Fork arm carrier

A technology for a fork frame and a fork, which is applied in the field of the fork frame, can solve the problems of single fork direction, high production cost, heavy weight, etc. of the fork frame, and achieves the effects of reasonable structural design, weight reduction and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

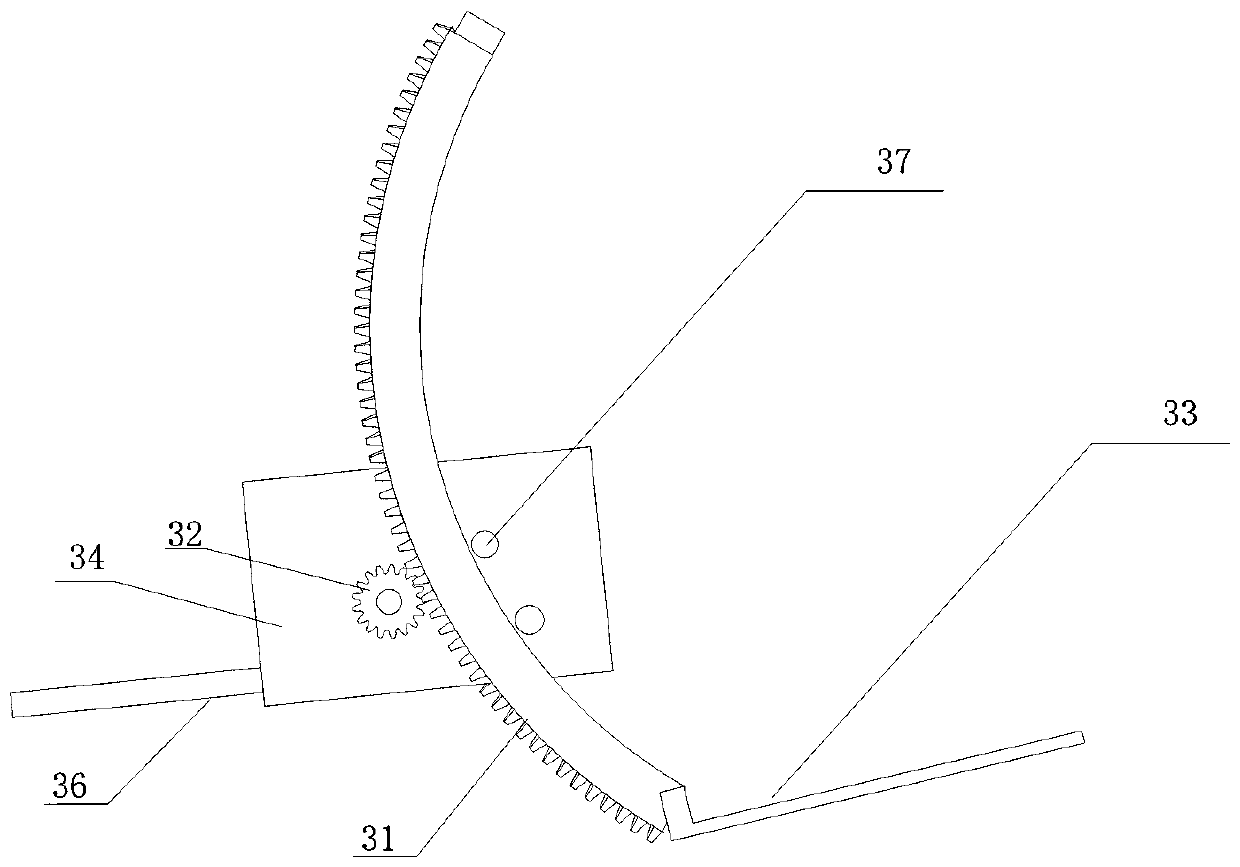

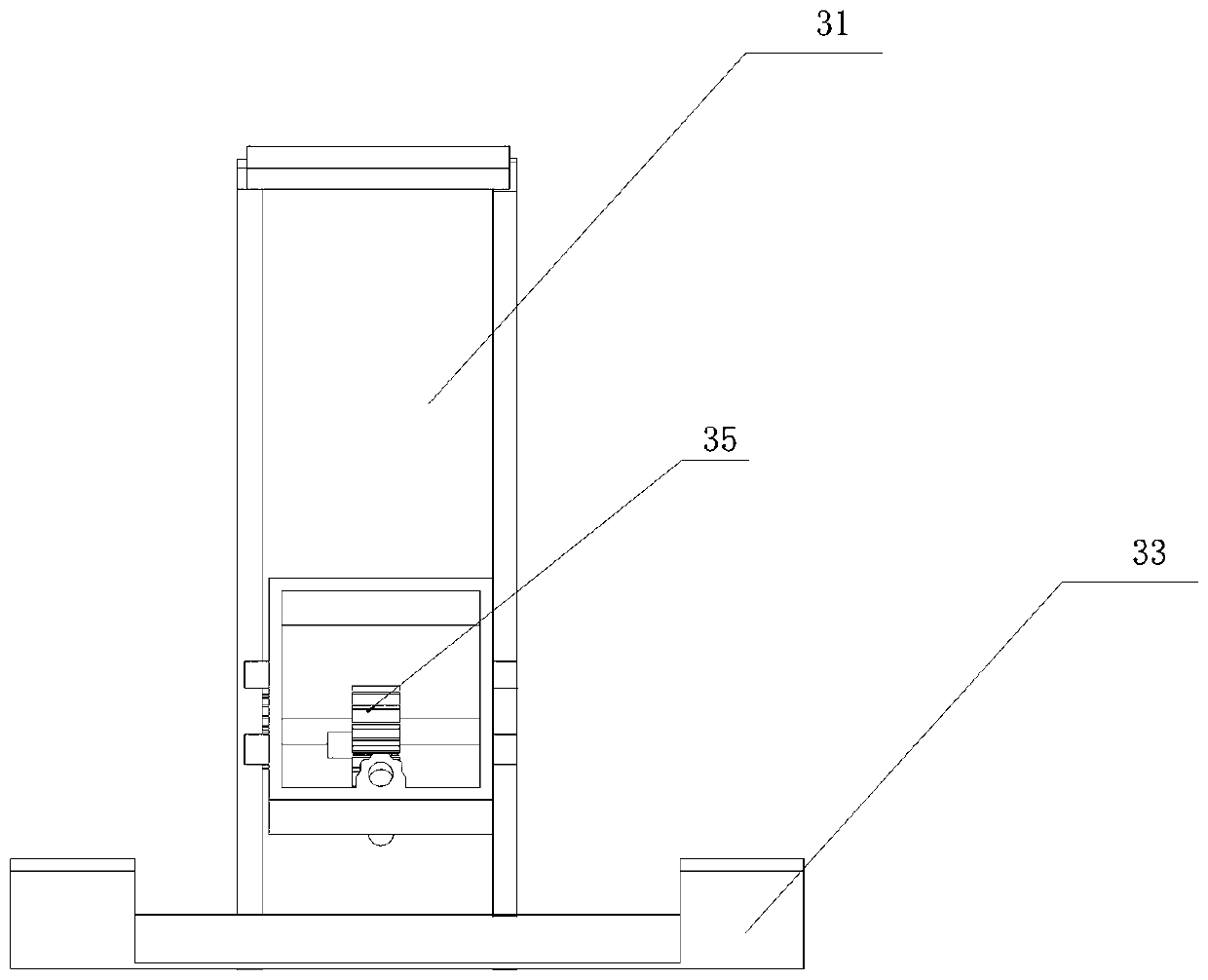

[0030] Such as Figure 1-6 As shown, a pallet fork frame of the present invention includes a drive assembly, a fixed workpiece frame and a pallet fork. The drive assembly includes a worm 36, and the worm 36 drives a worm gear 35 to rotate. Fork drive gear 32;

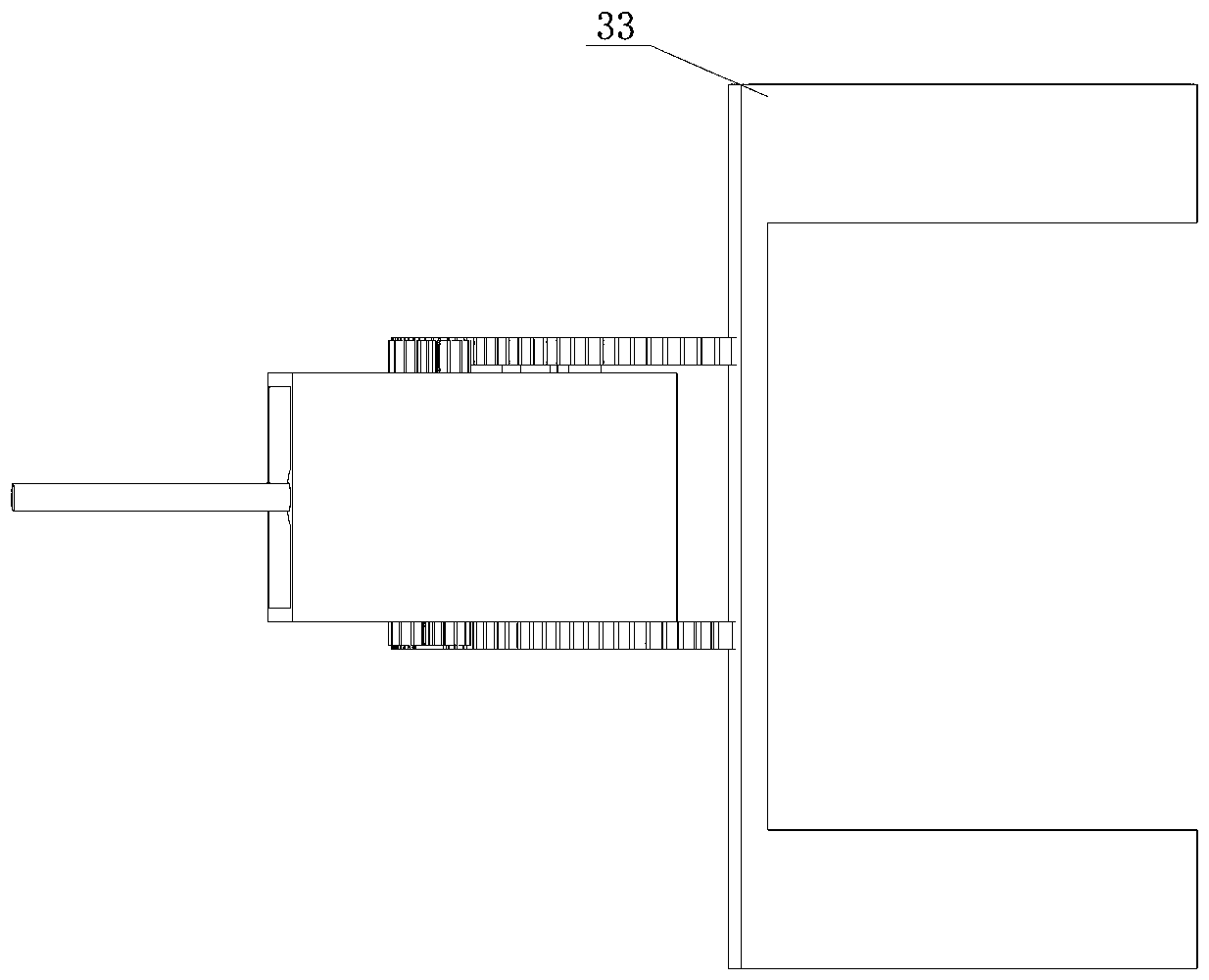

[0031] The fixed workpiece rack 34 is provided with a cavity for installing the worm 36, the worm 36 drives the turbine 35 to rotate in the fixed workpiece rack 34 cavity, the connecting shaft 38 is rotatably connected to the fixed workpiece rack 34, and the fork transmission gear 32 passes through the connecting shaft 38 Rotatably connected to the outer wall of the fixed workpiece frame 34;

[0032] The pallet fork includes an arc-shaped rack 31 and a yoke 33 fixed on the lower end of the arc-shaped rack 31, and the gear teeth of the arc-shaped rack 31 mesh with the gear teeth of the fork transmission gear 32;

[0033] The fixed workpiece frame 34 is provided with a limit bearing 37, and the limit bearing 37 cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com