Glue-dipping type braille printing device

A printing device and braille technology, applied in printing, typewriters, etc., can solve the problems of difficult recognition of braille books, high production cost, inconvenient maintenance, etc., and achieve the effect of improving dispensing work efficiency, reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

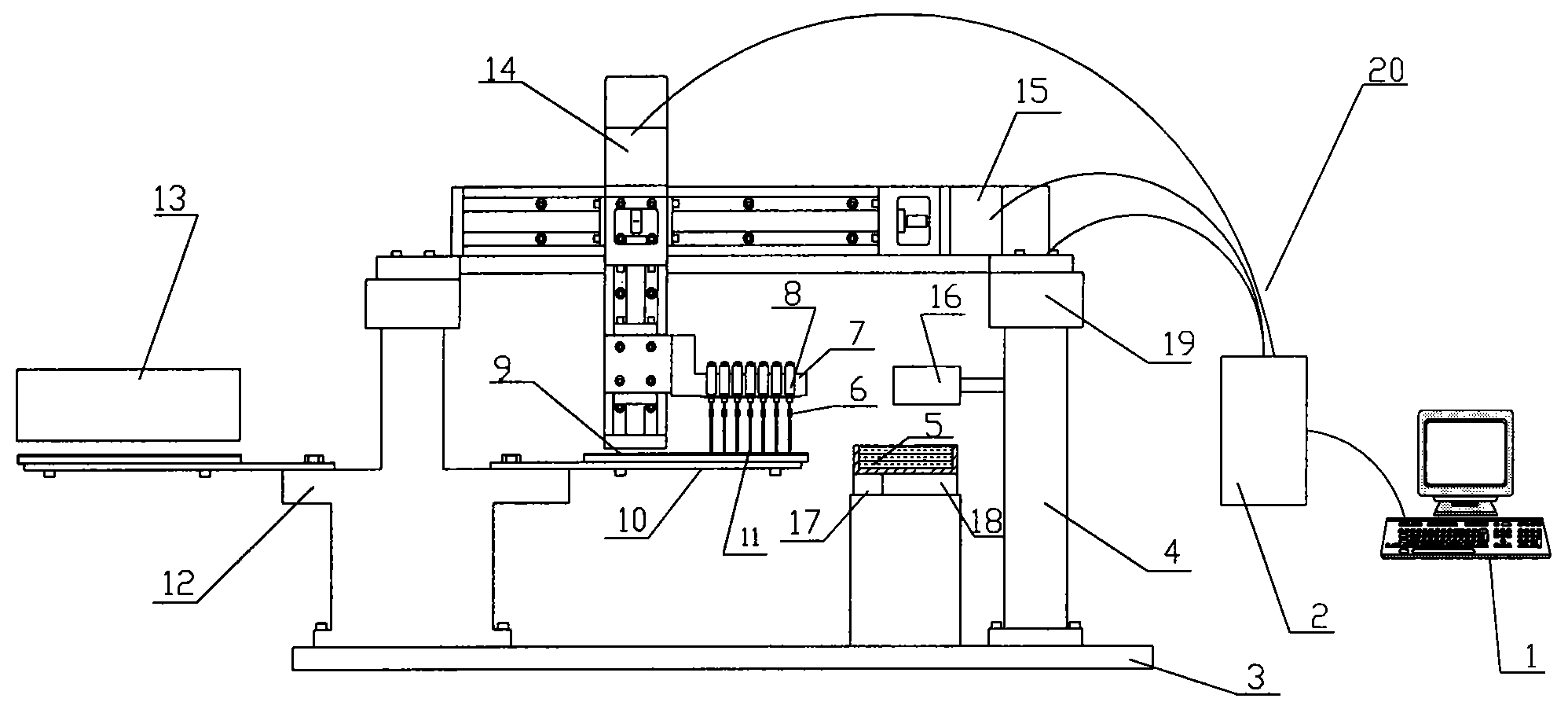

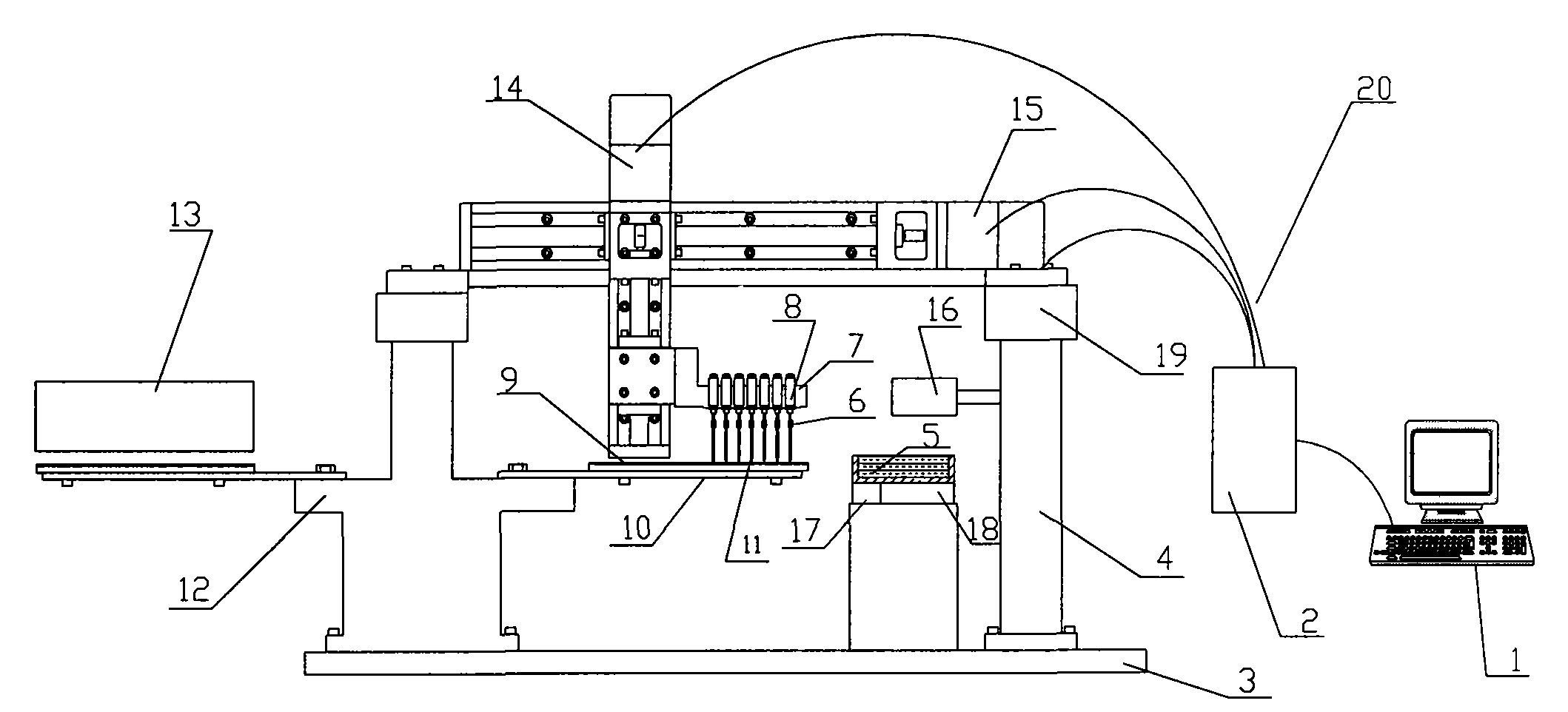

[0045] As shown in Figure 1, the glue-dipped braille printing device of the present invention is composed of a computer control system and a printing subsystem, wherein the computer control system includes a typesetting host computer 1 and a control driver 2, and the typesetting host computer 1 is configured with a device capable of converting ordinary documents It is an ordinary PC with braille document software conforming to national standards, the control driver 2 and the printing subsystem are electrically connected to each other through a cable 20, and the control driver 2 controls the printing subsystem to complete the corresponding operation.

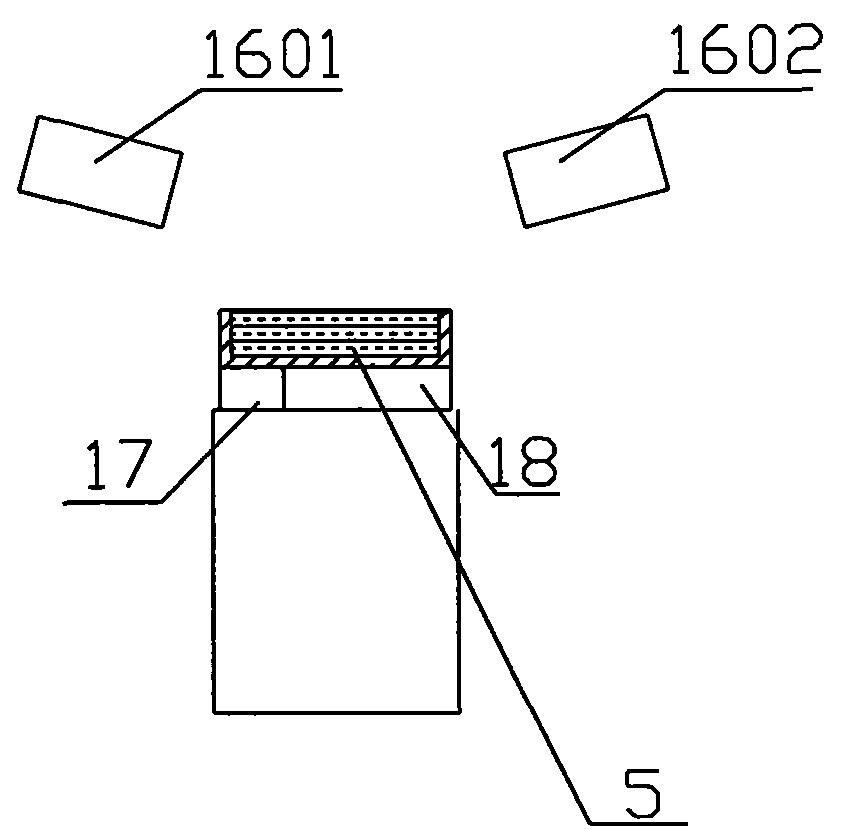

[0046] The printing subsystem consists of a body, a multi-dimensional motion mechanism, a glue supply unit, a glue dispensing unit and a curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com