Pressurized cavitation cleaning device and method for maritime work ship deck

A ship deck and cavitation technology, which is applied to ship cleaning devices, ship hulls, ship construction, etc., can solve the problems of deck cleaning work not being carried out normally, ship hull shaking, and regular cleaning of ship decks, so as to overcome low efficiency, improve efficiency, Achieve job requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

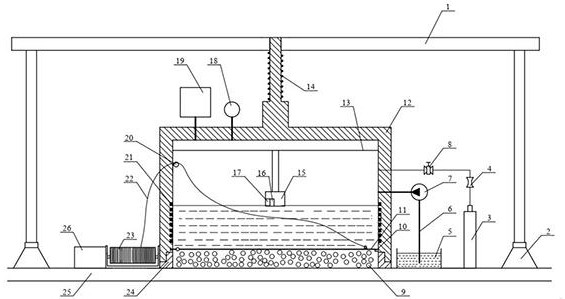

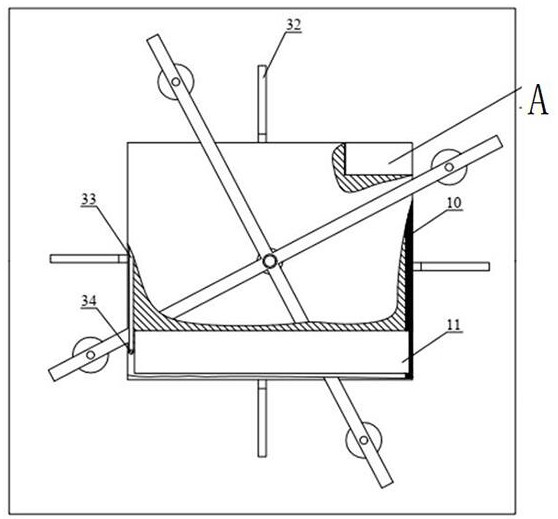

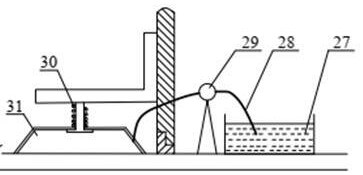

[0030]Specific embodiment: the vacuum suction cup is adsorbed on the surface of the deck after vacuuming, and the water suction cup contacts the surface of the deck under the action of the upper spring, and the limit pin of the universal wheel bracket is pulled out, so that the universal wheel bracket moves upward, and the bracket is downward at the same time Under the action of the spring and the bracket, the cleaning cabin is firmly fixed on the deck and maintains a good seal; inject the aqueous solution into the cleaning cabin to a height of 50 mm from the deck surface, and open the air inlet valve to increase the temperature of the cleaning cabin. Observe the intake flow from the micro mass flowmeter, control the pressure in the cleaning cabin through the pressure control device, open the intake valve to pressurize the cleaning cabin to 0.5MPa; open the ultrasonic vibration plate and move the ultrasonic vibration plate longitudinally to make it Several cavitation bubbles ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com