A large displacement integrated fracturing high and low pressure manifold device

A technology of low-pressure manifold and high-pressure manifold, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling, etc., can solve the problems of limited construction scale, high labor intensity, effective parking, small construction distance, etc., and achieve reduction The effect of reducing the number of connections, reducing labor intensity, reducing pipe wall friction and erosion safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

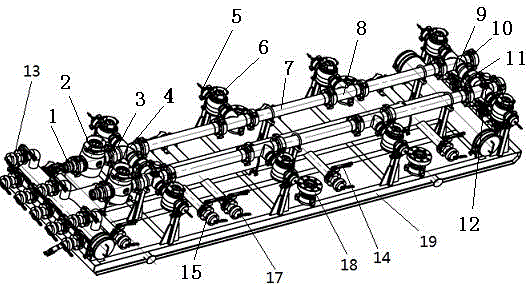

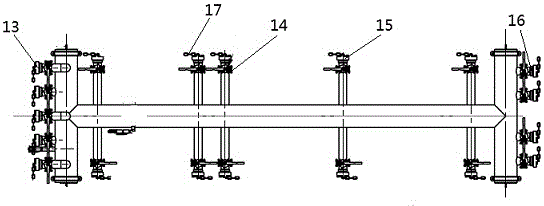

[0025] In order to overcome the defects of insufficient pressure in the discharge assembly of a single sand mixing vehicle and a long discharge liquid supply pipeline in the prior art, the present invention provides a large displacement integrated fracturing high and low pressure manifold device, such as figure 1 As shown, it includes a high-pressure manifold group and a low-pressure manifold group. The high-pressure manifold group is located directly above the low-pressure manifold group and is fixed on the manifold skid 19; the high-pressure manifold group and the low-pressure manifold group are skid-mounted The method is overall hoisting, the low-pressure manifold is on the inner side of the high-pressure manifold, so as to prevent the high-pressure manifold from rubbing against the high-pressure pipeline when connecting the wellhead elbow, so as not to reduce the service life of the high-pressure manifold; the connection of the two manifolds is firm and strong, suitable for ...

Embodiment 2

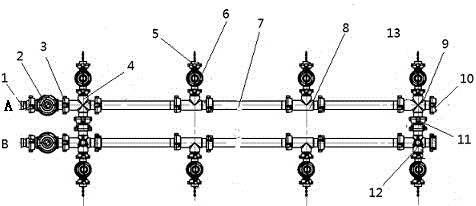

[0031] In order to distribute the displacements of the A pipeline and the B pipeline evenly, the cross joint 9 and the three-dimensional five-way joint 12 at the same end of the A pipeline and the B pipeline are connected through a short connection 11, wherein the length of the short connection 11 is 0.3 meters, The pipe diameter of short connection 11 is 4 ".

[0032]In order to conveniently select output from 2 branches or multiple branches according to the construction displacement requirements, the second high-pressure liquid inlet 4 is connected with a male union plug 5, and the second high-pressure liquid inlet 4 is connected to the male union plug. A first plug valve 6 is arranged between the union plugs 5, the plug diameter of the male union plug 5 is 3", the model is FIG1502, the valve port diameter of the first plug valve 6 is 3", the model is FIG1502. The second plug valve 2 is connected to the first high-pressure liquid inlet 3, and the second plug valve 2 is conn...

specific Embodiment approach

[0037] Specific implementation method: After the assembly of the high-pressure manifold group is completed, a 1.5-fold static pressure test is carried out. If there is no leakage, the installation can be carried out; after the assembly of the low-pressure manifold group is completed, the irrigation test is carried out. to install. According to the layout of the well site, the integrated high and low pressure manifold device is placed on a flat place, and the fracturing vehicles required for construction are placed symmetrically in two rows with the integrated manifold as the center; since the liquid inlet is controlled by a cock valve, the high pressure pipe The manifold can be output from two branches or multiple branches respectively according to the requirement of displacement, while reducing the pressure fluctuation of a single manifold. In addition, a mechanical safety valve must be installed on the manifold group to prevent the medium pressure in the pipeline from exceed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com