Glue injection method of high-precision mold guide sleeve

A high-precision, guide sleeve technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult mold maintenance, loss of precision, etc., to achieve the effect of ensuring precision and ensuring overall precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Method of the present invention comprises the steps:

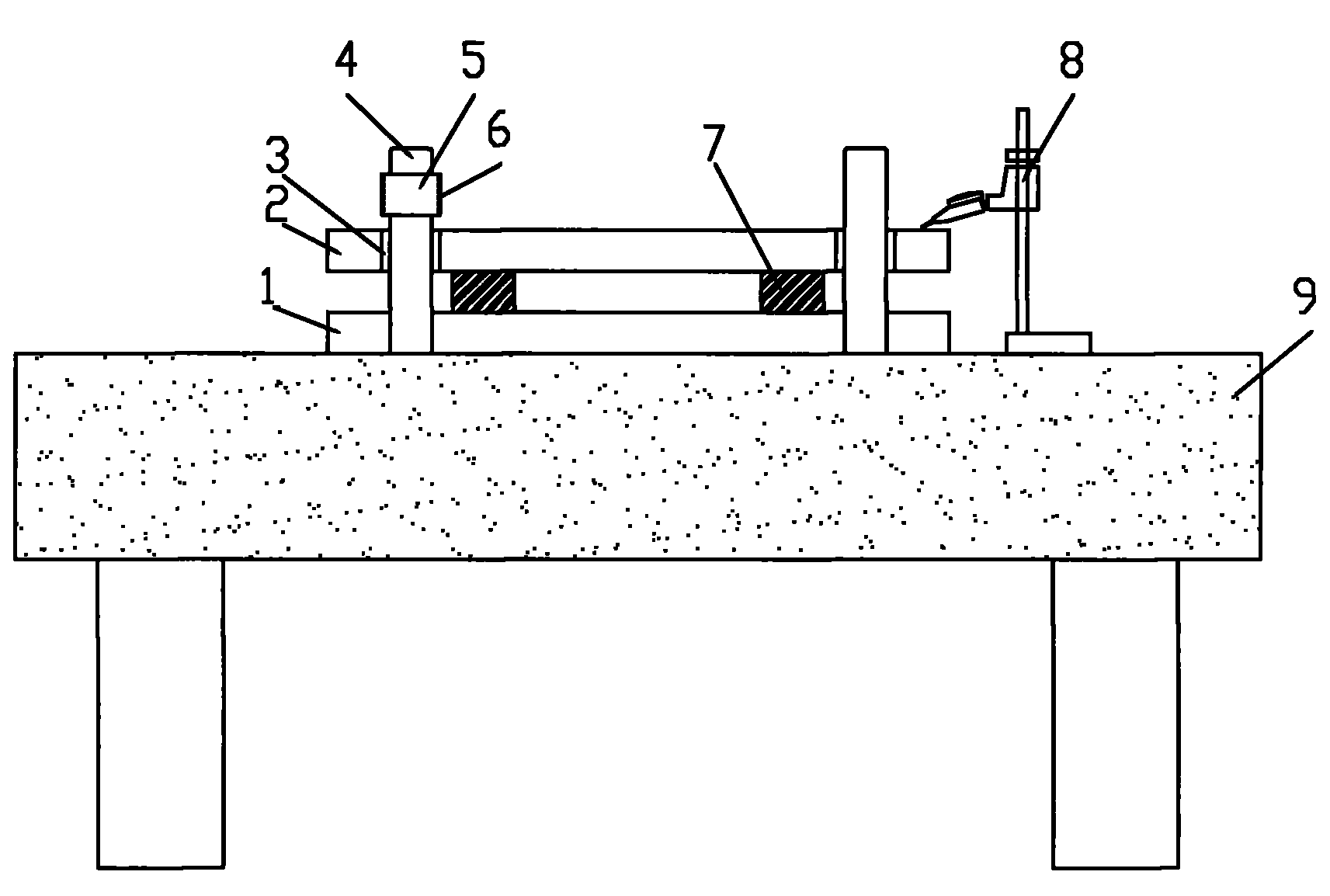

[0014] Step 1, place the fixed plate 1 with the guide post 4 on the working platform 9, place the parallel block 7 on the upper surface of the fixed plate 1, and then place the working plate 2 for fixing the guide sleeve 5 on the parallel block 7 above; if the working platform 9 is uneven firstly, the parallelism between the working plate 2 and the fixed plate 1 cannot be guaranteed accurately. The local wear of column 4 is intensified, and the movement is not smooth;

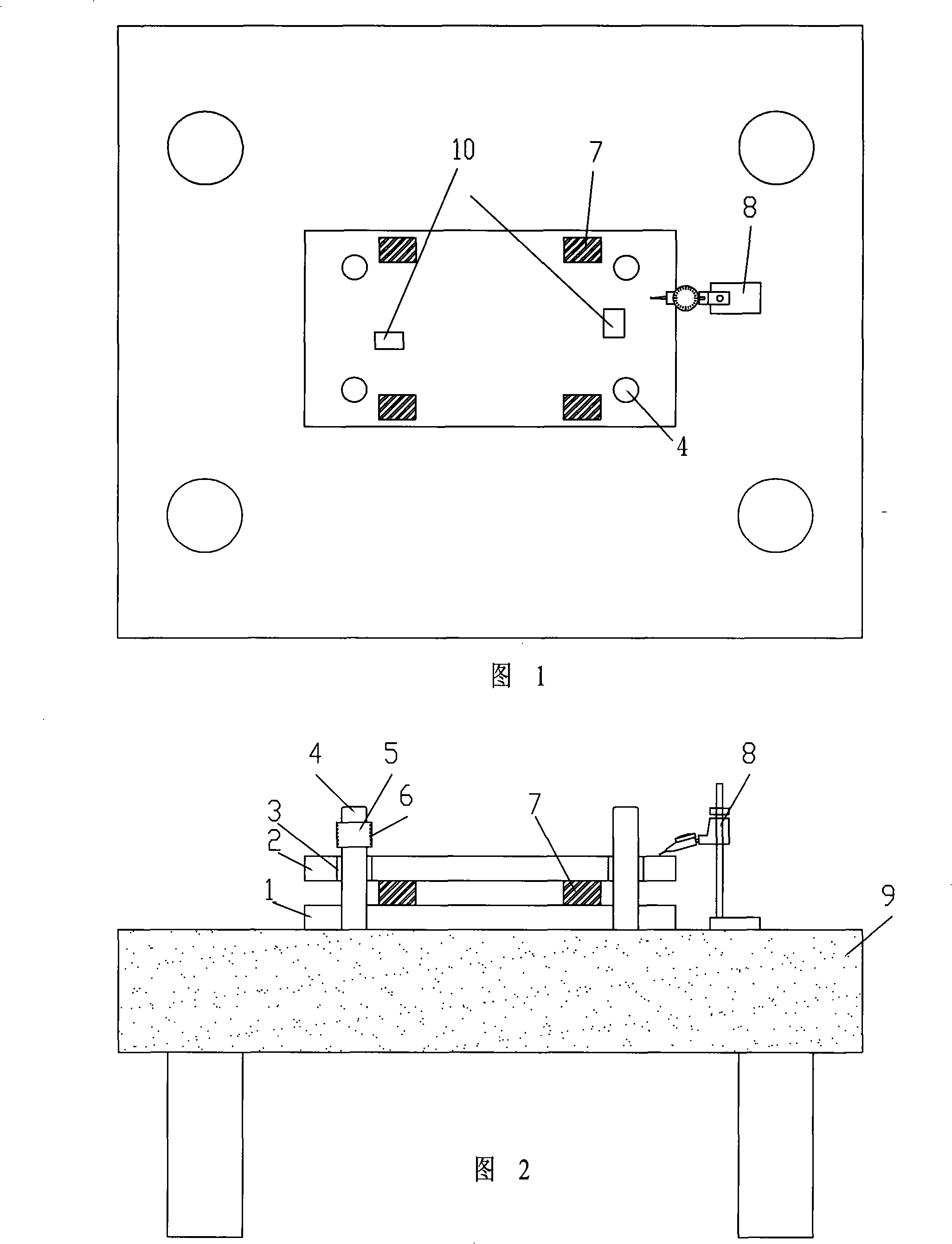

[0015] Step 2, using two identical special-shaped cavities 10 on the fixed plate 1 and the working plate 2, the positioning block that is prepared in advance and matched with the special-shaped cavity 10 will pass through the special-shaped cavity 10, so that the fixed plate 1 and the working plate 2 are positioned; insert the guide sleeve 5 into the guide post 4, confirm that the guide sleeve 5 can be freely placed in the guide sleeve hole 3, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com