Five-orientation-body multifunctional oil press

A hydraulic press, multi-functional technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve problems such as unsatisfactory, complicated processing and manufacturing, single work of the oil cylinder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] This embodiment will be further described below in conjunction with the drawings:

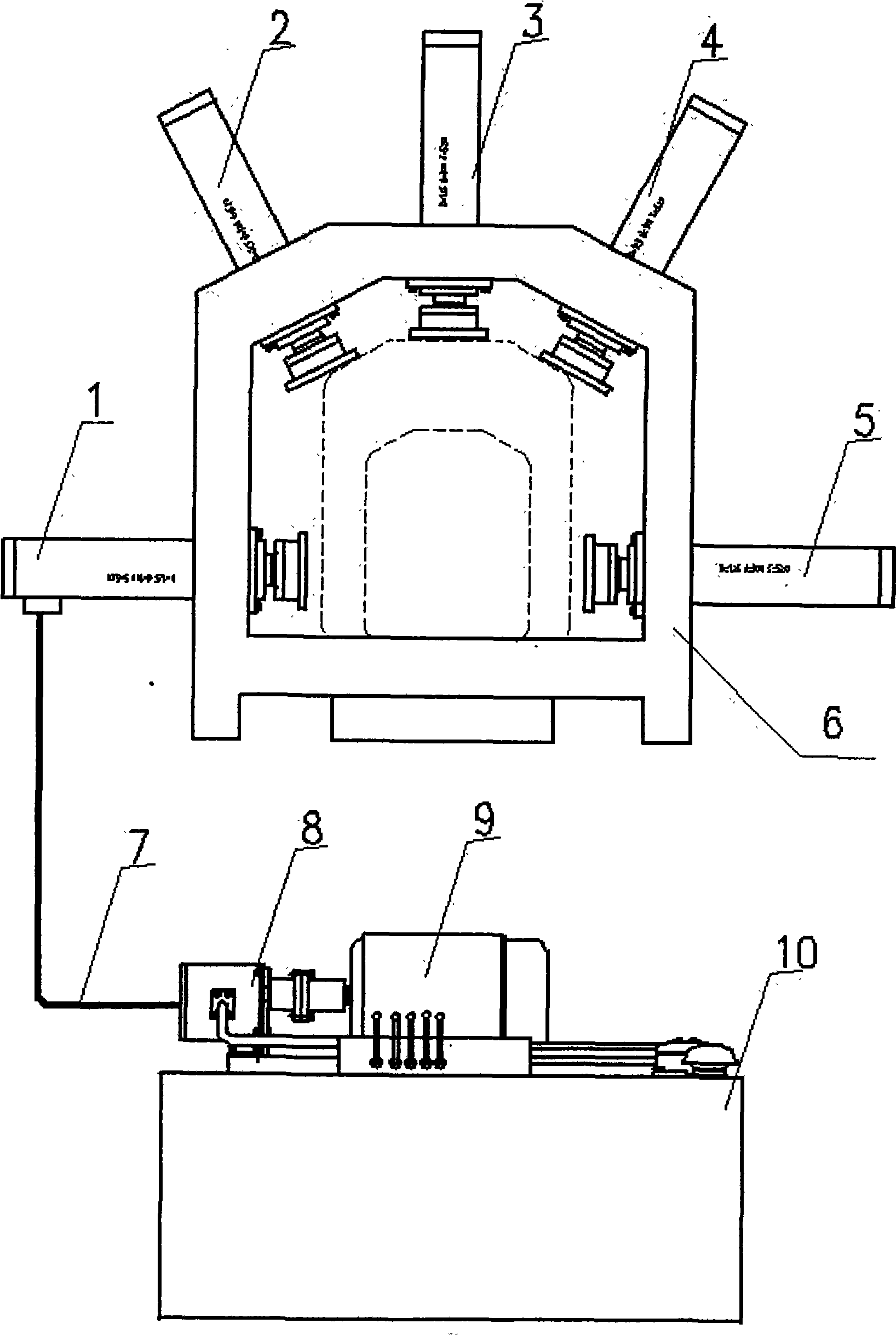

[0011] by figure 1 It can be seen that the five oil cylinders are fixed to the hydraulic machine frame 6 by bolts in five positions of 1 to 5 points, and the pressure plate is sleeved on the head of the oil cylinder by bolts to form a hinge. The workpiece to be repaired is placed in the middle of the frame 6 and the oil cylinders 1 to 5. . The operation of each oil cylinder is controlled by a five-link control valve. The motor 9 is connected to the gear pump 8. The gear pump 8 sucks oil from the oil tank 10 through the hydraulic oil pipe 7 and enters the oil cylinder through the control valve and the hydraulic oil pipe to realize the work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com