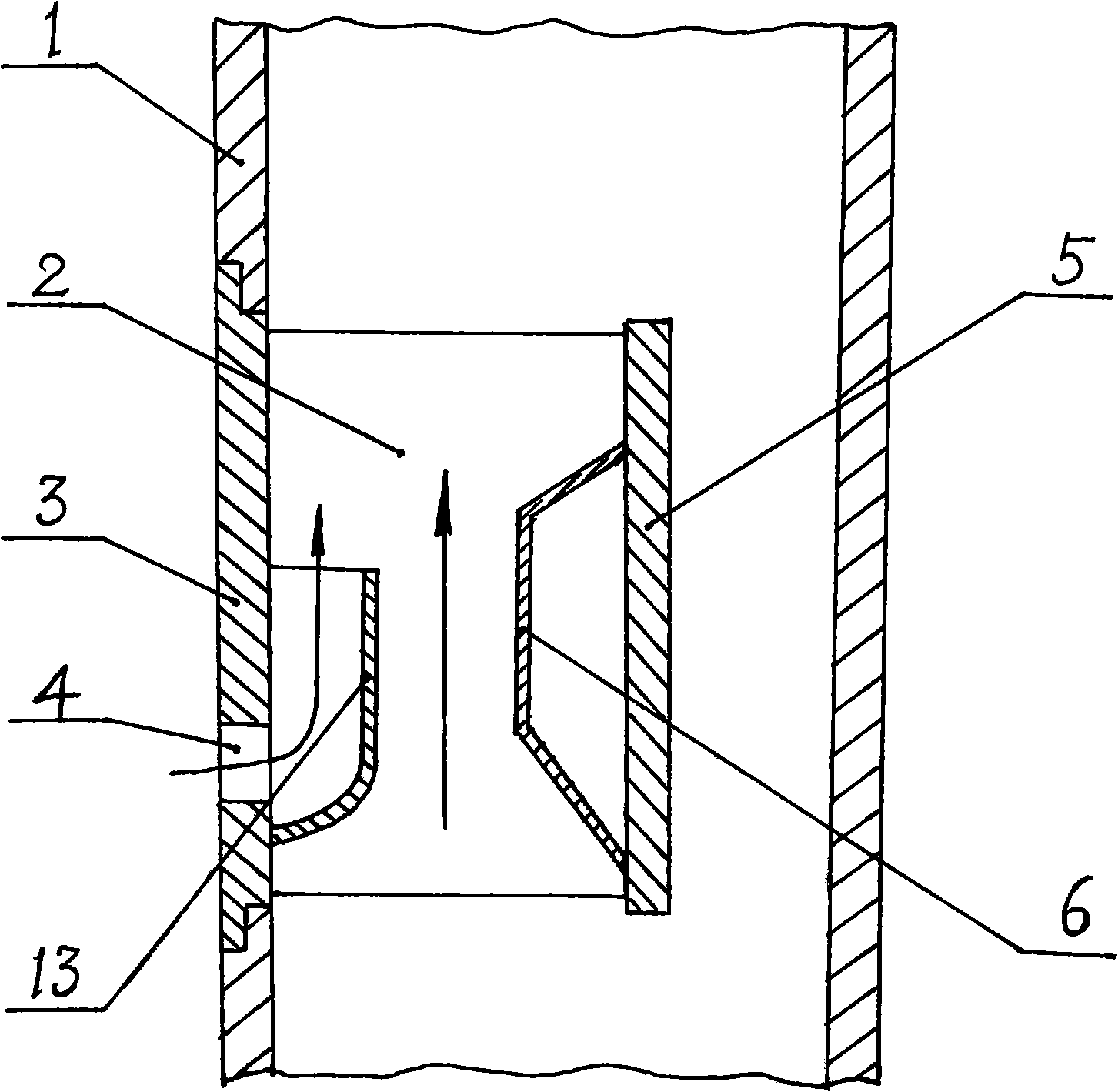

[0022] Example 1, in figure 1 In the structural schematic diagram shown, the present invention includes an exhaust pipe 1 and an airflow pressure changing part arranged on the exhaust pipe 1 and protruding into its inner cavity, wherein the airflow pressure changing part is reduced by narrowing its guide passage The air flow conduction cross-sectional area is used to change the air flow velocity, and the air inlet 4 is arranged on the outer assembly plate 3 of the air flow pressure transformation component, and the air flow pressure transformation component is assembled on the exhaust air flow through its outer assembly plate 3. On the gas pipeline 1, the two constitute a combined assembly structure. exist figure 1 Among them, the airflow pressure conversion component includes an outer assembly plate 3, an inner partition plate 5 and a connecting piece connecting the two as a whole, and it also includes an air intake guide pipe 13 arranged on the inner wall of the outer assem...

Embodiment 2

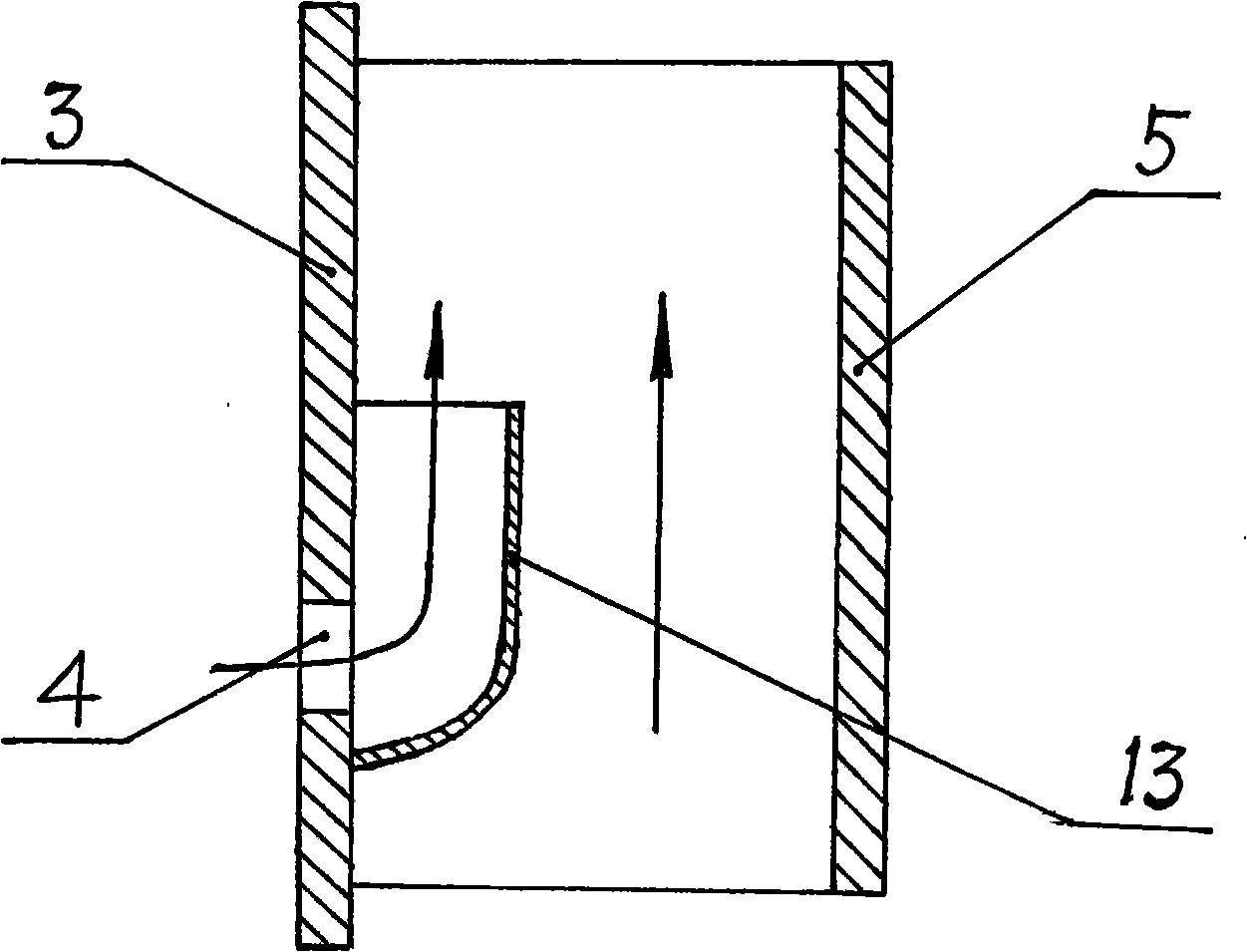

[0023] In Embodiment 2, the present invention has the same structure as that in Embodiment 1 except that the pressure-transforming protrusion is omitted. exist figure 2In the schematic diagram shown, the airflow pressure conversion part of the present invention includes an outer mounting plate 3, an inner partition plate 5 and a connecting piece connecting the two as a whole, and it also includes an air inlet arranged at the inner wall of the outer mounting plate 3. The guide pipe 13 , the air inlet of the air inlet guide pipe 13 and the air inlet 4 provided on the outer assembly plate 3 are butted and communicated with each other. The arrangement of the air intake guide pipe 13 reduces the cross-sectional area of the guide channel of the airflow pressure transformation component, thereby changing the flow rate of the airflow in the channel.

Embodiment 3

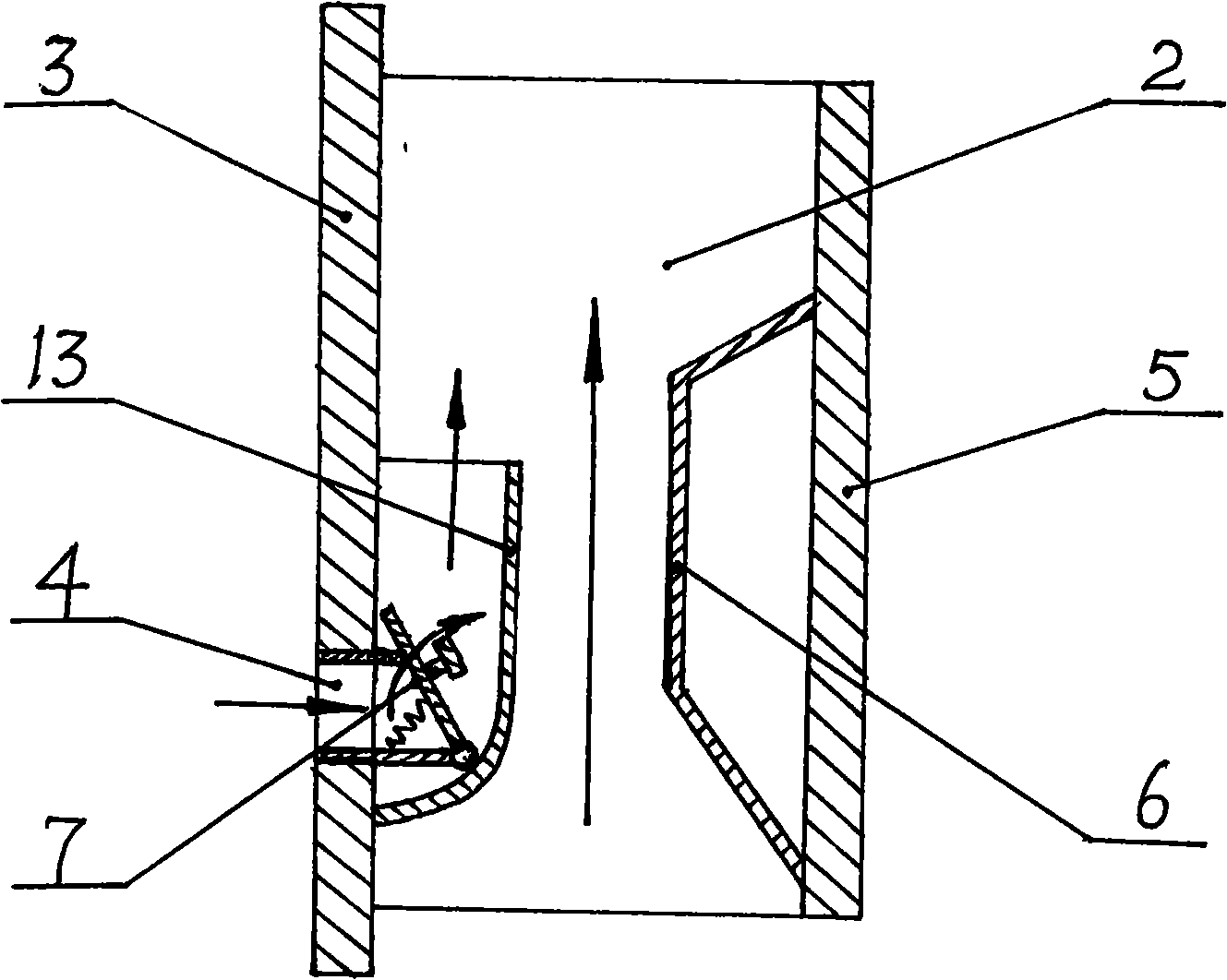

[0024] In Embodiment 3, the present invention has the same structure as that in Embodiment 1 except that a one-way exhaust valve is added. exist image 3 In the schematic diagram shown in the structure, the airflow pressure conversion part of the present invention includes an outer assembly plate 3, an inner partition plate 5 and a connecting piece connecting the two as a whole. The above-mentioned connecting piece is two connecting plane plates, and the connecting plane plate 2 is one of them. In addition, the air flow pressure changing component of the present invention also includes an air intake guide pipe 13 arranged on the inner wall of the outer mounting plate 3, a pressure changing protrusion 6 arranged on the inner wall of the inner partition 5, and a top when the air is inhaled. The one-way exhaust valve 7 that is automatically closed when it is open or does not take in air, the intake pipe mouth of the air intake guide pipe 13 is connected to the air inlet 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com