Patents

Literature

37results about How to "Fulfill job requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

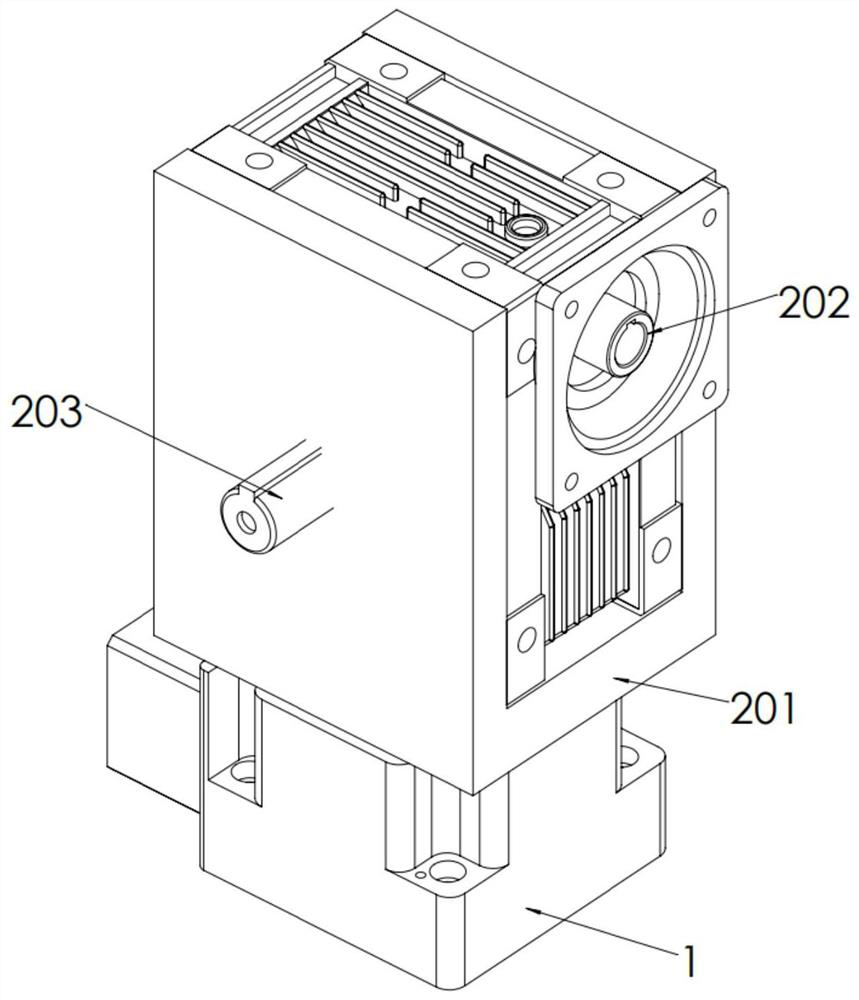

Vehicle-mounted unmanned aerial vehicle parking cabinet equipment

PendingCN109502039APrecision landingReduce the impact of interferenceCharging stationsVehicular energy storageIn vehicleEngineering

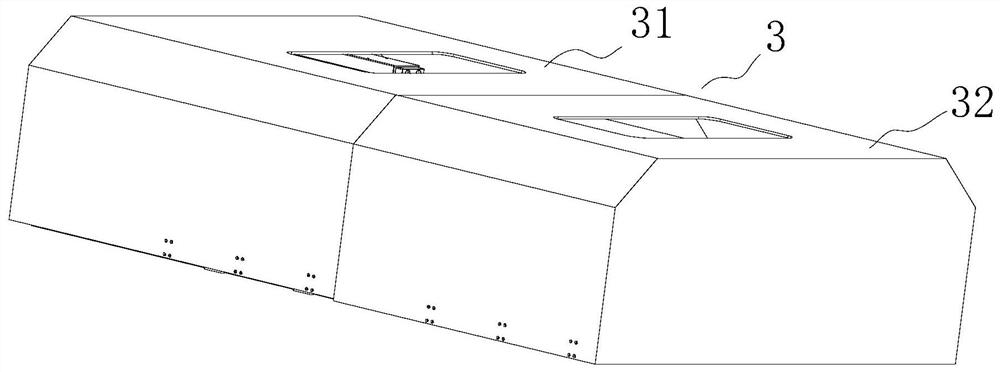

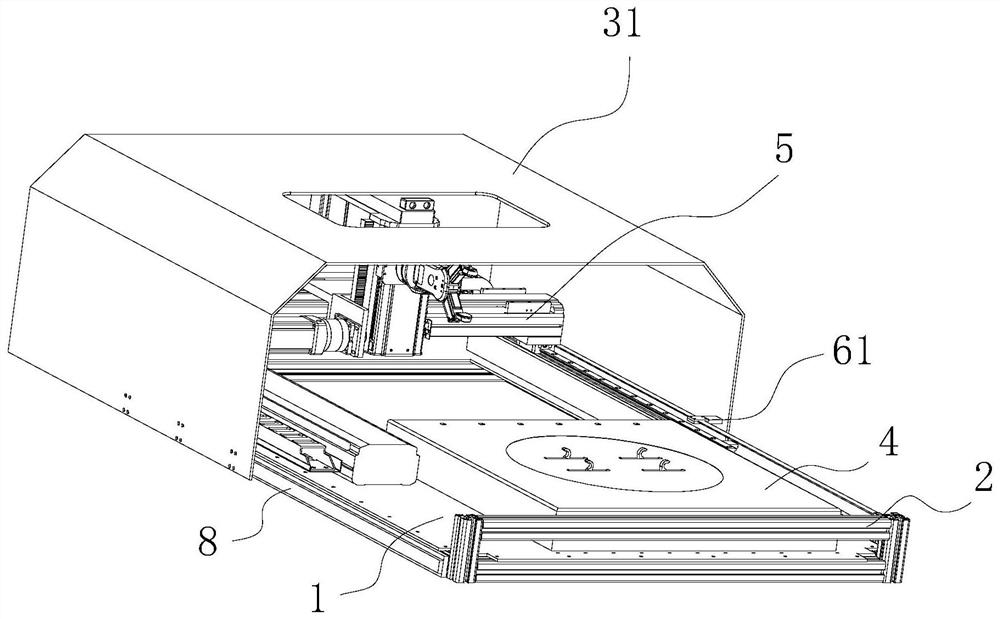

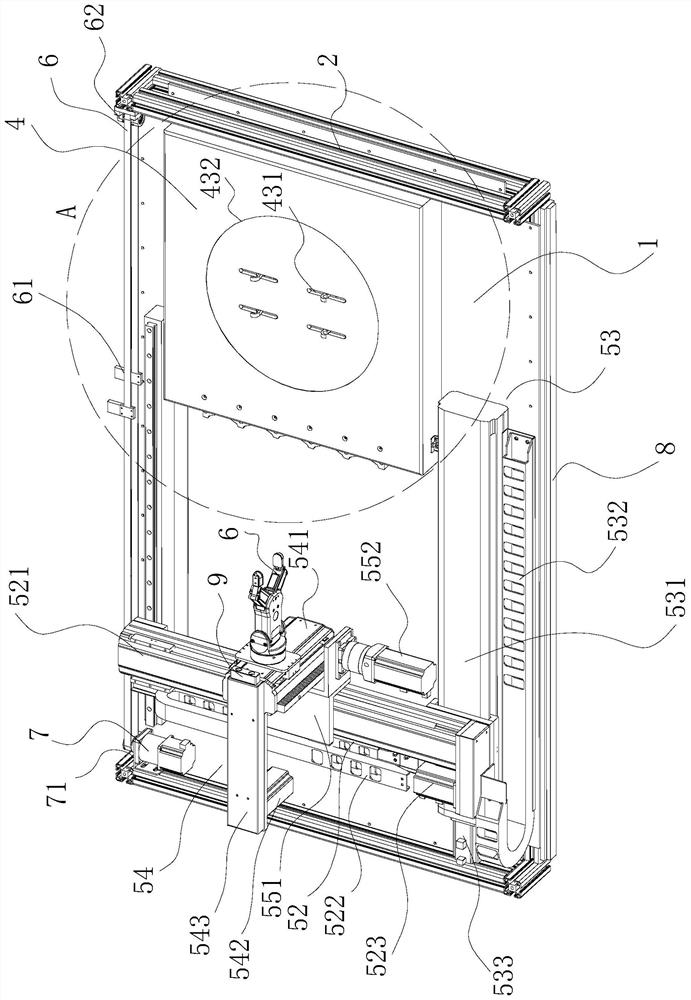

The invention discloses vehicle-mounted unmanned aerial vehicle parking cabinet equipment and an automatic battery replacement method and system. The vehicle-mounted unmanned aerial vehicle parking cabinet equipment includes a shell with the top open, an unmanned aerial vehicle parking apron, a mechanical arm and one or more charging cabinets, wherein a controller is arranged in the shell, and theunmanned aerial vehicle parking apron, the mechanical arm and the one or more charging cabinets are connected with the controller, and each charging cabinet is provided with several charging grooves.The controller monitors information of batteries in the charging grooves and controls the mechanical arm to take the batteries from unmanned aerial vehicles to vacant charging grooves and to take thefully charged batteries from the charging grooves to the unmanned aerial vehicles. Parking cabinets can assist the unmanned aerial vehicles to precisely land on the parking aprons in cabinet bodies,and then automatic replacement of the batteries is achieved.

Owner:SHANDONG UNIV

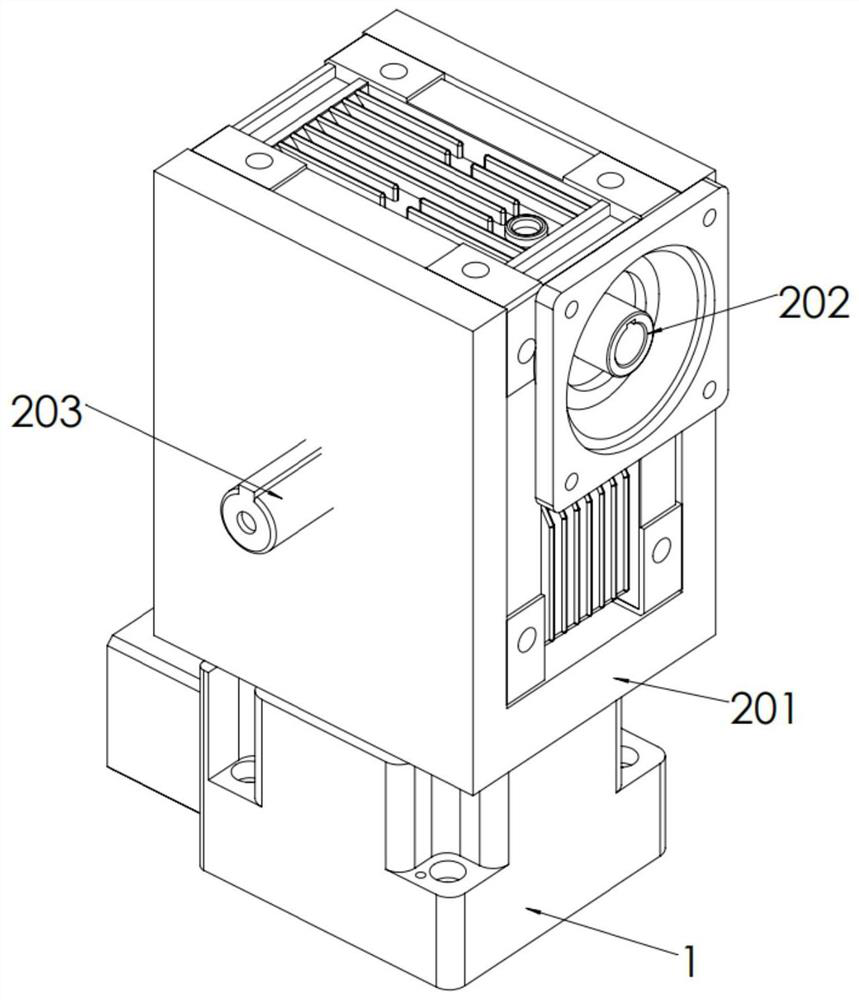

Mobile nest for automatically replacing battery of small unmanned aerial vehicle and parking apron thereof

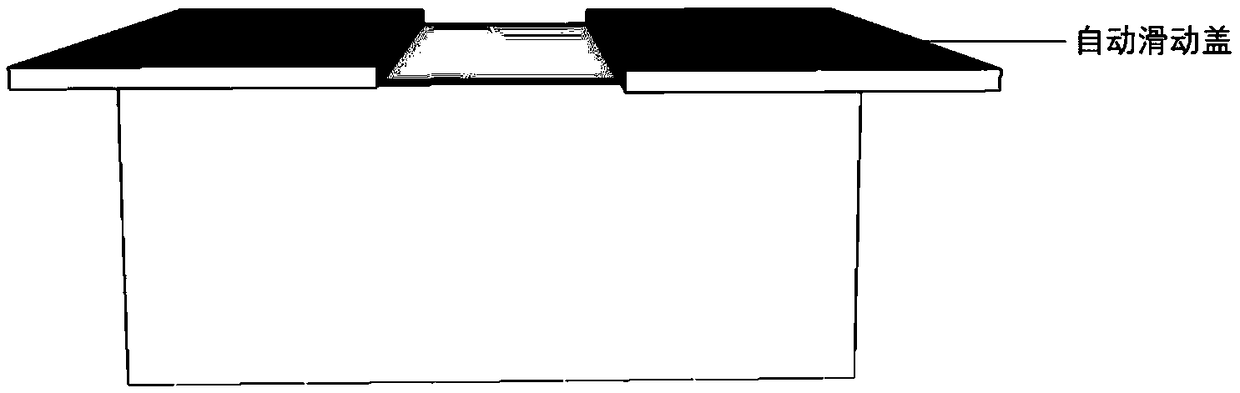

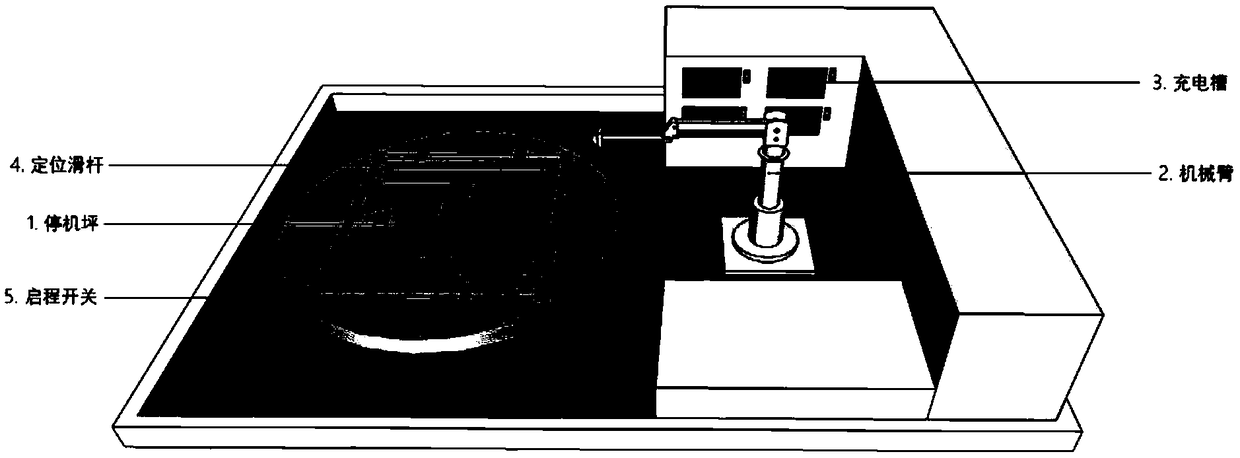

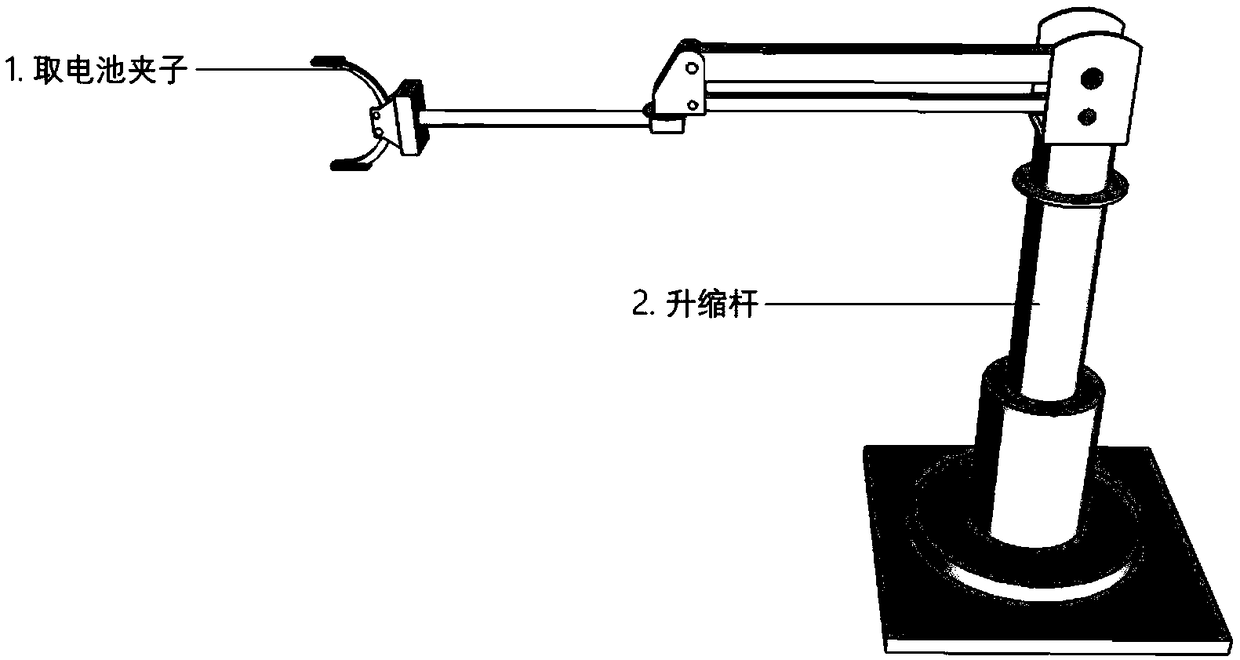

PendingCN112141354ASolve the problem of susceptibility to environmental interferenceExpand the scope of spaceCharging stationsVehicular energy storageMarine engineeringControl cell

The invention discloses a mobile nest for automatically replacing a battery of a small unmanned aerial vehicle. The mobile nest comprises a mobile nest body and a control unit. The movable nest body comprises a bottom plate, a bottom plate frame, a movable top cover, a parking apron arranged on the bottom plate, a three-dimensional module unit and a mechanical clamping jaw. A charging bin is arranged in the parking apron. The control unit comprises an industrial personal computer, a control module and a plurality of servo controllers, which are connected in sequence, the industrial personal computer sends instructions to the control module, and the control module executes the instructions of the industrial personal computer to control the servo controllers, so that an unmanned aerial vehicle is controlled to accurately land and be fixed on the parking apron; and the three-dimensional module unit moves, the mechanical clamping jaw moves the unmanned aerial vehicle to a fixed landing position, the battery is taken and placed between the unmanned aerial vehicle and the charging bin, and battery information in the charging bin is monitored. A platform capable of accurately landing andfastening the unmanned aerial vehicle is provided, a battery of the unmanned aerial vehicle can be continuously charged, and the mobile nest is an unattended and movable unmanned aerial vehicle intelligent parking apron system in the true sense.

Owner:HUAINAN POWER SUPPLY CO OF STATE GRID ANHUI ELECTRIC POWER CORPORATIO +3

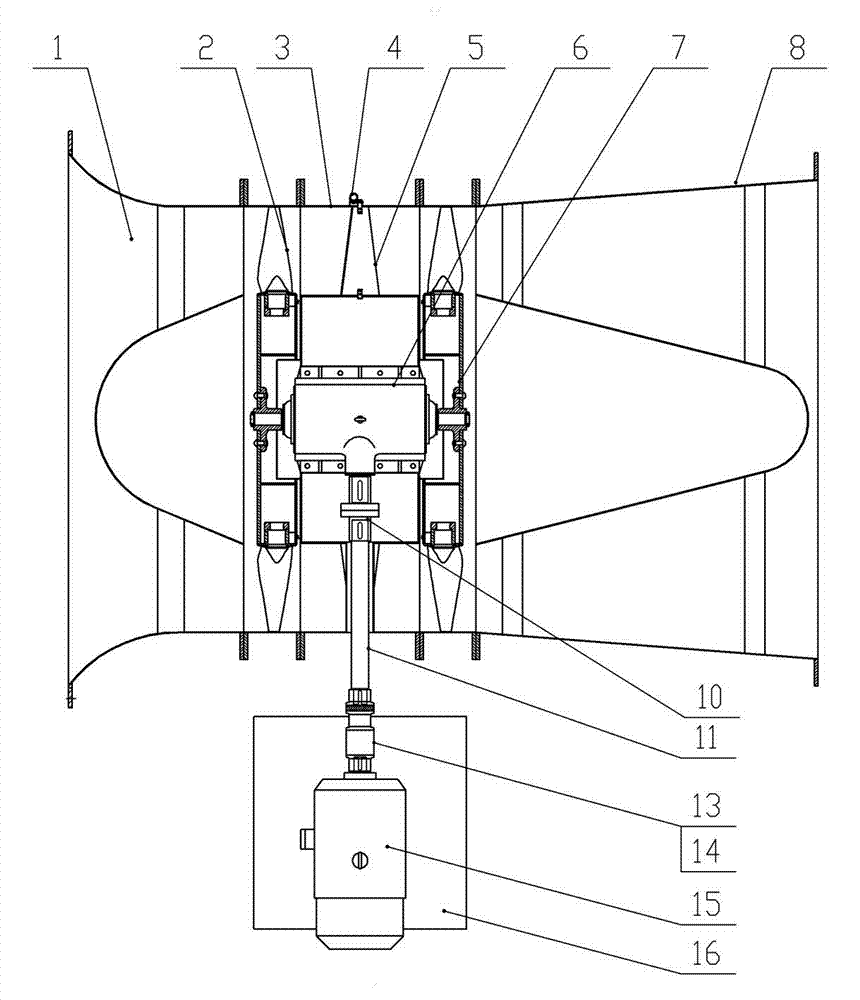

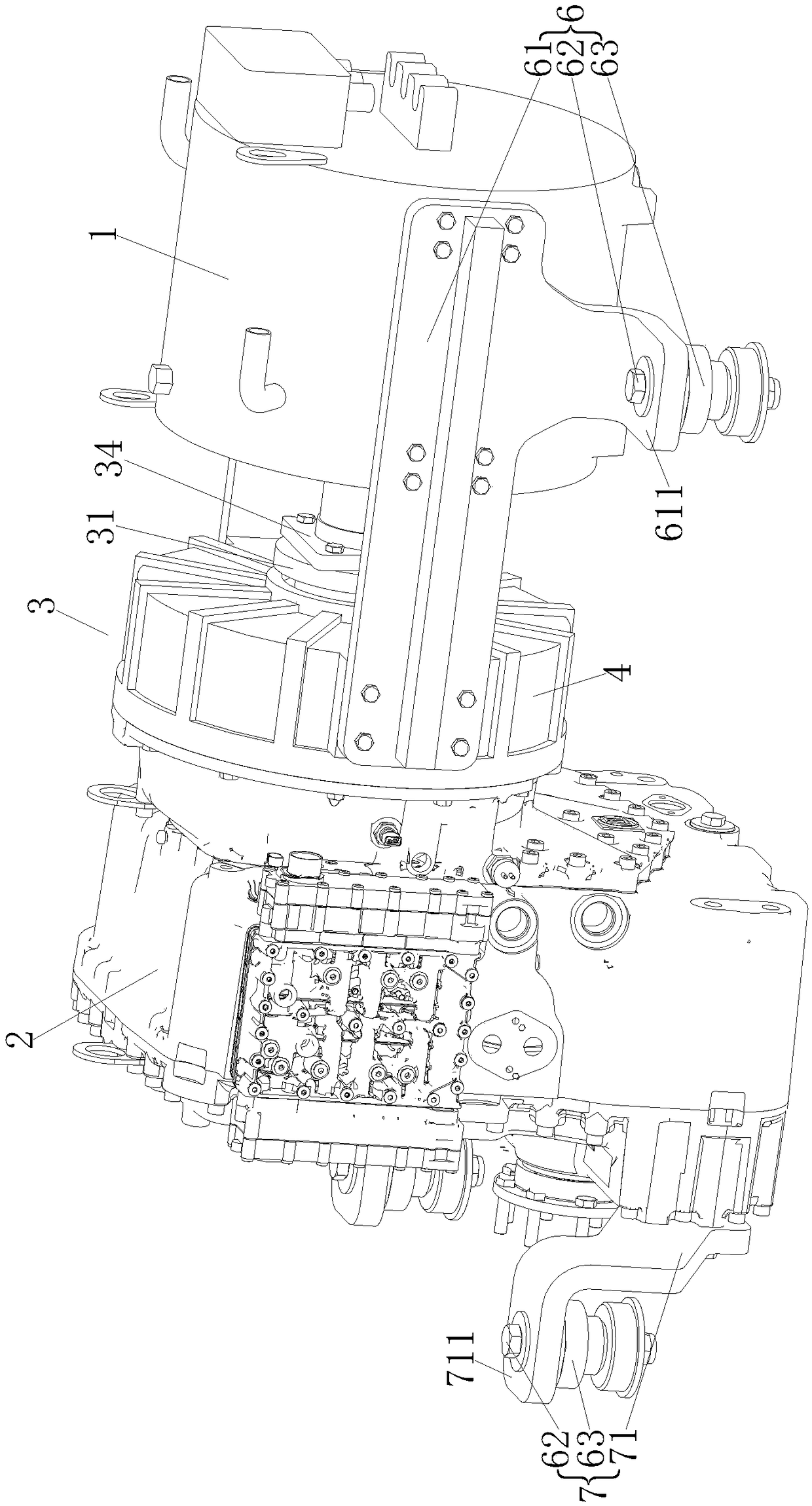

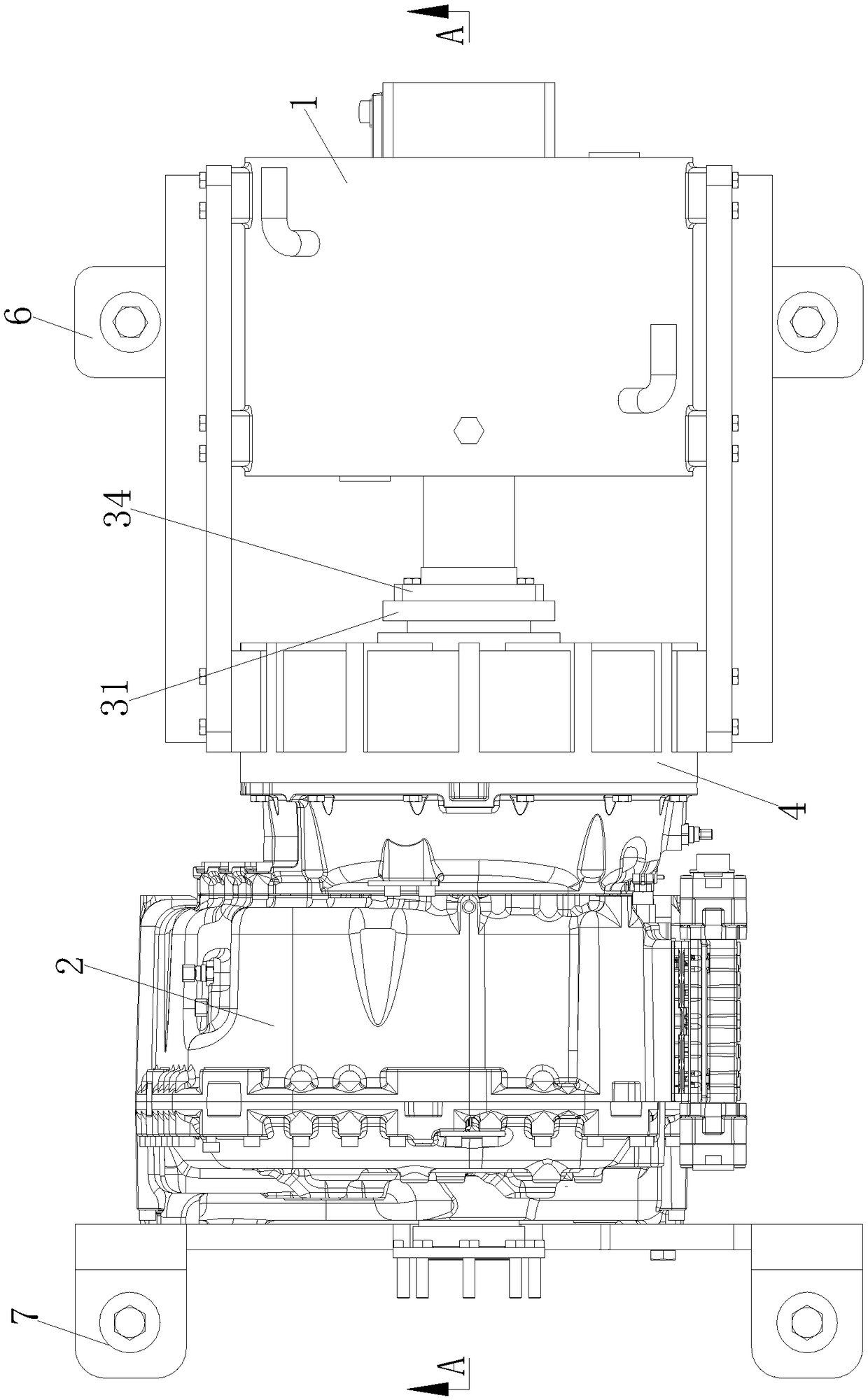

Contra-rotating axial-flow fan with lateral external-type one-driving-two motor

ActiveCN103486058ATo achieve the design goal of one drag twoAchieve the design purposePump installationsNon-positive displacement fluid enginesChemical industryImpeller

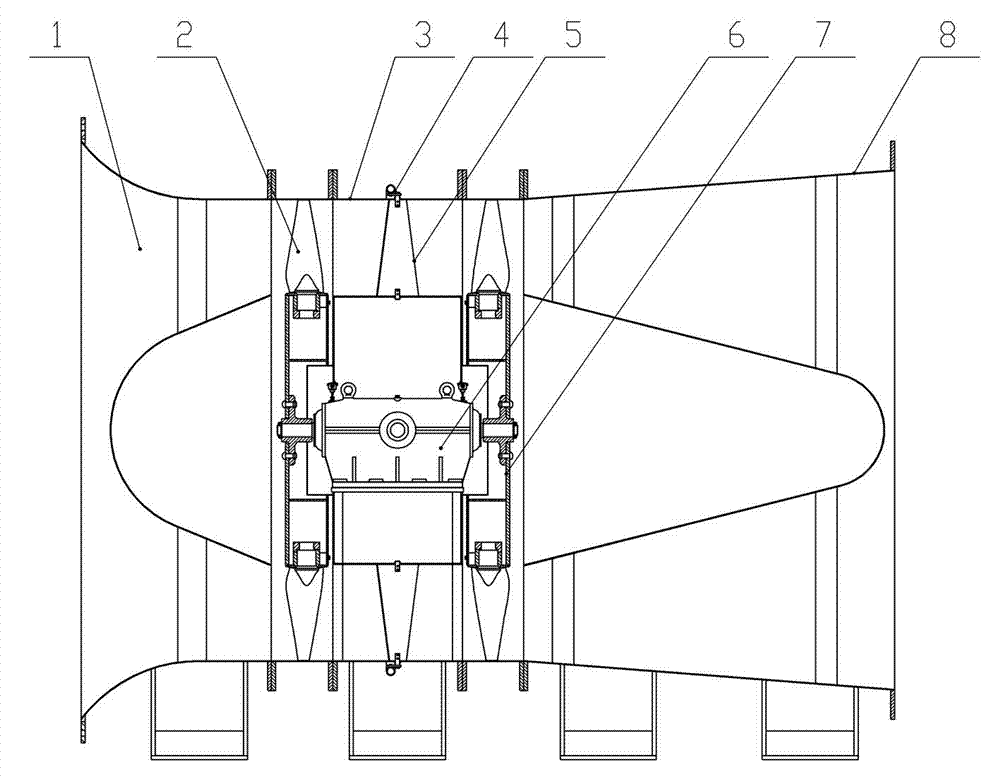

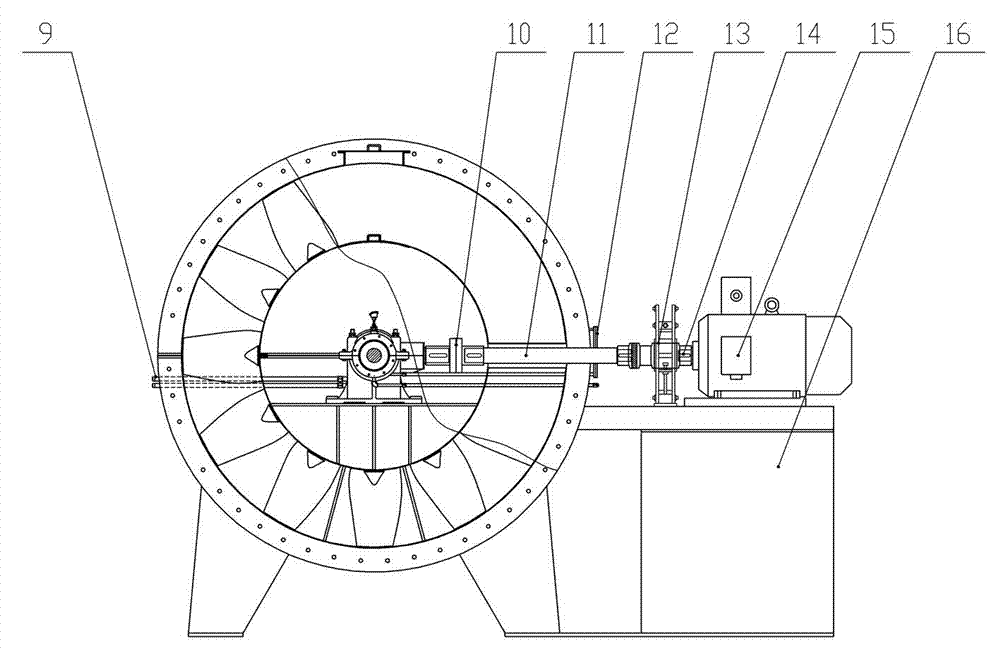

The invention relates to a contra-rotating axial-flow fan with a lateral external-type one-driving-two motor. The contra-rotating axial-flow fan with the lateral external-type one-driving-two motor mainly solves the technical problems that the manufacturing cost of the existing axial-flow fan is high, the operation reliability and safety are lower, the working difficulty in maintenance is great and the like, and improves the operating environment and the stress situation of the motor are improved. The technical scheme is that a front impeller (2) and a rear impeller (7) are fixedly and respectively installed on two output shafts of a transmission case (6) on a base in an inner cylinder of a main machine cylinder (3), flow guide blades (5) and a flow guide blade adjusting mechanism (4) are arranged in an annular passage between the two impellers, a motor support (16) is arranged outside the lateral direction of the main machine cylinder (3) and a motor (15) which is installed on the motor support (16) is connected with the transmission case (6). The contra-rotating axial-flow fan with the lateral external-type one-driving-two motor is a ventilation device which can be widely used in industries such as mining, metallurgy, chemical industry and power plants and can be especially used for working places of explosion, high temperature, corrosion and the like.

Owner:PINGAN ELECTRICAL

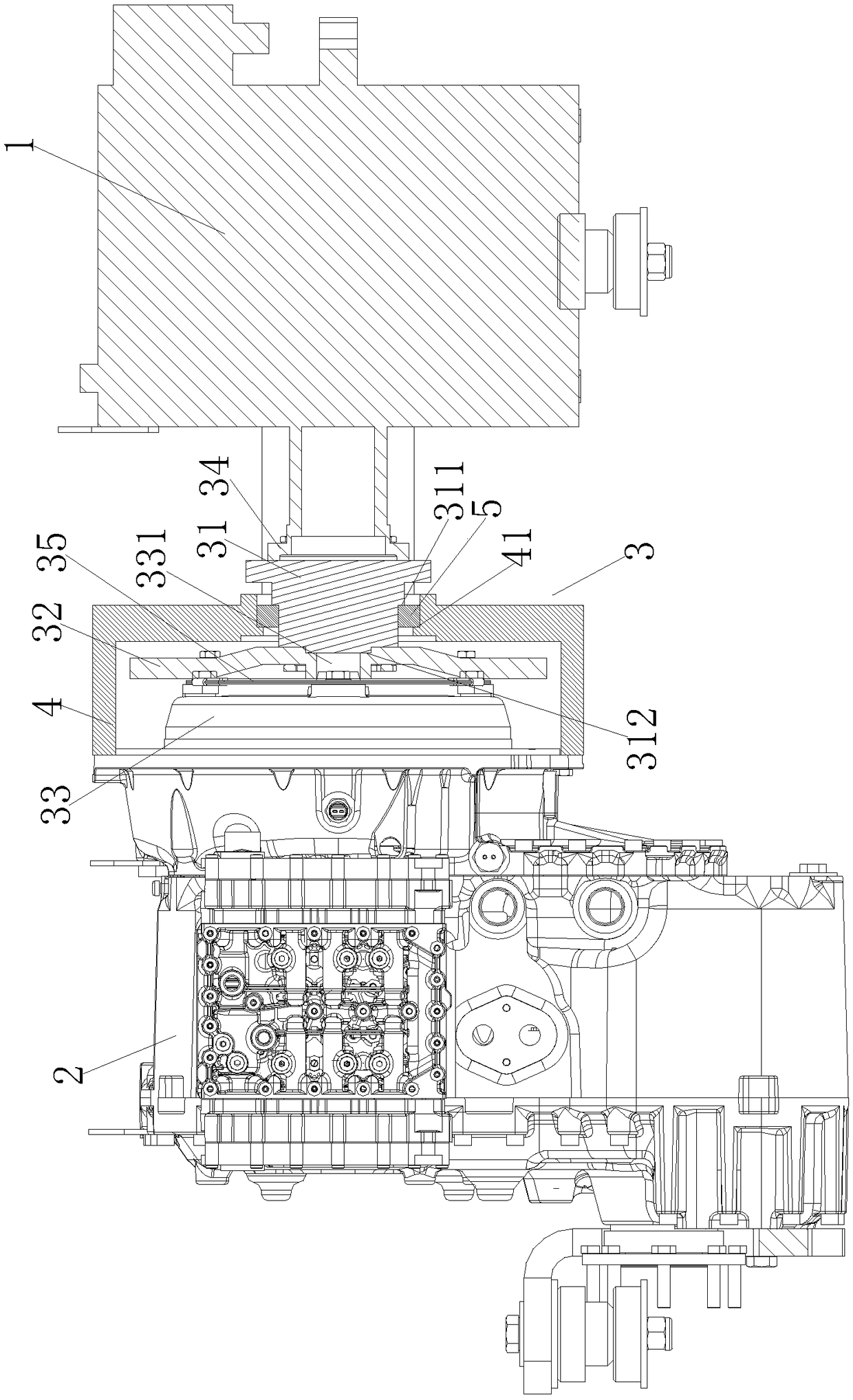

Small-section anchoring and rock drilling integrated machine

InactiveCN112696217AAchieving borehole anchor protectionArbitrarily adjust the drilling and anchor processing angleDerricks/mastsFlushingRock cuttingMachine

The invention discloses a small-section anchoring and rock drilling integrated machine. The small-section anchoring and rock drilling integrated machine comprises a net hanging manipulator, a drilling and anchoring sliding frame device and a hydraulic control device, wherein the net hanging manipulator comprises a rotating mechanism, a large arm lifting mechanism, a large arm telescopic mechanism, a large arm rotating mechanism, an angle adjusting mechanism and a net hanging mechanism which are used for rotating, lifting, extending and axially rotating a large arm B respectively; and the drilling and anchoring sliding frame device comprises a drilling and anchoring sliding frame adjusting mechanism, a rock drilling mechanism, an anchor rod mechanism and a positioning mechanism, and the rock drilling mechanism and the anchor rod mechanism are arranged on a drilling and anchoring sliding frame in parallel. The small-section anchoring and rock drilling integrated machine is applied to a small-section roadway of a mine and integrates multiple mechanical operation functions of rock drilling, tunneling, anchoring of an anchor net, an anchor rod and anchoring, the station can be adjusted at will by 360 degrees, rock drilling, tunneling and anchoring integrated operation can be carried out in all directions, the drilling and anchoring switching speed is high, the accuracy is high, the working intensity of workers is low, the mechanical operation efficiency and the safety coefficient are high, the supporting quality and the anchoring effect are good, and popularization of the mechanical level is facilitated.

Owner:滕开永 +1

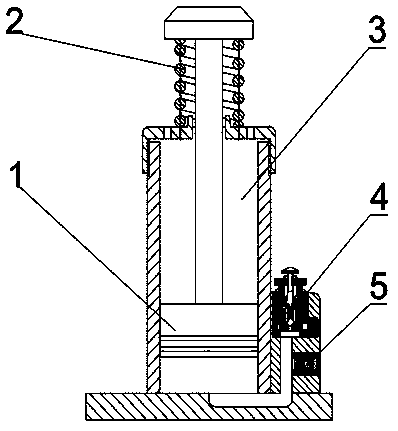

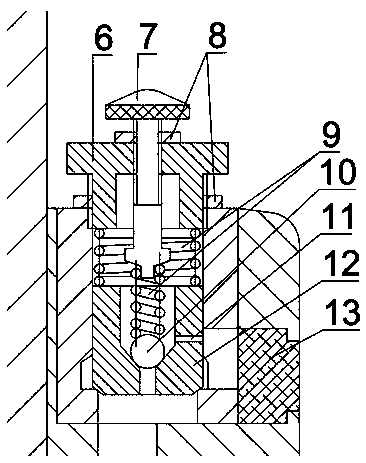

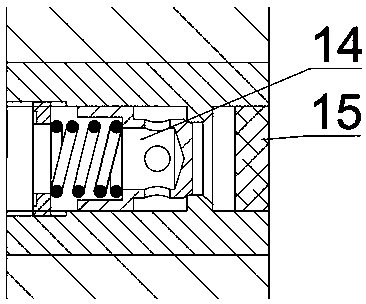

Adjustable air damping buffer

ActiveCN108953455ARealize two-dimensional adjustableLittle influence of temperatureSpringsGas based dampersAtmospheric airEngineering

The invention discloses a buffer mechanism based on a pilot overflow valve. The buffer mechanism comprises a piston rod, an air piston cylinder, a return spring, the pilot overflow valve and a fast reset one-way valve, wherein the main structures are the piston rod, the piston cylinder and the return spring, the auxiliary structures are the overflow valve and the one-way valve. When the impact acts on the piston rod, an air cavity is compressed, at the moment, the one-way valve is closed, air flows to the pilot overflow valve through a pipeline, the pressure of a valve element and the pressureof a damping hole can be adjusted through two adjusting knobs, then the gas flowing speed of the overflow valve can be adjusted, then the buffer pressure and time of the buffer can be adjusted, the gas is returned to the atmosphere through a silencer, when the impact is stopped, the return spring works, the pressure of the air cavity is enabled to be reduced to be less than the atmospheric pressure, at the moment, the one-way valve works, the air rapidly fills the air cavity through a filter, and then the buffer is enabled to be reset; and two air valves are embedded in a machine frame, so that assembly, disassembly and maintenance are convenient.

Owner:SOUTHEAST UNIV

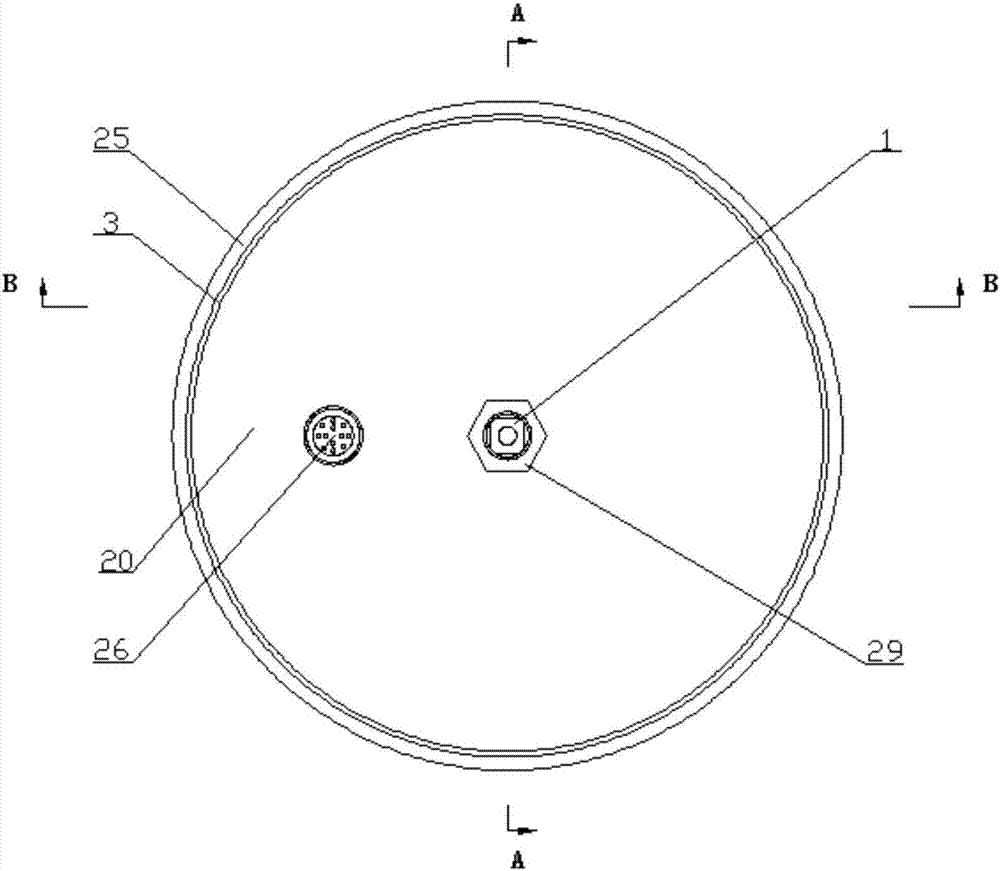

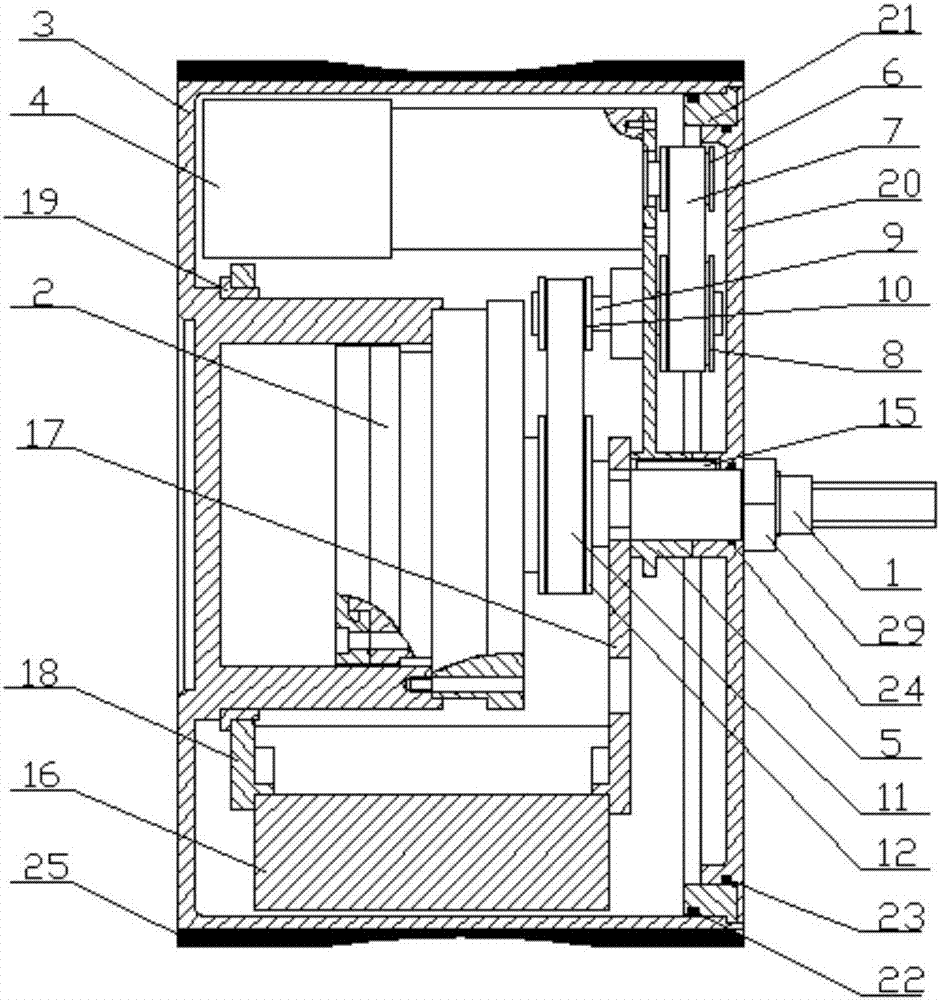

Driving integrated magnetic adsorption wheel type device

The invention relates to a driving integrated magnetic adsorption wheel type device. The driving integrated magnetic adsorption wheel type device is characterized by comprising a transmission shaft, a harmonic reducer, a wheel body rubber coating shell, a motor, a transmission support, a belt wheel shaft, a magnet and a wheel body end cover, wherein the wheel body rubber coating shell and the wheel body end cover are matched to form a closed space, the transmission shaft is installed on the center axis of the wheel body rubber coating shell, one end of the transmission shaft extends out of the wheel body rubber coating shell and the wheel body end cover and is connected with a car body, and the other end of the transmission shaft is connected with a rigid wheel through a flange plate; the motor and the magnet are arranged at the position, located at the two sides of the harmonic reducer, in the space of the wheel body rubber coating shell, one side of the magnet is fixed to a first copper sleeve through a second magnetic support, and the other side of the magnet is fixed to the transmission shaft through a first magnetic support; one end of the motor is fixed to the transmission shaft through the transmission support, the belt wheel shaft is fixed to the portion, between the transmission shaft and the motor, of the transmission support, an output shaft of the motor, the belt wheel shaft and the transmission shaft are parallel and transmit power in the mode of a synchronous belt.

Owner:HEBEI UNIV OF TECH

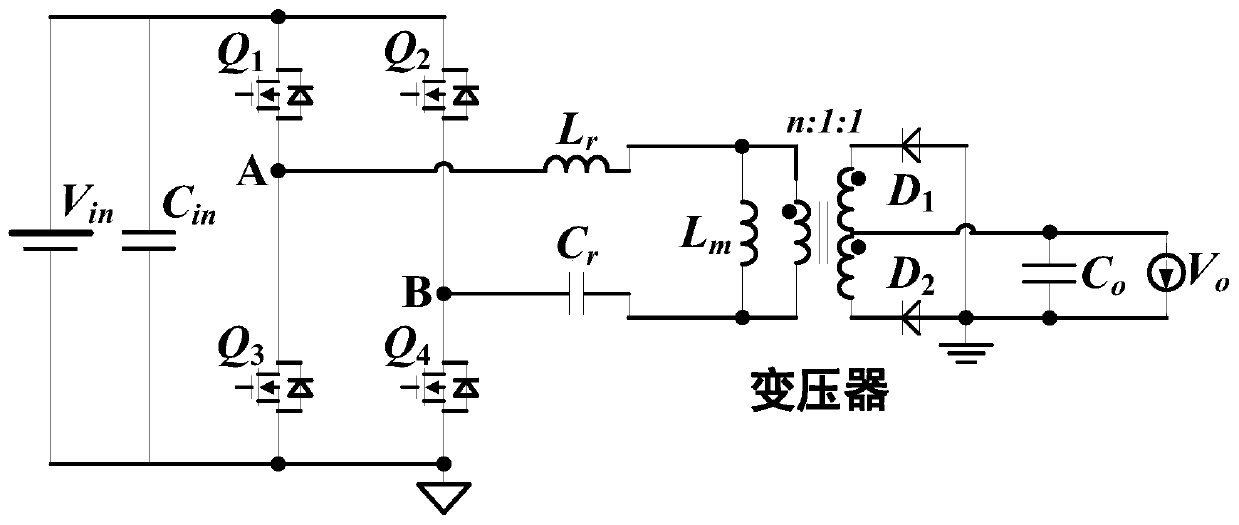

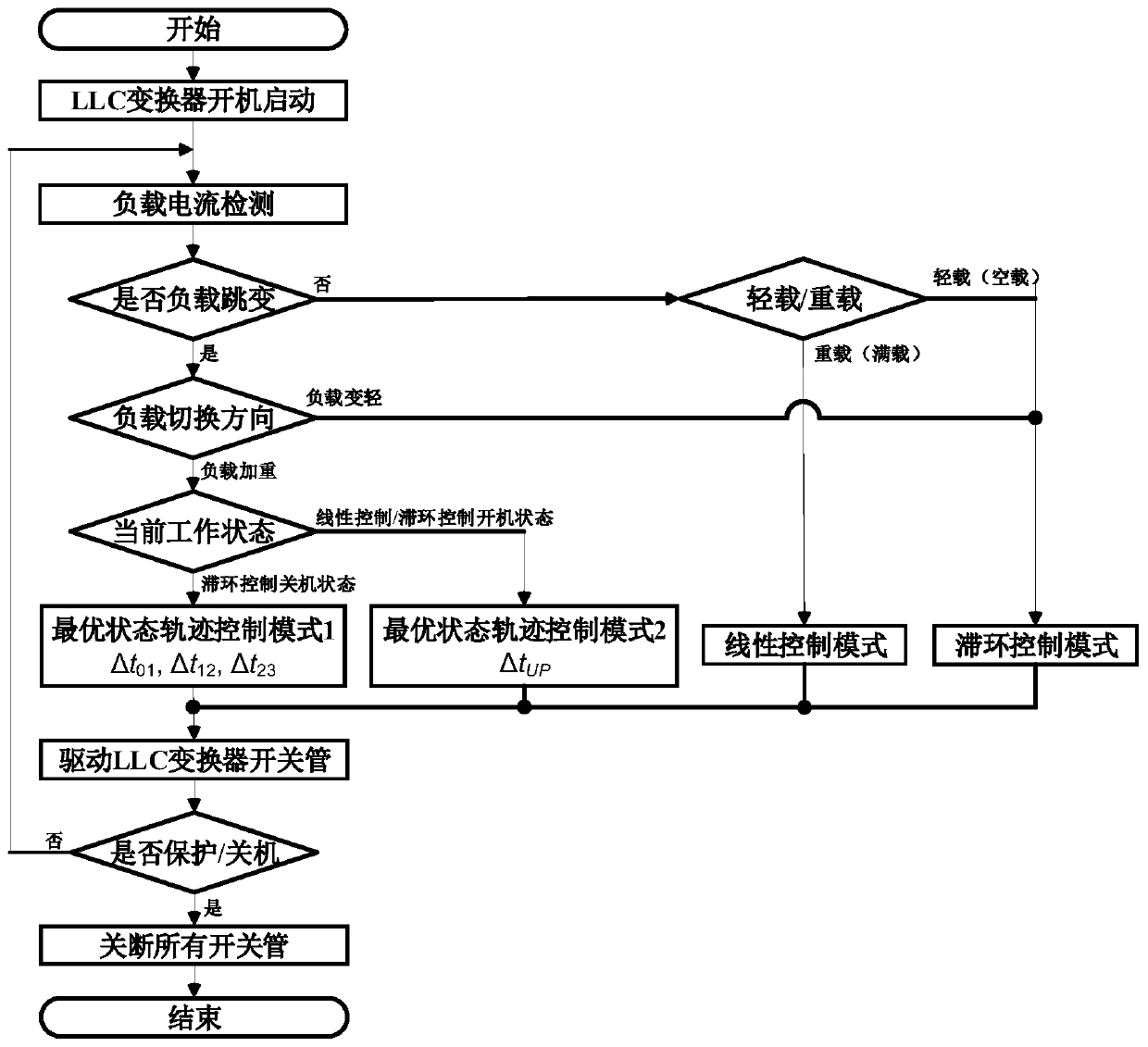

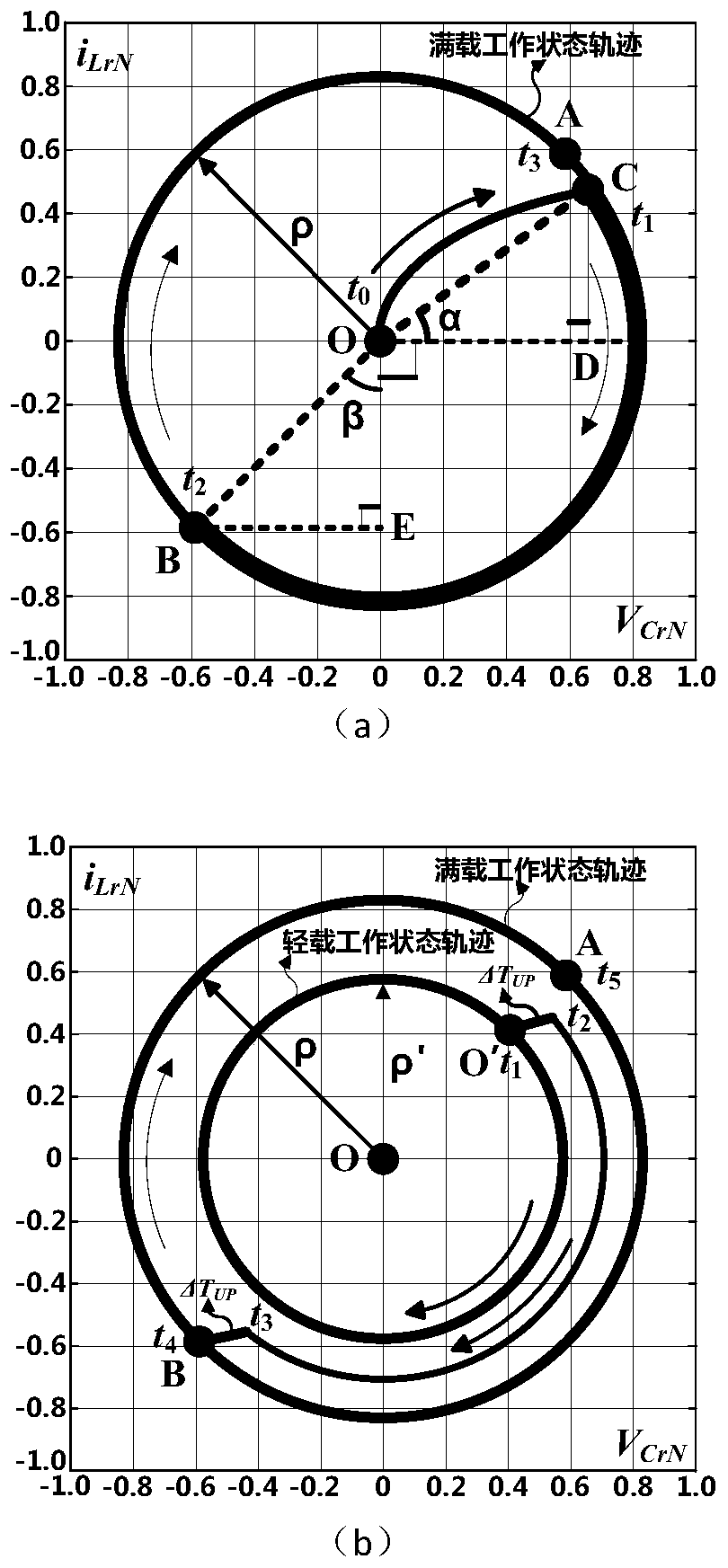

Optimal state trajectory control method for LLC converter adapting to rapid load mutation

ActiveCN110445390AStable output voltageImprove dynamic characteristicsEfficient power electronics conversionDc-dc conversionState variableLlc converter

The invention discloses an optimal state trajectory control method for an LLC converter adapting to rapid load mutation. In the method, the state variable of the converter is rapidly adjusted to a target working point by using optimal state trajectory control through recognizing the change of the load state of the LLC resonant converter. The method is rapid in dynamic response speed under the condition that the load current is changed rapidly, and the LLC resonant converter can work stably and reliably under the condition of rapid load mutation such as the pulse type load.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

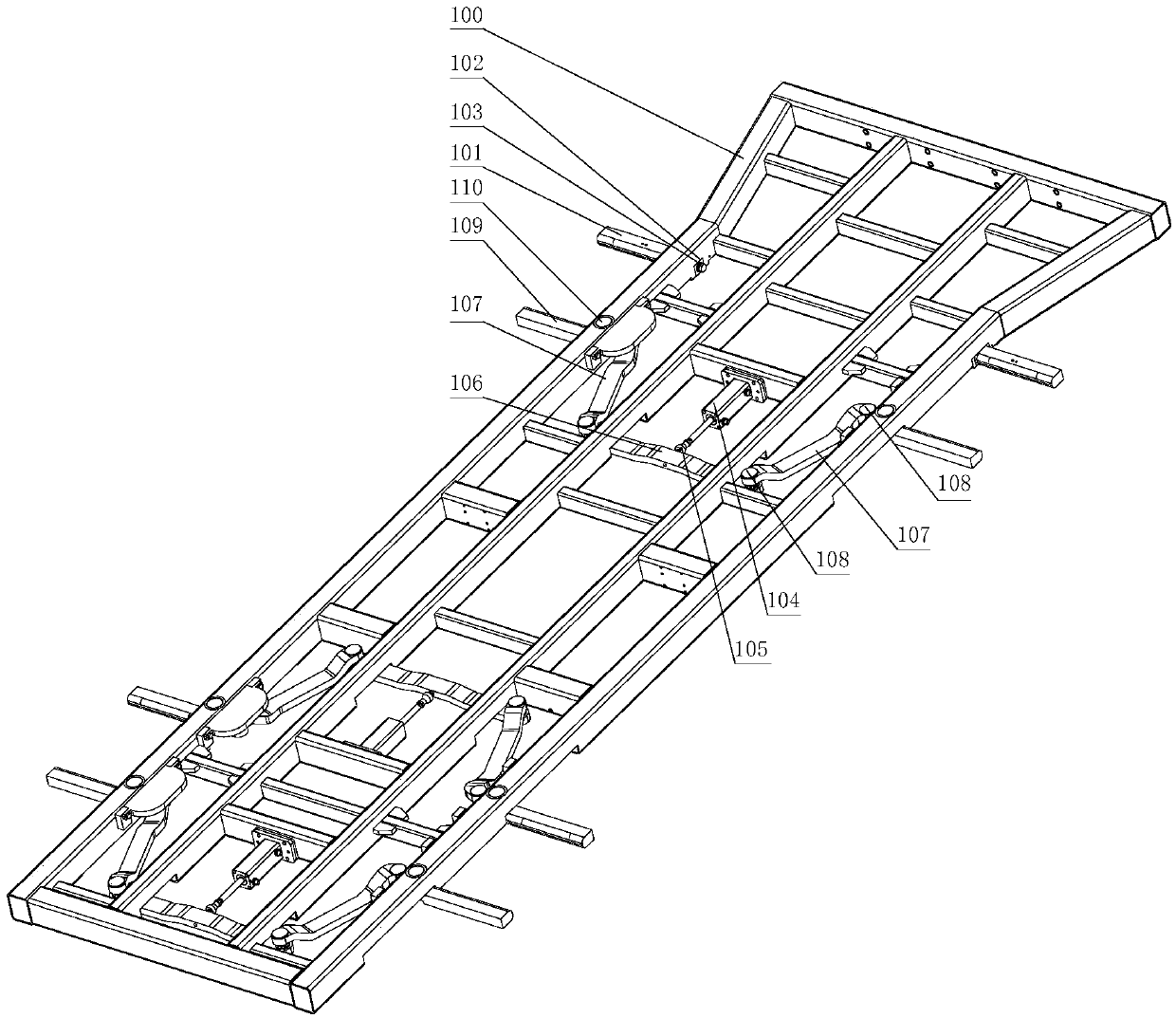

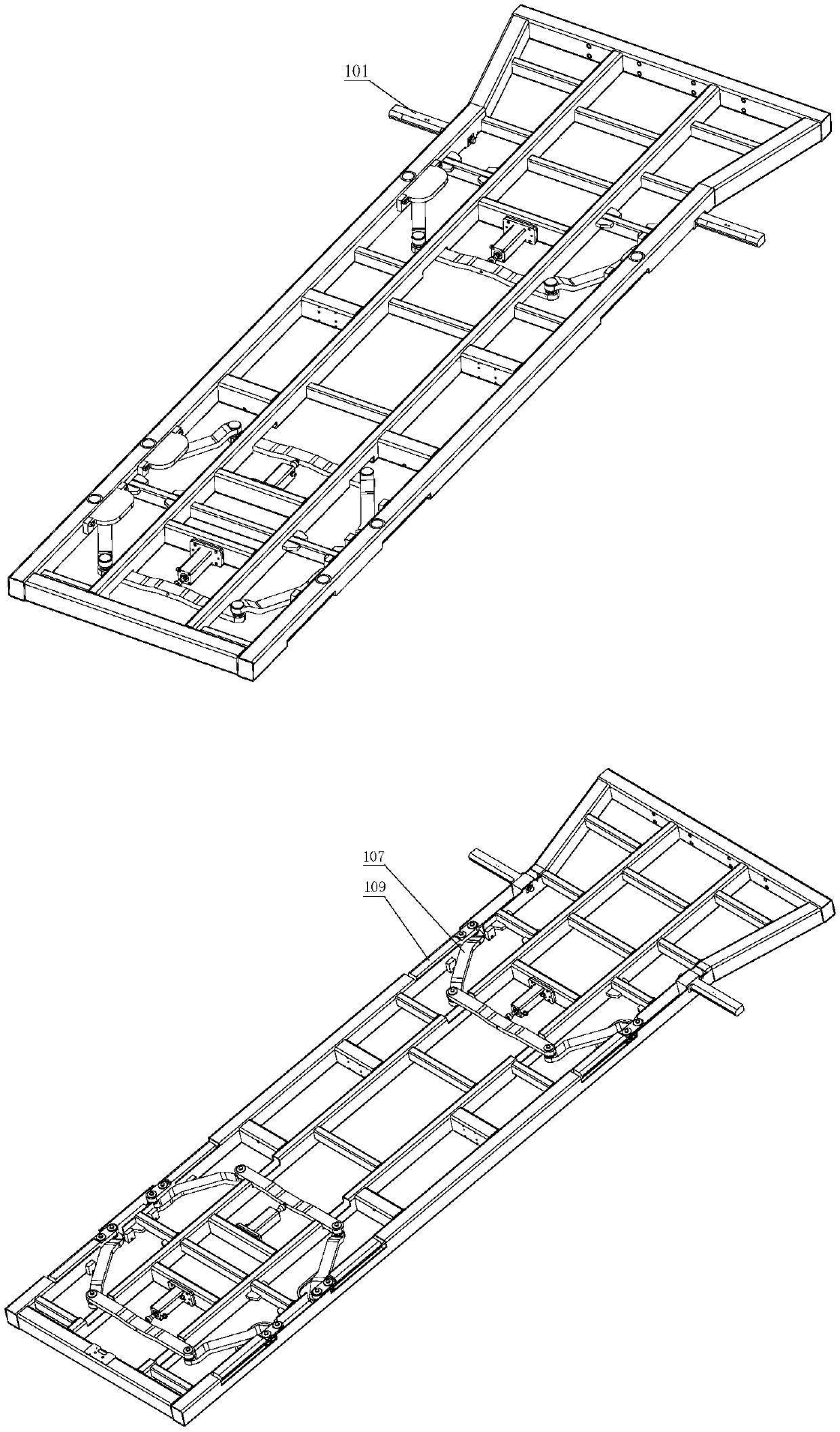

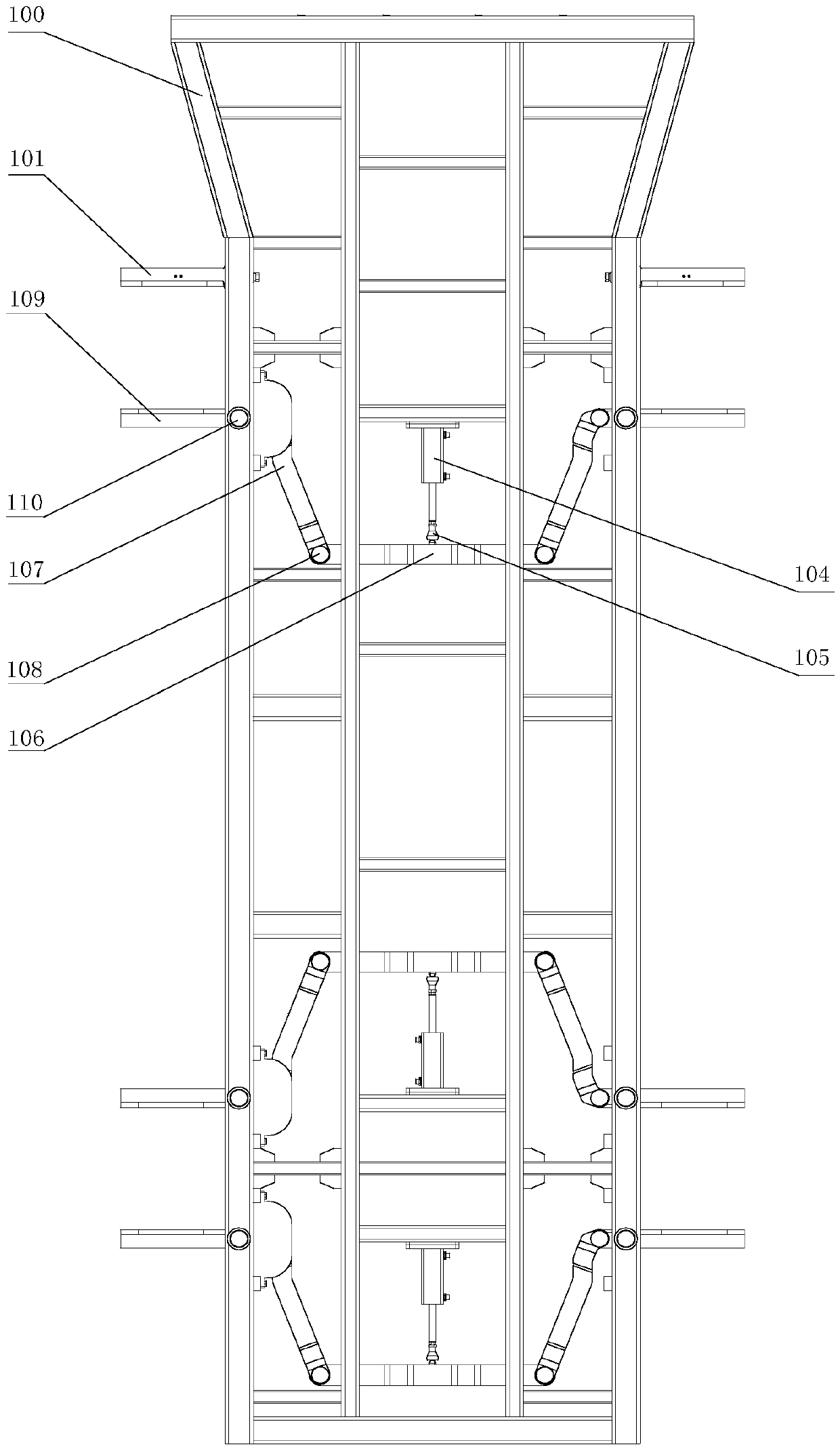

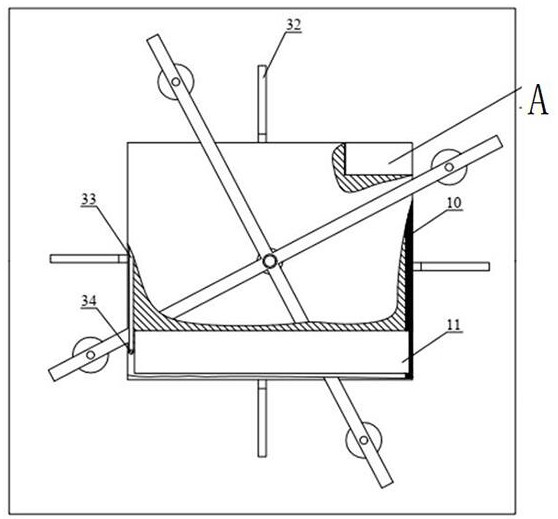

Tire clamping and folding device for automobile handling AGV (automatic guided vehicle)

The invention provides a tire clamping and folding device for an automotive handling AGV (automatic guided vehicle). The device comprises a driving hydraulic cylinder and a sliding block linkage mechanism, wherein the sliding block linkage mechanism comprises an unfolding sliding block, intermediate connecting rods and deployable support levers; the deployable support levers are connected with theunfolding sliding block through the intermediate connecting rods; the unfolding sliding block is connected with the driving hydraulic cylinder; the sliding block linkage mechanism is of a symmetricalstructure; the numbers of the intermediate connecting rods and the deployable support levers are two respectively; the two intermediate connecting rods and the two deployable support levers are symmetrically arranged with the unfolding sliding block as the center; unfolding mechanism rotating shafts are arranged at both ends of each intermediate connecting rod; the driving hydraulic cylinder comprises a driving hydraulic cylinder piston rod and a joint bearing; the driving hydraulic cylinder piston rod is connected to the middle position of the unfolding sliding block through the joint bearing. According to the device provided by the invention, the sliding block linkage mechanism is taken as a theoretical basis, the work requirements can be realized by the simple cooperation of the unfolding sliding block, the intermediate connecting rods and the deployable support levers, and the device is reliable in technology, simple in structure and convenient to install.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

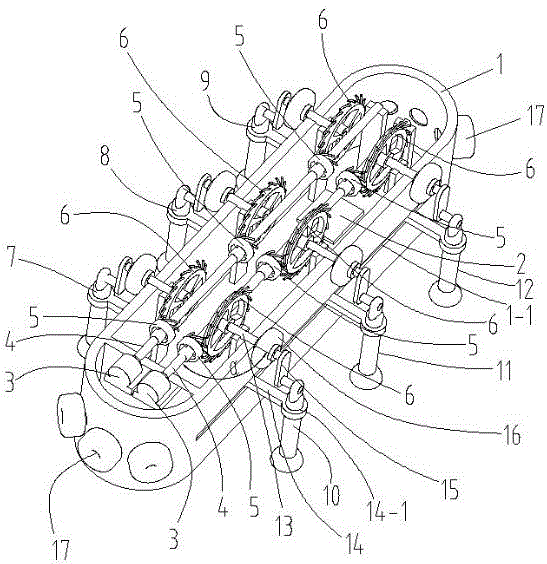

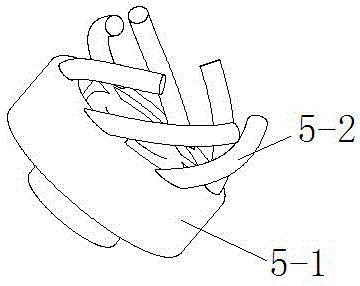

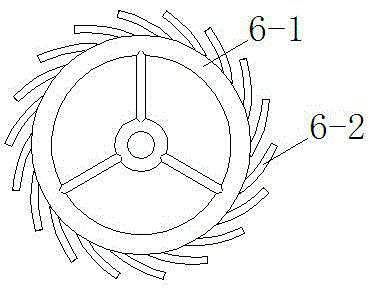

Linear gear drive based hexapod bionic robot

The invention relates to a linear gear drive based hexapod bionic robot which comprises a robot body, a single chip microcomputer, two micro-motors, two mutually-parallel drive shafts respectively connected with the two micro-motors, six driving wheels, six driven wheels and six vertical columnar feet.Each driving wheel comprises a driving wheel body and at least two spatial spiral line shaped driving linear teeth uniformly distributed on the end face of the driving wheel body in the peripheral direction, and each driven wheel comprises a driven wheel body and multiple circular-arc-line shaped driven linear teeth uniformly distributed in the peripheral direction of the driven wheel body.Each drive shaft fixes three driving wheel bodies, three output shafts fixing the driven wheel bodies are arranged on the two sides of the robot body respectively, included angles formed by the output shafts and the drive shafts are 0-180 degrees, the driving linear teeth are meshed with the driven linear teeth, the two sides of the robot body are respectively in sliding fit with three sliding rods, the feet movably penetrate through the sliding rods, connecting rods are arranged between the output shafts and the feet, and clutches are arranged between the output shafts and the connecting rods.The linear gear drive based hexapod bionic robot is small in size, low in cost, simple in control and large in drive ratio and can work in a tiny space or a complicated environment.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Connecting device for transmitting power

PendingCN109019444AGuaranteed stabilityGuaranteed uptimeNon-rotating vibration suppressionLifting devicesDrive shaftTransmitted power

The invention discloses a connecting device for transmitting power. The connecting device comprises a motor assembly, a hydraulic transmission assembly, and a connecting assembly arranged between themotor assembly and the hydraulic transmission assembly. The connecting assembly comprises a power transmission shaft, a power connection disc and a torque converter which are sequentially arranged. Alarge end plate of the power transmission shaft is connected with the power output end of the motor assembly through an output flange, and the tip of the small end of the power transmission shaft is fixedly connected with the power connection disc through a connecting piece. The connecting assembly arranged between the motor assembly and the hydraulic transmission assembly is compact in structureand reasonable in layout, all parts of the connecting assembly are easy to manufacture and low in machining cost, mounting and dismounting are convenient, the reliability requirements of radial and axial connection when the motor assembly and the hydraulic transmission assembly realize power transmitting through the connecting assembly are met, and the power transmitting effect is good.

Owner:ANHUI HELI CO LTD

Vision-based multi-sensor fusion intelligent epidemic prevention robot and system

ActiveCN113084776AImprove obstacle avoidanceImprove path planning capabilitiesProgramme-controlled manipulatorSensing radiation from moving bodiesRotational axisDrive wheel

The invention relates to a vision-based multi-sensor fusion intelligent epidemic prevention robot and a system. The vision-based multi-sensor fusion intelligent epidemic prevention robot comprises a robot upper cover and a robot main body which are arranged with one under the other, a rotating shaft and a rotating motor for driving the rotating shaft are arranged in the robot main body, a through hole for the rotating shaft to penetrate through is formed in the center of the robot upper cover, a sensor box is fixed at one end, penetrating through the through hole, of the rotating shaft, and an infrared camera and a high-definition camera are arranged on the sensor box; a depth camera, a monocular camera and a loudspeaker are arranged on the robot upper cover, and two driving wheels and two universal wheels are arranged below the robot main body; a control system is arranged in the robot main body; and the infrared camera, the high-definition camera, the depth camera, the monocular camera, the loudspeaker and the driving wheels are all connected with the control system. Compared with the prior art, the vision-based multi-sensor fusion intelligent epidemic prevention robot has the advantages that the capability of identifying and tracking the fever personnel is higher, and so on.

Owner:SHANGHAI UNIV OF ENG SCI

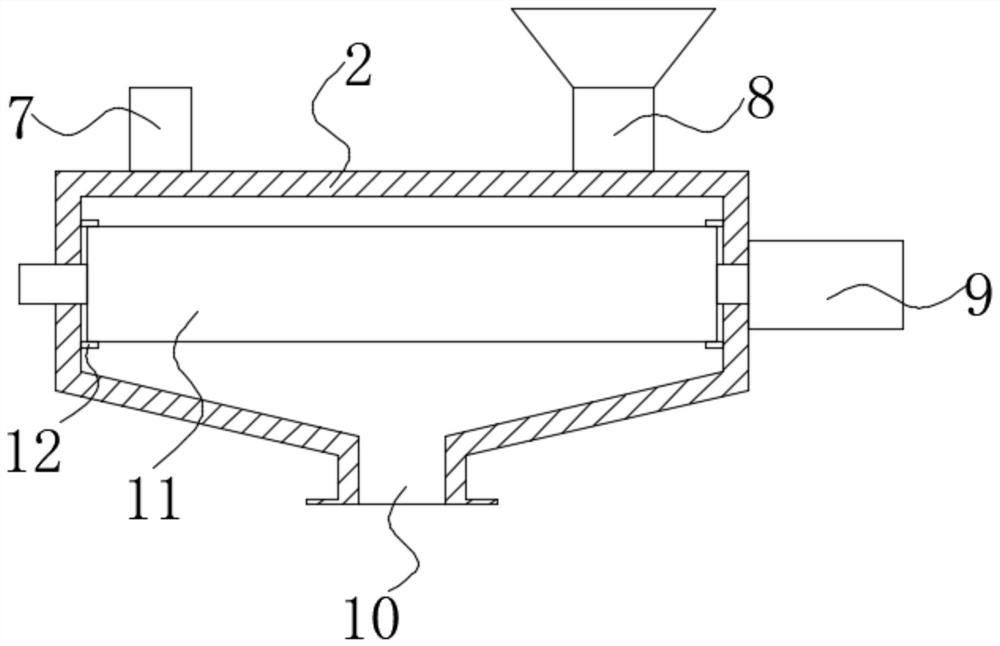

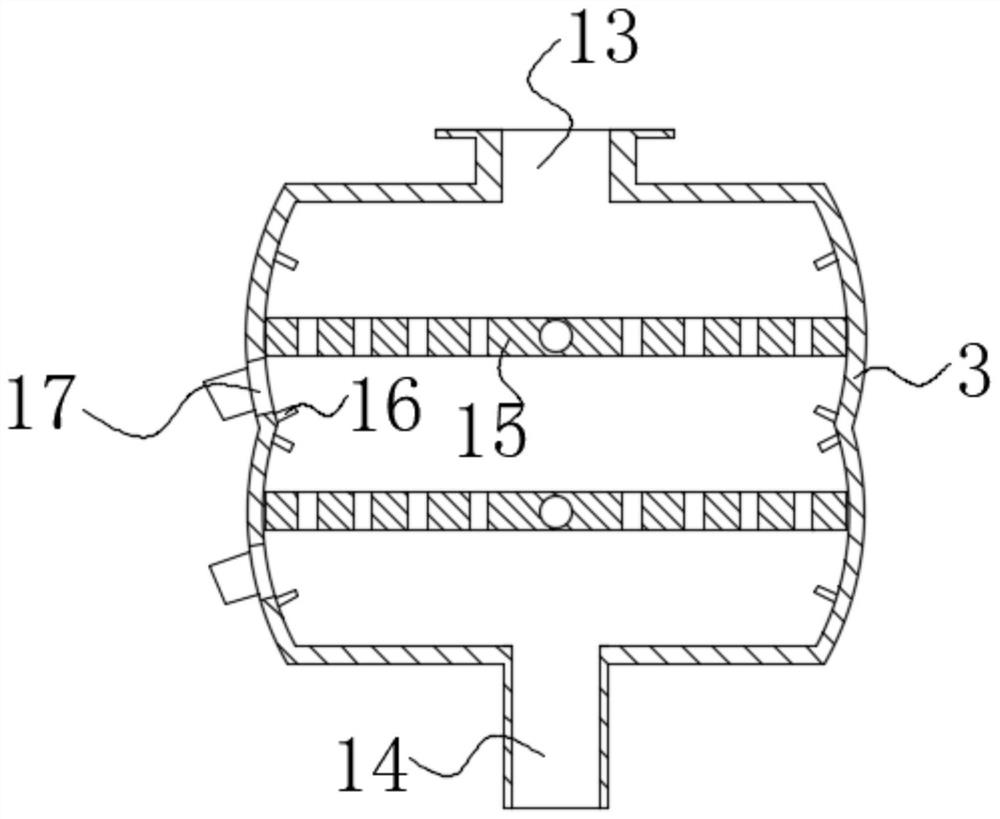

Raw material mixing device for production of hollow bricks

InactiveCN112123576ACompact structureInvolves reasonableDischarging apparatusMixing operation control apparatusBrickElectric machinery

The invention provides a raw material mixing device for the production of hollow bricks, which comprises a feeding screw conveyor, a crushing box, a screening box, a mixing box and a base, the mixingbox is fixedly mounted on the base through a bracket, the crushing box, the screening box and the mixing box are connected from top to bottom, the feeding screw conveyor is mounted between the crushing box and the screening box, a feeding hopper and a circulating feeding inlet are arranged at the top of the crushing box, the circulating feeding inlet is connected with a discharging end of the topof the feeding screw conveyor, a discharging outlet is arranged at the bottom of the crushing box, two crushing rollers parallel to each other are rotatably arranged in the crushing box, the crushingrollers are transversely arranged and are in transmission connection with a crushing motor, the upper end and the lower end of the screening box are respectively provided with a first feeding inlet and a first discharging outlet, the first feeding inlet is connected with the discharging outlet, two screening plates are rotatably arranged in the screening box and longitudinally distributed, and twosidewalls of the screening box are arc-shaped walls.

Owner:ANHUI KUNMENG NEW TYPE BUILDING MATERIAL CO LTD

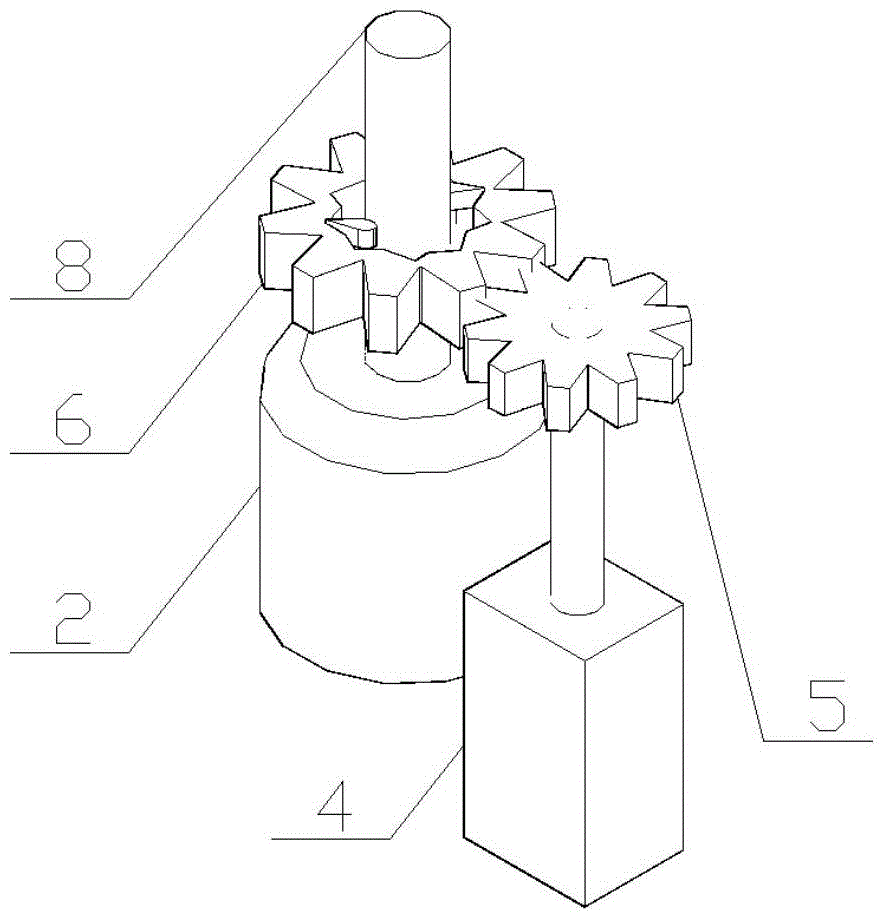

Fork arm carrier

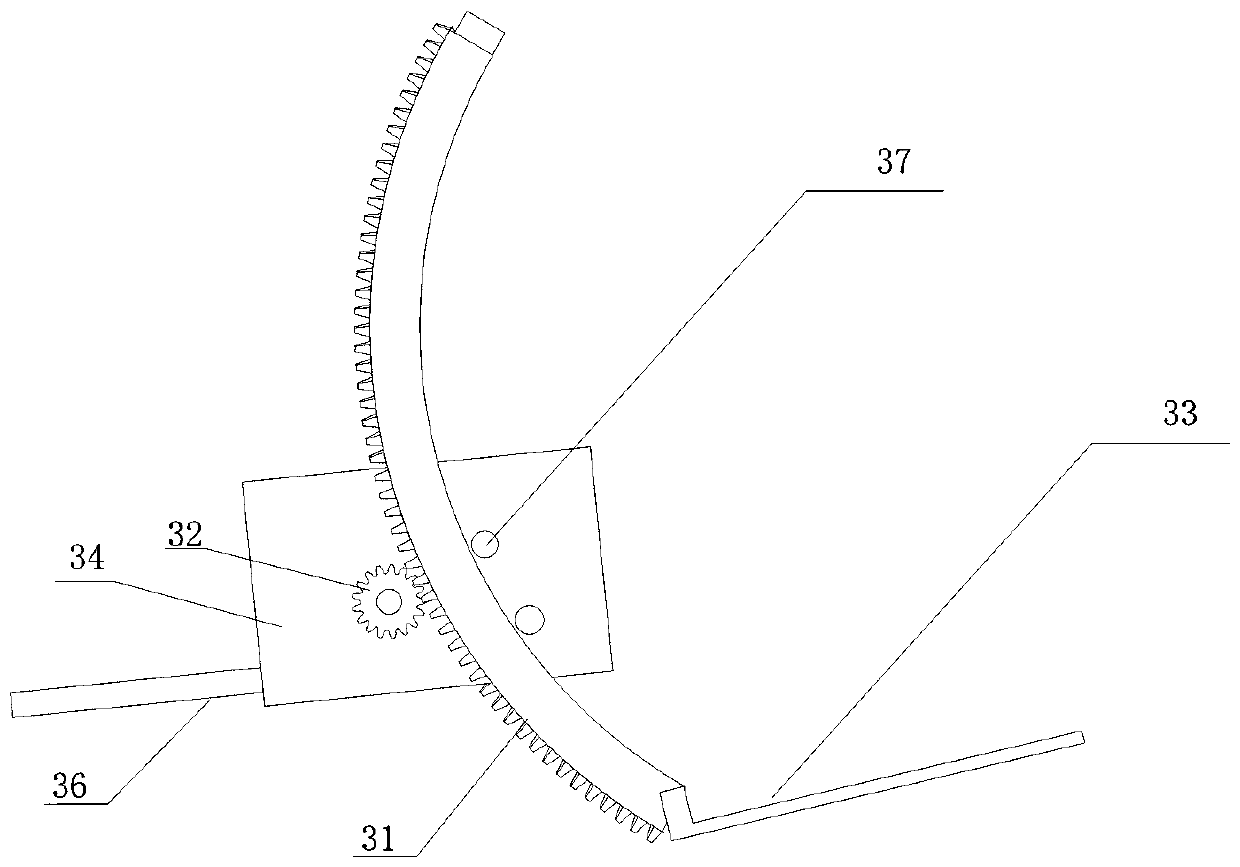

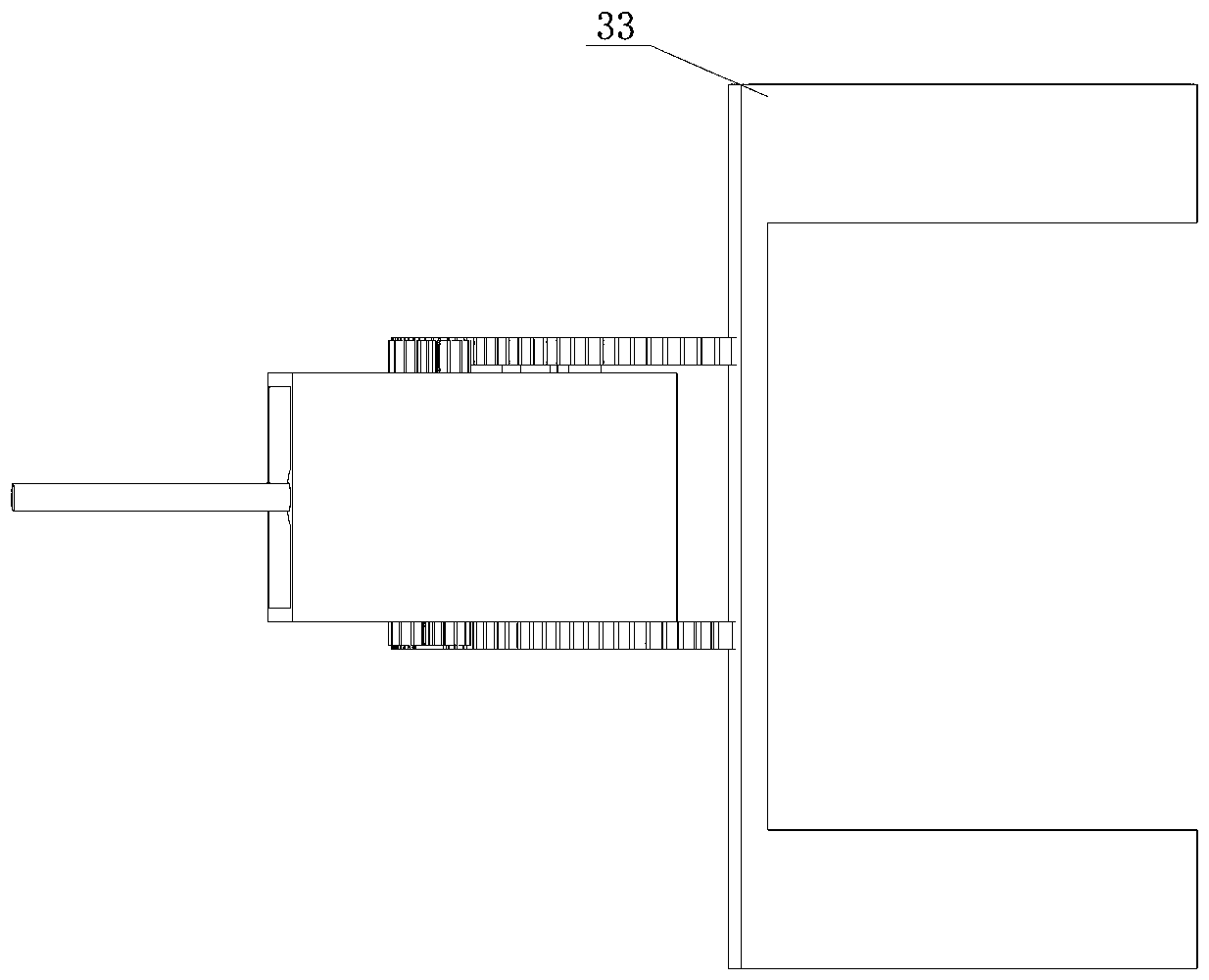

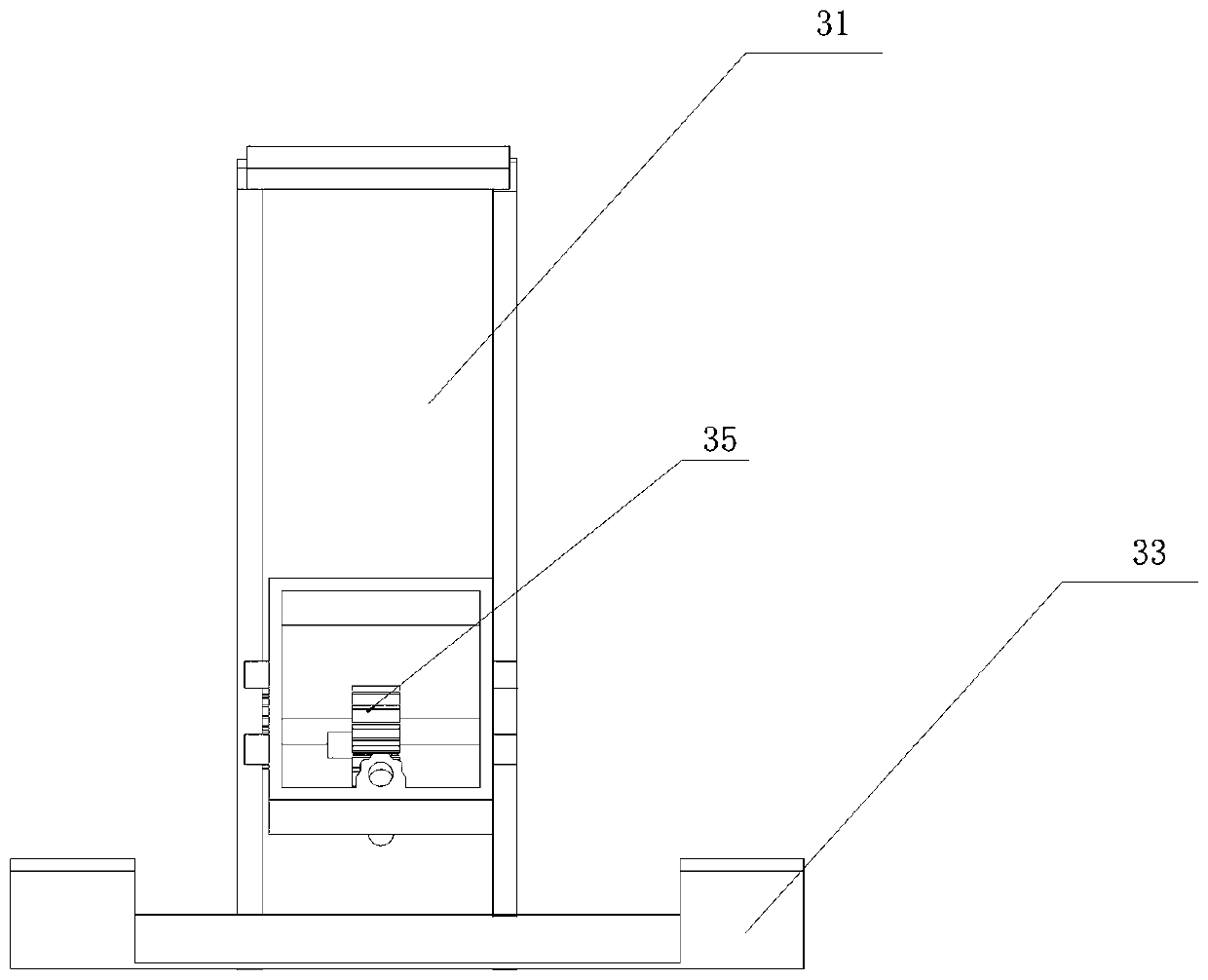

The invention provides a fork arm carrier. The fork arm carrier comprises a driving assembly, a fixing workpiece frame and a fork. The driving assembly comprises a worm, the worm drives a turbine to rotate, and the turbine transmits the power generated in the rotating process to a fork transmission gear through a connection shaft; the fixing workpiece frame is provided with a cavity which is usedfor mounting the worm, the worm drives the turbine to rotate in the cavity of the fixing workpiece frame, the connection shaft is rotatably connected to the fixing workpiece frame, and the fork transmission gear is rotatably connected to the outer wall of the fixing workpiece frame through the connection shaft; the fork comprises an arc-shaped rack and a fork arm fixed to the lower end of the arc-shaped rack, and gear teeth arranged on the arc face of the arc-shaped rack is engaged with gear teeth of the fork transmission gear; a limiting bearing is arranged on the fixing workpiece frame, andthe limiting bearing is matched with the fork transmission gear to limit, clamp and fix the arc-shaped rack. The fork arm carrier can easily adjust the angle of the fork, the stability in the carrying, loading and unloading processes of goods is ensured, the height of the fork can be easily adjusted as well, the turbine cannot reversely drive the worm, the structural design is reasonable, operation is safe, the fork arm carrier can be dismounted and mounted conveniently, and a large amount of labor is saved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

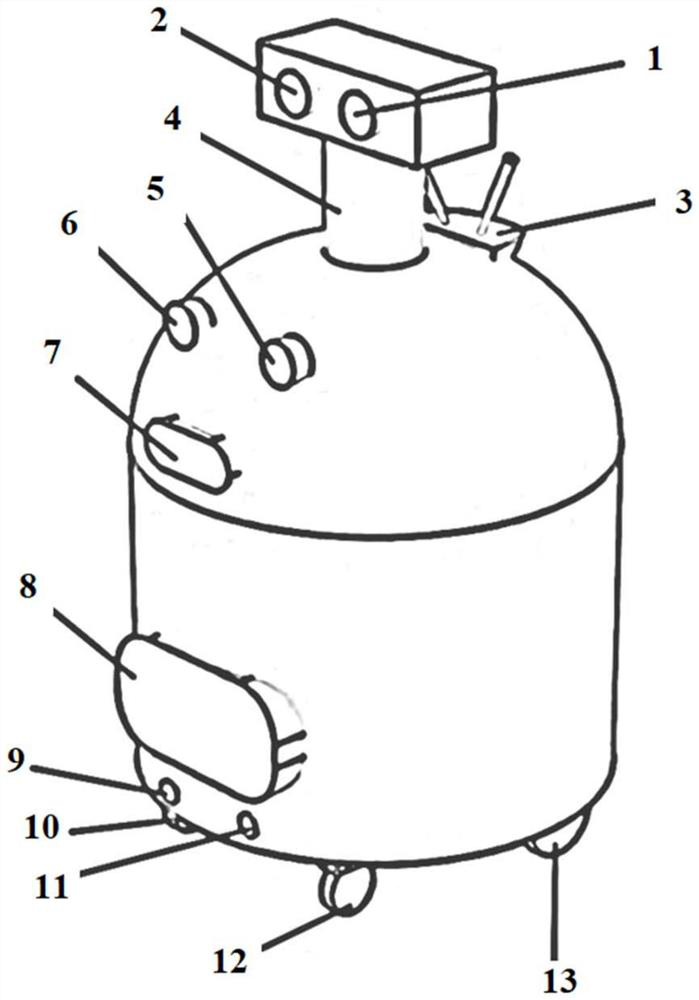

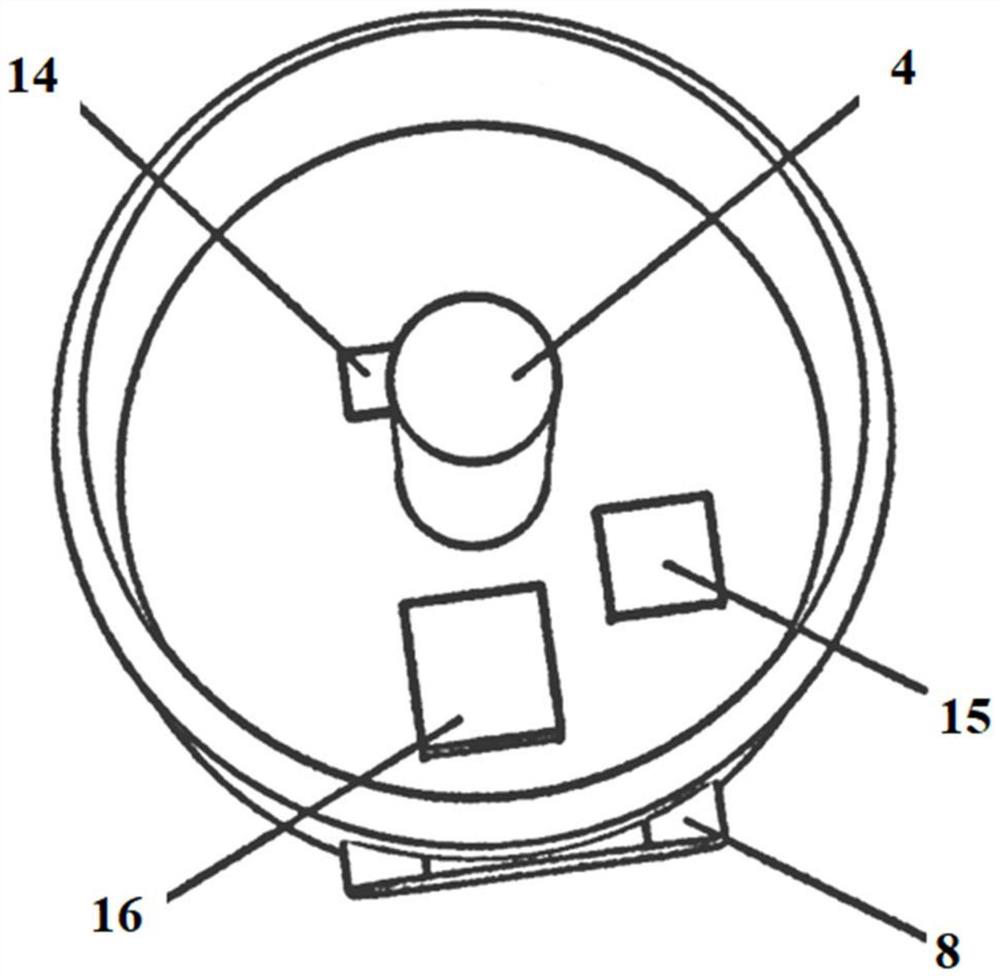

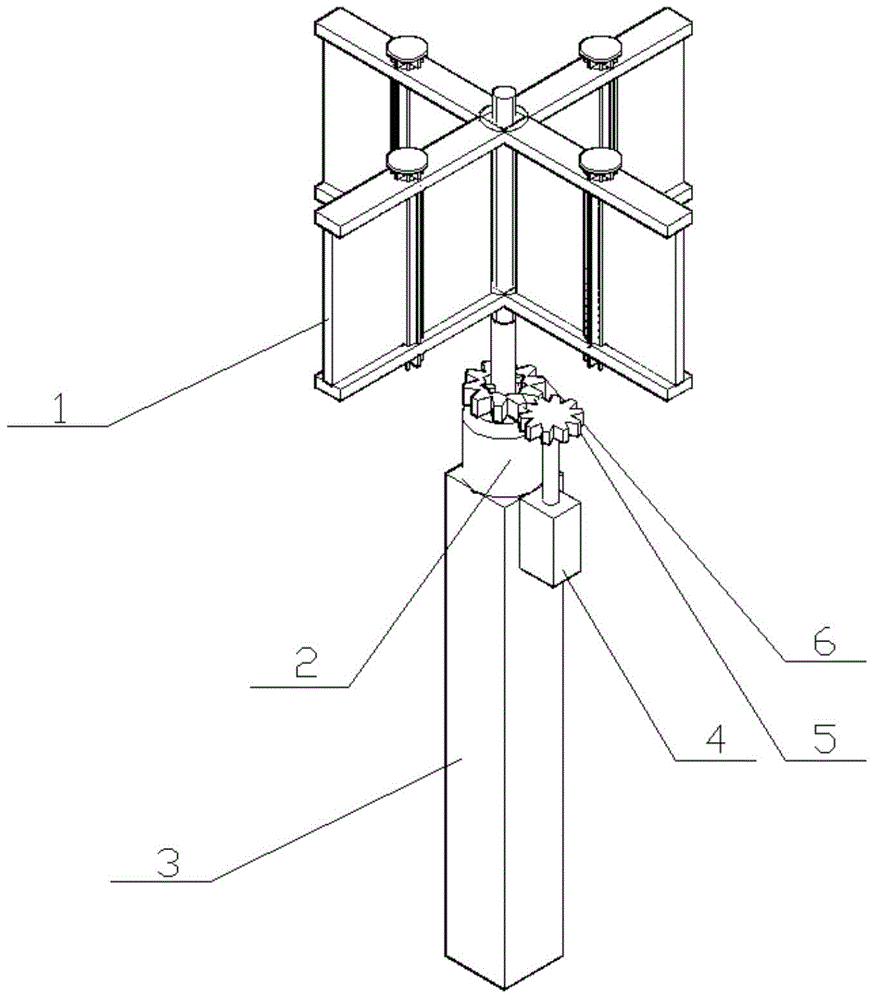

Vertical-axis wind power generation apparatus

InactiveCN105604792AImprove power generation efficiencyGuaranteed uptimeWind motor controlRenewable energy generationImpellerDrive shaft

The invention discloses a vertical-axis wind power generation apparatus. The vertical-axis wind power generation apparatus comprises a fan rod, wherein a power generator is arranged on the top end of the fan rod; a pneumatic device is arranged on the top end of a power generator rotor of the power generator; the pneumatic device comprises an impeller shaft connected with the top end of the power generator rotor; two upper supporting plates which are perpendicular to each other are arranged on the upper end of the impeller shaft; two lower supporting plates which are perpendicular to each other are arranged on the lower end of the impeller shaft; blades are arranged between the upper supporting plates and the lower supporting plates, and the blades are connected with the upper supporting plates and the lower supporting plates through a blade adjusting shaft; the blade adjusting shaft comprises an adjusting shaft cover and an adjusting column fixed on the lower end surface of the adjusting shaft cover; a pawl-and-ratchet mechanism is arranged on the power generator rotor and comprises a pawl arranged on the power generator rotor and a ratchet which is engaged with the pawl and provided with a gear; a gear which is engaged with the ratchet is arranged outside the ratchet and is connected with a driving shaft of a driving motor through keys. The vertical-axis wind power generator apparatus is simple in structure, capable of realizing the controllability of the pneumatic device and high in power generation efficiency, and the impeller and the wind direction angle are adjustable.

Owner:XIAN BOYU GREEN ENERGY

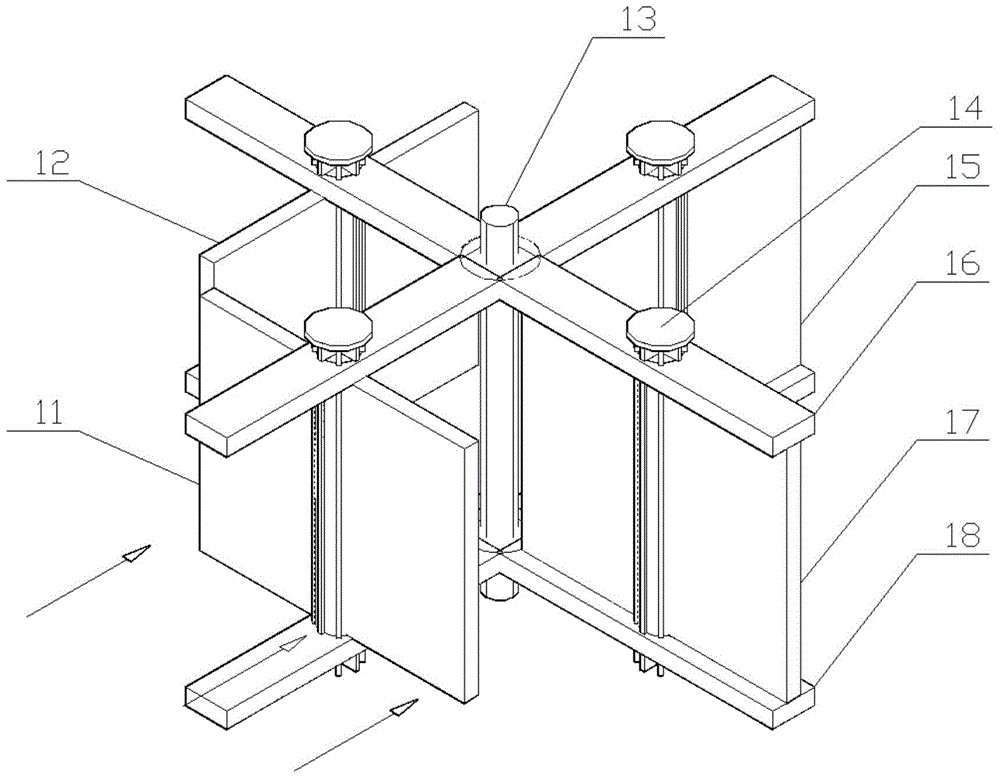

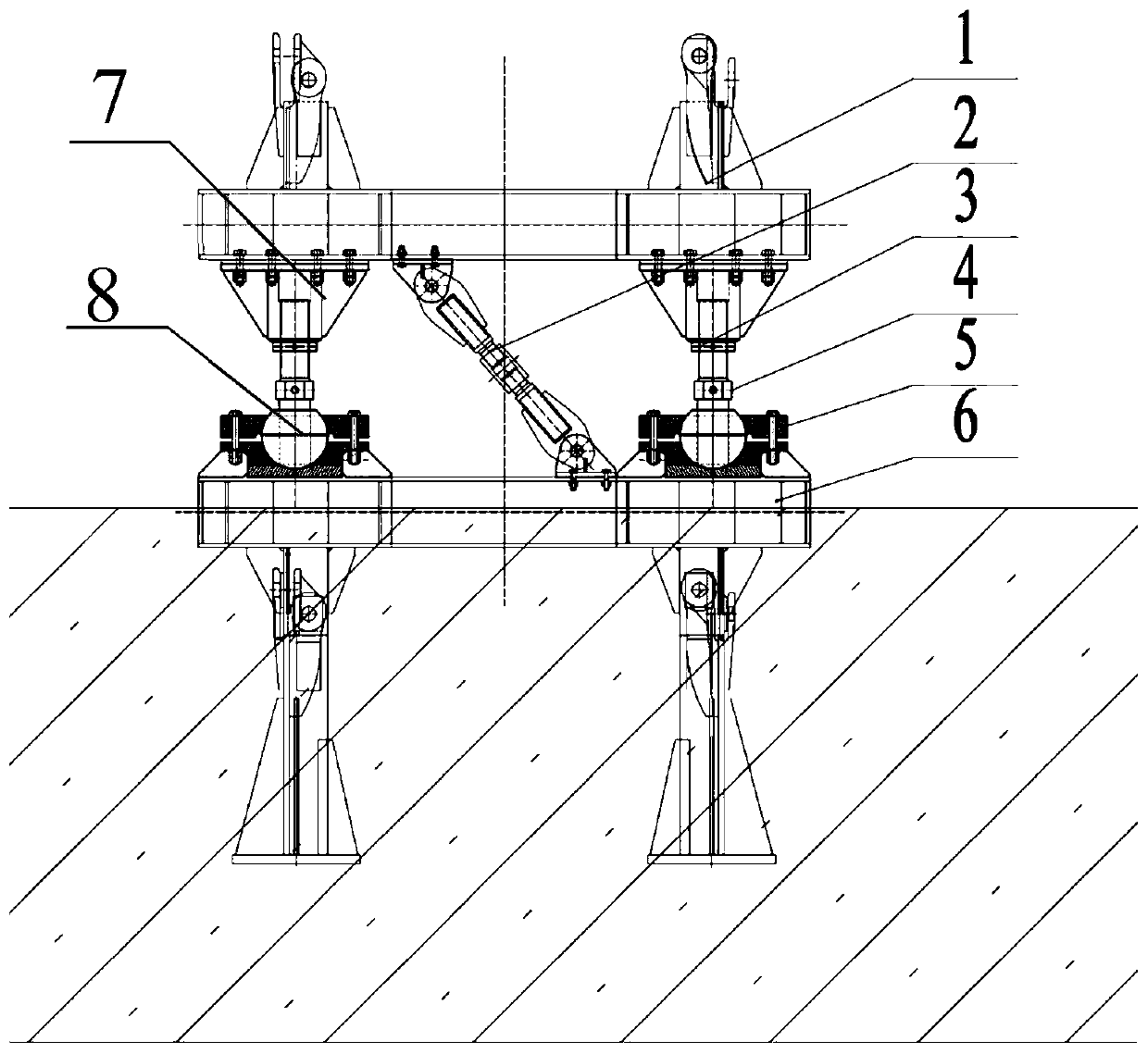

Leveling device and method for tilt of tower body after installation of tower-type crane

The invention discloses a leveling device and method for tilt of a tower body after installation of a tower-type crane. According to the technical scheme, the leveling device is characterized by comprising an upper underframe connected to the tower body of the crane and a lower underframe connected to a pre-buried foundation section, adjusting mechanisms are arranged between the upper underframe and the lower underframe, each adjusting mechanism comprises a thread sleeve arranged at the lower end of the upper underframe, an adjusting rod perpendicular to the horizontal plane, a locking memberarranged at the upper end of the lower underframe and a fixing member matched with the locking member, each fixing member is embedded into the corresponding locking member, one end of each adjusting rod is arranged at the lower end of the corresponding thread sleeve in a penetrating mode, the other end of each adjusting rod is connected with the corresponding fixing member, and at least one adjustable strut is arranged between the every two adjacent adjusting mechanisms. According to the leveling device, the tower-type crane does not need to be dismantled and re-installed, the construction process is reasonably reduced, the safety in the adjustment process is also improved, the safety coefficient of an operator is increased, the treatment period is effectively shortened, the construction cost of a project is significantly reduced, and the project progress can be effectively guaranteed.

Owner:ZHEJIANG HUBA CONSTR MACHINERY

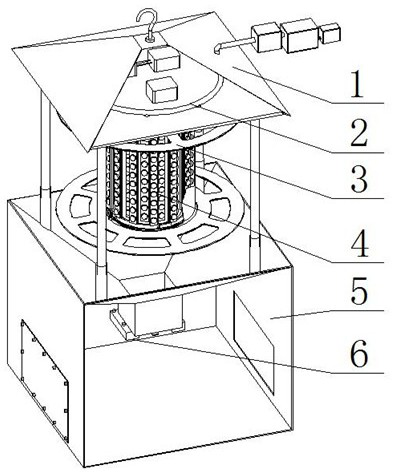

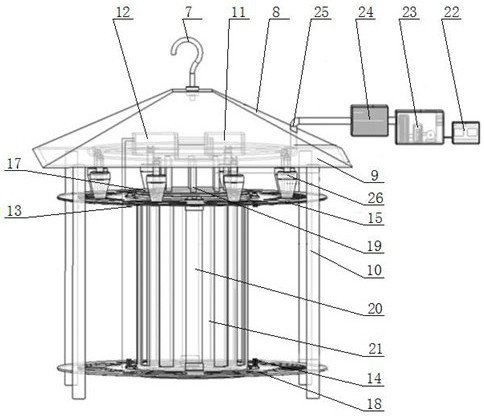

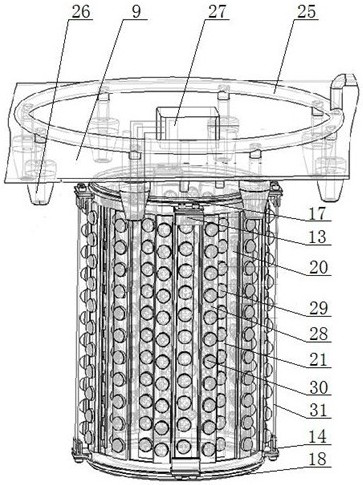

Lamp enhanced type thermoelectricity killing and collecting device for agricultural pests on illumination flexible induction heat regulation and control

PendingCN113142156APrevent escapeObtain photothermal coupling manipulation induction effectAnimal repellantsInsect catchers and killersThermodynamicsHigh voltage pulse

The invention discloses a lamp enhanced type thermoelectricity killing and collecting device for agricultural pests on illumination flexible induction heat regulation and control. The lamp enhanced type thermoelectricity killing and collecting device comprises a supporting system, a thermal fog conducting medium spraying system, a high-voltage pulse electric field system, a light source system, a collecting device and a negative pressure air suction closed system. An annular plastic pipeline in the thermal fog conducting medium spraying system is arranged on an upper surface of a supporting plate in the supporting system, a lower surface of the supporting plate in the supporting system is connected with an upper protection plate in the light source system through a hanging rod, the upper protection plate in the light source system is located in a circular hollow structure of an anode in the high-voltage pulse electric field system, a supporting rod in the supporting system is fixedly connected with a box body in the collecting device, and the negative pressure air suction sealing system is arranged at a lower end of a super-smooth funnel in the collecting device. The device implements photo-thermal trapping flexible regulation and control measures and thermoelectricity killing and collecting and air suction trapping measures of pests, such that problems that pest biological taxis trapping regulation and control are difficult and pests are difficult to kill and trap are solved.

Owner:HENAN INST OF SCI & TECH

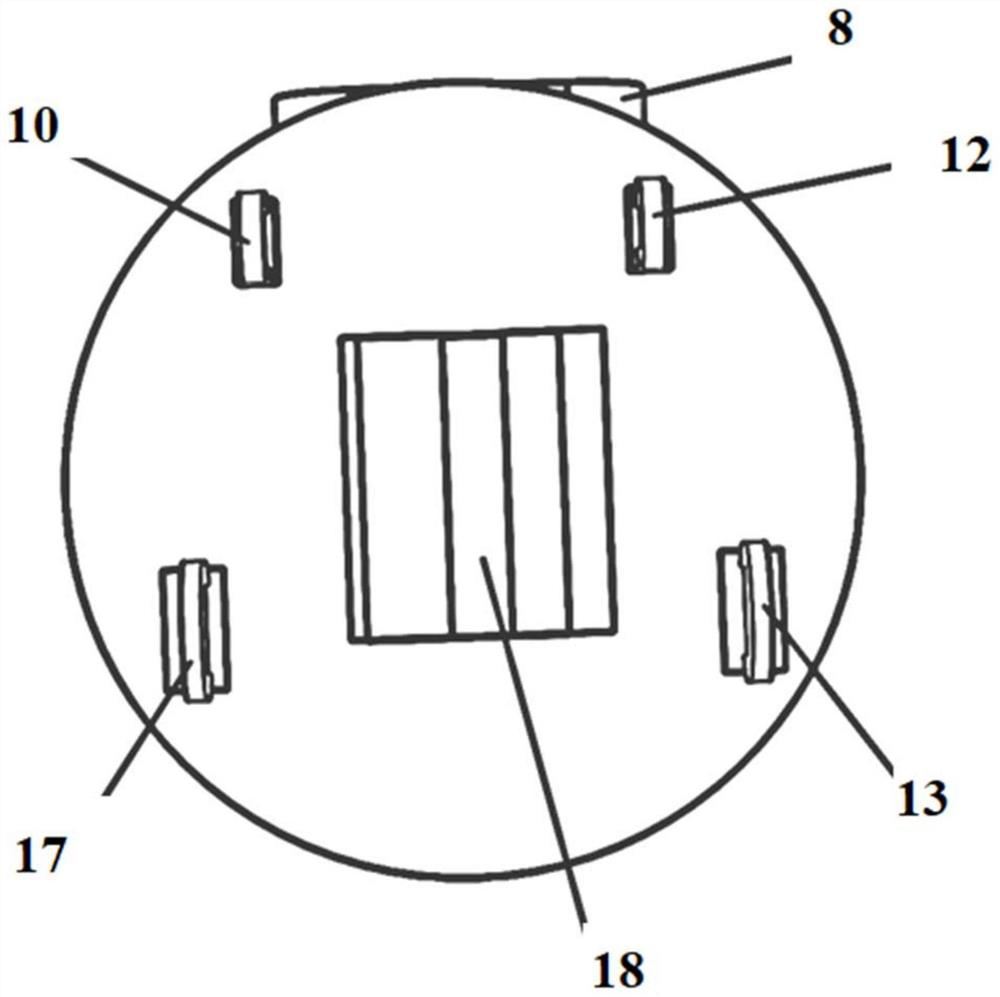

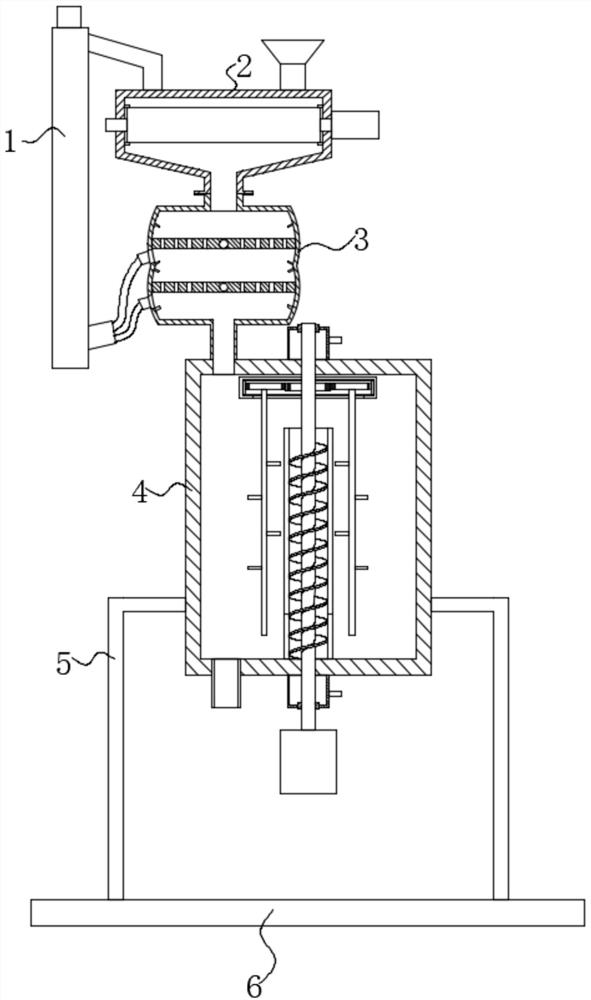

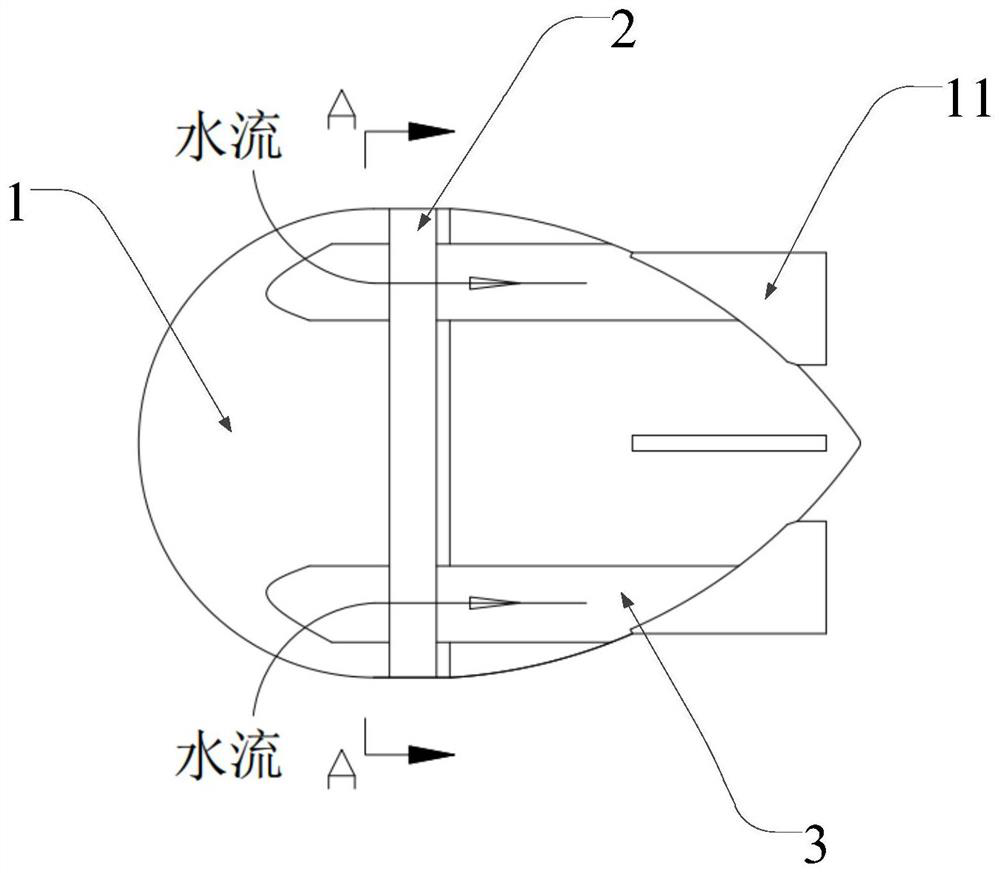

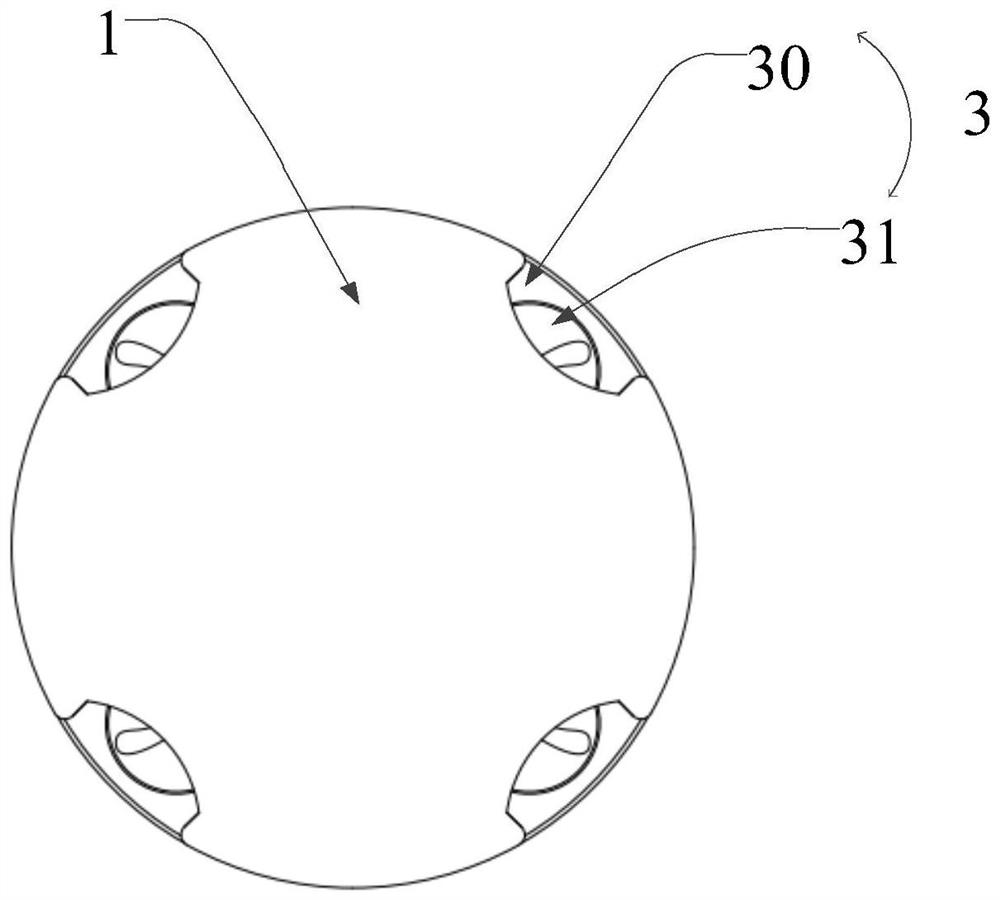

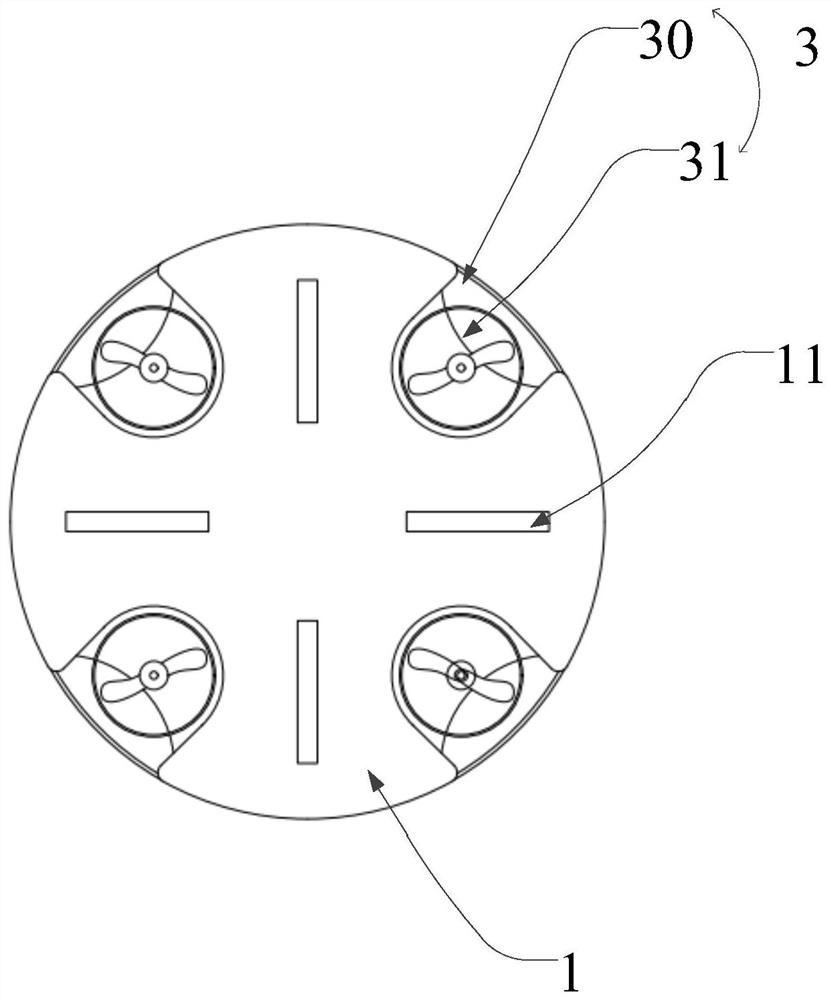

Unmanned aerial vehicle with underwater submerging function

PendingCN114750946AImprove multifunctional working abilityFulfill job requirementsFuselage framesConvertible aircraftsUnderwater navigationMarine engineering

The invention discloses an unmanned aerial vehicle with an underwater submerging function. The unmanned aerial vehicle comprises an aerial vehicle frame; the aircraft fuselage and the aircraft rack are arranged and installed in a matched mode; the flight function assembly is arranged on the aircraft rack and is matched with the aircraft body; the submerging function assembly is arranged on the aircraft frame and is matched with the aircraft body; the aircraft attitude adjusting assembly is matched with the aircraft body and used for adjusting the underwater navigation attitude of the aircraft in water. The unmanned aerial vehicle with the underwater submerging function has the capability of submerging in water while having the function of flying in the air, and can adjust the attitude in the water, so that the unmanned aerial vehicle can adapt to underwater submerging and flying in the air at the same time, and the attitude can be adjusted according to the requirements of functional devices carried by the unmanned aerial vehicle; therefore, the multifunctional operation capability of the unmanned aerial vehicle in a complex environment is greatly improved, and the unmanned aerial vehicle has a good application prospect.

Owner:UNIT 92609 OF PLA

Electrically-controlled tail-end-steerable mechanical arm

The invention provides an electrically-controlled tail-end-steerable mechanical arm. The electrically-controlled tail-end-steerable mechanical arm comprises a mechanical arm module and a painting module, wherein a driving element of the mechanical arm module is arranged on a platform at the bottom part; a first arm and a second arm do not have additional weight, excepting dead weight and the weight of supporting connecting rods, so that the characteristics such as quick moving of a tail end are realized; a working tail end which can be gyrated and rotated on own axis is mounted on the tail endof the second arm, thus the freedom of motion is increased, and various working demands are met; a gyrating driving assembly and a rotating driving assembly at the working tail end are mounted on theplatform, and moving parts of the driving assemblies are lighter than an existing mechanical arm; a painting head of the painting module is provided with pressure maintaining measures, the painting can be continuously performed for a while in case of material cutting off by accident, and thus unqualified products caused by material cutting off can be avoided; the painting head has the heating function and is capable of heating paint, so that the air temperature is increased while the atomizing effect of the paint is increased, and the paint can be quickly dried by air.

Owner:华南智能机器人创新研究院 +1

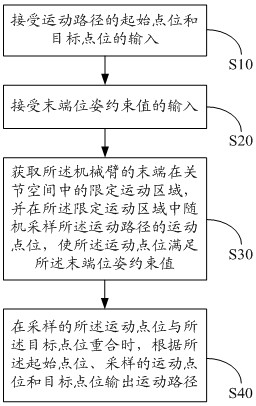

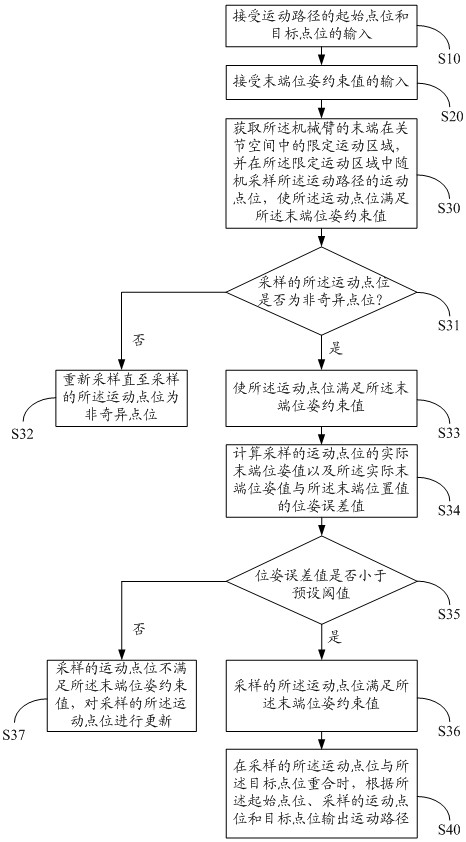

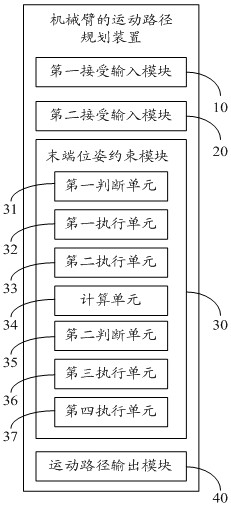

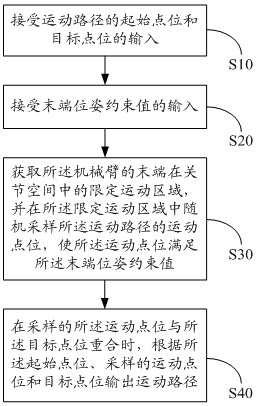

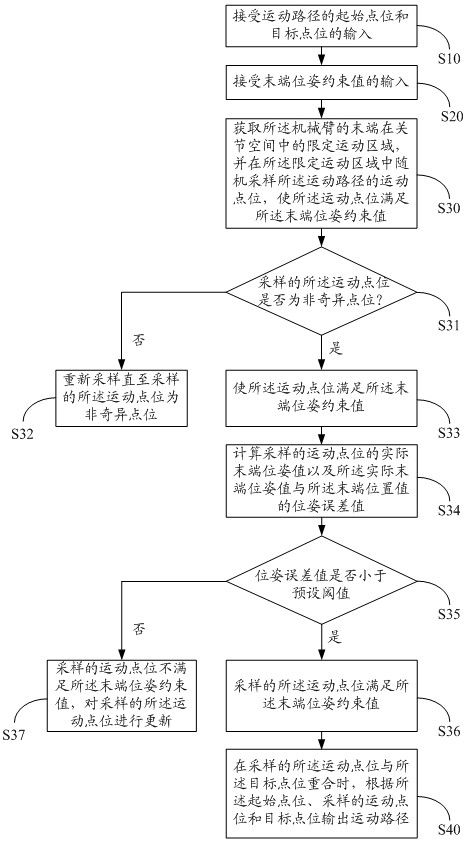

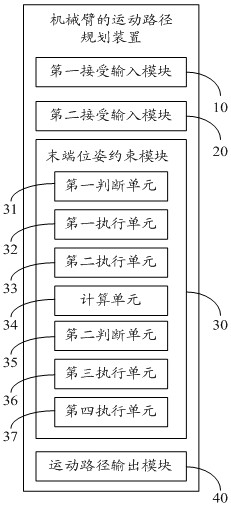

Motion path planning method, device, equipment, medium and robotic arm of robotic arm

The invention discloses a motion path planning method for a mechanical arm. The motion path planning method for a mechanical arm comprises: accepting the input of the starting point and target point of the motion path; accepting the input of the end pose constraint value; obtaining the mechanical The limited motion area of the end of the arm in the joint space, and the motion points of the motion path are randomly sampled in the limited motion area, so that the motion points satisfy the end pose constraint value; When the motion point coincides with the target point, the motion path is output according to the start point, the sampled motion point and the target point. The path points on the motion path planned and generated by the motion path planning method of the mechanical arm of the present invention can meet the given end pose requirements, realize specific operation requirements, and expand application scenarios.

Owner:SHENZHEN YUEJIANG TECH CO LTD

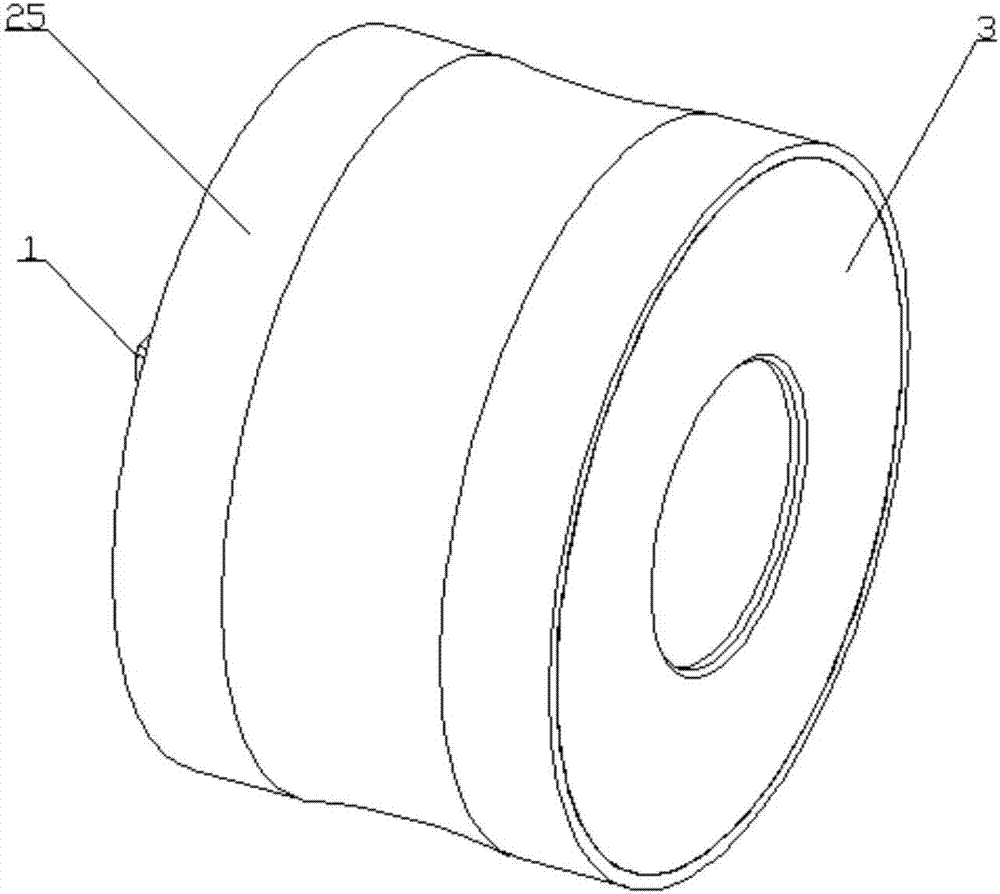

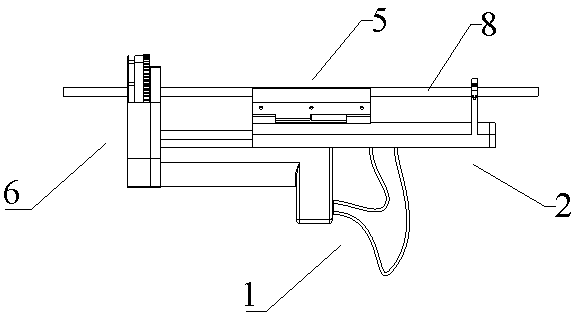

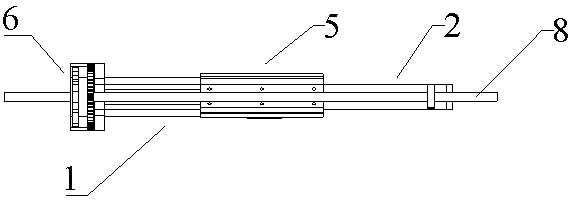

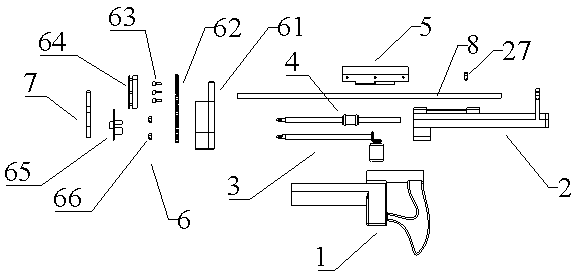

Aluminum tape automatic winder for overhead lines

InactiveCN106505462BAchieve windingEasy to wrapApparatus for overhead lines/cablesEngineeringConductor Coil

The invention discloses an aluminum armor tape automatic winder for an overhead line. The aluminum armor tape automatic winder includes a handle, a fixed device body, a power unit, a slave unit, a fixed lock plate and a winding device, wherein the power unit is arranged in the handle and a power output end of the power unit extends to the outside of the handle, the handle and the fixed device body are correspondingly arranged, the power output end of the power unit and a power receiving end of the slave unit are correspondingly arranged, the power unit can drive the slave unit to move, and the fixed lock plate is fixedly arranged on the fixed device body. The aluminum armor tape automatic winder for the overhead line can realize automatic winding, the winding efficiency is high, the overall structure is compact, the automatic winder can be hung on an electric wire, the workload is reduced, and safe and reliable operation is ensured; operation of workers is facilitated, a reference line can be determined in advance through positioning with the fixed lock plate, a winding position is relatively accurate, the length is easy to control, and the automatic winder is applicable to different situations, thereby realizing operation requirements of aluminum armor tapes; and the stability of the fixed device body is increased.

Owner:杨建伟

Motion path planning method, device and equipment of mechanical arm, medium and mechanical arm

The invention discloses a motion path planning method of a mechanical arm. The motion path planning method of the mechanical arm comprises the steps: receiving input of a starting point position and a target point position of a motion path; receiving the input of a tail end pose constraint value; acquiring a limited motion area of the tail end of the mechanical arm in a joint space, and randomly sampling a motion point location of the motion path in the limited motion area to enable the motion point location to meet the tail end pose constraint value; and when the sampled motion point location coincides with the target point location, outputting a motion path according to the starting point location, the sampled motion point location and the target point location. According to the motion path planning method of the mechanical arm, each path point location on the motion path planned and generated by the motion path planning method can meet the given tail end pose requirement, the specific operation requirement is met, and the application scene is expanded.

Owner:SHENZHEN YUEJIANG TECH CO LTD

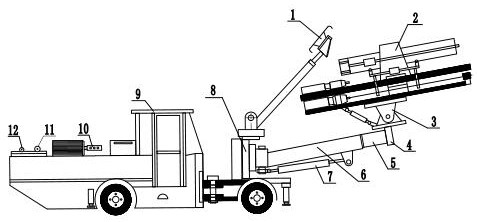

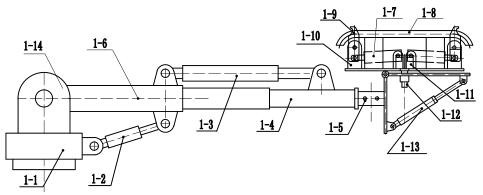

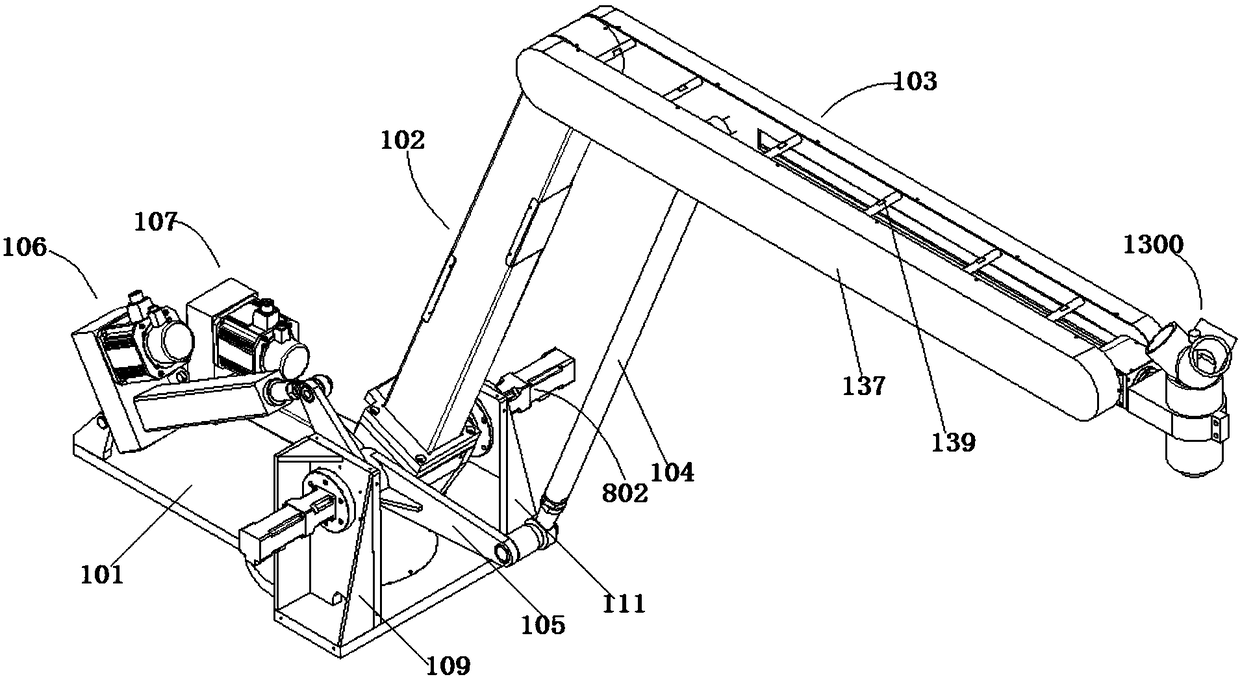

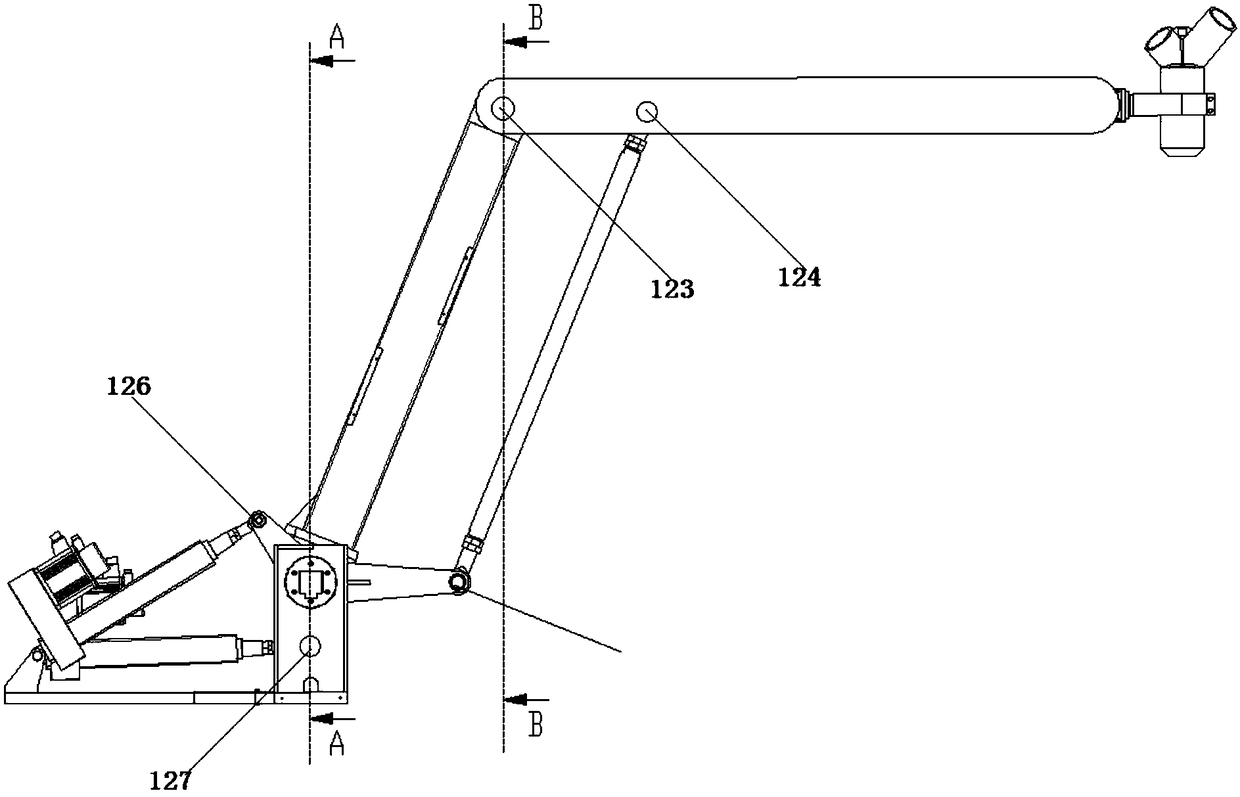

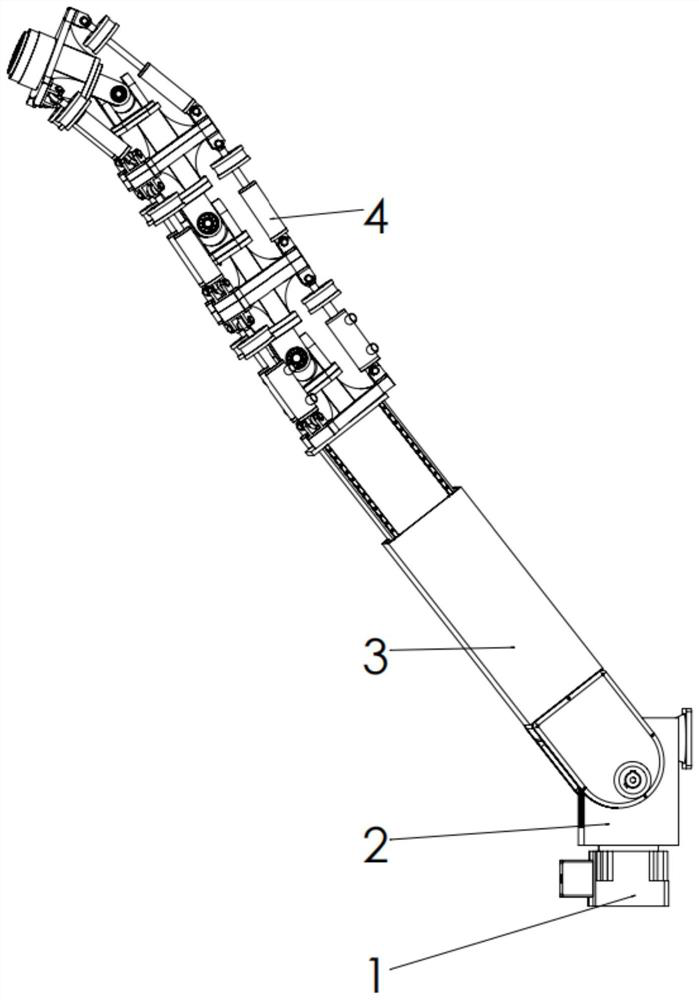

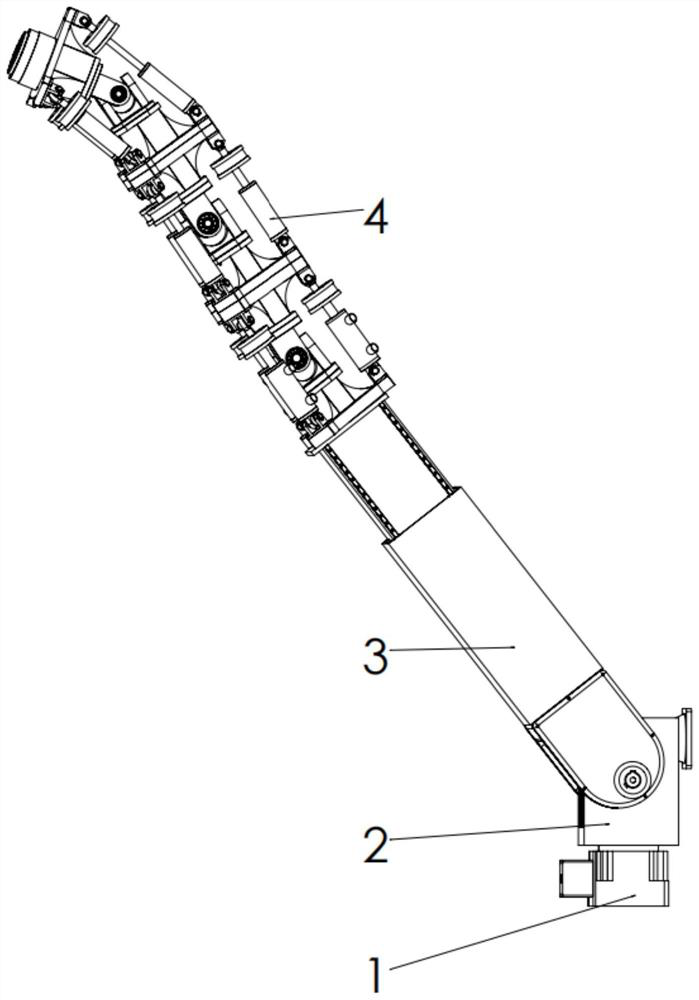

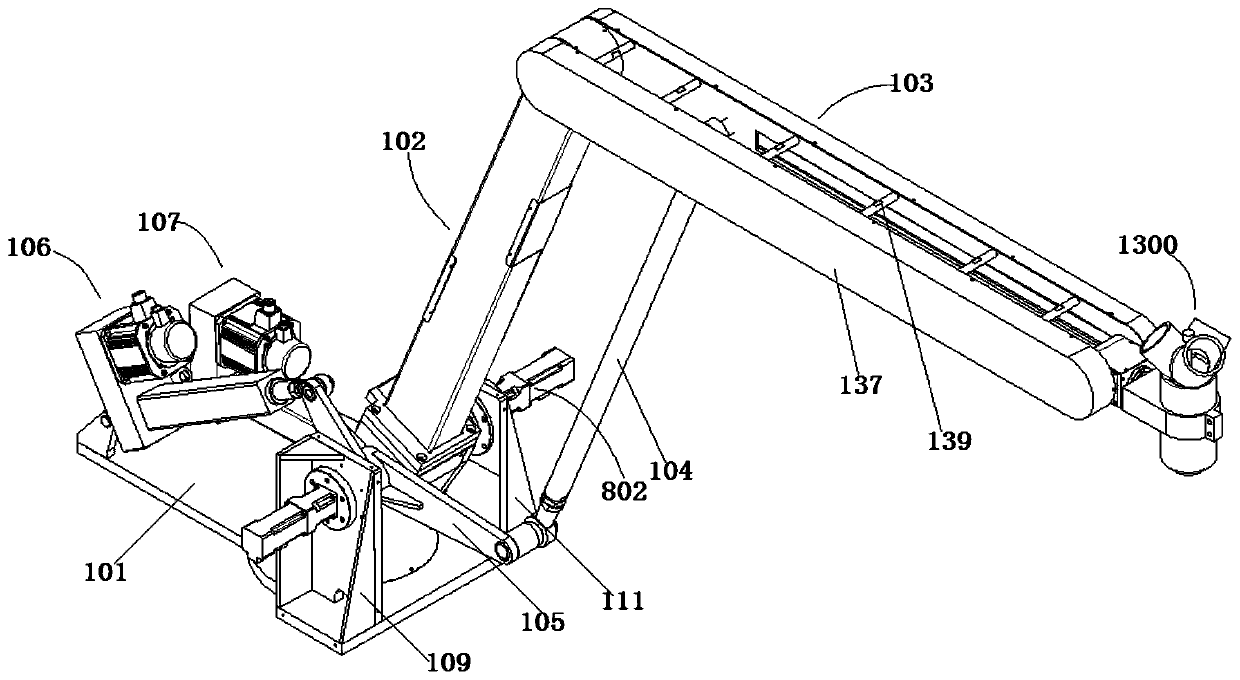

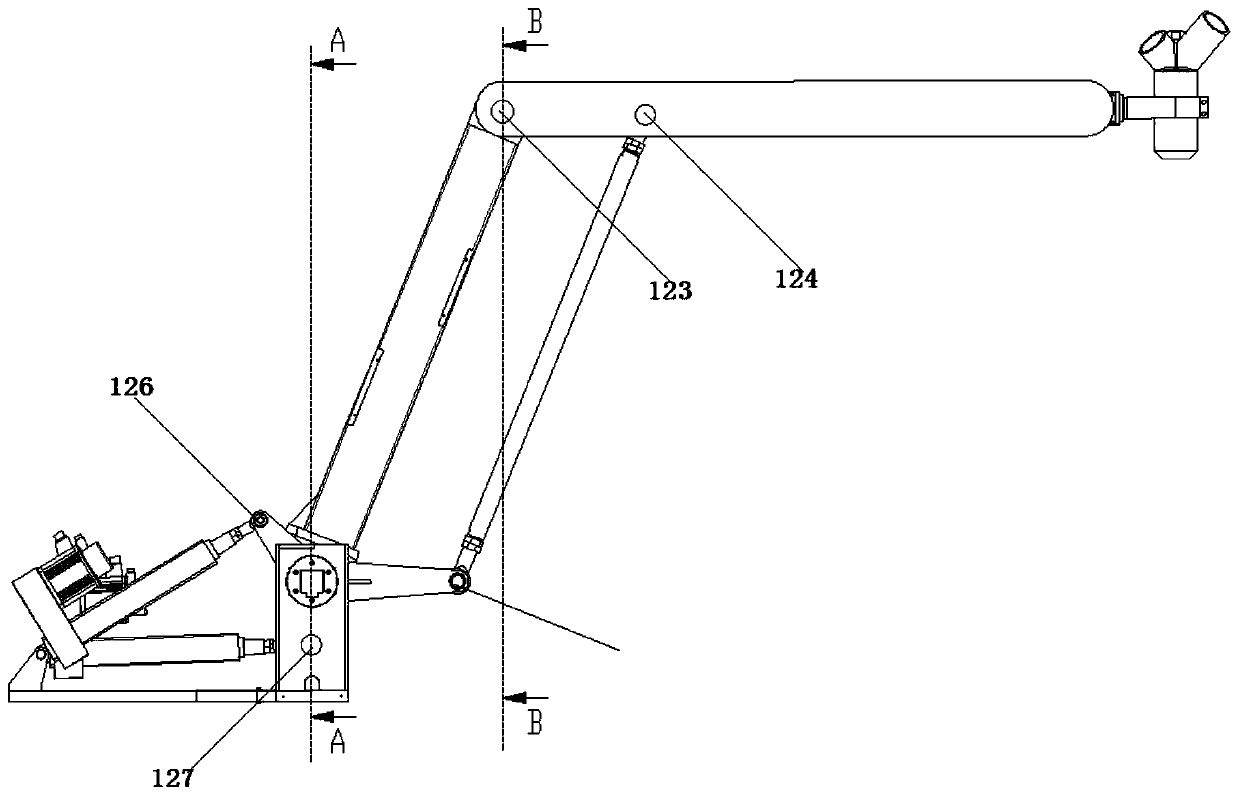

A special pipe string conveying device for vertical root workover equipment

ActiveCN113250631BAchieve regulationMeet the needs of useDrilling rodsDrilling casingsEngineeringTraveling block

The invention discloses a special pipe string delivery device for stand workover equipment, and relates to the technical field of oil field workover equipment. The deformation of the arm folding mechanism and the rotation of the rear lifting mechanism are respectively realized through a folding arm hydraulic cylinder and a lifting hydraulic cylinder. In order to realize the adjustment of any position of the bearing platform and meet the use of diversified platforms, the main points of the technical scheme are: including the frame, the trolley clamping mechanism installed on the frame, the trolley mechanism, the rear lifting mechanism, the lifting fluid Cylinder, feeding mechanism, blanking baffle mechanism, discharging mechanism, pushing mechanism, bearing platform, feeding liquid cylinder, blanking baffle hydraulic cylinder, folding arm mechanism and folding arm hydraulic cylinder.

Owner:山东泽元石油机械有限公司

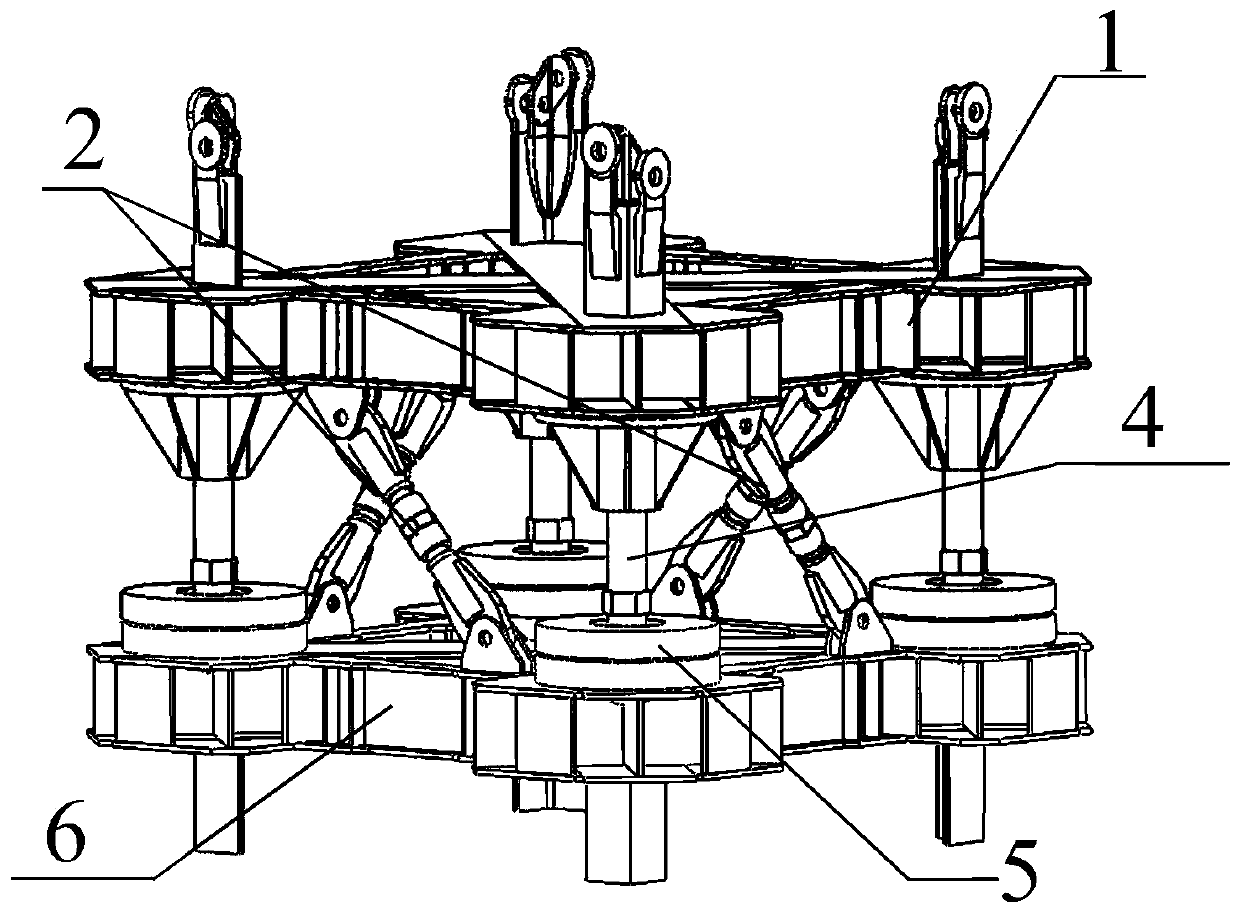

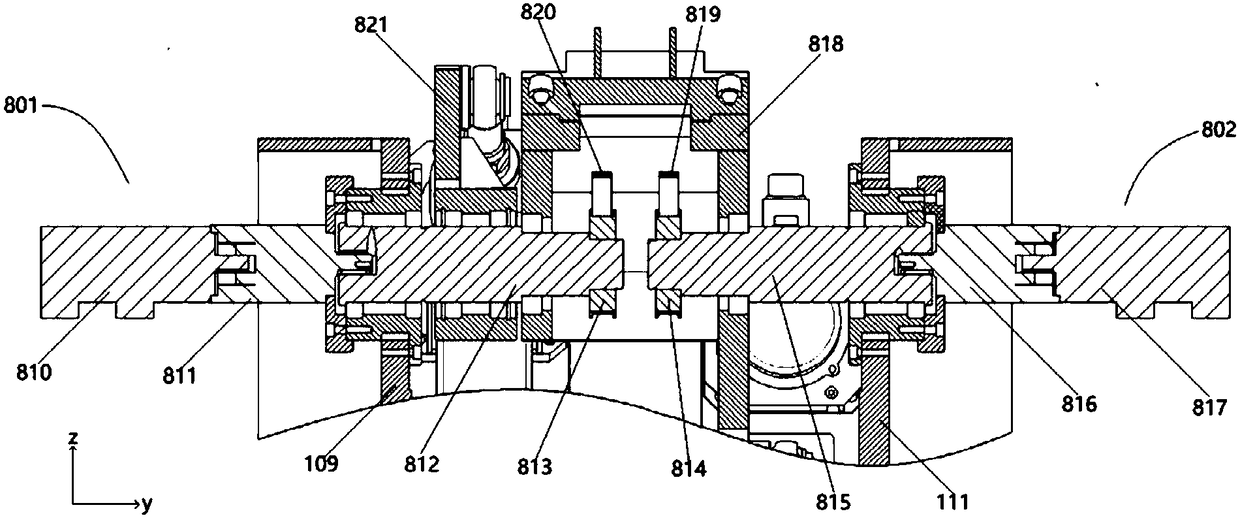

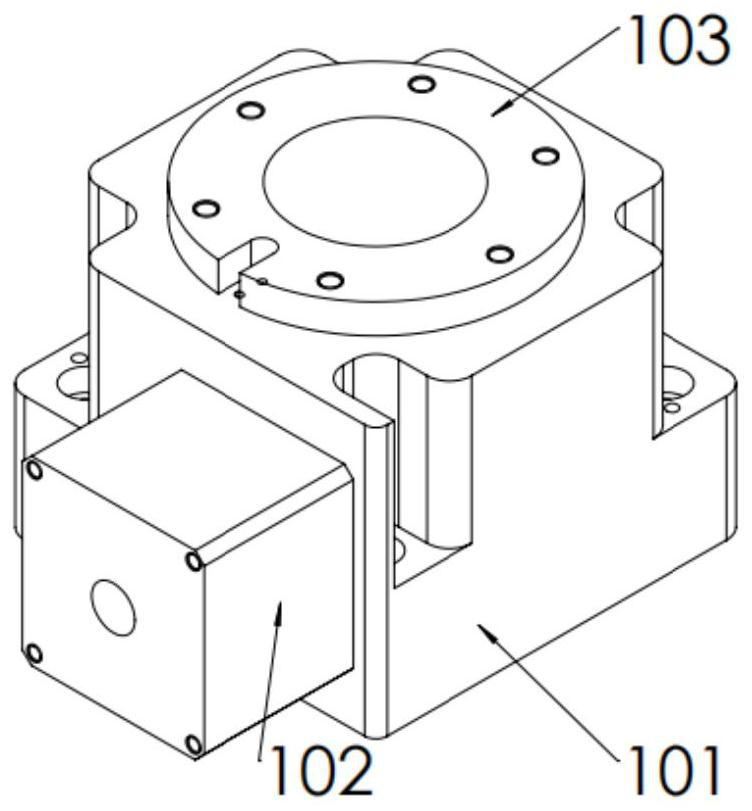

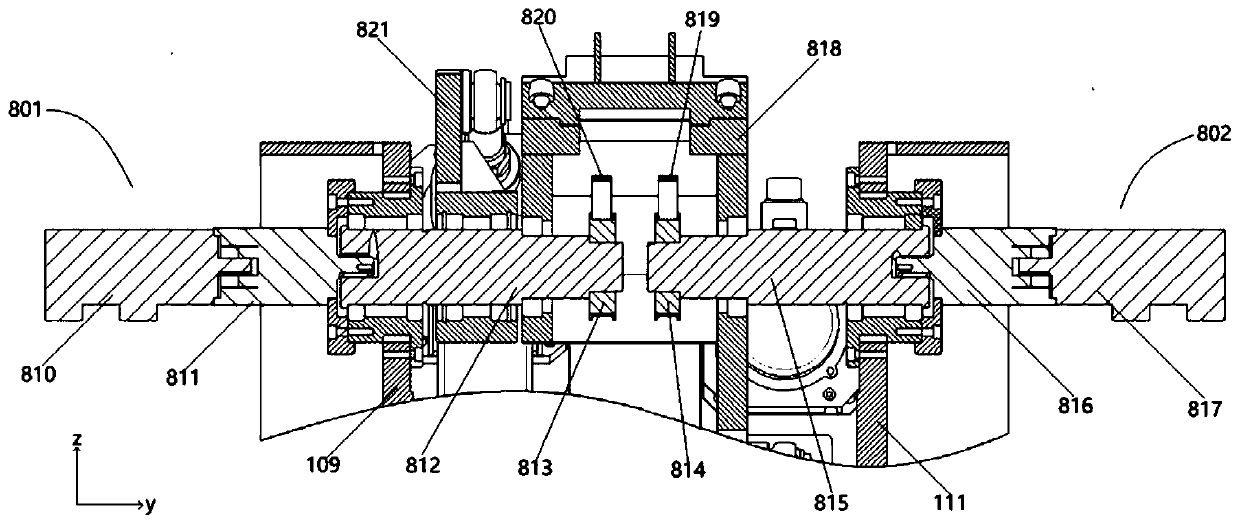

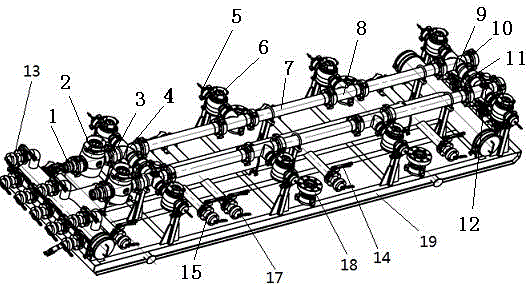

A hydraulic lightweight parallel manipulator

ActiveCN112621720BLight structureRealize stepless speed regulationProgramme-controlled manipulatorControl engineeringParallel manipulator

A hydraulic lightweight parallel mechanical arm belongs to the field of robot structure technology and is composed of a mobile platform connection component, a large arm mobile component, a mechanical large arm component and a hydraulic parallel mechanical small arm component. The large arm mobile component is installed on the mobile platform On the connection assembly, the mechanical boom assembly is installed on the boom moving assembly, and the hydraulic parallel mechanical small arm components are installed on the mechanical boom assembly. Compared with other existing methods, the advantages of the present invention are: using hydraulic components to assemble the small arm of the manipulator, which is lighter in structure, can realize stepless speed regulation during the movement of the manipulator, and has higher motion precision; adopts hydraulic parallel Combined assembly in a combined way to realize the six degrees of freedom of the robotic arm, compared with other existing robotic arms, it is lighter in weight and has a higher load-to-weight ratio; the assembled combined robotic arm can meet the requirements of various types of work, The flexible transformation of various terminal execution parts can be realized by using the replaceable execution terminal installation parts.

Owner:SHENZHEN INST OF ADVANCED TECH

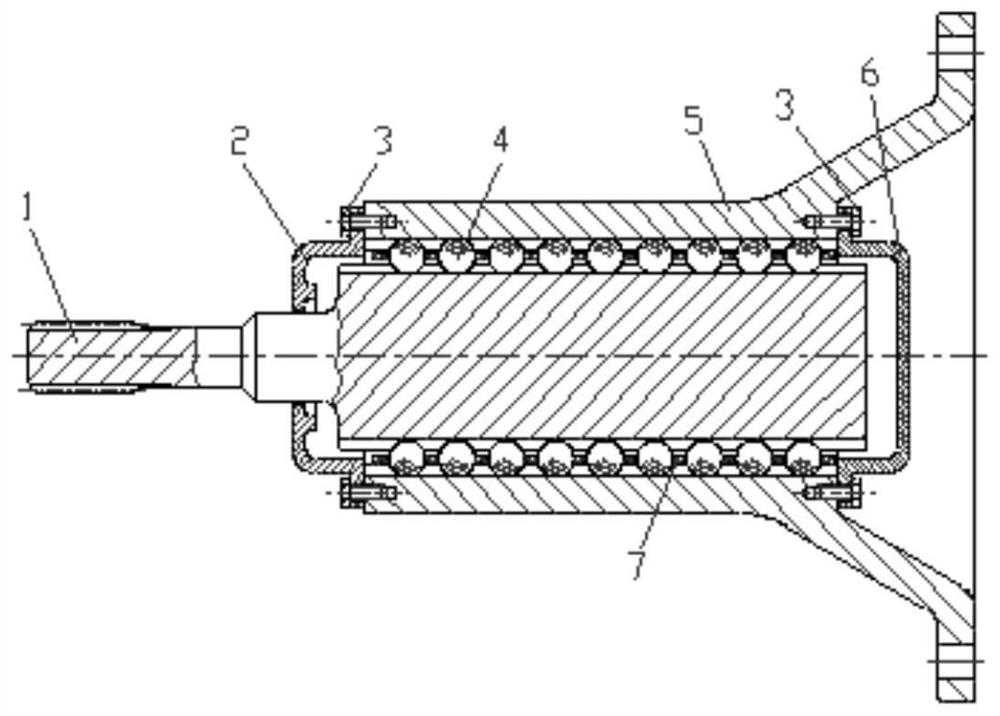

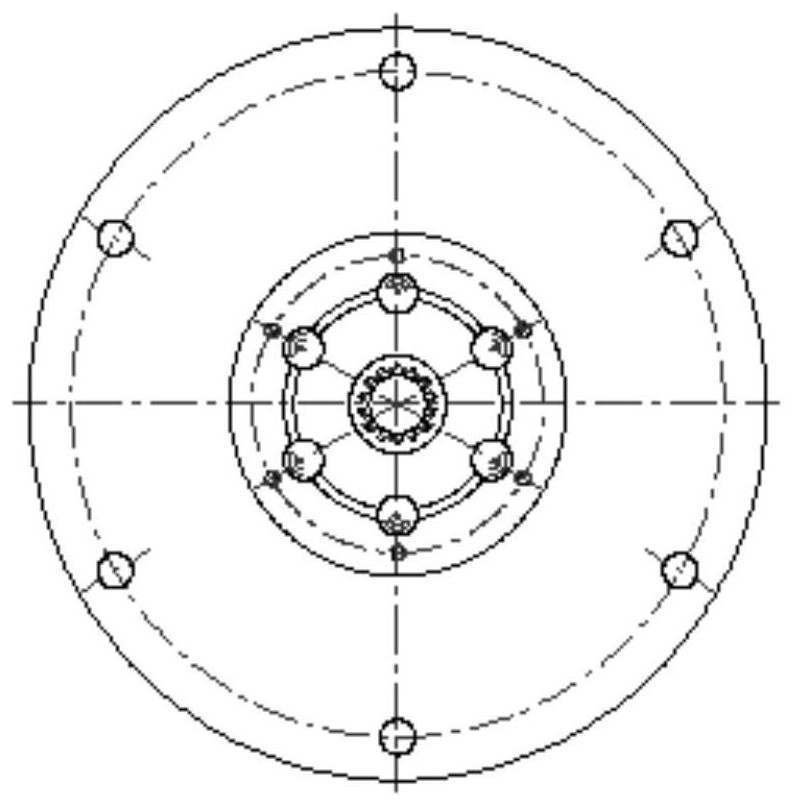

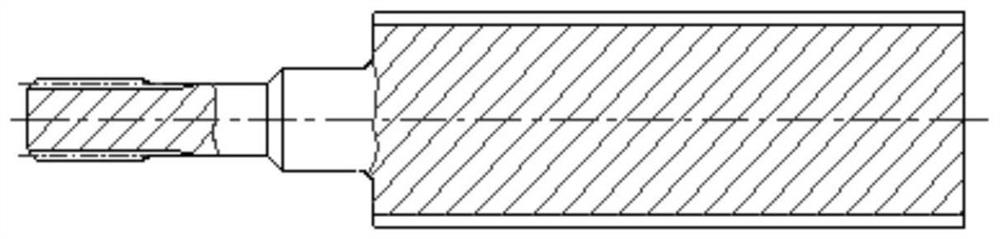

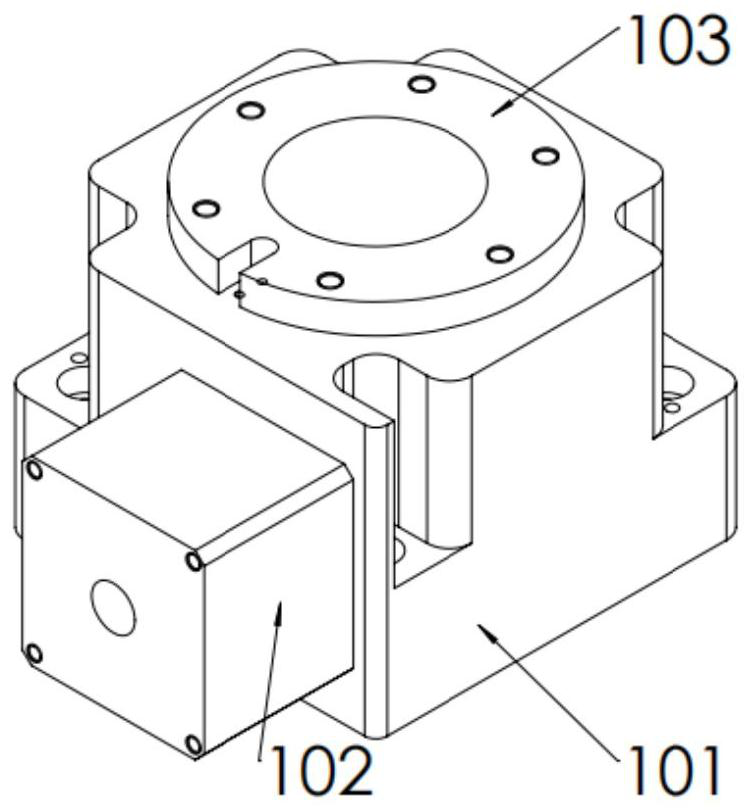

Coupling with retainer and without generating axial force

InactiveCN111911544AGenerate axial forceAchieving work requirements for axial force testingCouplings for rigid shaftsEngine lubricationPhysicsEngineering

The invention relates to the field of mechanical transmission, relates to a technology for transmitting power between two concentric shafts, and particularly discloses a coupler with a retainer and without generating axial force. The coupler is composed of an inner shaft, a left end cover, a screw, a steel ball, a transmission sleeve, a right end cover and the retainer; and in mechanical transmission, the coupler is used for transmitting circumferential movement and torque between the two concentric shafts, and due to the fact that the steel ball is used for transmitting the circumferential movement and the torque, the axial force generated in the using process is very small and can be ignored in general using occasions, so that the coupler can be called as a coupler which does not generate the axial force. The coupler is particularly suitable for special occasions where the axial force is not allowed to be transmitted when the circumferential movement and the torque are transmitted.

Owner:GUIZHOU HONGLIN MACHINERY

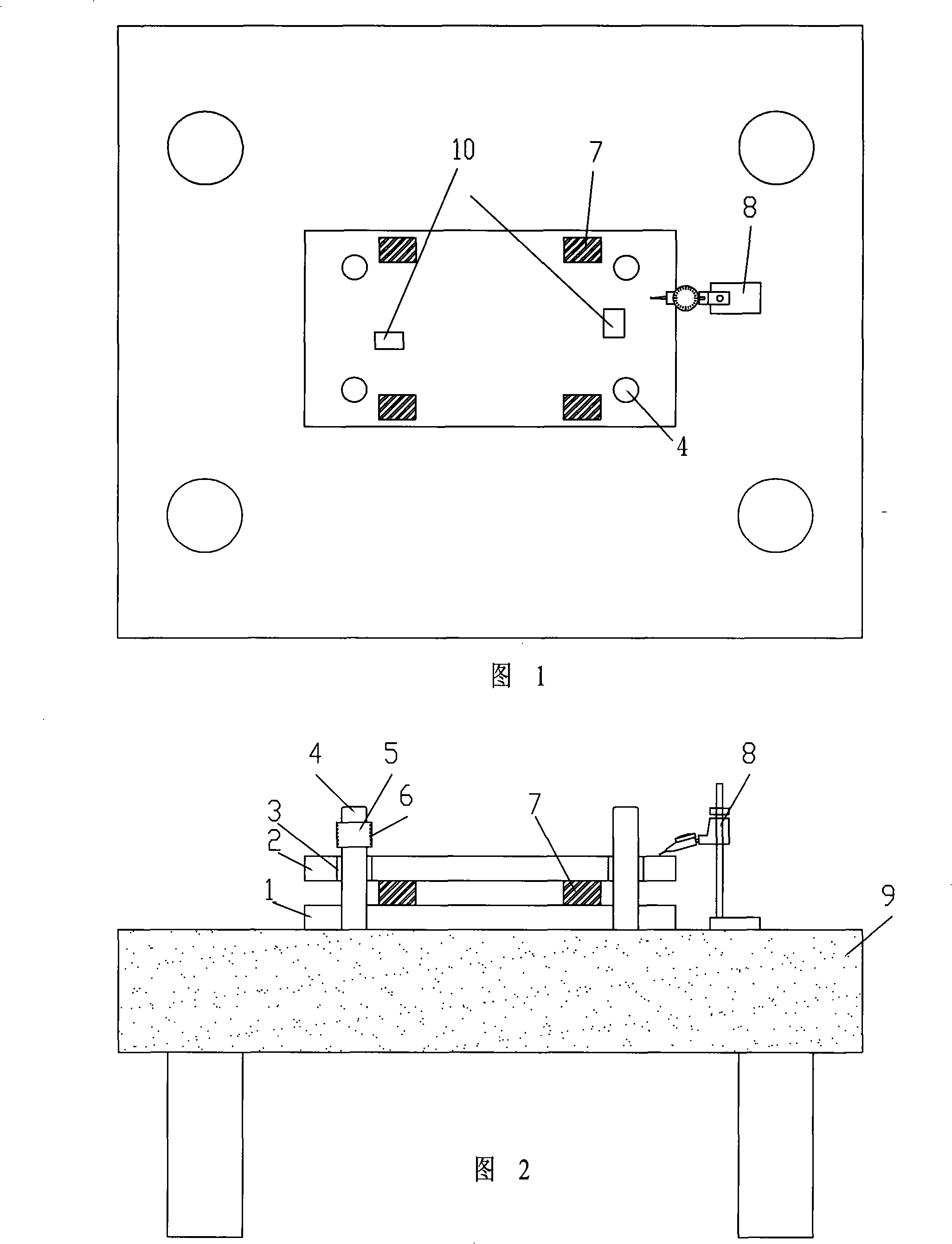

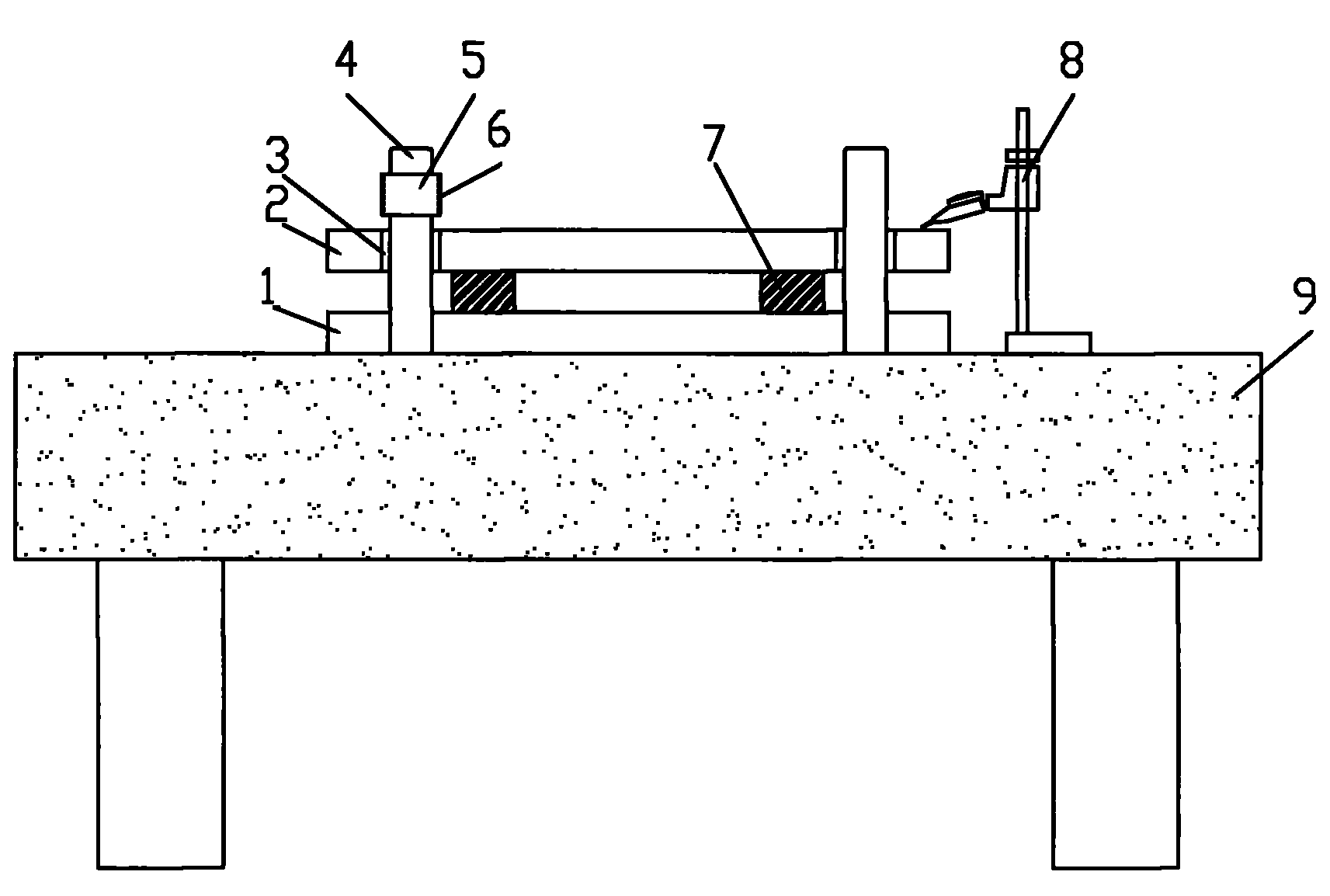

Glue injection method of high-precision mold guide sleeve

Owner:WUXI G S PRECISION TOOL

Hydraulic lightweight parallel mechanical arm

ActiveCN112621720ALight structureRealize stepless speed regulationProgramme-controlled manipulatorRobot handEngineering

A hydraulic lightweight parallel mechanical arm belongs to the technical field of robot structures and comprises a moving platform connecting assembly, a big arm moving assembly, a mechanical big arm assembly and a hydraulic parallel mechanical forearm part, the big arm moving assembly is mounted on the moving platform connecting assembly, the mechanical big arm assembly is mounted on the big arm moving assembly, and the hydraulic parallel mechanical forearm part is mounted on the mechanical big arm assembly. Compared with other existing methods, the method has the beneficial effects that a mechanical arm forearm is assembled through a hydraulic assembly, the structure is lighter and more convenient, stepless speed regulation of the mechanical arm in the movement process can be achieved, and the movement precision is higher; the six-degree-of-freedom mechanical forearm is combined and assembled in a hydraulic parallel connection mode, six degrees of freedom of the mechanical forearm are achieved, and compared with other existing mechanical arms, the six-degree-of-freedom mechanical forearm is lighter and has a higher load self-weight ratio; and the assembly type combined mechanical arm is adopted, the requirements of various types of work can be met, and flexible conversion of various terminal execution components can be achieved through a replaceable execution terminal installation part.

Owner:SHENZHEN INST OF ADVANCED TECH

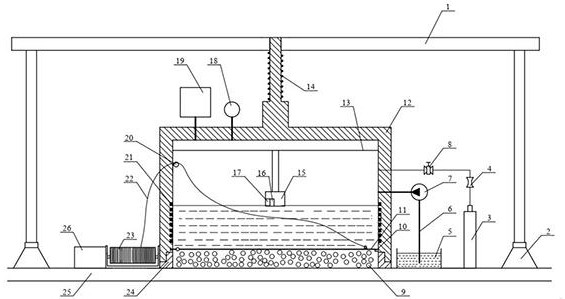

Pressurized cavitation cleaning device and method for maritime work ship deck

ActiveCN113277029AImprove mechanical propertiesEnhance the effect of cleaning and rust removalVessel cleaningHullsUltrasonic cavitationEngineering

The invention relates to the field of cavitation cleaning, in particular to a device and method for cleaning the surface of a deck through cavitation bubbles. The innovation point of the device is that a maritime work ship deck cleaning and rust removing device which can be adsorbed on the surface of a deck and can still work normally when a ship body is violently shaken is designed, and a brand new device for improving the cavitation effect by adjusting the pressure of a cleaning cabin is provided; according to the method for conducting rough cleaning and fine cleaning rust removal on the deck through the ultrasonic cavitation technology and the laser cavitation technology, the fixed-point cleaning rust removal of the deck can be achieved, and the rust removal efficiency is improved.

Owner:JIANGSU UNIV

An electronically controlled terminal steerable arm

ActiveCN108435448BImprove atomization effectSpeed up dryingSpray nozzlesArmsAir temperatureMoving parts

The invention provides an electrically-controlled tail-end-steerable mechanical arm. The electrically-controlled tail-end-steerable mechanical arm comprises a mechanical arm module and a painting module, wherein a driving element of the mechanical arm module is arranged on a platform at the bottom part; a first arm and a second arm do not have additional weight, excepting dead weight and the weight of supporting connecting rods, so that the characteristics such as quick moving of a tail end are realized; a working tail end which can be gyrated and rotated on own axis is mounted on the tail endof the second arm, thus the freedom of motion is increased, and various working demands are met; a gyrating driving assembly and a rotating driving assembly at the working tail end are mounted on theplatform, and moving parts of the driving assemblies are lighter than an existing mechanical arm; a painting head of the painting module is provided with pressure maintaining measures, the painting can be continuously performed for a while in case of material cutting off by accident, and thus unqualified products caused by material cutting off can be avoided; the painting head has the heating function and is capable of heating paint, so that the air temperature is increased while the atomizing effect of the paint is increased, and the paint can be quickly dried by air.

Owner:华南智能机器人创新研究院 +1

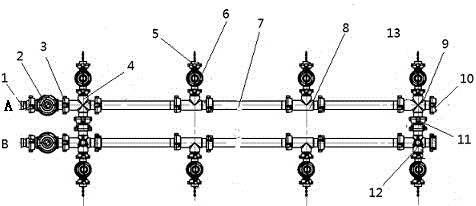

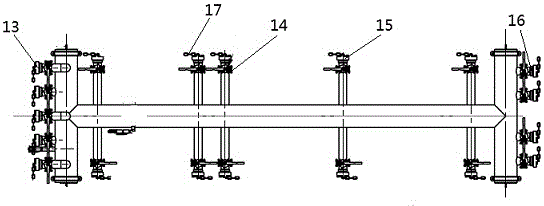

A large displacement integrated fracturing high and low pressure manifold device

ActiveCN104033142BReduce the number of connectionsReduce frictionFluid removalHorizontal wellsHigh pressure

The invention belongs to the technical field of volumetric fracturing of horizontal wells in tight oil, and specifically provides a large displacement integrated fracturing high and low pressure manifold device, including a high pressure manifold group and a low pressure manifold group, characterized in that: the high pressure manifold The group is located directly above the low-pressure manifold group and is fixed on the manifold skid; the high-pressure manifold group is a type II double-pipeline structure composed of A pipeline and B pipeline, and the low-pressure manifold group is " The I" structure is composed of a transverse tube and a longitudinal tube connected at both ends of the transverse tube. The invention realizes the good fluid supply of a single sand mixing truck to 10-14 fracturing trucks for the volume fracturing of tight oil horizontal wells, realizes the displacement discharged by the sand mixing truck, the remote transmission of the discharge pressure and the energy gathering supply, and solves the problem of The shortcomings of insufficient pressure of the discharge assembly of a single sand mixer and the long distance of the discharge liquid supply pipeline are eliminated; the number of connections of high-pressure pipelines on site is reduced, and the 10m 3 The high-pressure and low-resistance injection at the wellhead with displacement per minute greatly reduces pipe wall friction and erosion safety hazards.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

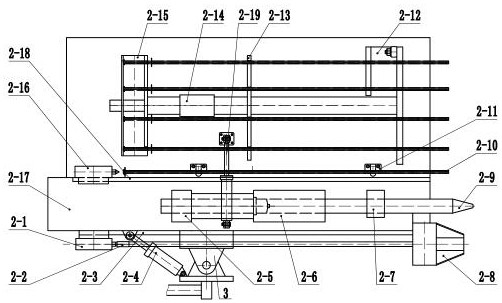

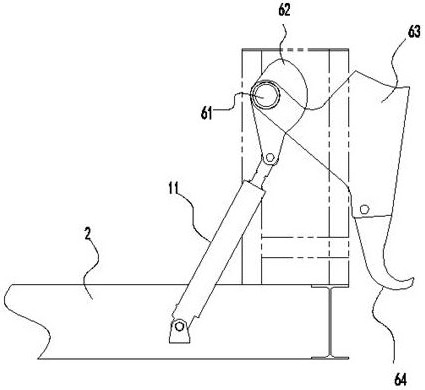

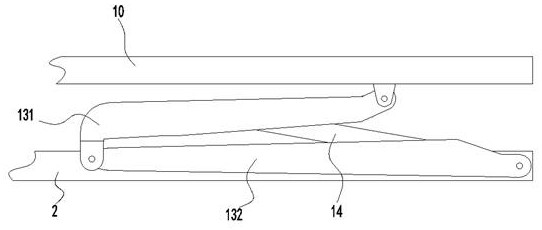

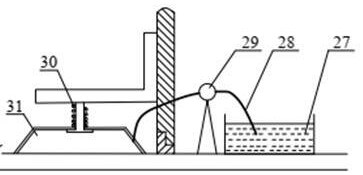

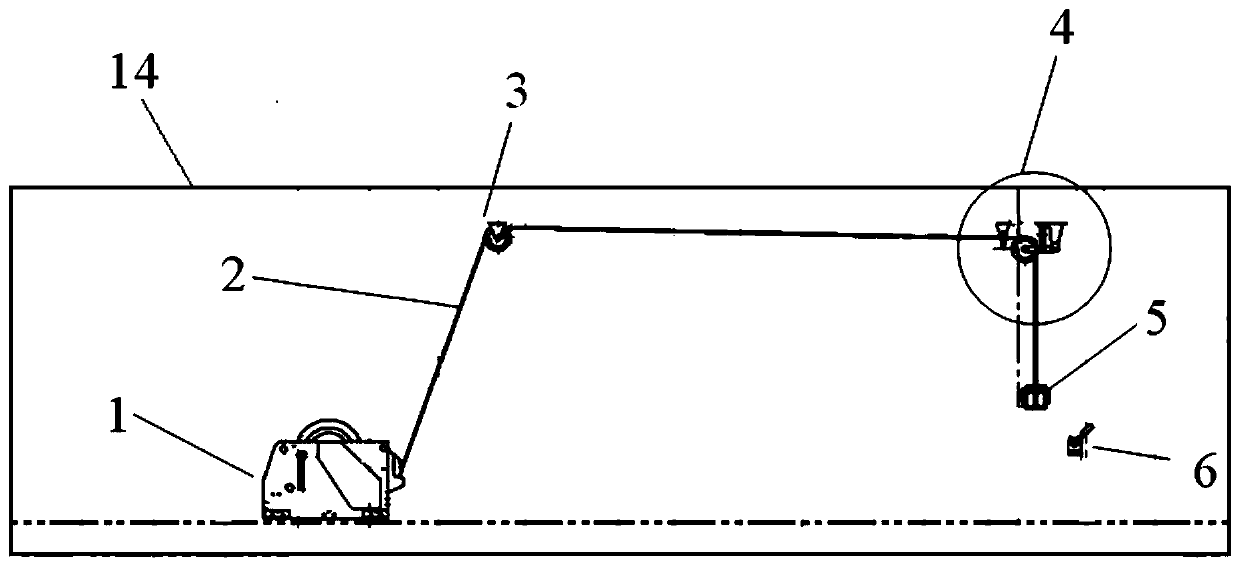

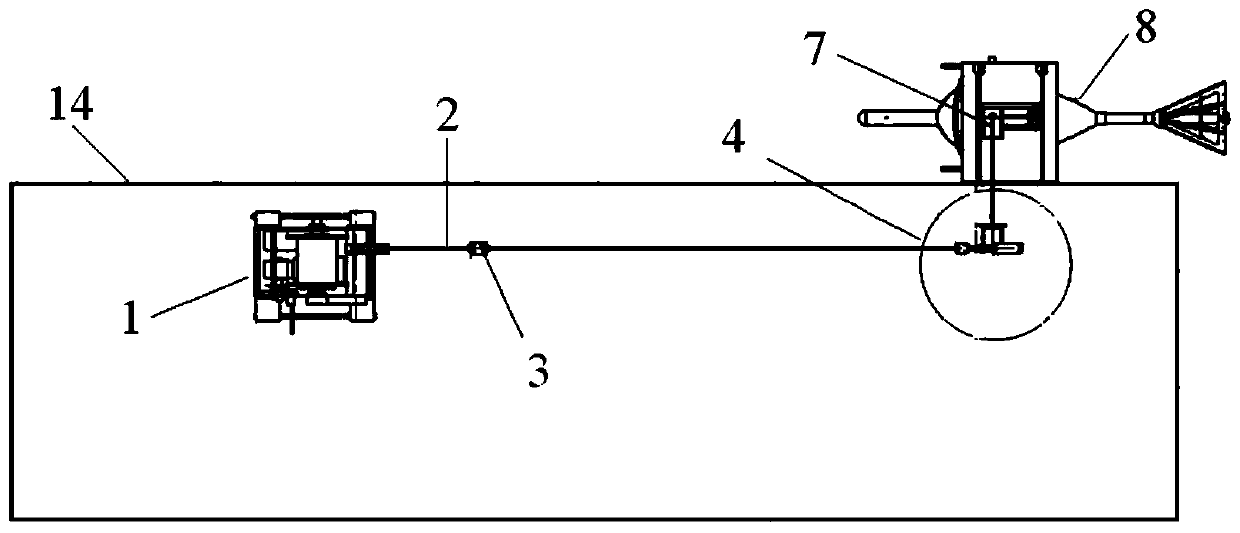

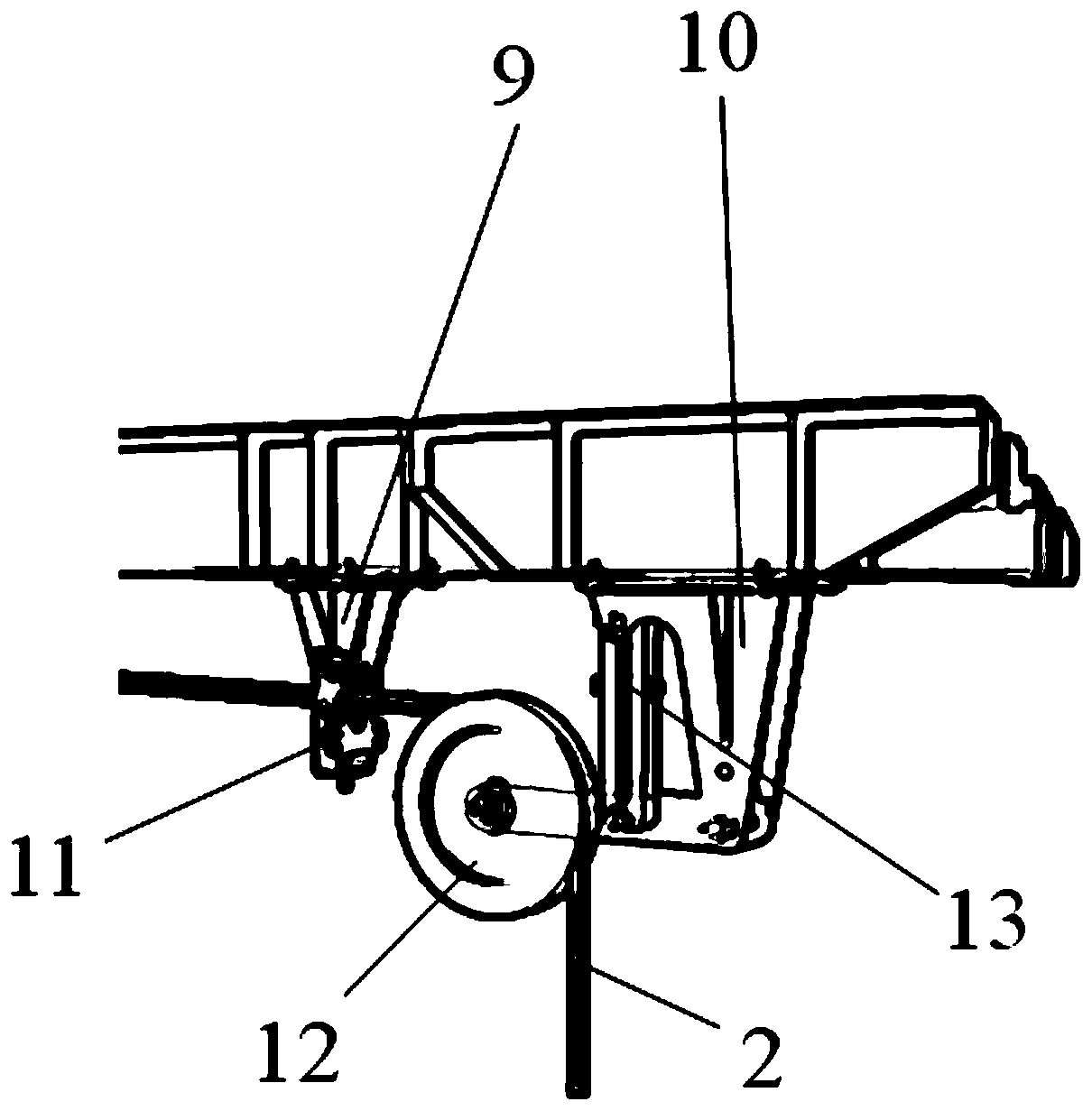

Flexible dragging pod folding and unfolding mechanism and folding and unfolding method

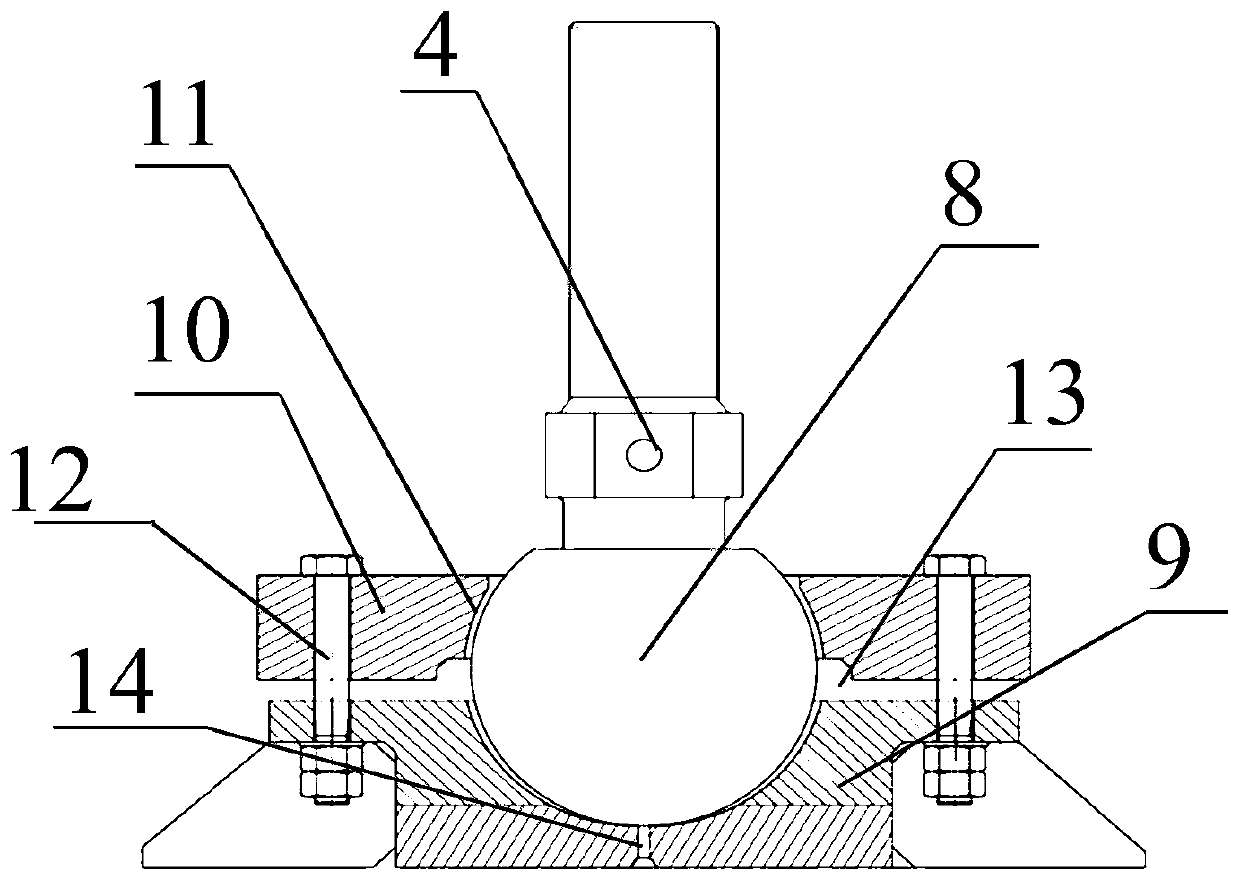

PendingCN110789724ASolve the problem of emergency throwingFulfill job requirementsAircraft componentsWinchIndustrial engineering

The invention provides a flexible dragging pod folding and unfolding mechanism. The flexible dragging pod folding and unfolding mechanism is mounted on an airplane shell 14, and comprises a drive winch 1, a suspension cable 2 and an overload automatic cutting-off device 4, one end of the suspension cable 2 is wound on the drive winch 1, the other end of the suspension cable penetrates through theoverload automatic cutting-off device 4 and is fixedly connected with a pod 8, the overload automatic cutting-off device 4 comprises a front support 9, a first guide pulley 12 and a friction lock 13,the front support 9 is fixedly connected with the airplane shell 14, a chopping-off groove 11 is formed in the front support 9, a tool is arranged in the chopping-off groove 11, one end of the friction lock 13 is fixed to the airplane shell 14, the other end of the friction lock 13 is fixedly connected with the first guide pulley 12, and the friction lock 13 is broken under the determination loadeffect. Throwing of the pod under the remote dragging and emergency conditions can be achieved.

Owner:HARBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com