Butter process without generating carcinogen and foodstuff atomization low-temperature fryer

A technology for food oil and carcinogens, applied in the fields of food frying and frying, can solve the problems of the impact, threat and pollution of fried food, and achieve the effect of not abandoning and wasting, and saving oil consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

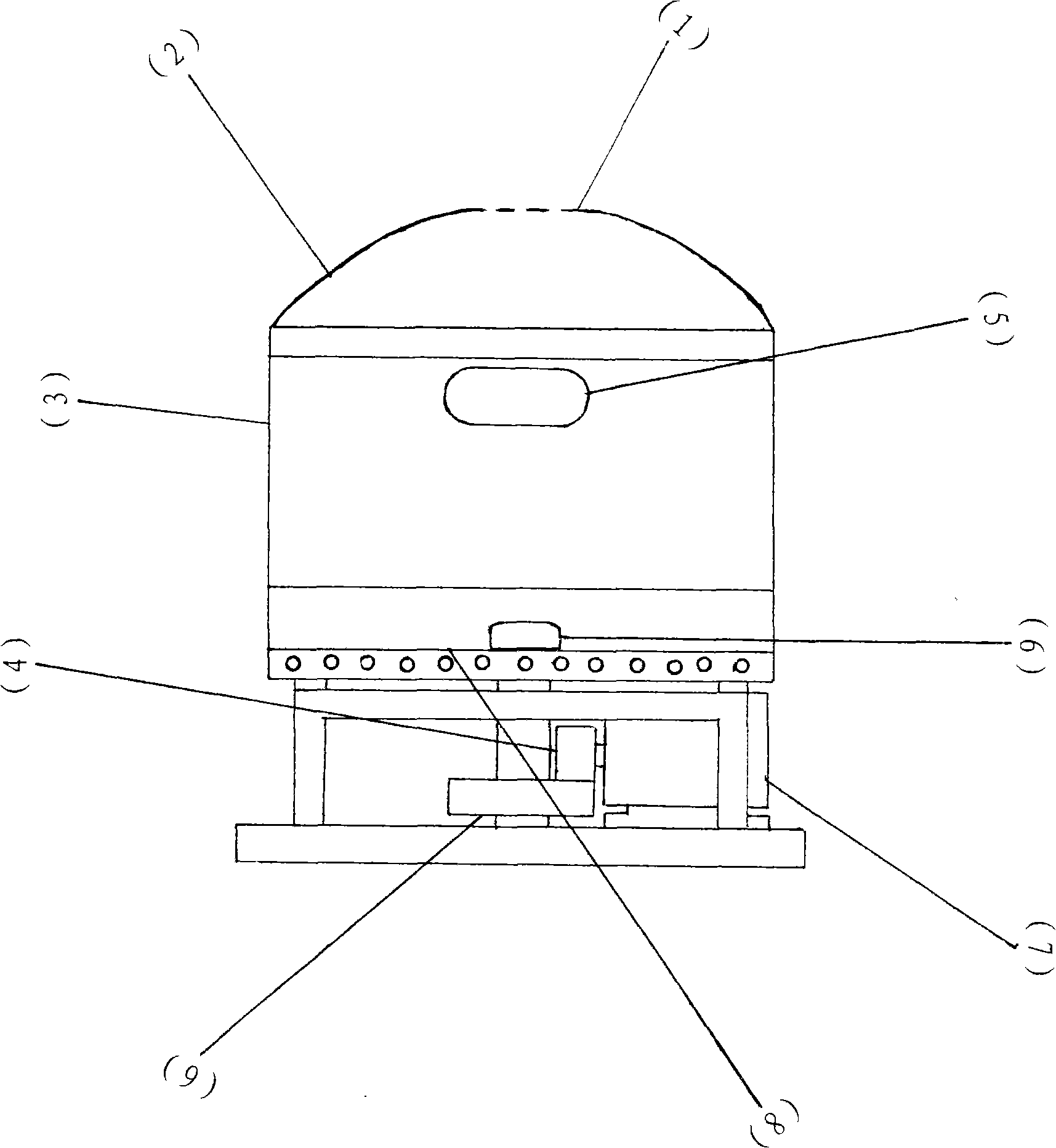

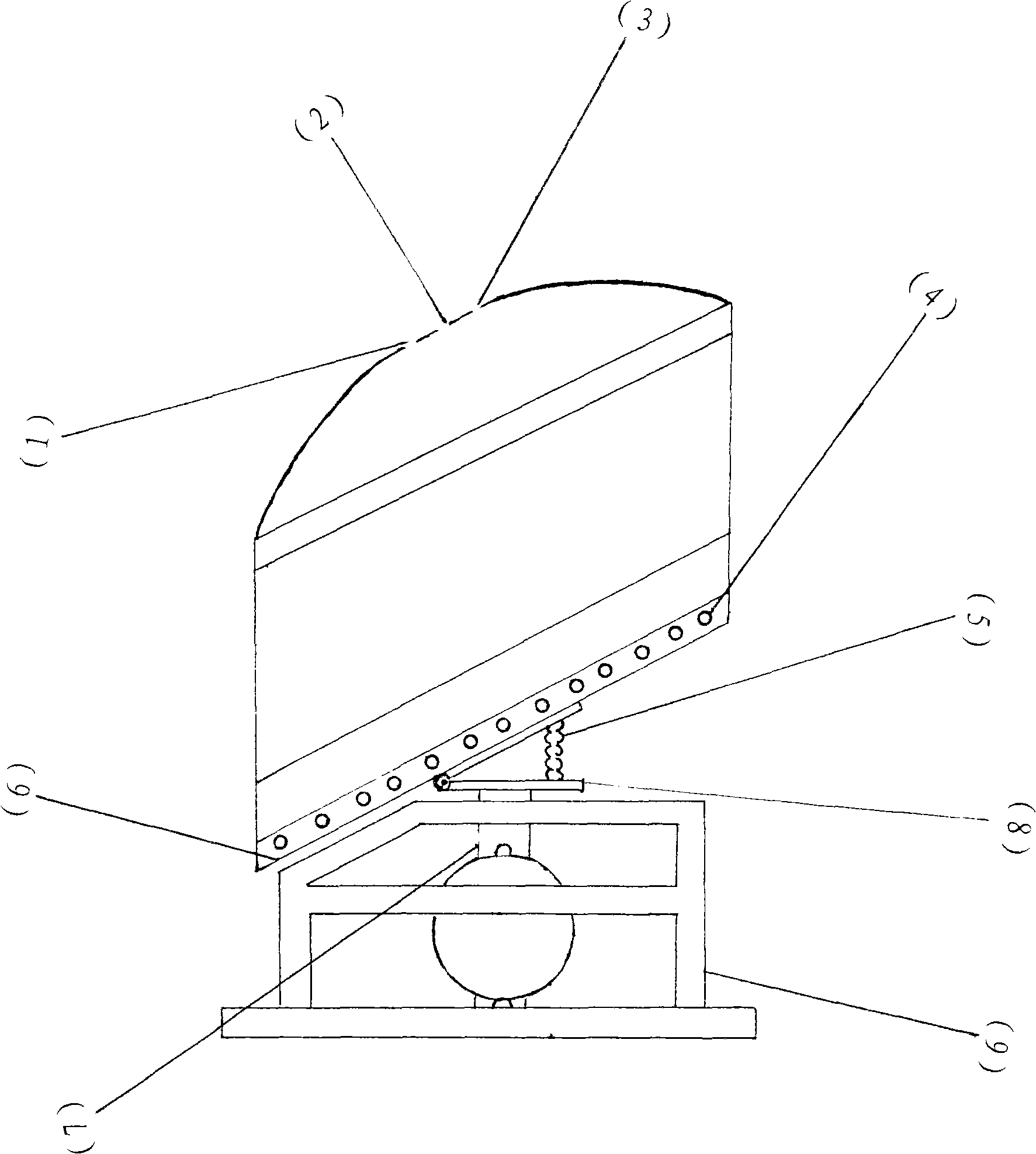

[0029] 25kg of round roll blanks are atomized with low-temperature ghee in a food atomization low-temperature fryer. The specific steps are:

[0030] 1. Calculate the weight of the fuel for injection. According to the national standard, the oil content is ≤24%. The round roll blank is 17% of the fragrant rice roll blank. Through calculation, its weight is 4.25kg, and it is heated to 105 at one time. ℃~115℃.

[0031] 2. Pour the dried round roll blanks into the food atomization low-temperature fryer from the feed port of the sealed container, close the feed port door, and the vacuum degree is 2370pa-2670pa.

[0032] 3. Start the food atomization low-temperature fryer, heat and rotate, and the round roll blank will automatically roll in the pot. When the temperature rises to 105°C-115°C, check whether the vacuum degree is lower than the 100pa-300pa vacuum degree of formal ghee. After the numerical value, stop vacuuming, and spray the oil heated to 105°C to 115°C for one time di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com