Leveling device and method for tilt of tower body after installation of tower-type crane

A tower crane and leveling device technology, applied in cranes and other directions, can solve problems such as hidden safety hazards, impact on construction progress, large human and material resources, etc., and achieve the effects of reducing construction costs, ensuring project progress, and extending service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

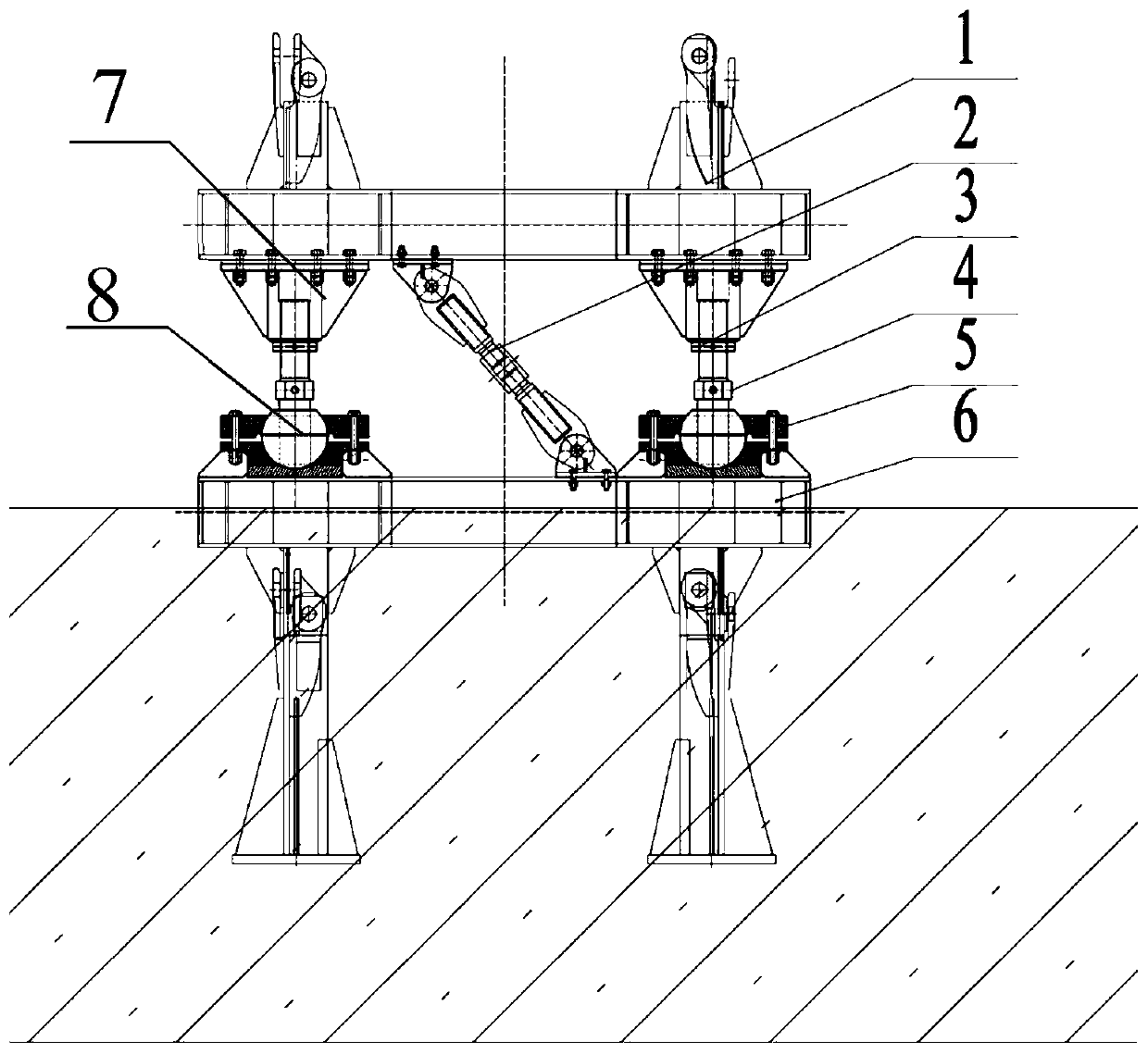

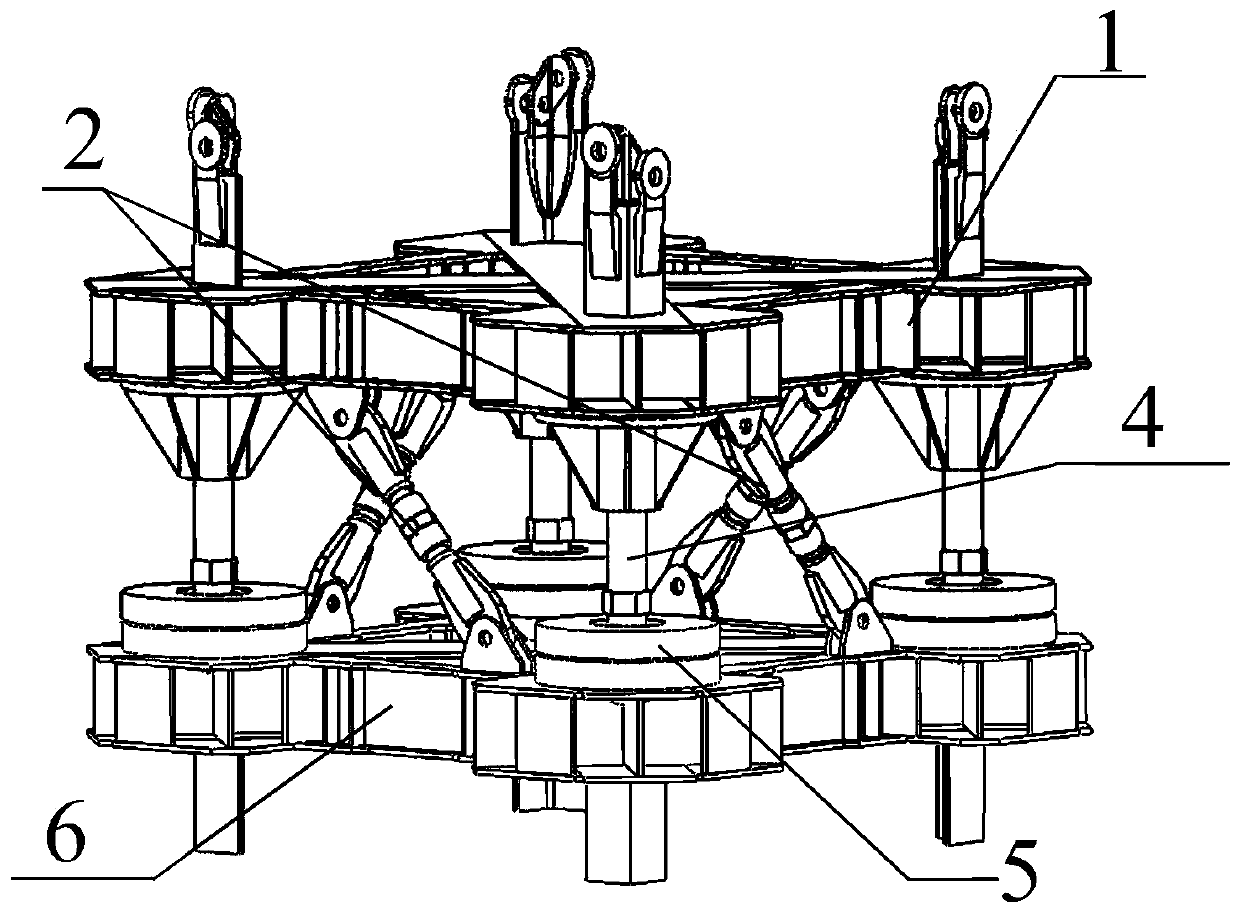

[0042] refer to Figure 1 to Figure 7 As shown, the leveling device used for tower crane tilting after installation includes an upper chassis 1 connected to the tower body of the crane and a lower chassis 6 connected to the embedded foundation section, the upper chassis 1 and the lower An adjustment mechanism is arranged between the chassis 6, and the adjustment mechanism includes a threaded sleeve 7 arranged at the lower end of the upper chassis 1, an adjustment rod 4 arranged on a vertical horizontal plane, a locking member 5 arranged at the upper end of the lower chassis 6 and a matching lock The fixing part 8 of the tightening part 5, the fixing part 8 is embedded in the locking part 5, one end of the adjusting rod 4 is set through the lower end of the threaded sleeve 7, and the other end is connected with the fixing part 8, and the adjacent At least one adjustable strut 2 is arranged between the adjustment mechanisms.

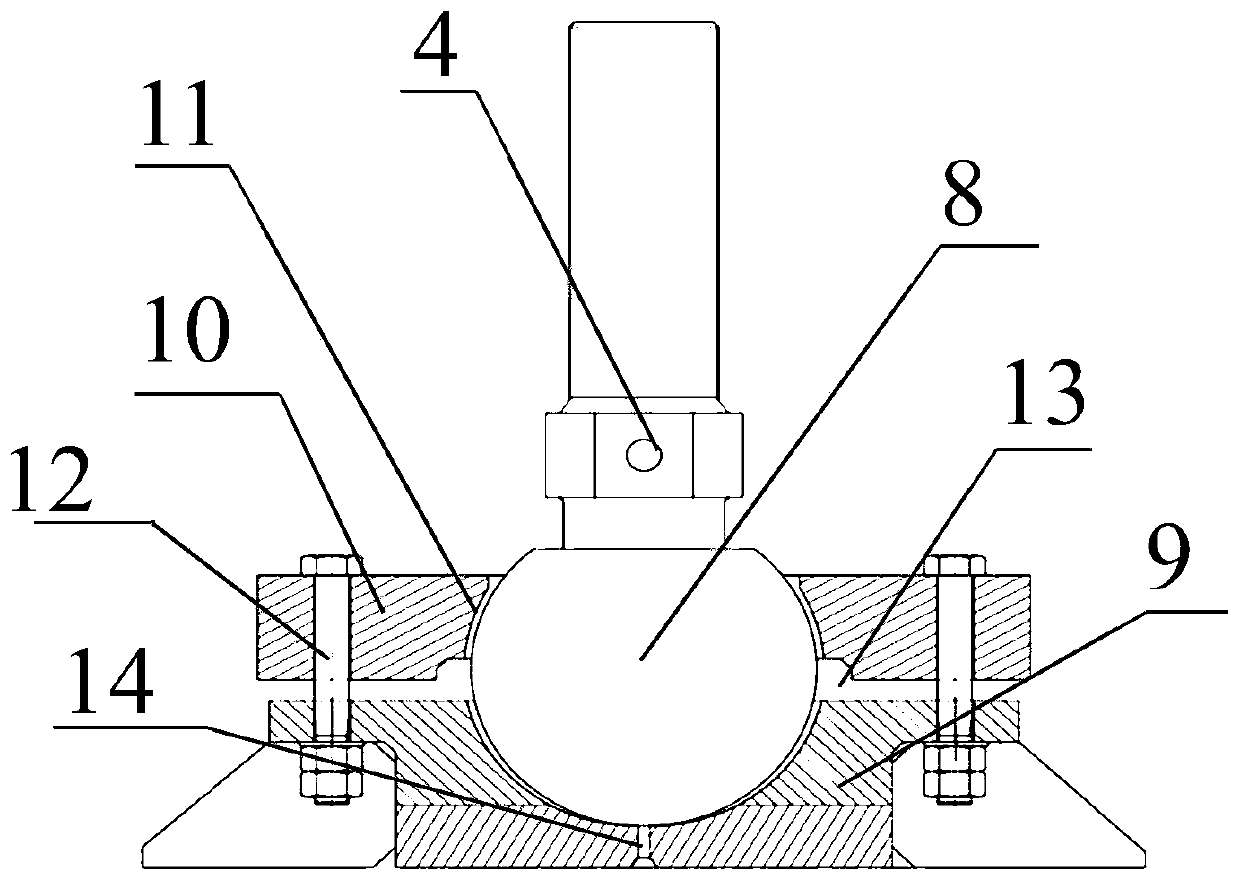

[0043] The fixing member 8 is a sphere with an open...

Embodiment 2

[0059] The adjustment mechanisms are respectively arranged at the four corner fulcrums between the upper chassis 1 and the lower chassis 6, and the adjustable struts 2 are arranged in parallel in pairs.

[0060] The two ends of the adjustable struts 2 are connected to the upper chassis 1 and the lower chassis 6 through rotatable parts, and the two adjustable struts 2 parallel to each other are arranged alternately.

Embodiment 3

[0062] The inner wall of the lower end of the upper pressing plate 10 is provided with a groove 13 , and the lower pressing plate 9 is provided with a through groove 14 .

[0063] By adopting the above technical scheme, the leveling base frame is installed behind the bottom feet, and the structure is as follows: figure 1 As shown, this state ensures that the pressure plate compresses the lower sphere of the adjusting rod 4 by pre-tightening the high-strength bolts. According to the load on the whole tower crane, design reasonable adjustment rod 4 thread, material and sphere diameter, so that the adjustment rod 4 can meet the different requirements in the normal operation of the tower crane and the tilt adjustment process; after the tower crane tilts, the tower crane should be leveled , to ensure that the four adjustment rods 4 are under pressure. The tower crane balance refers to a means of balancing the weight of the front and rear arms to reduce the bending moment of the tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com