Draining and air guide sleeve used for rushing and ejecting entad pile-sinking method

A technology of diversion cover and pile sinking, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., which can solve the problems of piling machine loss and poor slag discharge effect, and achieve the effect of reasonable structure and overcome the poor slag discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

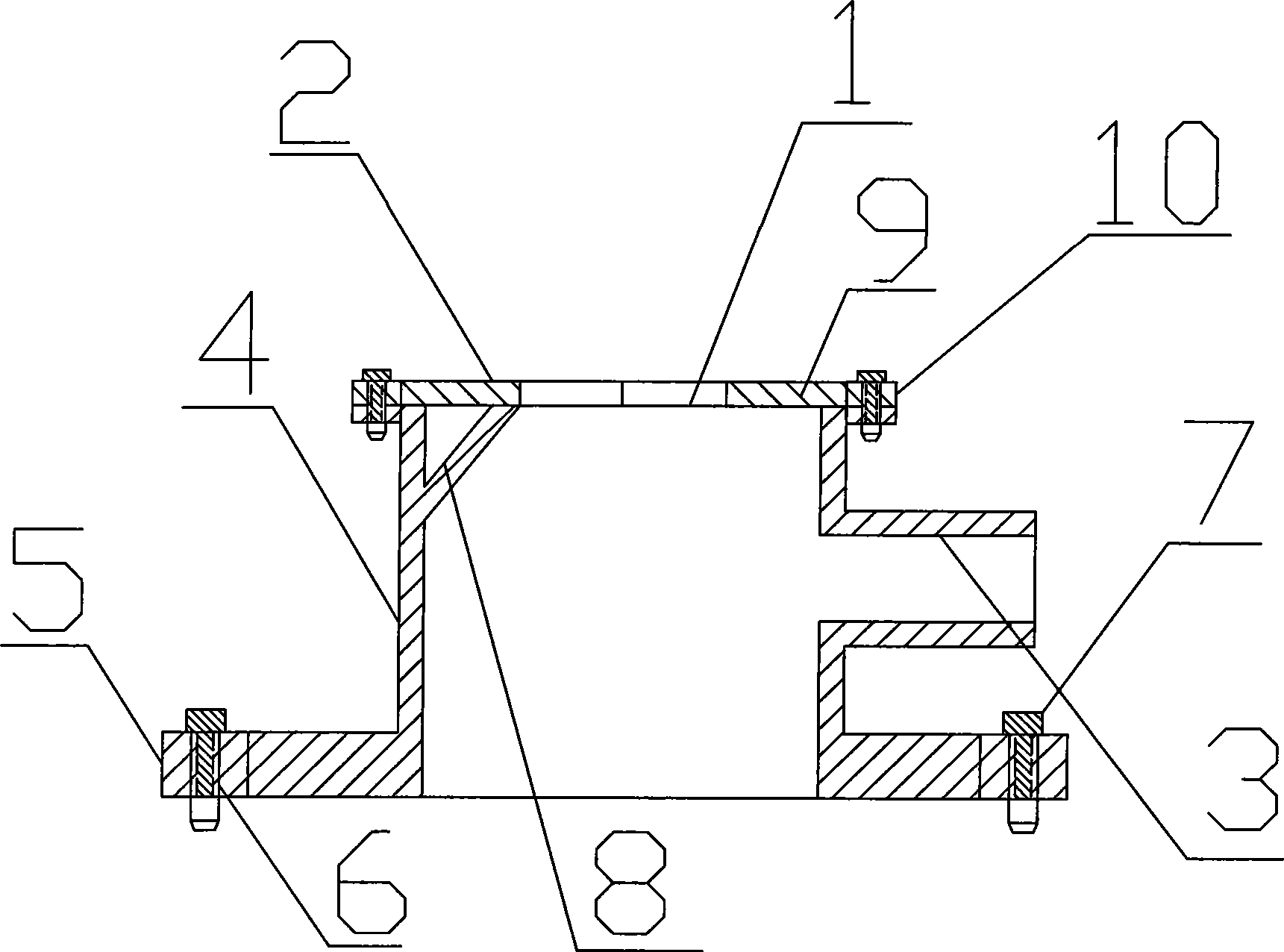

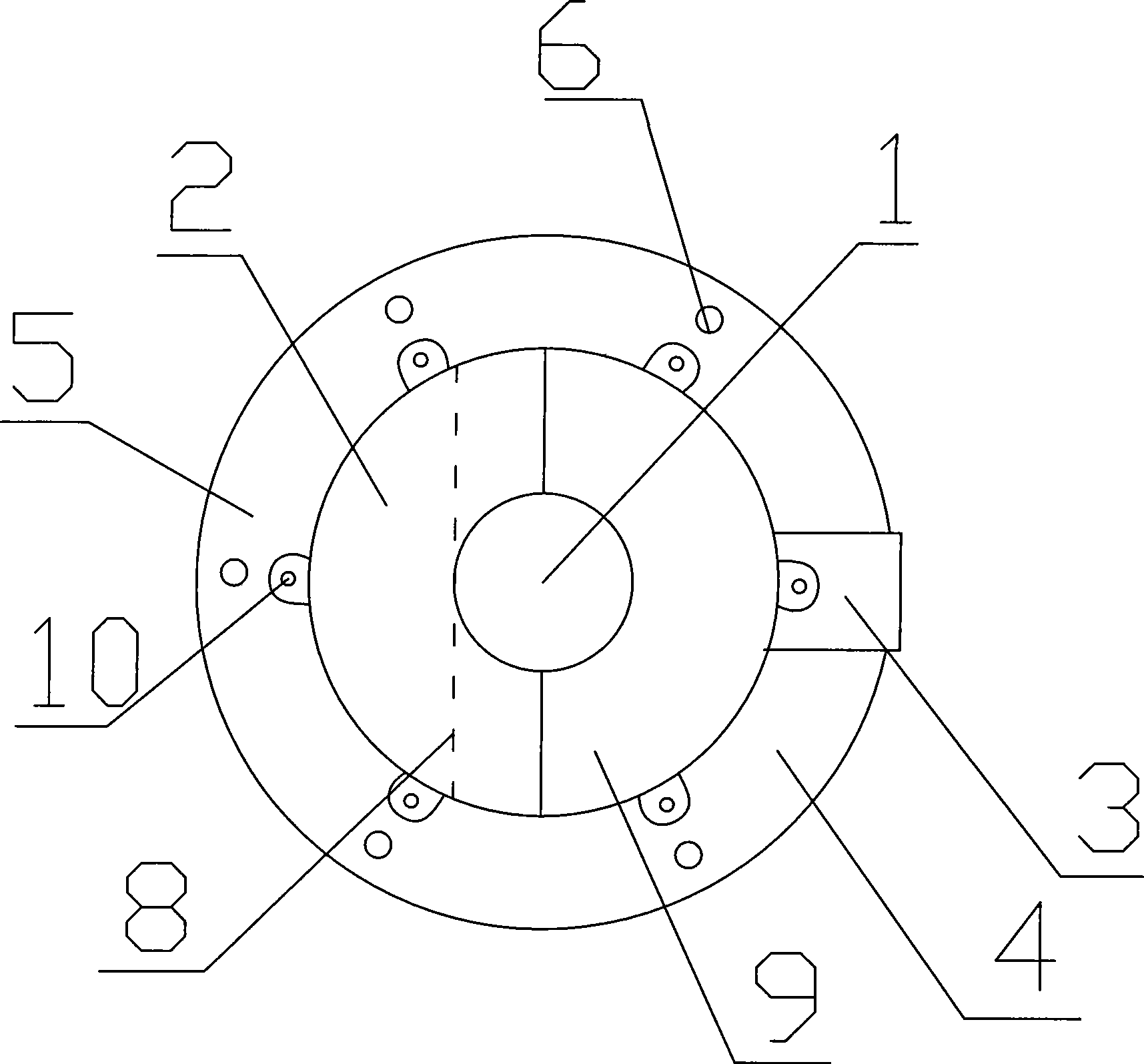

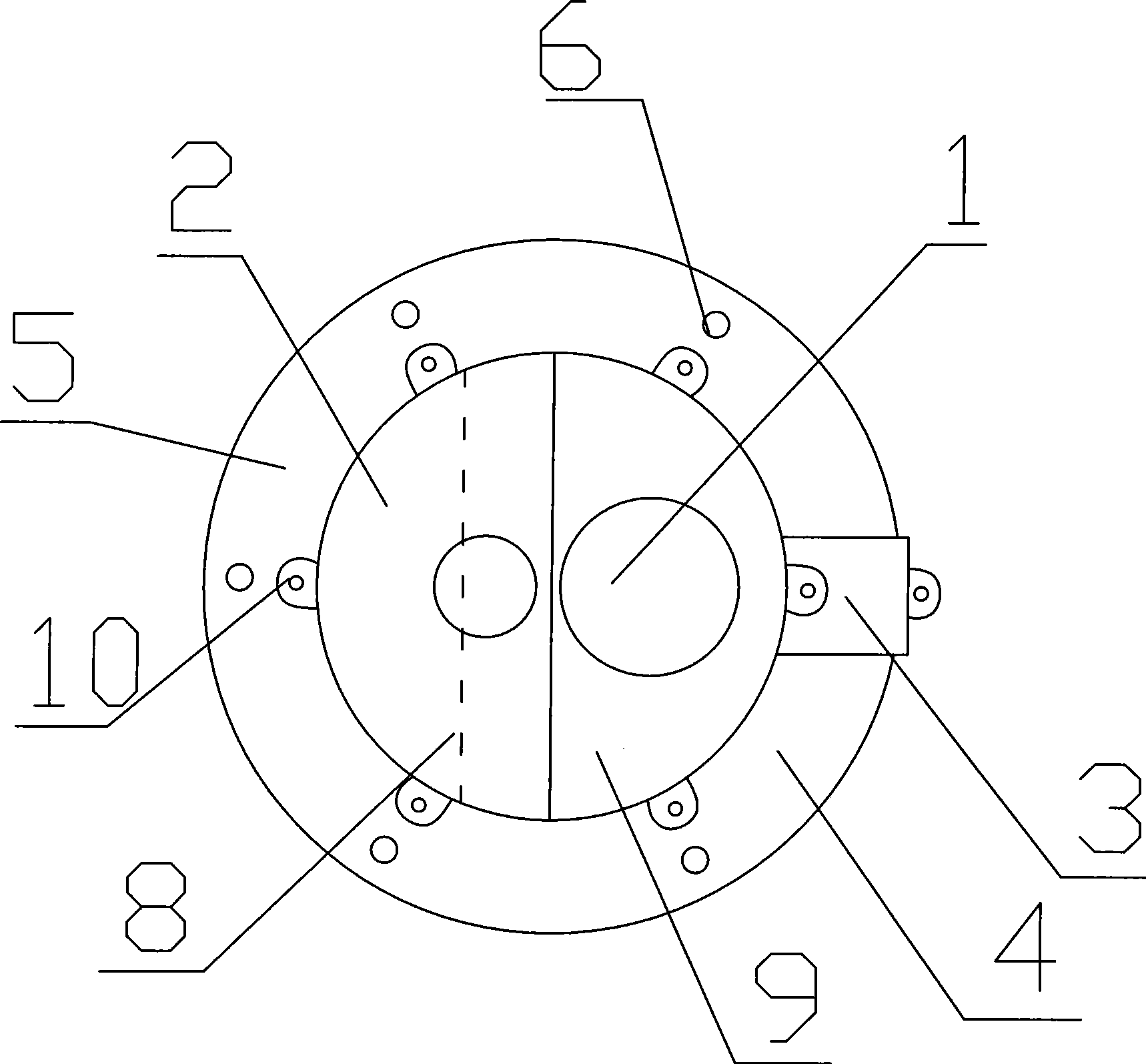

[0012] The embodiment of the present invention is characterized in that it consists of an upper cover 2 with a through hole 1 in the middle and a skirt 4 with a slurry discharge pipe 3 on the side wall connected by a detachable connection mechanism.

[0013] The lower side of the above-mentioned shroud skirt is provided with a connecting ring piece 5, and the connecting ring piece is provided with a connecting bolt through hole 6 and a bolt 7 corresponding to the threaded hole of the pile end plate.

[0014] A slurry discharge pipe is provided on one side of the above-mentioned slurry discharge guide skirt, and a slurry slant plate 8 is provided on the other side to facilitate the flow of the upper discharge slurry to the slurry discharge pipe. The upper cover is composed of two halves 9, and the The screw connection 10 on its peripheral lug is connected to the skirt.

[0015] When installing, buckle the present invention on the upper port of the pile body, and connect and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com