Assembled crusher

A crusher and combination technology, which is applied in the fields of cocoa, grain processing, food science, etc., can solve the problems of small crushing ratio, single crushing force mode, and ideal particle size requirements of refractory ore into the mill, so as to achieve low energy consumption and high crushing efficiency. greater effect than

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

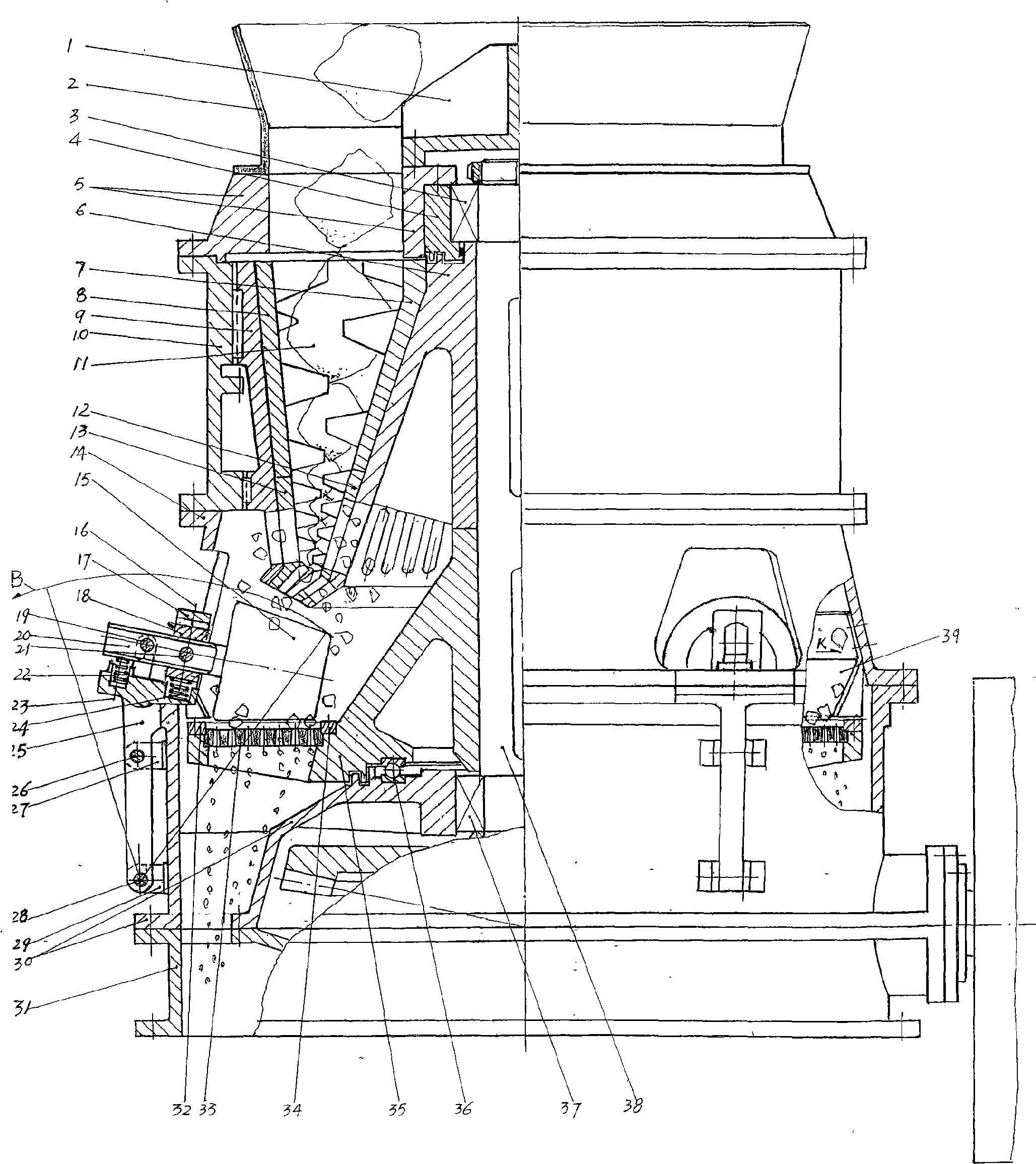

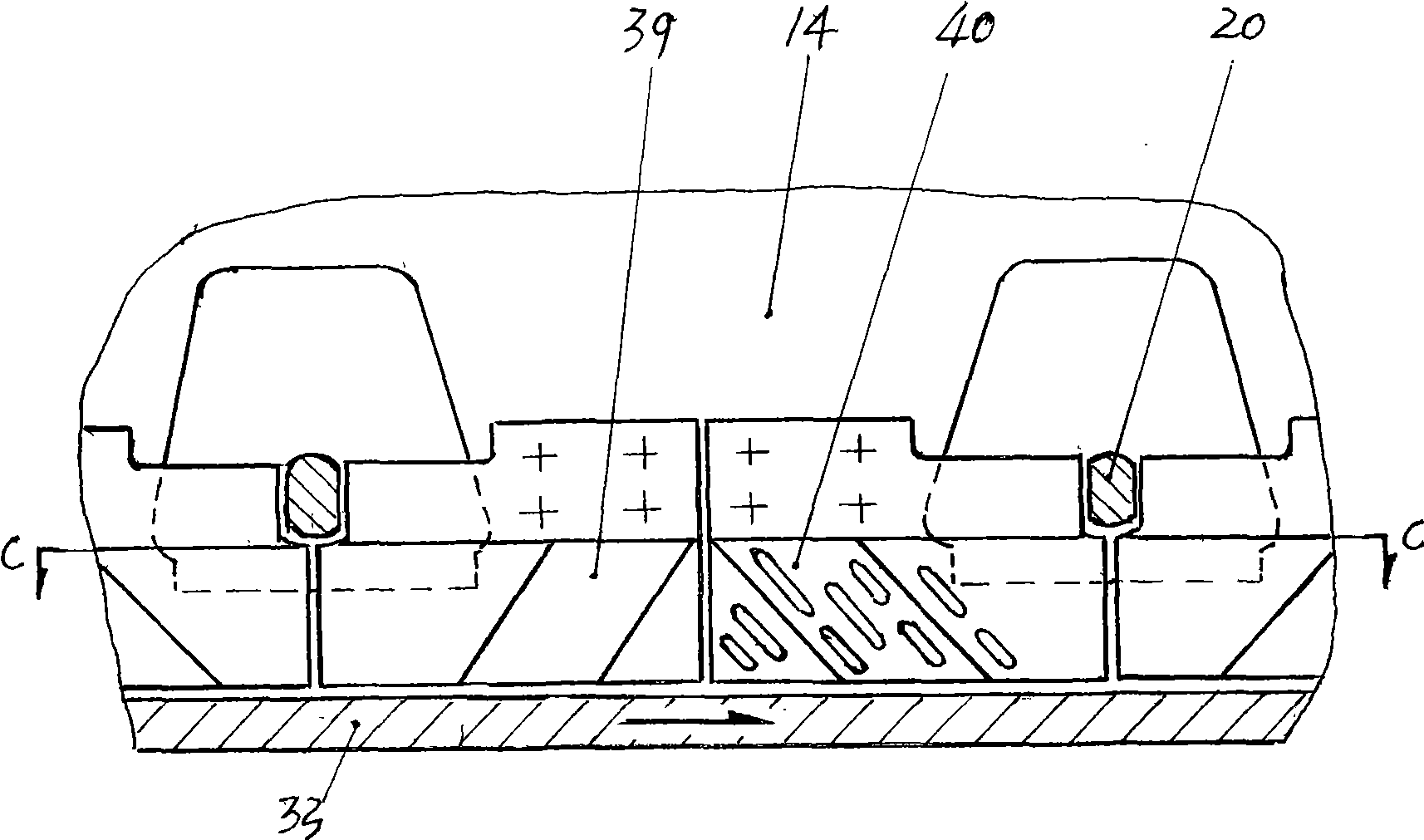

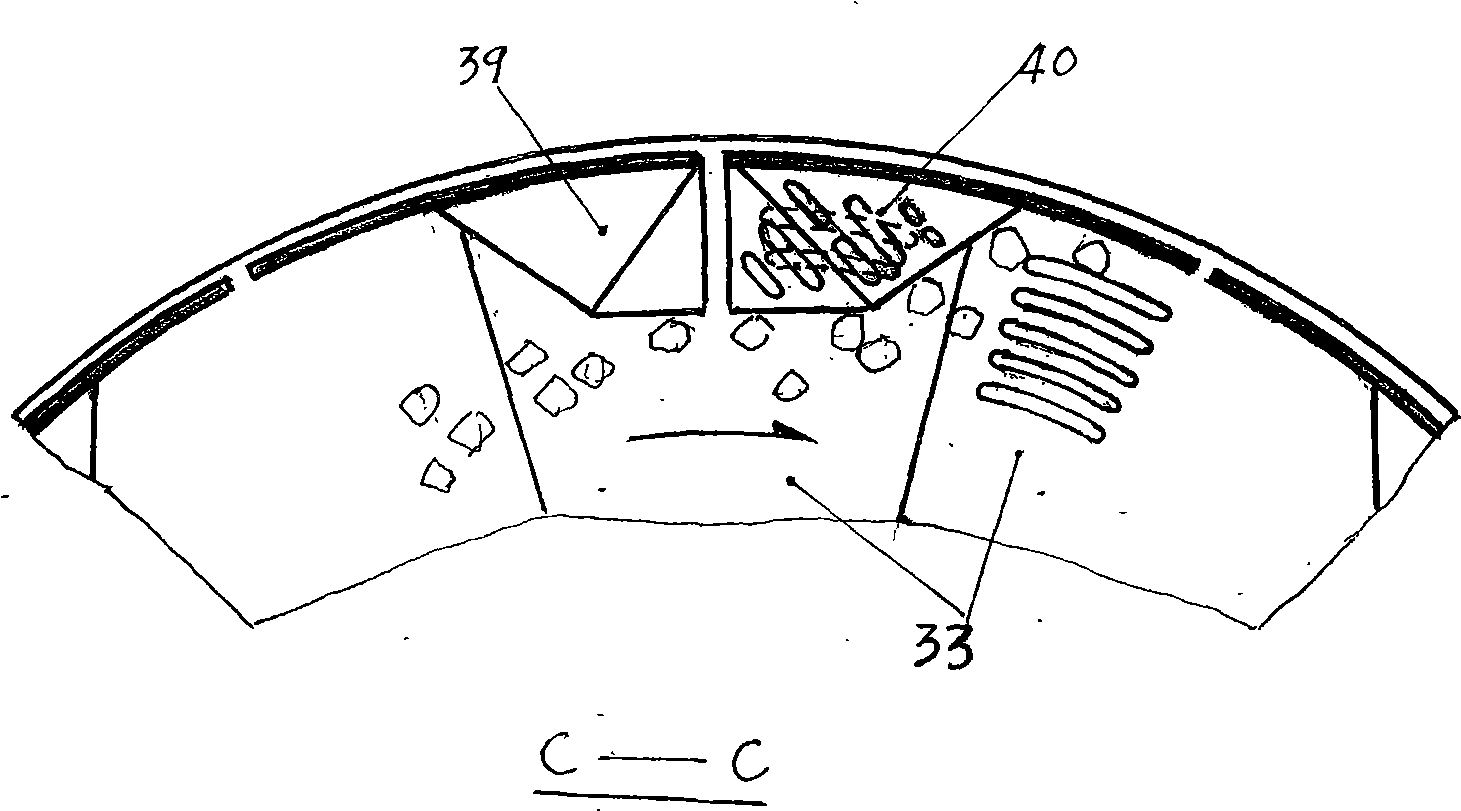

[0013] exist figure 1 Among them, the main shaft [38] is connected with the upper box [30] of the reducer by the lower bearing [37], and the main shaft [38] is keyed to the disc supporting sleeve [35], the dynamic cone sleeve [6], and connected to the upper bearing [3] , the pressure bearing [36] under the disc support sleeve sits on the upper box [30] of the reducer, and there is a split disc [33] with sieve holes on the outer ring surface of the disc support sleeve [35]. [32], the inner bevel [34] is connected with the disc support sleeve [35]; the upper movable bevel tooth plate [7] and the lower movable bevel tooth plate [12] are installed on the conical surface of the movable cone sleeve [6]; The outer circle of the bearing [3] is installed with the bearing sleeve [4], the spoke rib cover [5] of the shaft sleeve, the inner upper part is connected with the material guide cap [1], and the hopper [2] is installed on the outer circle of the spoke rib cover [5] of the axle sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com