Circular groove skeleton type optical cable

A skeleton optical cable and circular groove technology, which is applied in the field of optical cables, can solve the problems of increased friction and extrusion of optical fibers, small space in rectangular grooves of skeleton cables, and loss, etc., to increase the number of loads, reduce fiber loss, and improve accommodation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

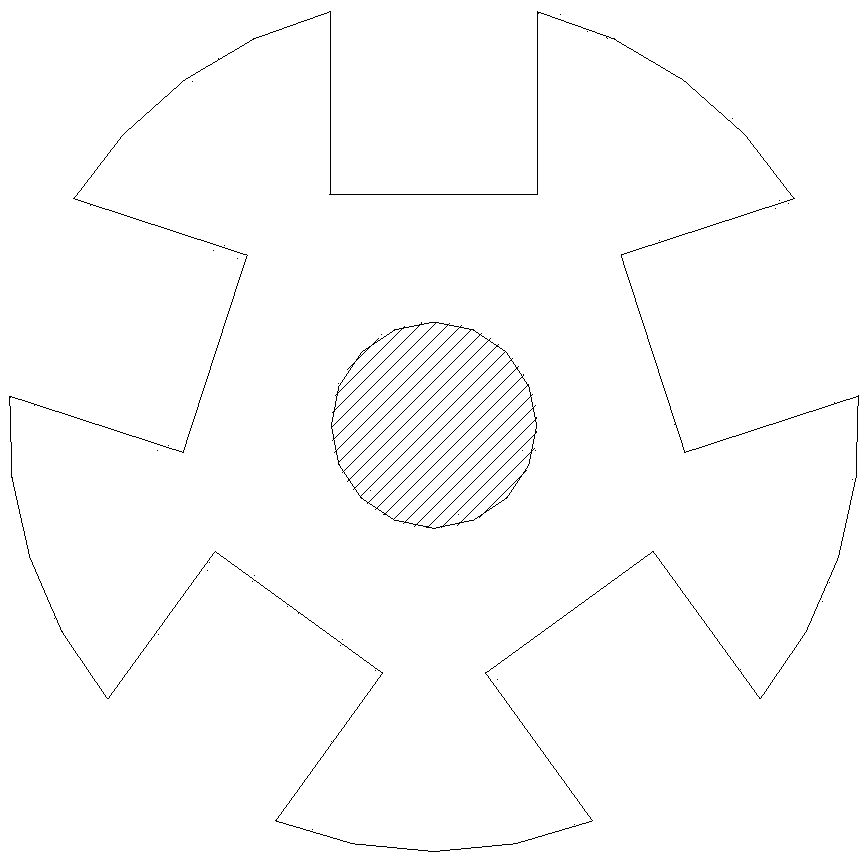

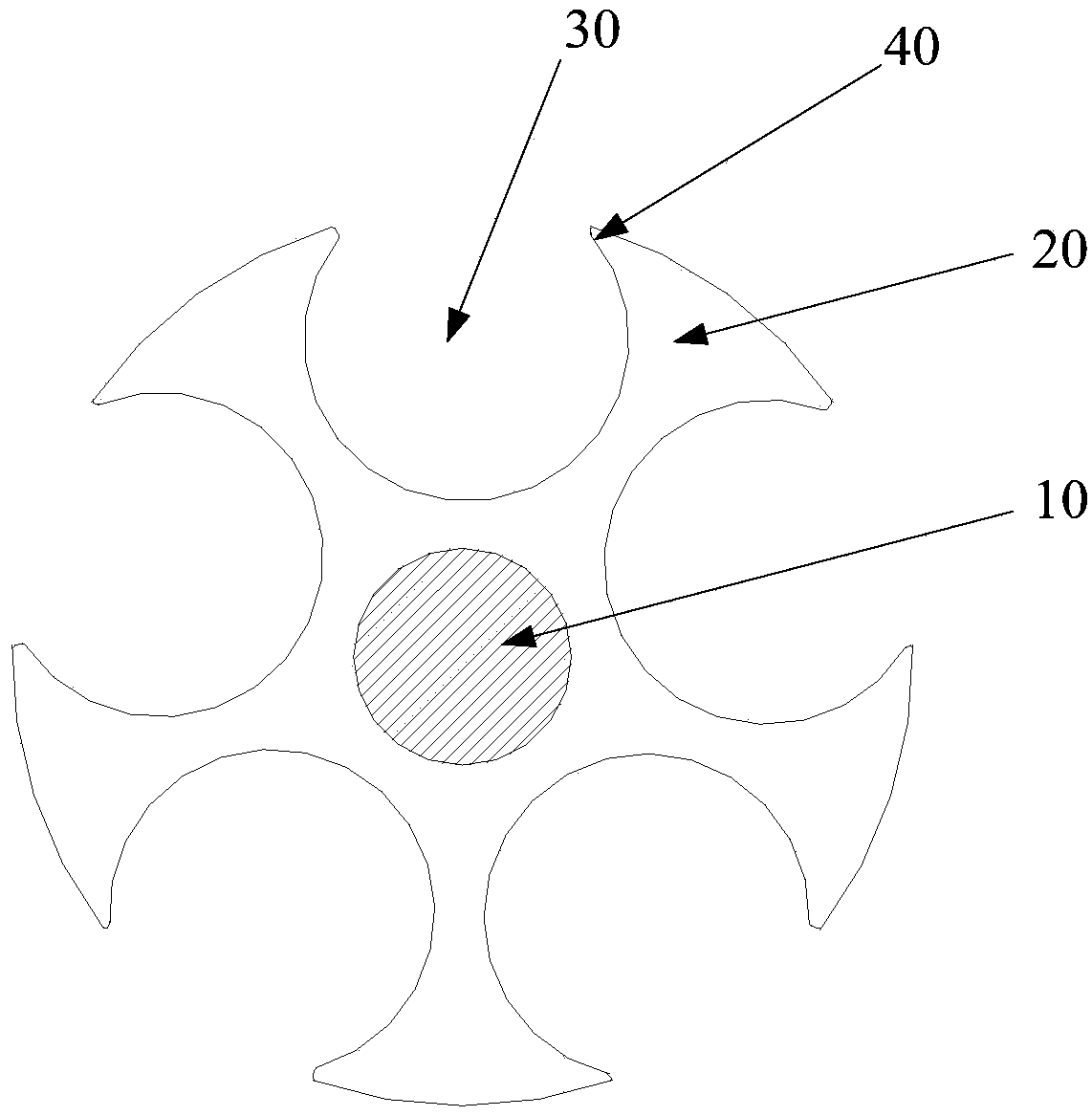

[0021] Considering that the skeleton groove of the current skeleton optical cable generally adopts a rectangular groove or a U-shaped groove, the optical fiber ribbon in it is easy to damage the optical fiber when it is subjected to extrusion, side bending, friction, tensile stress and compressive stress, thereby causing loss. Therefore, the present invention provides a circular groove skeleton type optical cable.

[0022] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a preferred embodiment of the circular groove skeleton optical cable of the present invention.

[0023] Such as figure 2 As shown, the circular groove skeleton type optical cable proposed in this embodiment includes a strengthening member 10 and a skeleton 20 arranged on the outer periphery of the strengthening member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com